Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

S 184 Content

Caricato da

A Sattar M El-farraDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

S 184 Content

Caricato da

A Sattar M El-farraCopyright:

Formati disponibili

PDHonline Course S184 (2 PDH)

Flexible Metal Deck Roof Diaphragms

Instructor: D. Matthew Stuart, P.E., S.E., F.ASCE, F.SEI, SECB, MgtEng

2013

PDH Online | PDH Center

5272 Meadow Estates Drive Fairfax, VA 22030-6658 Phone & Fax: 703-988-0088 www.PDHonline.org www.PDHcenter.com

An Approved Continuing Education Provider

www.PDHcenter.com

www.PDHonline.org

Sheardiaphragmsareessentiallyplanarstructuralsystemsfoundinroofs,floors,andwallsof buildings.Theyarecomprisedofinterconnectedunits,attachedtosupportingmembers,such thattheentireassemblypossessesbothinplaneshearstrengthandstiffness.Themajor componentsofadiaphragmincludetheindividualdeckpanels,thestructuralmemberstowhich theyareconnectedandtheconnectingdevicesorfasteners.Fastenertypesincludewelds, screws,powerdrivenpins,orothermechanicaldevicesthathaveapredictablecapacity.The strengthandstiffnessofadiaphragmdependsonthepanelproperties,thespanarrangements, andthequalityoftheconnections.

Figure1illustratesthebasicconceptforaroofandwalldiaphragm.InFigure1windpressureon thewallsparalleltolengthLactonthebuilding.Alineloadreactionofthispressureis distributedtothetopofthewallattheroofplaneviatheverticalspanningcapacityofthe claddingoverheightH.Theroof,actingasasimplespanhorizontalgirderofdepthB,distributes thewindlineloadasashearreactionalongthetopoftheendwallsperpendiculartoL.Theend wallsinturnactasdiaphragmsbetweentheroofandfoundationlevels.

D.MatthewStuart

www.PDHcenter.com

www.PDHonline.org

Fortheroofinthisexample,thetotaluniformloadonthediaphragmequalsthecombined effectsofthewindwardandleewardcladdingreactions(ww +wL).The maximumendreaction(R) oftheroofdiaphragmtherefore is((ww +wL)xL)/2.RdividedbylengthBequalsthecollector loadormaximumuniformshearforceinthediaphragm.Themaximumroofdiaphragmmoment (M)equals((ww +wL)xL2)/8.Thecorrespondingdiaphragmchordforcesarethereforeequalto MdividedbythediaphragmdepthB.Themaximumunitshearonthewalldiaphragmisalso equaltotheroofreaction,R,dividedbyB.However,thewalldiaphragmmomentequalsRxH. Itshouldalsobenotedthat: a. Adiaphragmactslikeashortdeepbeam. b. Themaximumaverageshear(R/B)occursattheendsoftheroofdiaphragm. c. Zonesnearthemidspanoftheroofaresubjectedtolessunitshearthereforeless diaphragmstrengthisrequired. d. Thelargerdesignshearsmayberesistedbyusingbothheaviergagepanelsandfewer connectionsorby ymorefrequently q yconnectedlighter g g gage g p panels.Thereforethemost efficientuseofmaterialsmaynotbemetbyusingasinglediaphragmdesignforthe entireroofarea.However,fromapracticalconstructabilitystandpointitismore commontouseasingledeckandconnectortypeoveranentireroofandincreasethe frequencyoftheconnectorsinordertoresistgreaterinplaneshearforces.

Roofdiaphragmsmaybeassembledfrom awidevarietyofpanelprofilesincluding NarrowRib(NR),IntermediateRib(IR)and WideRib(WR).Eachofthesedifferent decktypesaredescribedintheSteelDeck Institute(SDI)PublicationNo.31,Design ManualforCompositeDecks,FormDecks andRoofDecks.Roofdiaphragmpanels typicallyvaryfrom0.0295inchesto0.064 inchesinthicknessandcomeinwidthsof 18inchesto36inchesormore.

D.MatthewStuart

www.PDHcenter.com

www.PDHonline.org

Adiaphragmshouldbedesignedandassembledtocoveraspecifiedareainsuchawaythatin planeshearstrengthandstiffnessispredictable.Theprincipalelementsdeterminingthese factorsincludespacingofthesupportframing,thesizeandthicknessoftheindividualdeck panelsandtheinterconnectingfasteners.Ametalroofdeckdiaphragmisafairlyflexiblesystem somewhatanalogoustoatrussasshowninFigure2.Priortoinstallingthetrussdiagonalor attachingthediaphragmtothesupports(andeachadjacentsheetviasidelapconnectors), neitheroftheframespossessmuchstrengthorstiffness.Theshearstrengthofadiaphragm systemislimitedbythestrengthofconnections,localpanelbucklingandthegeneralplatelike bucklingcharacteristicsoftheentirediaphragmarea.

Inadditiontoneedingtoresistplanarshearforces,inorderforadiaphragmtofunctionproperly itisalsonecessarytoprovidemembersalongtheextremeedgesofthedeckasrequiredtoresist theflexuraltensionandcompressioncomponentsofthedeepbeammember.Thisisanalogous tothetopandbottomchordsofatrussresistingthecompressionandtensionforcesofthe member.

Source: CSI

D.MatthewStuart

www.PDHcenter.com

www.PDHonline.org

Thestrengthofadiaphragmcanalsobelimitedbyproperattentiontotheedgeandend terminationconditions.Inaddition,atinteriorpositions,panelsmustbesufficientlyoverlapped toprovideadequateenddistancesfortheconnectorused.Ifpanelsarebuttedattheirends ratherthanendlapped,asiscommonwithfloordecks,theneachpanelmustbeindividually connectedatitsendswiththespecifiedpattern. Theoverlappingedgesofpanelsshouldbeinclosecontactinordertominimizetheeccentricity onfastenersatthelap. lap Thisisalsoacriticalfactoratsidelapconditions conditions.Inaddition, addition fasteners usedattheoverlapconditionshouldalsobeinstalledontheedgepanelatthediaphragm perimeterwherethesidelapconnectorwouldnormallyoccuriftherewereanotheradjacent panel.Otherwisetheshearstrengthalongthefirstinteriorsidelapmayexceedthatalongthe perimetermemberthusdiminishingthecontributionofthedeckendconnectionatthe supportingshearwallorverticalXbracedframe.

Source: TataSteel

Fasteners

Establishingwhattypeoffasteneristobeusedisacriticalcomponentofdesigninganddetailing adiaphragm.Fastenerscommonlyincludewelds,screwsandpowderdrivennaillikepins. Structuralconnectionsincludefastenersthatconnectoneormoresheetstoheavierorthicker frameorstructuralmembers.Sidelapconnectionsincludefastenersthatconnectadjacentpanels toeachotherandnottothesupportingframemembers.Stitchconnectionsareanothername forsidelapconnections.

Source: Hilti;MetalDeckSupply;HobartBrothers

D.MatthewStuart

www.PDHcenter.com

www.PDHonline.org

WeldedConnections:

Arcspotwelds,orpuddlewelds,areproducedbystrikinganarcontheuppersheet,thereby causingaholetoform,whilethelowersheetisbeingraisedtofusiontemperature.Withthe attainmentofthepropertemperature,theelectrodeismovedinacircularpatternuntilthehole isfilledandfusionattainedonthearcpuddleperimeter.Therelativestrengthinaseriesofwelds canvarysignificantlybymodestchangesinweldingtimes. Arcspotwelds A ld tostructural lmembers b (i.e. (i welding ldi of fthinner hi sheets h tothicker hi k structural l members)requiredirectcontactbetweentheunitsforproperheattransfer.Inaddition,aproper balancebetweentheweldingtimeandtheelectrodeburnoffrateisessentialtogoodquality welding.Weldingmachinepowersettingsrequiredusuallyarewellbelowthoseneededfor weldinginhotrolledsteels.Thetimerequiredperweldmayvarybetween3and6secondsor moredependingofthepropertiesofpartsbeingconnected.

Source: PalmBeachCountySchools

Weldwashersfunctionasaheatsinkallowingholeformationinthinnerpanelswithoutexcessive growthofthehole,asthetemperatureoftheunderlyingpanelisincreased.Thewasheris subsequentlyfilledwiththeweldstemgrowingintothelowerpanelwhichbecomesanchoredon thewashersholeperimeter.Uponcooling,thewasherisclampeddownontheattachedsheet. Weldwashersarerecommendedforpanelsthinnerthan0.0280inches.

Source: MetalDeckSupply

D.MatthewStuart

www.PDHcenter.com

www.PDHonline.org

AllweldsshouldbemadebyqualifiedoperatorsfollowingAWSD1.3Specifications.Asindicated previously,weldingthinmaterialusuallyrequiresamuchlowerpowersettingandlowerburnoff ratethanwithheavysteelunits.Particularcareisalsorequiredwhenweldingdecktojoistsin ordertoavoiddamagetothejoistchords.Preliminaryfieldqualitycontrolcheckscanbemadeby placingapairofweldsinadjacentvalleysatoneendofapanel.Avisualinspectionwillshowif theweldmaterialisfusedproperlyandincontactwiththeunderlyingpanel.Intermittent contactmayindicateexcessivepowersettings.Separationbetweenthepanelsmayindicate insufficientweldingtimeandpoorfusion.Theterminationoftheweldingoperationmaynot permitcompletefusionaroundtheentireperimeter perimeter.Weldfusionshouldbevisibleovernoless thanthreequartersoftheweldperimeter. Inadjacentdiaphragmpanelswithnestableorflatoverlappingedges,sheettosheetorstitch connectionsaretypicallyrequiredawayfromthesupportingmembers.Theplacementofarc spotweldsatsuchsidelapsisdifficult.Inaddition,thethinnerthematerial,themoredifficultthe weldingoperationbecomes.Weldingofsidelapsisnotrecommendedformaterialof0.0295inch orthinner.Theamountofslipormovementexperiencedasweldsareloadedinshearinthin steelelementsisverysmallrelativetothatformostothermechanicalconnectors.The movementisessentiallylimitedtopaneldistortionaroundtheweld.

SidelapScrewConnector Source: Bondek

ScrewConnections:

Screwsmustbeinstalledusingproperlycalibratedtoolsinordertoavoidoverdrivingwhichcan stripthethreadsatsidelapsorseverthescrewwhenitisplacedintoathickersupporting member.Thequalityofscrewconnectorsingeneralistypicallynotamajorproblemalthough thesetypesofconnectorscansometimesfracturewhenbeingdrivenintoathickersupporting material.Themostcommonproblemwithscrewconnectorsinvolvesallowingthescrewto threadupontheuppersheetbeforebecomingengagedinthelowersheetthusleavingmajor gapsbetweentheseparatepanels.Suchscrewsshouldberemovedandredrivennearbywhile forcingsheetlayerstoremainindirectcontact.

Source: Simpson

D.MatthewStuart

www.PDHcenter.com

www.PDHonline.org

PowderDrivenFasteners:

Powderdrivenfastenersmustbeinstalledfollowingthemanufacturersrecommendations.Care mustbeexercisedinsettingthedrivingforcetoobtaintheproperdepthofpenetration.Once drivenproperly,thesenaillikefastenersareveryresistanttoextractionbyupliftforces.Inuplift testsonsheetmaterial,theusualmodeoffailureinvolvestearingthesheetaroundtheheador washerleavingthefastenerinplace.

Source: Hilti

ButtonPunchedSidelaps:

Thequalityofbuttonpunchingisdifficulttomaintainbecausetheattachmentdependsonthe careandtheenergyusedbytheinstallerandthetoolthatisused.

Source: Metaldeck.com

D.MatthewStuart

www.PDHcenter.com

www.PDHonline.org

Miscellaneous:

1. Strengthvs.Cost:Itistypicallybettertoachievetherequireddiaphragmstrengthwitha greaternumberofweakerbutlessexpensivefasteners.Howeveritisrecommendedthatthe designershouldcheckthedeflectionofthediaphragm. 2. Theinsurancefireratingorwindupliftrequirementsofabuildingmaynotallowa substitutionoffastenersorchangeinspacingasgovernedbydesign. design 3. Thecommonavailabilityofanygivendeckattachmenttool,equipmentorpowersourcemay dictatethechoiceoffastenerforanygivenproject. 4. Theexposedundersideappearanceofthedeckmaybeimportant.Ifappearanceiscritical sidelapscrewsorevenveryweakbuttonpunchesmayberequiredeventhoughanincreased numberoftheseconnectorswouldbeneededoverthatprovidedbywelding. 5. Atthistimetherearenostandardtestsforupliftloadingsonfasteners.However,uplift failureofadeckpanelunderserviceloadingisveryuncommon.Thisisbecausethespacing offastenersasdictatedbydiaphragmdesignorinsurancerequirements(FactoryMutualor UnderwritersLaboratories)typicallyexceedsanynetupliftforces.

HowtoFastenSteelDeck

Fasteningofmetaldecktothesupportsatonetimewasonlydonebyweldinguntilselfdrilling screwsbecameavailable.Inaddition,weldingofdeckhasalsobeenreplacedtosomedegreeby fastenersthatareshotin(eitherairorpowderactuated).Allthreeofthesemethodsof attachmentperformthesamefunctionofholdingthedeckinplaceandthusallowingshear strengthandstiffness(thatcanbepredicted)tobedeveloped. Becausetheconnectionofthedeck(bothsidelapsandtothesupports)isaveryimportant componentofthediaphragmcapacity,forbothstructuralstabilityandinsuranceandfirerating approvals,itisuptothedesignertochoosethecorrectfastenerstobespecifiedandbeableto judgethemeritsofsubstitutionsrequestedbythecontractor.

Source: BarsinProducts

D.MatthewStuart

www.PDHcenter.com

www.PDHonline.org

WeldedConnections:

Welding,whenproperlyexecuted,providesthestrongestandstiffestdeckconnections.Welding alsorequiresthemostskillandthereforeshouldbeinspectedthoroughly.Becausemostvisible welddiametersusedwithsteeldeckarebetweeninchesandinchesneitherAISInorAWS capacityformulasshouldbeused.However,testingperformedbytheSDIhasestablished strengthsforwelddiametersbetweeninchandinches.Theultimatestrengthformulawas determinedtobethatshownonthisslide.ThecorrespondingAISIformulaindicatesthatgreater weldstrengthscanresultwithmultiplemetalthickness(suchasatoverlaps),however theSDI testssuggeststhatformetaldeckthiseffectshouldbeignored.TheSDIalsorecommends,based onthedistributionofthetestresults,thatasafetyfactorof2.75beusedfortheseweldsrather thanasafetyfactorof2.56assuggestedbytheAISISpecifications. Qf =2.2*t*Fu *(dt)[inkips] Where: d=averagevisiblediameter[inches] Fu =steelstrength[ksi] t=basemetalthickness[inches]

Itisgoodpracticetouseweldwashersfordeckswithametalthicknesslessthan0.0280inches.It isalsorecommendedtouse5/8inchpuddleweldswithoutwashersformaterialthicknesses greaterthan0.0280inches.Innocaseshouldwashersbeusedoninteriorsidelaps. Inadjacentdeckpanelswithnestableorflatoverlappingedges,sheettosheet(stitch) connectionsarerequired.Theinstallationofarcspotweldsatsidelapscanbeproblematic.In addition,thethinnerthematerial,themoredifficulttheweldingoperation.Weldingofsidelaps isnotrecommendedformaterialthicknessesof0.0295 0 0295inchesorthinner. thinner

Source: Cordeck

D.MatthewStuart

www.PDHcenter.com

www.PDHonline.org

ScrewConnections:

Screwconnections,suchasBuildexTEKSscrews,maybeeitherselfdrillingortheselftapping typethatrequiresapredrilledholepriortoinstallation.Themostcommonlyusedscrewsizeto attachdecktobarjoistsorstructuralsteelareNo.12andNo.14.SmallerNo.8andNo.10 screwsaremorecommonlyusedforsidelapconnections. Wh connecting When ti thi thinmetal t ldeck d kt tothi thicker k structural t t lmembers b such hasb barj joists i t orb beam flanges,littledifferenceexistsintheshearstrengthforNo.12andNo.14screws.Thisisbecause thefailuremodeofthedecktendstoinvolvearolluporcrushingofthedeckonthebearing sideofthescrewwithfracturelinessubsequentlydevelopinginthedecking. Forstitchconnectionsbetweensheets(atthesidelaps)adifferenttypeoffailureoccurs.The screw,whennotanchoredintoathickermorerigidelement,tipsovermoreeasilyandismore flexible.Althoughtheresultingstrengthmaybelimitedbybearingandtearinginthemetaldeck, withsufficientrotationofthesidelap,acombinedtearingandpulloutfailuremayalsooccur. TheSDIscrewstudiesindicatethatstitchscrewshearcapacityisindependentoftheyield strengthofsteeldeckthatiscommonlyusedforflexiblediaphragms.Themostcommon prematurefailureproblemwithsidelapattachmentsoccurswhenthescrewisallowedtothread upontheuppersheetbeforebecomingfullyengagedinthelower,thuscreatingmajorgaps betweentheadjacentunits.Suchimproperlyinstalledscrewsshouldberemovedandredriven whileforcingtheoverlappingsheetstoremainincontact.

PowderDrivenFasteners:

Metaldecktostructuralsupportconnectionscanalsobemadebyusingnaillikefasteners,driven eitherpneumaticallyorwithpowderactuatedtools.Suchfastenersaremadefromhardened steelandusuallyhaveaheattreatedshafttoenhanceanchorage.Theshaft,whichmayhavea slighttaper,canbefittedwithwashers,concavetothedrivingdirectiontoabsorbthefinaldriving energyandclampthesheetinposition. Sincetherearenopredrilledholesrequiredwiththesetypesofconnectors,theinstallation processdisplacesmaterialandleavesitlockedunderthewasher,resultinginverystiff connections.Thedrivingdepthiscontrolledbythepowerselectionforthetoolused.Fastener strengthisinfluencedbythedrivingdepth.TestsconductedbyWestVirginiaUniversityalso indicatethatthethicknessoftheunderlyingmaterialhasnoeffectonshearstrengthsincethe thinnersheetmaterialwillcontrolperformance. Adrivenfastenershouldbeinstalledsotheheadprojectsoutward,fromtheattachedpart,to limits li it set tby b th themanufacturer. f t Th Theaxis i of fthe th fastener f t must tbe b perpendicular di l to t the th sheet h tprior i todriving,usuallywithinplusorminus10degreesofvertical.Inaddition,itisrecommendedthat edgeandendfastenershaveaminimumsidelapedgedistanceof3/8inchandaminimumend andendlapdistanceof1inch.

D.MatthewStuart

10

www.PDHcenter.com

www.PDHonline.org

ButtonPunchedSidelaps:

Incertainpanels,oneedgehasanupstandingsingleelement,whiletheoppositesidehasa foldedoverdoubleelement.Aspanelsareplaced,thesingleelementisinsertedintothedouble element,producinganupstandingsidelapthatcanbebuttonpunchedtoprovideinterlockingof thetwoadjacentsheets. Ahand h doperated t dpunching hi tool t lforms f ath threelayer l nest tof fsmall llconesth that ti isl left fti inaslightly li htl loosestate,becauseofelasticrebound,astheformingforceisremoved.Manualbuttonpunched sidelapsdostabilizepaneledgesbutcontributelittlediaphragmstrengthastheycanvarygreatly inshapeandeffectiveness.Thequalityofhandinstalledbuttonpunchesisdifficulttomaintain. Theattachmentdependsonthecareandtheenergyusedbytheinstallerandthetoolused.A safetyfactorofthreeisrecommended.

Miscellaneous:

Atconditionswherejoistsspanperpendiculartoandterminateatashearwall,theedge mostdiaphragmpanelmaynotbeindirectcontactwiththewall.Attheseconditionsthe requiredperimeterdiaphragmconnectionscanbeaccomplishedbyinstallingablockspacer orcollectoralongthetopofthewallbetweenthejoiststhatmatchesthedepthofthe bearingassembly.Acontinuousangleattacheddirectlytothetopofandperpendicularto thejoistmayalsobeusedaslongasthebearingassemblyofthejoistsiscapableof transferringthecollectorforcetothetopofthewallbelow. below AllowableloadtablesareavailablefromtheSDIandanumberofdifferentdeck manufacturers.Loadtablesaretypicallycategorizedbythemeansofconnection,thepanel widthandthickness,spanlengths,thefasteningpatternandthetypeoffastenerandsidelab connector. Thestiffnessofadiaphragmisadirectindicationofhowsusceptiblethedeckistodistortions undertheinfluenceofinplaneshearforces.Theneedtoknowthemagnitudeofmovement isparticularlyimportantwhenassessingthetransferofforces,throughadiaphragm, betweenadjacentframesorshearwalls.Inaddition,thehorizontaldeflectionofthe diaphragmcanhaveanimpactontheswayofexteriorcladdingmembers,suchasprecastor tiltuppanels,inadditionaltothelocalizedflexuraldeflectionofthesameasaresultofwind loadsperpendiculartothespanofthediaphragm. Steeldeckdiaphragmsmaybereinforcedwithoverlaymentssuchas insulatingconcrete, structuralconcrete,orbydirectlyattachingflatpanelssuchasplywoodtoproduceaflat surface.Thesupplementalmaterialprovidesadditionalpathsthroughwhichshearforces maytraversethediaphragm. Itisalsopossibletoinstallhorizontaldiagonalsteelbracingorstrapsbeneaththedeckin ordertosupplementorsupplanttheshearcapacityofthedeck.

D.MatthewStuart

11

www.PDHcenter.com

www.PDHonline.org

DesignExample

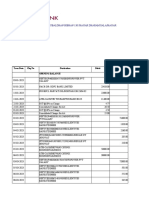

Thefollowingdesignexampleisforasimpleonestoryrectangularbuildingexposedtoatotalwindward andleewardpressureof35PSF.Itshouldbenotedthatinthisexamplethewindwardandleeward pressurereactionsatthetopofthecladdingandalongtheedgeofthediaphragmareshownasa combinedlineloadof245PLF. Asindicatedintheexample,thediaphragmreactionof16.54kipsisdividedbythelengthoftheend walltoarriveattheunitcollectordiaphragmshearforceof367.5PLF.Atthesametimeashear diagramisdevelopedfortheentirediaphragmspaninordertoassistintheestablishmentofdifferent fastenerzonesasrequiredtosatisfythevaryingmagnitudesofplanarshearresistanceresultingfrom theimposedloads. AnAllowableDiaphragmShearStrengthTable(availablefrommostoftheroofdeckmanufacturesas wellastheSDI)isthenreferredtoinordertoassessthemostappropriatefastenerspacingforthe appliedloads.Inthisexample,36inchwide,1inch,TypeB,22Gagemetalroofdeckusing5/8inch puddleweldsand#10TEKscrewsidelapfastenershavebeenpreselectedasthetypeofdeckand fastenerstobeused.ItshouldbenotedthatthecapacitiesintheShearStrengthTablealreadyincludea 1/3increaseforwind. Forajoistspacingof6feetandapreselectedweldpatternof4uniformlyspacedpuddleweldsacross the h 36inch i hwide id panel, l ashear h capacity i of f374 3 PLFcanb beobtained b i dusing i 8uniformly if l spaced dsidelap id l screwsalongthe6feetspanofthedeck.Thisvalueisgreaterthanthe367.5PLFendshearreaction calculatedintheexample. Nextatanarbitrarylocationapproximatelyofthediaphragmspanfromtheendsupportwallis analyzedinordertoallowforareductioninthenumberoffastenersoverthemiddlehalfoftheroof. Theequivalentuniformshearloadatthislocationonthediaphragmis193PLF.Referringagaintothe AllowableShearStrengthTableindicatesthatusingaweldpatternof3uniformlyspacedpuddlewelds acrossthe36inchwidepanel,ashearcapacityof193PLFcanbeobtainedusing2uniformlyspaced sidelapscrewsalongthe6feetspanofthedeck.

Detailingoftheconnectionofthemetalroofdecktotheendshearwallsisnotcoveredinthisexample, howevertypicallyacontinuousembeddedsteelplateinthetopofthewallwouldbeprovidedinorder forthedecktobesecuredtothetopofthewall. Shearinthedeckdiaphragmisalsocheckedforwindloadsagainsttheshortsideofthebuildingin whichthediaphragmonlyhastospan45feet betweenthe135feet longCMUshearwalls.The calculatedmaximumunitcollectordiaphragmshearforceof41PLFislessthantheminimum193PLF shearcapacityofthedeckintheotherorthogonaldirection,thereforethefastenerpatterndeveloped inthefirstpartoftheexampleisadequateforwindloadsintheoppositedirection.However,asthe joistbearingassemblyseparatesthetopedgeofthedeckfromtheCMUshearwallitisnecessaryfor the h collector ll force f tob betransmitted i dfrom f the h diaphragm di h tothe h topof fthe h wall llthrough h hthe h j joist i bearing b i assemblies.Amaximumrolloverforceof246poundsiscalculatedateachjoist,whichislessthanthe typicalindustrystandardjoistbearingassemblycapacityof1,650pounds,thereforenocollectorblockis requiredbetweeneachjoisttotransfertheshearforcestothetopofthewall. Inorderforthediaphragmtofunctionproperly,inadditiontoananalysisoftheplanarshearforces,itis necessarytoprovidechordmembersalongtheextremeedgesofthedecktoprovideresistancetothe extremeflexuraltensionandcompressioncomponentsofthedeepbeamdiaphragmanalogy.Forthis examplethemaximumchordforceiscalculatedasfollows: Mmax=((245PLF)*(135FT)2)/8=558.14KipFeet;ChordForce=558.14KF/45FT=12.4Kips Assumingthatcompressioncontrols,themaximumallowablecompressivestressof10.14ksiis calculatedfora36ksi,continuousL3x3xbracedat6feetoncenterwereitisconnectedtothetopof thejoistbearingassemblies.Theactualcalculatedcompressivestressof8.61ksiintheL3x3islessthan theallowable.Itisimportanttounderstandthatthischordmembermustbeprovidedalongboth135 feetlongedgesofthedeckwithbuttweldsprovidedatalljointsoftheL3x3.Thechordmemberfor windforcesintheoppositedirectionisprovidedbythecontinuousembeddedsteelplatelocatedinthe topofthe45feetlongendshearwallsasdescribedinthepreviousslide.

D.MatthewStuart

12

www.PDHcenter.com

www.PDHonline.org

D.MatthewStuart

13

www.PDHcenter.com

www.PDHonline.org

Source:SDI

D.MatthewStuart

14

www.PDHcenter.com

www.PDHonline.org

Thefollowingareillustrationsofroofdeckattachmentdiagramsandschedulesfromanexample project.Thisinformationshouldbeprovidedonallprojectsinordertoprovideclearinstructions tothedeckinstallerconcerningtherequiredfastenertype,spacingandextent.

D.MatthewStuart

15

Potrebbero piacerti anche

- Connectors PresDocumento10 pagineConnectors PresMohammed HassanNessuna valutazione finora

- Department of Civil Engineering Faculty of Engineering and Technology University of Ilorin, Ilorin Kwara State, NigeriaDocumento2 pagineDepartment of Civil Engineering Faculty of Engineering and Technology University of Ilorin, Ilorin Kwara State, NigeriaAshutosh KumarNessuna valutazione finora

- An Overview of Inverter-Based Resource Interconnection StandardsDocumento11 pagineAn Overview of Inverter-Based Resource Interconnection Standardsp61466365Nessuna valutazione finora

- Cioata18 Study - of - The - Stiffness - of - Modular - Fixtures - Using - T PDFDocumento10 pagineCioata18 Study - of - The - Stiffness - of - Modular - Fixtures - Using - T PDFMonica IordacheNessuna valutazione finora

- IEEE Guide For Testing Medium-Voltage Metal-Enclosed Switchgear For Internal Arcing FaultsDocumento27 pagineIEEE Guide For Testing Medium-Voltage Metal-Enclosed Switchgear For Internal Arcing FaultsFebry AryantoNessuna valutazione finora

- Metal Building Systems: Pdhonline Course S120 (1 PDH)Documento11 pagineMetal Building Systems: Pdhonline Course S120 (1 PDH)DrGanesh KameNessuna valutazione finora

- Metal Building Systems: Pdhonline Course S120 (1 PDH)Documento11 pagineMetal Building Systems: Pdhonline Course S120 (1 PDH)SunilBhargavSanathiNessuna valutazione finora

- Photovoltaic System GroundingDocumento29 paginePhotovoltaic System GroundingLuis PerdomoNessuna valutazione finora

- Stability in Steel Building Construction: Architecture Structural Engineering WallDocumento4 pagineStability in Steel Building Construction: Architecture Structural Engineering WallK RaghuNessuna valutazione finora

- Steel Related LitDocumento1 paginaSteel Related LitDaveNessuna valutazione finora

- Design of Guardrail PDFDocumento31 pagineDesign of Guardrail PDFVladimir SimeunovicNessuna valutazione finora

- IEEE 802.23afDocumento133 pagineIEEE 802.23afSniffer 1100% (1)

- IEEE Guide For The Application of Surge-Protective Devices For Low-Voltage (1000 V or Less) AC Power CircuitsDocumento63 pagineIEEE Guide For The Application of Surge-Protective Devices For Low-Voltage (1000 V or Less) AC Power Circuitsrafaelv123Nessuna valutazione finora

- IEEE Guide For The Protection of Network Transformers: IEEE Power Engineering SocietyDocumento38 pagineIEEE Guide For The Protection of Network Transformers: IEEE Power Engineering SocietymansourNessuna valutazione finora

- Now and Get: Best VTU Student Companion App You Can GetDocumento22 pagineNow and Get: Best VTU Student Companion App You Can Get1JS 17CV011Nessuna valutazione finora

- GS Ee134Documento8 pagineGS Ee134Prabh GurayaNessuna valutazione finora

- 4597 AAB SC 07 Addendum 2 R0v0 34Documento1 pagina4597 AAB SC 07 Addendum 2 R0v0 34danieldumapitNessuna valutazione finora

- Non Permanent Joints: Héctor Alejandro Ramírez Villalpando Elvira Graciela Córdova NúñezDocumento19 pagineNon Permanent Joints: Héctor Alejandro Ramírez Villalpando Elvira Graciela Córdova NúñezHeKtor RamiRezNessuna valutazione finora

- Analysis of Stability of Tall Building by The Use of Efficient Outrigger and Wall Belt System Under Earthquake Response A ReviewDocumento9 pagineAnalysis of Stability of Tall Building by The Use of Efficient Outrigger and Wall Belt System Under Earthquake Response A ReviewIJRASETPublicationsNessuna valutazione finora

- IEEE 1547 National Standard For Interconnecting Distributed Generation: How Could It Help My Facility?Documento9 pagineIEEE 1547 National Standard For Interconnecting Distributed Generation: How Could It Help My Facility?José SánchezNessuna valutazione finora

- Steel Deck 1Documento47 pagineSteel Deck 1Kiếm Trần HoànNessuna valutazione finora

- SteerBridge JD - CFM-IDIQ San Francisco - Electrical EngineerDocumento3 pagineSteerBridge JD - CFM-IDIQ San Francisco - Electrical Engineersmrasteg12Nessuna valutazione finora

- Electrical Engineer Sample Resume: Professional ExperienceDocumento1 paginaElectrical Engineer Sample Resume: Professional ExperienceAnand SinhaNessuna valutazione finora

- DSS Site Visit ReportDocumento13 pagineDSS Site Visit Report39 - Deep MandokarNessuna valutazione finora

- Electrical Engineer (Power Systems)Documento2 pagineElectrical Engineer (Power Systems)Mark Jecel RapirNessuna valutazione finora

- Ce 103 LM 1Documento13 pagineCe 103 LM 1shuckss taloNessuna valutazione finora

- Paper 011 PDocumento13 paginePaper 011 Pfoush bashaNessuna valutazione finora

- Ijsi 2013 44 457-476Documento21 pagineIjsi 2013 44 457-476Muhd RadzifNessuna valutazione finora

- Lightning Protection System ExplainedDocumento2 pagineLightning Protection System Explainedabuzar12533Nessuna valutazione finora

- Neutral Axis Depth Page 53Documento130 pagineNeutral Axis Depth Page 53Prachi TaoriNessuna valutazione finora

- Explain - Deformation CompatibilityDocumento18 pagineExplain - Deformation CompatibilityArnold ApostolNessuna valutazione finora

- Introduction To ConnectorsDocumento1 paginaIntroduction To ConnectorsAutor AutorNessuna valutazione finora

- ACI 550.1R-01 Emulating Cast-In-Place Detailing in Precast Concrete StructuresDocumento16 pagineACI 550.1R-01 Emulating Cast-In-Place Detailing in Precast Concrete StructuresnoijpNessuna valutazione finora

- Lightning Proection System1Documento2 pagineLightning Proection System1Pratheep SelvakumaranNessuna valutazione finora

- Uwm Electrical Eng BrochureDocumento2 pagineUwm Electrical Eng Brochurefandhiejavanov2009Nessuna valutazione finora

- Mse Wall GuidelinesDocumento49 pagineMse Wall Guidelinesamandeep0910Nessuna valutazione finora

- Solento Smith Resume Navy ResumeDocumento4 pagineSolento Smith Resume Navy Resumeapi-272610056Nessuna valutazione finora

- Previews IEEE 1100-2005 PreDocumento15 paginePreviews IEEE 1100-2005 PreJorge Rodriguez AlvaradoNessuna valutazione finora

- Box 30001/ Dept 3 SOLAR: States DepartmentDocumento6 pagineBox 30001/ Dept 3 SOLAR: States Departmentlos_erizosNessuna valutazione finora

- Smart Patch For Monitoring The Integrity of Steel Frame JointsDocumento9 pagineSmart Patch For Monitoring The Integrity of Steel Frame JointsjovanaNessuna valutazione finora

- Littelfuse Fuseology Selection Guide PDFDocumento87 pagineLittelfuse Fuseology Selection Guide PDFmahesh reddy mNessuna valutazione finora

- Ieee691-2001. Guide For Transmission StructureDocumento193 pagineIeee691-2001. Guide For Transmission StructureAlexis Fernandez Cordova88% (8)

- Available At: HTTP://WWW - Fema.gov/earthquake-Publications/fema-E-74-Reducing-Risks-Nonstructural-Earthquake-Damage Last Modified: December 2012Documento11 pagineAvailable At: HTTP://WWW - Fema.gov/earthquake-Publications/fema-E-74-Reducing-Risks-Nonstructural-Earthquake-Damage Last Modified: December 2012Chelivery CKNessuna valutazione finora

- Review of Documents On Seismic Strengthening of Existing BuildingsDocumento12 pagineReview of Documents On Seismic Strengthening of Existing Buildingsm7j7a7Nessuna valutazione finora

- IPD and Illumination - 11Documento23 pagineIPD and Illumination - 11Milan AcharyaNessuna valutazione finora

- 1656 2010Documento19 pagine1656 2010Antonio Francisco Leite NetoNessuna valutazione finora

- High Fidelity IBR Generic Model Development and Validation For Planning Operating and Protection StudiesDocumento102 pagineHigh Fidelity IBR Generic Model Development and Validation For Planning Operating and Protection StudiesAbdel-Rahman SaifedinNessuna valutazione finora

- Class Presentation in Simplified Rehabilitation & ArchitecturalDocumento18 pagineClass Presentation in Simplified Rehabilitation & ArchitecturalGirijesh Prasad SahNessuna valutazione finora

- IEEE - PES 1547andPVSeminar 06NOV10 F2b PDFDocumento4 pagineIEEE - PES 1547andPVSeminar 06NOV10 F2b PDFwahlgren9483Nessuna valutazione finora

- Manual For Design and Construction Monitoring of Soil Nail WallsDocumento3 pagineManual For Design and Construction Monitoring of Soil Nail Wallsmauricio buenoNessuna valutazione finora

- Pre Engineered BuildingsDocumento8 paginePre Engineered BuildingsPunya SureshNessuna valutazione finora

- Welded ConnectionsDocumento10 pagineWelded ConnectionsminaNessuna valutazione finora

- Empowering Networks: A Comprehensive Guide to Medium Voltage SwitchgearDa EverandEmpowering Networks: A Comprehensive Guide to Medium Voltage SwitchgearNessuna valutazione finora

- Unified Power Flow Controller Technology and ApplicationDa EverandUnified Power Flow Controller Technology and ApplicationValutazione: 4 su 5 stelle4/5 (5)

- High Speed Digital Design: Design of High Speed Interconnects and SignalingDa EverandHigh Speed Digital Design: Design of High Speed Interconnects and SignalingNessuna valutazione finora

- Power Electronics Diploma Interview Q&A: Career GuideDa EverandPower Electronics Diploma Interview Q&A: Career GuideNessuna valutazione finora

- Nuclear Power Plant Safety and Mechanical Integrity: Design and Operability of Mechanical Systems, Equipment and Supporting StructuresDa EverandNuclear Power Plant Safety and Mechanical Integrity: Design and Operability of Mechanical Systems, Equipment and Supporting StructuresValutazione: 5 su 5 stelle5/5 (1)

- S 184 ContentDocumento16 pagineS 184 ContentA Sattar M El-farraNessuna valutazione finora

- Handbook of Steel Construction 9th Edition, CISCDocumento1.034 pagineHandbook of Steel Construction 9th Edition, CISCArmando Moreno Sanchez90% (50)

- AECT480-Lecture 26-TABELA DE CONVERSÃODocumento11 pagineAECT480-Lecture 26-TABELA DE CONVERSÃORicardo GrangeiroNessuna valutazione finora

- Seismic-Resistant Design - CBFs PDFDocumento31 pagineSeismic-Resistant Design - CBFs PDFciviliiiNessuna valutazione finora

- 544 3r-08webDocumento2 pagine544 3r-08webA Sattar M El-farraNessuna valutazione finora

- Steel Fiber Reinforced ConcreteDocumento9 pagineSteel Fiber Reinforced Concretespiridisp100% (1)

- Steel Fibre-Reinforced Concrete - Present and Future in Engineering ConstructionDocumento9 pagineSteel Fibre-Reinforced Concrete - Present and Future in Engineering ConstructionA Sattar M El-farraNessuna valutazione finora

- Bridge Design Manual 2006 PDFDocumento672 pagineBridge Design Manual 2006 PDFElisabetta BolzoniNessuna valutazione finora

- Steel Fibre-Reinforced Concrete - Present and Future in Engineering ConstructionDocumento9 pagineSteel Fibre-Reinforced Concrete - Present and Future in Engineering ConstructionA Sattar M El-farraNessuna valutazione finora

- NRCC 50275Documento4 pagineNRCC 50275A Sattar M El-farraNessuna valutazione finora

- 0007 02 BluewaterbridgeDocumento3 pagine0007 02 BluewaterbridgeA Sattar M El-farraNessuna valutazione finora

- Modern Practice On Bridge Construction On World RailwaysDocumento37 pagineModern Practice On Bridge Construction On World RailwaysA Sattar M El-farraNessuna valutazione finora

- Final Quiz 2 - Attempt ReviewDocumento6 pagineFinal Quiz 2 - Attempt Reviewkoraijohnson7Nessuna valutazione finora

- Uniden PowerMax 5.8Ghz-DSS5865 - 5855 User Manual PDFDocumento64 pagineUniden PowerMax 5.8Ghz-DSS5865 - 5855 User Manual PDFtradosevic4091Nessuna valutazione finora

- A Detailed Lesson PlanDocumento5 pagineA Detailed Lesson PlanIsaac-elmar Agtarap74% (23)

- LAB REPORT - MGCLDocumento5 pagineLAB REPORT - MGCLKali stringsNessuna valutazione finora

- M2252D PS PDFDocumento36 pagineM2252D PS PDFCarmen da SilvaNessuna valutazione finora

- Royal British College Dancesport TeamDocumento10 pagineRoyal British College Dancesport TeamAnna rose CabatinganNessuna valutazione finora

- Task of ProjectDocumento14 pagineTask of ProjectAbdul Wafiy NaqiuddinNessuna valutazione finora

- MC4 CoCU 6 - Welding Records and Report DocumentationDocumento8 pagineMC4 CoCU 6 - Welding Records and Report Documentationnizam1372100% (1)

- Ferrero A.M. Et Al. (2015) - Experimental Tests For The Application of An Analytical Model For Flexible Debris Flow Barrier Design PDFDocumento10 pagineFerrero A.M. Et Al. (2015) - Experimental Tests For The Application of An Analytical Model For Flexible Debris Flow Barrier Design PDFEnrico MassaNessuna valutazione finora

- STW 44 3 2 Model Course Leadership and Teamwork SecretariatDocumento49 pagineSTW 44 3 2 Model Course Leadership and Teamwork Secretariatwaranchai83% (6)

- XXXX96 01 01 2023to28 08 2023Documento18 pagineXXXX96 01 01 2023to28 08 2023dabu choudharyNessuna valutazione finora

- Lecture 7 - Friction - NptelDocumento18 pagineLecture 7 - Friction - Nptels_murugan02Nessuna valutazione finora

- Week 1 Familiarize The VmgoDocumento10 pagineWeek 1 Familiarize The VmgoHizzel De CastroNessuna valutazione finora

- 12 Logarithm Approximate FloatingDocumento6 pagine12 Logarithm Approximate FloatingPhilippe Englert VelhaNessuna valutazione finora

- Cella Di Carico Sartorius MP77 eDocumento3 pagineCella Di Carico Sartorius MP77 eNCNessuna valutazione finora

- Chapter 9Documento28 pagineChapter 9Aniket BatraNessuna valutazione finora

- 3-Phase Short-Circuit Current (Isc) at Any Point Within A LV Installation - Electrical Installation GuideDocumento6 pagine3-Phase Short-Circuit Current (Isc) at Any Point Within A LV Installation - Electrical Installation GuideYuukinoriNessuna valutazione finora

- Chapter 1 INTRODUCTION TO LITERATUREDocumento4 pagineChapter 1 INTRODUCTION TO LITERATUREDominique TurlaNessuna valutazione finora

- Full Download University Physics With Modern Physics 14th Edition Young Test Bank PDF Full ChapterDocumento13 pagineFull Download University Physics With Modern Physics 14th Edition Young Test Bank PDF Full Chapterpoetrycloudyzjm12q100% (19)

- WD Support Warranty Services Business Return Material Authorization RMA Pre Mailer For ResellerDocumento3 pagineWD Support Warranty Services Business Return Material Authorization RMA Pre Mailer For ResellerZowl SaidinNessuna valutazione finora

- Dress Code19sepDocumento36 pagineDress Code19sepapi-100323454Nessuna valutazione finora

- Periodic Table Lab AnswersDocumento3 paginePeriodic Table Lab AnswersIdan LevyNessuna valutazione finora

- Construction Drawing: Legend Notes For Sanitary Piping Installation General Notes NotesDocumento1 paginaConstruction Drawing: Legend Notes For Sanitary Piping Installation General Notes NotesrajavelNessuna valutazione finora

- Aircraft Flight Control SystemDocumento25 pagineAircraft Flight Control Systemthilina jayasooriyaNessuna valutazione finora

- Immobilization of Rhodococcus Rhodochrous BX2 (An AcetonitriledegradingDocumento7 pagineImmobilization of Rhodococcus Rhodochrous BX2 (An AcetonitriledegradingSahar IrankhahNessuna valutazione finora

- Storage-Tanks Titik Berat PDFDocumento72 pagineStorage-Tanks Titik Berat PDF'viki Art100% (1)

- Present Perfect and Present Perfect ProgressiveDocumento5 paginePresent Perfect and Present Perfect ProgressiveKiara Fajardo matusNessuna valutazione finora

- NCERT Solutions For Class 10 Maths Chapter 5 Arithmetic Progression (Ex 5.1) Exercise 5.1Documento8 pagineNCERT Solutions For Class 10 Maths Chapter 5 Arithmetic Progression (Ex 5.1) Exercise 5.1Akash DasNessuna valutazione finora

- Essay On Stem CellsDocumento4 pagineEssay On Stem CellsAdrien G. S. WaldNessuna valutazione finora

- WCDMA Radio Access OverviewDocumento8 pagineWCDMA Radio Access OverviewDocMasterNessuna valutazione finora