Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

A Better Kiln Coating

Caricato da

amirDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

A Better Kiln Coating

Caricato da

amirCopyright:

Formati disponibili

KILN MAINTENANCE

I A better kiln coating?

by Guilherme Ferreira and After studying the kiln preheating and feeding procedures of

Luiz Pinho, Dynamis Ltda, hundreds of kilns around the world, Dynamis experts show two

Brazil opposite tendencies and examine the characteristics of each one. This

article discusses how the proper formation of kiln internal coating

can dramatically improve the life of refractory bricks.

S

ometimes one may face a pretty the kiln operation has reached a steady chamber (red dotted line), while in other

intriguing fact: two kilns constructed situation. The use of one of those fuels is cases the raw meal feeding starts at even

according to the same design, proper for a better combustion control, higher temperatures (solid blue line).

practically at the same time and fed with making it easier to adjust temperature Two main tendencies can be identified,

virtually the same raw meal and fuel peak position and to follow the heating not properly referring to the preheating

present different behaviour. When you ask curve through an accurate handling itself, but concerning the flame

the operators which kiln is best, they will of fuel flow. Additionally, those fuels adjustment after the desired smoke

be unanimous: kiln “A” is better than kiln make flame stability a lot easier under chamber temperature had been reached

“B”. Why do these things happen? cold secondary air conditions, even at and raw meal feeding had started.

Every equipment has its own history. relatively low excess-air rates. Also, it

Incidents that may have occurred to is important to control the combustion 1. Classical procedure

one may never happen to the other. We gases draft, which has an important role Most of kiln operators had the tendency

know that, depending on the kind of using a narrow and soft flame,

of incident that can occur to a kiln, in many cases a very long one.

its performance can be affected for Sometimes the flame length was a

a long time, if not for the rest of its requirement, but normally it was a

working life. Particular fails demand mere consequence of the combustion

specific maintenance solutions and the parameters that had been adopted to

succession of different events to each protect the bare lining and nothing

part of the kiln can lead to different could be done to shorten the flame,

behaviour with identical kilns. if so wanted. The lack of resources

This article deals with one of the in the main burner for shaping the

most important operations that will flame is often worsened by the cold

affect a clinker kiln performance, secondary air. Figure 2 presents a

especially concerning refractory lining diagram showing the evolution of the

Figure 1: kiln heating variations

life: the phases of preheating and protective coating over the refractory

feeding a new kiln or one that has brick lining in a kiln running under the

suffered a large lining change. During in the temperature profile, including both so-called classical procedure.

many years, Dynamis experts have been kiln and preheating tower. Normally, the

designing and putting to work hundreds oxygen content of those gases will vary What can we say about this

of combustion systems for rotary kilns. within 4-6 per cent at preheater exhaust, procedure?

During new burner start-up operations, depending on kiln characteristics (general • the operator must keep the flame away

normally following major refractory dimensions, number of cyclone stages, from the bricks even after a significant

maintenances, it was very common to false air infiltrations, etc). increase in fuel flow

hear from operation managers: “Let us Figure 1 shows some variations • as the flame tends to be long,

follow the recommended time multiplied concerning kiln pre-heating procedures. temperature peak will probably be located

by the temperature curve at the smoke The diagram indicates preheating can at upper transition zone

chamber” – and also: “Don’t allow that take 20 to 36 hours, depending on the • the hot meal reaches the upper

flame to impinge on the new bricks!”. type of refractory, as well as the extension transition zone and starts to form the

The manager was totally right. But were of the maintenance services. Mode 1 coating that protects the bricks there

those two recommendations enough to refers to short warm-up. Mode 2 refers to • the coating formation proceeds from

guarantee the desired performance of the a more conventional heating rate. Finally, upper to lower sections passing through

brand new bricks? – Certainly not. Mode 3 corresponds to extended warm- burning/clinkering zone and then to lower

We know that the preheating and up period, which is recommended after transition zone

feeding of a rotary kiln are critical large refractory maintenance or after the • lower transition zone bricks are put

operations. Normally, they are conducted cast of refractory concretes. In some cases under moderate to intense heat flux for a

either with natural gas or fuel-oil until the kiln is fed with 750˚C at the smoke long period of time.

ICR DECEMBER 2005

KILN MAINTENANCE

formation at burning/ may take 20-36 hours, depending on the

clinkering zone and then extension of refractory services. Equally

at upper transition zone; important is a non-interrupted preheating

• lower transition zone process, as break-offs during the operation

bricks are put under may lead to high temperature gradients

intense heat flux for a along brick thickness.

short period of time. Additionally, the smoke chamber (back

end) temperature at which the raw meal

Comments feeding starts is important and defines

The differences between how long the new bricks at lower kiln

the two opposite sections are kept under overheating

procedures become more risk. The use of kiln shell cooling fans

Figure 2: conventional coating formation process critical and take a more in combination with the readings of a

important role in the temperature scanner as important tools

2. Alternative procedure modern kilns, as SHL (Kiln Specific Heat to help operators to shape the internal

The alternative procedure is becoming Loading) increases. For reference, we can coating as required. Concerning those

more and more common and requires make a relation between dry-process kiln fans, both practical observation and

a very good flame pattern control. It technologies and SHLs as follows: theoretical studies show the superiority

consists of working with a shorter flame, Long Dry Kilns 1 to 2 Gcal/hm2 of the high-velocity air streams from

not only during warm-up, but mainly Preheater Kilns 2.5 to 4.5 Gcal/hm2 centrifugal fans over the low-velocity

during kiln feed. Naturally, the care Precalciner Kilns 2.5 to 4 Gcal/hm2 flows from axial fans.

for avoiding flame impingement over Short Precalciner Kilns 3.5 to 5 Gcal/hm2 Finally, adequate coating formation

refractory bricks remains a priority. It should not be a surprise to notice depends very much on the resources for

Figure 3 shows the evolution of the that some precalciner kilns have faced flame shaping offered by the kiln burner,

protective coating over the refractory brick refractory problems – for instance, a provided that raw meal composition is

lining in this case. 90-day basic brick campaign – either at adequate, refractory “coatability” is ok,

burning/clinkering or transition zones solid fuel fineness is according to the

What can be said about this since their start-up and rendered some specifications and a series of secondary

procedure? headaches to people involved until a requirements have been met. _________I

• the operator must have a good control solution was found. On the other hand,

on combustion conditions to place there are records of

temperature peak at lower transition zone; preheater kilns with quite

• once the kiln is fed, the hot meal must good refractory campaigns

reach the lower transition zone as fast as – 1200 days for aluminous

possible, to start coating formation at that bricks at calcining zone

point and protect the bricks; and 400 days for basic

• a little ‘cold blood’ and confidence in bricks at transition and/or

the combustion system resources are clinkering/burning zones.

necessary to the operators, who will see Other operational

the raw meal approaching – but not factors that may have an

passing through – the kiln discharge; influence on the refractory

• once initiated, the coating at lower performance refer to the

Figure 3: alternative coating formation process

transition zone ‘supports’ the coating warm-up period, which

DECEMBER 2005 ICR

Potrebbero piacerti anche

- Kiln Ring GapDocumento3 pagineKiln Ring Gapamir100% (2)

- Chapter 5 - Lubrication ManagementDocumento41 pagineChapter 5 - Lubrication ManagementAdinz DinNessuna valutazione finora

- SF Cross-Bar Cooler FLSDocumento8 pagineSF Cross-Bar Cooler FLSamir100% (4)

- Blaine Vs ResiduesDocumento3 pagineBlaine Vs ResiduesVisnu Sankar100% (2)

- 04.04 Kiln Operations Guide Lines - ENGDocumento23 pagine04.04 Kiln Operations Guide Lines - ENGbrenbra50% (2)

- Circulation Phenomena in the Clinkerization ProcessDocumento58 pagineCirculation Phenomena in the Clinkerization ProcessZein Khalifa100% (2)

- Kiln Emergency YSDocumento50 pagineKiln Emergency YSShadi Al Habbal100% (3)

- Cement Milling I Blue Circle PDFDocumento24 pagineCement Milling I Blue Circle PDFIrshad HussainNessuna valutazione finora

- Pyro ProcessingDocumento29 paginePyro ProcessingMKPashaPasha100% (2)

- Co Processing Cement KilnsDocumento10 pagineCo Processing Cement Kilnshanhccid0% (1)

- Report On Cement MillDocumento9 pagineReport On Cement MillYounas Khan100% (1)

- Kiln Inlet Lamella Seal FLSDocumento2 pagineKiln Inlet Lamella Seal FLSamir100% (3)

- PID-Fuzzy Controller For Grate Cooler in Cement PlantDocumento5 paginePID-Fuzzy Controller For Grate Cooler in Cement PlantamirNessuna valutazione finora

- Heat correction of kiln cranks is cost effectiveDocumento4 pagineHeat correction of kiln cranks is cost effectiveMohamed Shehata100% (2)

- VDZ-Onlinecourse 2 4 enDocumento16 pagineVDZ-Onlinecourse 2 4 enAnonymous iI88LtNessuna valutazione finora

- NG Candle Wax Guide: Paraffin, Soy, Beeswax & MoreDocumento8 pagineNG Candle Wax Guide: Paraffin, Soy, Beeswax & MoreNancyHendryNessuna valutazione finora

- VDZ-Onlinecourse 7 3 enDocumento20 pagineVDZ-Onlinecourse 7 3 enAnonymous iI88LtNessuna valutazione finora

- Structural Calculation MemoriesDocumento43 pagineStructural Calculation MemoriesScott Wade100% (1)

- VDZ-Onlinecourse 4 5 enDocumento30 pagineVDZ-Onlinecourse 4 5 enAnonymous iI88LtNessuna valutazione finora

- Red RiverDocumento16 pagineRed RiverNael100% (1)

- IKN Pendulum CoolerDocumento11 pagineIKN Pendulum Cooleramir100% (3)

- SO3 Build Up and ControlDocumento6 pagineSO3 Build Up and ControlM. Ali Parvez100% (1)

- Cement Kiln ReportDocumento22 pagineCement Kiln Reportamir100% (1)

- Raw Material Preparation: Raw Meal Homogenization and Kiln Dust Management Pe Latam 2012Documento26 pagineRaw Material Preparation: Raw Meal Homogenization and Kiln Dust Management Pe Latam 2012Pedro PastenNessuna valutazione finora

- Advancement in Refractories used for Cement Rotary kiln(CRKDocumento75 pagineAdvancement in Refractories used for Cement Rotary kiln(CRKmahendra sen100% (1)

- Flame For Cement Kilns KP Pradeep KumarDocumento62 pagineFlame For Cement Kilns KP Pradeep KumarHuyentrang Nguyen100% (1)

- Maintaining Stable Kiln OperationDocumento6 pagineMaintaining Stable Kiln OperationJCSNessuna valutazione finora

- Cement Kilns-Chlorine Impact On ProcessDocumento27 pagineCement Kilns-Chlorine Impact On Processmuhaisen2009100% (4)

- Snowman CompositionDocumento7 pagineSnowman CompositionSunil MohanNessuna valutazione finora

- Clinker CoolersDocumento74 pagineClinker CoolersMuhammed EmamiNessuna valutazione finora

- Lucie MillDocumento50 pagineLucie MillJoko DewotoNessuna valutazione finora

- Annual Audit of CM 1Documento26 pagineAnnual Audit of CM 1Tamer Fathy100% (1)

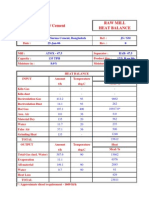

- Raw Mill Heat BalanceDocumento1 paginaRaw Mill Heat BalanceElwathig Bakhiet100% (1)

- Handbook of Biopolymers Advances and Multifaceted Applications (Ahmed, Shakeel Kanchi, Suvardhan Kumar Etc.)Documento323 pagineHandbook of Biopolymers Advances and Multifaceted Applications (Ahmed, Shakeel Kanchi, Suvardhan Kumar Etc.)Tecuitlatl100% (3)

- Welding CrackingDocumento8 pagineWelding CrackingjensdcvNessuna valutazione finora

- VDZ-Onlinecourse 6 5 enDocumento30 pagineVDZ-Onlinecourse 6 5 enSuadNessuna valutazione finora

- Manufacturing Workforce Training - Optimized Kiln Control GuideDocumento26 pagineManufacturing Workforce Training - Optimized Kiln Control GuideOUSSAMA LAKHILI100% (1)

- By Pass SystemDocumento56 pagineBy Pass SystemIrshad Hussain100% (2)

- Clinker FormationDocumento120 pagineClinker FormationDragos PlaesuNessuna valutazione finora

- Specialized coal and pet-coke combustion designDocumento6 pagineSpecialized coal and pet-coke combustion designary.engenharia1244Nessuna valutazione finora

- CM 2 Filling DegreeDocumento9 pagineCM 2 Filling DegreeElwathig BakhietNessuna valutazione finora

- The Use of Nano-Materials For The Conservation of Historic ArchitectureDocumento25 pagineThe Use of Nano-Materials For The Conservation of Historic ArchitecturelovnishNessuna valutazione finora

- Lime Kiln Control Using Simple Advanced Pid Control PDFDocumento4 pagineLime Kiln Control Using Simple Advanced Pid Control PDFIwan TirtaNessuna valutazione finora

- Burning DashboardDocumento3 pagineBurning DashboardMehmet C100% (1)

- 117 - DWP Difficult Solid Fuel Burning 191207 - RDB&YJBDocumento10 pagine117 - DWP Difficult Solid Fuel Burning 191207 - RDB&YJBmkpqNessuna valutazione finora

- Measure Clinker Temperature at Cooler ExitDocumento3 pagineMeasure Clinker Temperature at Cooler ExitTamer FathyNessuna valutazione finora

- Duoflex BurnerDocumento6 pagineDuoflex Burnersinghite100% (1)

- Forms of Alkalies and Their Effect On Clinker FormationDocumento11 pagineForms of Alkalies and Their Effect On Clinker Formationkonstantina139Nessuna valutazione finora

- Cement IndustryDocumento27 pagineCement IndustryAhmed Mahmoud100% (1)

- Maximizing Alternative Fuel Use in Cement ProductionDocumento4 pagineMaximizing Alternative Fuel Use in Cement Productionmohamadi42100% (1)

- The Effects of Oxygen Enrichment On ClinkerDocumento9 pagineThe Effects of Oxygen Enrichment On ClinkerNael100% (1)

- Odudimu Certification ScenerioDocumento50 pagineOdudimu Certification Scenerioabosede2012Nessuna valutazione finora

- Mastering Preheater Kiln Build-up ControlDocumento13 pagineMastering Preheater Kiln Build-up ControlJoko Dewoto100% (1)

- Measuring False Air in Pyroprocessing SystemsDocumento3 pagineMeasuring False Air in Pyroprocessing SystemsharyantoaditNessuna valutazione finora

- 03.01 PR PYR P06 02 How To Start-Up & Optimize A Burner v1Documento6 pagine03.01 PR PYR P06 02 How To Start-Up & Optimize A Burner v1rupesh soniNessuna valutazione finora

- Refractory Science Refractories - : 1.1 Composition and StructureDocumento14 pagineRefractory Science Refractories - : 1.1 Composition and StructureNikki AlbiosNessuna valutazione finora

- Advances in Cement Technology: Critical Reviews and Case Studies on Manufacturing, Quality Control, Optimization and UseDa EverandAdvances in Cement Technology: Critical Reviews and Case Studies on Manufacturing, Quality Control, Optimization and UseValutazione: 4.5 su 5 stelle4.5/5 (12)

- Cement KilnDocumento2 pagineCement Kilnamir100% (2)

- Energy Auditing and Recovery For Dry Type Cement Rotary Kiln Systems A Case StudyDocumento12 pagineEnergy Auditing and Recovery For Dry Type Cement Rotary Kiln Systems A Case Study1977julNessuna valutazione finora

- Dry Process KilnDocumento20 pagineDry Process KilnISLAM I. Fekry100% (8)

- Mechanism of Clinker Coating Formation & FlameDocumento39 pagineMechanism of Clinker Coating Formation & FlameNael93% (14)

- PREHEATER BLOCKAGES Problem Diagnosis and Solution - INFINITY FOR CEMENT EQUIPMENTDocumento19 paginePREHEATER BLOCKAGES Problem Diagnosis and Solution - INFINITY FOR CEMENT EQUIPMENTali100% (2)

- Rotary Kilns: Transport Phenomena and Transport ProcessesDa EverandRotary Kilns: Transport Phenomena and Transport ProcessesValutazione: 4.5 su 5 stelle4.5/5 (4)

- New Technology For Indirect Thick Slurry Heating System: Hatch Associates LTD, Perth, WA, AustraliaDocumento5 pagineNew Technology For Indirect Thick Slurry Heating System: Hatch Associates LTD, Perth, WA, AustraliaRogerio CannoniNessuna valutazione finora

- 4 Seven Refractories Power Plants and Incinerators 2019 WEB 1Documento15 pagine4 Seven Refractories Power Plants and Incinerators 2019 WEB 1Kristanto WahyudiNessuna valutazione finora

- Heatwoodccn GasifierDocumento4 pagineHeatwoodccn GasifiermbenattiakNessuna valutazione finora

- The Heart of Operations - World Cement - 02-2015Documento4 pagineThe Heart of Operations - World Cement - 02-2015fetniNessuna valutazione finora

- LOW-E Tempering PrincipleDocumento3 pagineLOW-E Tempering PrincipleZoljargal TsegmidNessuna valutazione finora

- Kuliah11 FiringEnglishDocumento34 pagineKuliah11 FiringEnglishsoonvyNessuna valutazione finora

- Improve Vacuum Heater Reliability: Hydrocarbon ProcessingDocumento4 pagineImprove Vacuum Heater Reliability: Hydrocarbon Processingros56Nessuna valutazione finora

- Tuyere Stock TechnologiesDocumento5 pagineTuyere Stock TechnologiesSubbuNessuna valutazione finora

- Introduction to Boiler Types and ClassificationsDocumento9 pagineIntroduction to Boiler Types and ClassificationsGH Eco RJNessuna valutazione finora

- Compact System For Secondary FuelsDocumento8 pagineCompact System For Secondary FuelsamirNessuna valutazione finora

- Coolax Grate Cooler FLSDocumento4 pagineCoolax Grate Cooler FLSamirNessuna valutazione finora

- Reactive & Functional Polymers: Li Liu, Jun Zhang, Ren-Cheng TangDocumento8 pagineReactive & Functional Polymers: Li Liu, Jun Zhang, Ren-Cheng TangAnonymous bkXWlFidNessuna valutazione finora

- Sika ViscoCrete 4203 NSDocumento2 pagineSika ViscoCrete 4203 NSSantosh Kumar GoudaNessuna valutazione finora

- Sop Magnesium Anode Installation - ThiessDocumento10 pagineSop Magnesium Anode Installation - ThiessbonnicoNessuna valutazione finora

- Solid, Liquid, Gas Explanation TextDocumento2 pagineSolid, Liquid, Gas Explanation Textnettexts100% (1)

- June 2001 Practice DiplomaDocumento42 pagineJune 2001 Practice DiplomaElaine LauNessuna valutazione finora

- MSDS of Methyl PalmitateDocumento8 pagineMSDS of Methyl PalmitateAmm MarakataNessuna valutazione finora

- Cera Crystalline IntegralDocumento2 pagineCera Crystalline IntegralR.ThangarajNessuna valutazione finora

- 1ST Law of ThermodynamicsDocumento7 pagine1ST Law of ThermodynamicsKen BorjaNessuna valutazione finora

- Avionics Fiber Optical CablesDocumento6 pagineAvionics Fiber Optical CablesT/ROX100% (1)

- ASTM A694 F60 - Heat Treatment and Mechanical Properties - ICRF 2012Documento3 pagineASTM A694 F60 - Heat Treatment and Mechanical Properties - ICRF 2012Noushad Bin JamalNessuna valutazione finora

- 12.3 PPTDocumento22 pagine12.3 PPTKingProNessuna valutazione finora

- Cryogenic Transfer Line ChilldownDocumento10 pagineCryogenic Transfer Line ChilldownIgnacio ChaparroNessuna valutazione finora

- Synthesis of Fuel From Waste PlasticDocumento63 pagineSynthesis of Fuel From Waste Plasticamirah1999Nessuna valutazione finora

- Leaflet SPM and SOPDocumento4 pagineLeaflet SPM and SOPAbdullah Al-ZahraniNessuna valutazione finora

- Rubifloor 2021Documento43 pagineRubifloor 2021Sandro CaeiroNessuna valutazione finora

- MCQ Questions For Class 10 Science Chemical Reactions and Equations With AnswersDocumento12 pagineMCQ Questions For Class 10 Science Chemical Reactions and Equations With AnswersNadim BashirNessuna valutazione finora

- Renu Yarn List: Type Quality Brightness Country of Origin MOQDocumento4 pagineRenu Yarn List: Type Quality Brightness Country of Origin MOQSharif0721Nessuna valutazione finora

- Instrumental 3.2Documento4 pagineInstrumental 3.2deon kumukwayaNessuna valutazione finora

- Machined Seals: Product RangeDocumento43 pagineMachined Seals: Product RangeAnonymous r3MoX2ZMTNessuna valutazione finora

- Construction Tech II Door TypesDocumento105 pagineConstruction Tech II Door Typessydney augustNessuna valutazione finora

- Smart Supercapacitors From Materials To DevicesDocumento13 pagineSmart Supercapacitors From Materials To DevicesRavi SuryaNessuna valutazione finora

- Removal of H2S in down-flow GAC biofiltration using sulfide oxidizing bacteriaDocumento3 pagineRemoval of H2S in down-flow GAC biofiltration using sulfide oxidizing bacteriaมาร์ค มัธยมNessuna valutazione finora

- Load CalculationsDocumento3 pagineLoad CalculationsWilkenn TuazonNessuna valutazione finora