Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Threads - Thread Gages Are Not Enough Inspection

Caricato da

tugordoDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Threads - Thread Gages Are Not Enough Inspection

Caricato da

tugordoCopyright:

Formati disponibili

About the Author/JOE GREENSLADE

Joe Greenslade is President of Greenslade & Company, Inc. in Fort Worth, Texas, a supplier of fastener inspection products, inspection software, and ISO 17025 (A2LA) accredited calibration services. He also provides a variety of consulting services including serving as Expert Witness in fastener related litigations. Joe has been in the fastener industry in a variety of capacities since 1970. He has written over 220 fastener technology related articles and has spoken to many fastener industry organizations throughout the United States. Joe has been awarded 12 U.S. Patents for fastener inspection devices. Joe is an active member of the American Society of Mechanical Engineers (ASME), the American Society for Testing and Materials (ASTM), the National Fastener Distributors Association (NFDA), and a member of the Board of Directors of the American Association for Laboratory Accreditation (A2LA). He is a former member of the Industrial Fasteners Institute (IFI). He was a member of the Fastener Quality Act Task Force representing the fastener industry. Joe also serves on the Screw Thread Improvement Task Force working with government and industry to improve aerospace related thread specifications, and thread gaging and calibration procedures.

Inspecting Threads With Thread Gages Is NOT Enough

here is a wide-spread, potentially dangerous misunderstanding by fastener suppliers that if a threaded fastener is acceptable using the appropriate size GO and NOGO thread gages that the thread is acceptable for ALL characteristics. The use of GO and NOGO thread gages to inspect threads is NOT adequate and they do not even inspect the most critical characteristics on the thread. The GO and NOGO thread gages only determine if the pitch diameter of the inspected part is within acceptable size. When a part passes the GO and NOGO thread gage inspection that only indicates that the evaluated part will go together with a counter par t that has also passed its GO and NOGO thread gage inspection. These inspections do NOT indicate whether or not these threads will strip out of a mating part when they are placed into service. The pitch diameter size alone does NOT predict thread strength.

within specified size the failure mode will always be the bolt breaking.

Thread Stripping

Thread stripping is by far a more dangerous type of fastener failure than is bolt breaking. Application stresses are determined based on the tensile strength of the screws or bolts used. When threads strip, the strength of the screw or bolt has not been completely utilized. When a screw or bolt major diameter is undersized or when the nut minor diameter is oversized, the amount of thread overlap is decreased. This means there is less material mass between the external and internal threads to resist a shearing action between them when the stresses of tightening or the stresses of the application are exerted on the joint. The shearing away of either the internal thread or the external thread is what is referred to as thread stripping.

GO/NOGO Thread Gages

GO and NOGO thread ring gages do NOT inspect the major diameter of a screw or bolt. The major diameter in a ring gage is larger than the maximum product thread major diameter. Threaded ring gages cannot and will not detect an undersized product threads major diameter. GO and NOGO threaded plug gages do NOT inspect the minor diameter of nuts. The minor diameter of GO and NOGO

What inspection DOES evaluate potential thread strength?

The most critical thread characteristic on an external thread (screws and bolts) is the MAJOR DIAMETER. The most critical characteristic on an internal thread (nuts) is the MINOR DIAMETER. It is the amount of overlap between the external threads MAJOR DIAMETER and the internal threads MINOR DIAMETER that determines whether or not the threads will strip out of one another when the applications stresses are applied to the product joint. Standard bolt and nut products are designed so that when the major diameter of a screw or bolt is within specified size and the minor diameter of the mating nut is

Bolt entering GO ring gage.

Bolt not entering GO ring gage.

threaded plug gages are smaller than the smallest allowable minor diameter of the nut thread. The GO and NOGO thread plug gage will never detect an oversized nut minor diameter.

absolutely no assurance of thread strength. Always inspect the major diameter of external threads and the minor diameter of internal threads assurance of potential thread strength.

Inspecting bolts major diameter.

GO threaded plug gage enters nut.

What should fastener suppliers do?

In addition to inspecting screw and bolt threads with GO and NOGO ring gages or Tri-roll thread gages, they should also inspect the major diameters of screw and bolt threads using a micrometer, caliper, or a NOGO cylindrical ring gage made at the applicable limits of the major diameter. In addition to inspecting nut threads with GO/NOGO threaded plug gages internal threads should be inspected using GO/NOGO cylindrical plug gages manufactured at the applicable internal thread minor diameter.

What constitutes the minimum acceptable thread inspection process?

The simplest acceptable thread inspection system, as defined by the American Society of Mechanical Engineers (ASME) in the thread acceptability standard ASME B1.3, is System 21. The requirements of a System 21 Inspection are the evaluation of the limits or size of the following thread characteristics: External Threads GO Maximum Material GO Threaded Ring Gage NOGO Minimum Material NOGO Threaded Ring Gage Major Diameter Micrometer Internal Threads GO Maximum Material GO Threaded Plug Gage NOGO Minimum Material NOGO Threaded Plug Gage Minor Diameter GO Cylindrical Plug Gage NOGO Cylindrical Plug Gage When inspecting screws, bolt, and nut threads, do not stop with the GO/NOGO thread gage evaluation. Passing a GO/NOGO threaded gage evaluation provides

NOGO threaded plug gage does not enter nut.

GO cylindrical plug gage enters nut minor diameter.

NOGO cylindrical plug gages does not enter nut minor diameter.

For more information on this or other quality assurance matters related to specifications, procedures, and/ or equipment, contact the author at sales@greenslade andcompany.com.

Reprinted from Distributors Link Magazine, Winter 2006

Potrebbero piacerti anche

- RCA Mini Guide PDFDocumento15 pagineRCA Mini Guide PDFIldzamar Haifa WardhaniNessuna valutazione finora

- MC Daniel IIDocumento6 pagineMC Daniel IItugordoNessuna valutazione finora

- 6a Gate Valves PDFDocumento24 pagine6a Gate Valves PDFchonubobbyNessuna valutazione finora

- Acme ThreadsDocumento3 pagineAcme ThreadsUNIISCRIBDNessuna valutazione finora

- MC Daniel IIIDocumento2 pagineMC Daniel IIItugordoNessuna valutazione finora

- International Organization For StandardizationDocumento24 pagineInternational Organization For StandardizationtugordoNessuna valutazione finora

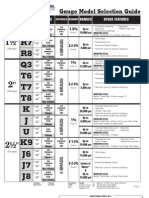

- S R7 R8 Q3 T6 T7 T8 K: Gauge Model Selection GuideDocumento4 pagineS R7 R8 Q3 T6 T7 T8 K: Gauge Model Selection GuidetugordoNessuna valutazione finora

- S R7 R8 Q3 T6 T7 T8 K: Gauge Model Selection GuideDocumento4 pagineS R7 R8 Q3 T6 T7 T8 K: Gauge Model Selection GuidetugordoNessuna valutazione finora

- MC DanielDocumento6 pagineMC DanieltugordoNessuna valutazione finora

- MC Daniel IIDocumento6 pagineMC Daniel IItugordoNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- As 4118.1.7-1996 Fire Sprinkler Systems Components - Alarm Valves (Dry)Documento7 pagineAs 4118.1.7-1996 Fire Sprinkler Systems Components - Alarm Valves (Dry)SAI Global - APACNessuna valutazione finora

- Parts Manual for OTPC 300/400/600 Amp Transfer SwitchDocumento44 pagineParts Manual for OTPC 300/400/600 Amp Transfer SwitchWilly Alexander RamirezNessuna valutazione finora

- 7390141Documento6 pagine7390141Anonymous rzYSnirA3Nessuna valutazione finora

- W169 Rear Door ModuleDocumento3 pagineW169 Rear Door ModuleAlex100% (1)

- 1.ZTE ZNV Cameras GuideDocumento131 pagine1.ZTE ZNV Cameras GuideAndrew E. KhalilNessuna valutazione finora

- Anodes in Cooling Water Exchangers PDFDocumento12 pagineAnodes in Cooling Water Exchangers PDFcbrittaivNessuna valutazione finora

- 33 Owners ManualDocumento42 pagine33 Owners ManualWm Smith0% (1)

- Efk 1Documento4 pagineEfk 1Jennifer YuanNessuna valutazione finora

- Bolt and Weld Capacity - Red Book 1999Documento2 pagineBolt and Weld Capacity - Red Book 1999White_rabbit2885764Nessuna valutazione finora

- EarthingDocumento19 pagineEarthingraoNessuna valutazione finora

- Igo 11 MemoDocumento169 pagineIgo 11 Memowildcatamir11100% (1)

- Picklist VCMM Xc60 b85604Documento3.183 paginePicklist VCMM Xc60 b85604shukur86Nessuna valutazione finora

- Ductmate PDFDocumento6 pagineDuctmate PDFgoodti0% (1)

- Qty. Description CR 4-30 A-A-A-BUBE: Company Name: Created By: Phone: DateDocumento12 pagineQty. Description CR 4-30 A-A-A-BUBE: Company Name: Created By: Phone: Dateabhe prasetyaNessuna valutazione finora

- CMM 25-70-04Documento49 pagineCMM 25-70-04MinhToànNessuna valutazione finora

- GRAPADORADocumento36 pagineGRAPADORARafaelChochoaNessuna valutazione finora

- BoltCalcs R5Documento4 pagineBoltCalcs R5Homer SilvaNessuna valutazione finora

- Shear Connections AISC 360Documento64 pagineShear Connections AISC 360jatinNessuna valutazione finora

- Warning: InletDocumento4 pagineWarning: Inletmiguel castellanosNessuna valutazione finora

- Wedge Anchor Technical Data SheetDocumento10 pagineWedge Anchor Technical Data SheetSajid ShahNessuna valutazione finora

- Log Building News - Issue No. 78Documento20 pagineLog Building News - Issue No. 78ursindNessuna valutazione finora

- Installation Manual for SD Reefing SystemDocumento10 pagineInstallation Manual for SD Reefing SystemrobertoNessuna valutazione finora

- Materials and AccessoriesDocumento8 pagineMaterials and AccessoriesJohn SamataNessuna valutazione finora

- Bolt-Nut BrochureDocumento13 pagineBolt-Nut BrochureLong Beautéophile100% (1)

- Steel BookDocumento477 pagineSteel BookAKSHEYMEHTANessuna valutazione finora

- Comparative of BOQ - Finishing ItemDocumento202 pagineComparative of BOQ - Finishing Itemanjanepal100% (1)

- Kansai WX-8800 Series Instruction ManualDocumento31 pagineKansai WX-8800 Series Instruction ManualVictor Hugo Tabares HerreraNessuna valutazione finora

- Ditch Witch JT1720 - Parts ManualDocumento231 pagineDitch Witch JT1720 - Parts Manualkingtux4561100% (1)

- r4 Navigation System Installation ManualDocumento85 paginer4 Navigation System Installation ManualSerhiiNessuna valutazione finora

- Volvo D13H Shop Armed Vol2Documento34 pagineVolvo D13H Shop Armed Vol2Juan José AldanaNessuna valutazione finora