Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Introduction To SC - Basics

Caricato da

Moses MuputisiDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Introduction To SC - Basics

Caricato da

Moses MuputisiCopyright:

Formati disponibili

Transcript

Page 1 of 22

Introduction to Supply Chain - Basics

CLOSE

Introduction

Overview

What are the basic components of a supply chain? And how do they work together? The majority of companies today utilize five supply chain components to get products into the marketplace. The five components are Suppliers, Manufacturers, Distributors, Retailers, and Consumers. Lets walk through a high-level example using a stereo. An electronics companys Suppliers work with their own suppliers to send multiple components and parts to the electronics companys Manufacturing sites. There, the stereo is assembled, packaged, labeled, and sent to a vast number of different Distributors. These distributors work with Retailers, catalogers, and other customers to sell the stereo. Finally, you as the Consumer walk into a retailer and purchase it. Connecting the five basic components together are three items flowing up and down the supply chain. The three items are Products, Information, and Financial Resources. Effectively integrating and managing the supply chain components and processes not only helps to reduce costs and improve customer service. It can also provide a new set of capabilities which may help a company increase revenues and achieve a competitive advantage in the marketplace. In this course, youll start to learn how activities across the supply chain should be performed to achieve this integrated supply chain management.

Course Objectives

Introduction to Supply Chain is a 3-part course series. Introduction to Supply Chain Basics provides an overview of supply chain components and activities and discusses the criticality of having an integrated supply chain. Introduction to Supply Chain Pitfalls and Opportunities provides an overview of the common pitfalls, or problems, that companies face in designing and managing supply chains. But you dont just learn what the problems are. You also find out about opportunities, or solutions, that companies can implement in order to avoid these pitfalls and achieve real value. Introduction to Supply Chain Value Chain Case Study provides an opportunity to apply what youve learned in the Basics and Pitfalls and Opportunities courses to a case company. The case study involves an electronics manufacturer whose rollout of a new line of high-definition televisions is in jeopardy due to supply problems with a low cost component the remote control devices. After you complete the Introduction to Supply Chain Basics course, you should be able to: Explain the concept of integrated supply chain management Justify the use of integrated supply chain management in order to achieve real value and a competitive advantage

https://www2.supplychainacademy.com/Courses/Uploaded/1000003173/transcript.htm

2011/02/03

Transcript

Page 2 of 22

Supply Chain Components

Overview

It's Wednesday night, but it sure feels like the week has been longer than 3 days. You've been up until all hours working on a major project. Not to complain... but you can feel the dark circles forming under your eyes. But... on the positive side, only two days left 'til the weekend. And you're done for the night, at least. Just one stop left before you get to your apartment: the local grocery store to pick up a frozen pizza and some beer. You pull into the parking lot and drag your tired self in. With your eyes barely still open you grab a six-pack of beer and head for the Frozen Foods aisle. You locate the pizza and open the freezer door to snatch your favorite brand... you know... one of those rising crust ones. The regular frozen ones just don't cut it. Taste like cardboard. Bad cardboard. But the pizza isn't there. Sure, there are others. But not the one you want. The product label is there - taunting you with the price and name. But no pizza. Gone. All you can see is the back of the freezer. "It's out of stock," a store employee tells you. "We'll get a shipment tomorrow. Actually, several people have been looking for it... must be a popular item," he adds. Why was this product out-of-stock? Especially if there was high demand for it, as the store employee indicated. While this is a very minor example, it highlights a problem that occurs in supply chain management - the focus of this course. According to the International Center for Competitive Excellence (1994), integrated supply chain management can be defined as "the integration of key business processes from end user through original suppliers that provides products, services, and information that add value for customers and other stakeholders." Adds value for customers and other stakeholders? What does that mean? Defining what value and competitive advantage means for the supply chain will be among the primary focal points of this course. Additionally, how companies are using information technology and other means to achieve these ends will be explored.

Lambert, Stock, and Ellram, Fundamentals of Logistics Management, (New York, New York: Irwin McGraw-Hill, 1998), pp. 275-277.

Components

So, if that pizza had been in the store, how would it have gotten there? The answer - it would have traveled through the pizza manufacturer's supply chain. Then you would have been able to enjoy it, instead of going home with some other brand. That you really didn't want. But, anyway, back to the course. A typical supply chain consists of five main components: Suppliers. Source of raw materials, component parts, semi-manufactured products, and other items that occur early in the supply chain - unfinished or nonconsumable products. Manufacturers. Makers of products. Many consider them to be the heart of the supply chain. Actually, both suppliers and manufacturers are producers of products. Suppliers produce components or subassemblies, while manufacturers perform the task of final assembly or product integration. Distributors. Responsible for the packaging, storing, and handling of materials at receiving docks, warehouses, and retail outlets.

https://www2.supplychainacademy.com/Courses/Uploaded/1000003173/transcript.htm

2011/02/03

Transcript

Page 3 of 22

Retailers. These are the manufacturer's customers - the stores that buy the actual products. Throughout this course, retailers will also be referred to simply as customers. Consumers. This is you - the person who goes into a store and buys the product. Like the pizza.

Components (continued)

The majority of companies today utilize all five components in the supply chain in order to get products into the marketplace. Not all firms have utilized this exact supply chain model, however. One company has skipped the distributors component of the supply chain completely. The company simply takes orders - pulling the components from inventory sent by its suppliers - and performs final assembly (the manufacturer's role) and ships the computers directly to consumers. Supply chains also exist for services, although they will not be covered directly in this course. For example, a commercial bank has a supply chain, as evidenced by the fact that financial transactions flow along different components or elements of the supply chain. Inventory is represented in this example by each bank teller's capacity, or time to serve customers. An out-of-stock would occur when consumers have to wait in line for service. A major challenge for banks is to effectively manage this availability of its teller resources. In another service example, trucking companies typically have a measurable amount of capacity in terms of trucks or vehicles available for service. Much like the bank teller example, this capacity must be managed carefully, as it represents a valuable and scarce resource. Also, like the bank tellers, these productive resources are "perishable," in that the capacity is available only for specific periods of time. If unused, it is not possible to access this same capacity at a future point in time.. Is anyone else involved in the supply chain? Is the supply chain limited to the five components just mentioned (suppliers, manufacturers, distributors, retailers, and consumers)? Definitely not! Actually, there are many other players in the supply chain who also play valuable and important roles in getting products to the end consumer. For example, consider the facilitating roles outside parties, such as the following, play in important areas of the supply chain: Logistics providers. Perform individual tasks such as transporting products from one place to another, or operating strategically placed warehousing or distribution operations. Sometimes, logistics providers offer multiple, integrated services, in which case they may be referred to as third party logistics providers. Contract manufacturers. Provide subcontract manufacturing for manufacturers. As firms specialize and focus on core competencies, the use of contract manufacturers, or "co-packers" has become a well-accepted practice. Information-based service providers. Refers to firms which have either software or other information technologies which assist with the activities of supply chain planning and/or execution. Information-based service providers may include IT firms, which provide and manage systems for individual firms and for overall supply chains. Financial institutions. Includes banks and other financial institutions, which provide supply chain services such as freight payment and billing, inventory financing, and inter-firm transaction management. Services may be for individual firms or combinations of firms in the supply chain.

https://www2.supplychainacademy.com/Courses/Uploaded/1000003173/transcript.htm

2011/02/03

Transcript

Page 4 of 22

Activities

There are several main activities that cut across the components of the supply chain, as well as link them together. Purchasing Order processing Demand planning Inventory management Warehousing Transportation Customer service The activities of the Supply Chain will be explored in greater detail in the upcoming topic, Supply Chain Activities?

Flows

Looking again at the supply chain model introduced earlier in this module, you can see that three items flow along the chain, connecting the five components. These items are: Product Information Financial resources This topic will be investigated further in the upcoming topic, Integrated Supply Chain.

Historical Focus

If a company produced a product fifty years ago as consumer demand exploded after

https://www2.supplychainacademy.com/Courses/Uploaded/1000003173/transcript.htm

2011/02/03

Transcript

Page 5 of 22

World War II, for the most part it could be fairly confident that consumers would purchase it. "If we made it, they would buy it," one manager commented. But times changed quickly. The use of information technology accelerated, markets globalized, political economies stabilized... causing the boundaries of the world to suddenly become much smaller. As a result, an increasing number of world-class companies emerged and began competing on a global basis. What did companies do? Once they realized that their survival was threatened, they began to change. The different decades have seen the following shifts: 1970s. Companies focused on making internal changes. While these changes mainly emphasized reducing inventories and distribution costs, they also targeted reductions in plant lead times, supplier lead times, and safety stock. In addition, other pressures, such as skyrocketing fuel prices and interest rates as high as 20%, forced firms to focus on transportation and inventory management. 1980s. The decade of the '80s saw three major movements. Over the first several years, manufacturers focused on reengineering supply chain cost structures to lower operating costs and assets. The second major movement of the decade was a shift from cutting costs towards improving customer service. Finally, the third movement involved the internal integration of logistics within companies. 1990s. Customer service continued to be a focal point of manufacturers' initiatives in this decade. Companies entered into new arrangements with existing channel partners as well as rationalized existing distribution channels. Firms began to realize the importance of forming external partnerships, versus solely focusing on cooperation and communication within their own walls. The '90s also brought about a trend towards integrated logistics. Figures indicate that 60% of all companies today have made significant progress toward having an integrated logistics system. 2000s. Initiatives resulting from an emphasis on technology, such as RFID (radio frequency identification), continue to emerge and evolve. Increased global sourcing and collaboration on design, forecasting, and planning among supply chain members have also emerged as key areas in the 2000s. As a result, there is a strategic growth in both national and international supply chain alliances. And while globalization has increased, environmental, social and security considerations are playing a greater role in supply chain decisions.

Traditional View of Supply Chain

At the end of the '90s, a new focus began to emerge - an emphasis on integrated supply chain management. But what is this? And how is it different from what was done in previous decades? As shown below, the traditional view of the supply chain considers the individual companies and elements within a firm as separate, "functional" entities.

https://www2.supplychainacademy.com/Courses/Uploaded/1000003173/transcript.htm

2011/02/03

Transcript

Page 6 of 22

Progressive View of Supply Chain

Under this model, the different components of the supply chain often end up battling one another in their endeavors towards sometimes-conflicting objectives. Doesn't sound ideal? You're correct. This undesirable situation results in a supply chain that is both inefficient and unresponsive to customer needs. Thus, companies have improved their level of integration across the supply chain, as shown in the graphic below.

Companies have realized the power of supply chain management. That a supply chain can be a tool to create value, not just save money. These companies are now using rapidly advancing information technology, such as the Internet, to redefine their supply chain structures, reach out to new customer segments, and design new products and services for customers. What are these companies getting out of the deal? Anything? Try an increase in market share, improved profits and return-on-markets, and an increase in the overall value of the firm. Not bad, huh?

Supply Chain Activities

https://www2.supplychainacademy.com/Courses/Uploaded/1000003173/transcript.htm

2011/02/03

Transcript

Page 7 of 22

Overview

To get products, like a pizza, from one component to another in the supply chain takes the help of several activities, or processes. This topic will highlight the following activities, common to most supply chains: Purchasing. Activities related to the purchase of all goods and services required by a particular company to operate. Order processing. Functions needed to fill customers' orders, such as order receipt, order picking, and order shipment. Demand planning. Process of predicting customer demand based on forecasts, actual sales, and current inventory levels. Inventory management. Encompasses multiple activities to monitor stock levels including forecasting, proper positioning of stock, and the active observation of product age and availability. Warehousing. The holding of goods with an emphasis on moving product into, through, and out of warehouses in a timely manner. Transportation. Movement of products from one specific destination to another. May involve one or more of the modes of transport, such as motor, rail, water, air, pipeline, or intermodal. Customer service. Includes all sales or after-sales related activities that occur between the buyer and seller. These functions include order status, post-sale support, etc. All seven of these processes can be mapped to and associated with the majority of the five components of the supply chain (suppliers, manufacturers, distributors, retailers, and consumers). However, for most, there are a few components that are more closely tied with that particular activity. These connections will be identified over the next several screens.

Purchasing

Without the purchasing process, manufacturers wouldn't be able to produce any products! Purchasing represents the single largest expense of doing business for companies in today's marketplace. Thus, purchasing is - and should be - an area that is constantly investigated. It directly contributes to the success or failure of a company. Purchasing essentially involves all of the components of the supply chain, in that manufacturers purchase from suppliers. Distributors purchase from manufacturers. Retailers purchase from distributors. Consumers typically purchase from retailers. However, the main focus of supply chain purchasing is on suppliers and manufacturers. Why? The purchase of material by manufacturers from suppliers is one of the critical starting points in the supply chain process. In the past, purchasing was very much a clerical activity. Typically, it consisted of wellestablished and defined procedures, such as creating purchase orders and communication

https://www2.supplychainacademy.com/Courses/Uploaded/1000003173/transcript.htm

2011/02/03

Transcript

Page 8 of 22

with suppliers to get pricing information or to obtain status on late products. Today, however, purchasing is a very strategic part of the supply chain process.

Purchasing (continued)

The purchasing activity involves the procurement of all necessary materials for a manufacturer: (1)component parts, (2) raw materials, (3)operating suppliers, (4)support equipment, (5)process equipment, and (6)services. In other words, a tremendous amount of widely varied items. For example, juice manufacturers typically purchase all of the products below in order to produce juice: Ingredients. Includes apple concentrate, raspberry concentrate, orange concentrate, and concord grape concentrate. Packaging. Includes glass, plastic, and corrugated cardboard. MRO & Utilities. Includes drums, chemicals, pallets, electricity, general suppliers, and gas. Considerable emphasis is being placed on the following initiatives within purchasing: Focusing on total net-landed costs Companies need to look carefully at more than just the initial purchase price of material when determining what suppliers to work with. They need to determine the total cost of having that product delivered. Exploiting the capabilities of information technology Today, good manufacturers are trying to establish closer ties to their suppliers. One of the ways they can do so is through information technology. It may be used for a variety of purposes including inventory status, order status, and financial transactions. Supplier relationships Companies today are working to establish partnership relationships with their suppliers - a far cry from the adversarial relationships of the past. These partnerships are designed to provide benefits to both parties. True supplier partnerships involve components such as joint planning, joint operating controls, communications, risk/reward sharing, trust and commitment to each other's success, and investment in financial, technological, and personnel commitments. Consolidation of suppliers In the past, firms tended to have large amounts of suppliers. The thought was that you could obtain better prices if more players were involved. Now, firms are narrowing down their pool of suppliers to a select few that will hopefully provide them with top quality service and good prices, as well as function in more of a partnership role.

Order Processing

https://www2.supplychainacademy.com/Courses/Uploaded/1000003173/transcript.htm

2011/02/03

Transcript

Page 9 of 22

Large companies may have thousands of customers. And each of these customers may stock hundreds of different products and order them at different times, in different amounts. How do companies keep all of this information straight? Effective order processing! Order processing is associated with three of the components of the supply chain: manufacturers, distributors, and retailers. How so? Retailers place orders. Manufacturers and distributors work in conjunction with one another to fulfill these orders. Order processing involves the following steps: Customer places order Order received by manufacturer Order processed Credit checked and verified Order picked and packed Order shipped to customer Order received by customer and placed in inventory

Order Processing (continued)

Reducing the time involved in these steps - the order cycle time - can contribute to the success of a company's supply chain. A customer's order is, in a sense, what launches and controls processes within the supply chain. Slow or inaccurate order processing can impact every segment of the supply chain and result in lost customers. A technology being used more frequently today in order processing is Electronic Data Interchange (EDI). This technology is defined by Coyle, Bardi, and Langley (1996) as "The computer-to-computer communication between two or more companies that such companies can use to generate bills of lading, purchase orders, and invoices. It also enables firms to access the information systems of suppliers, customers, and carriers and to determine the up-to-the minute status of inventory, orders, and shipments. Examples of information transmitted through EDI include bills of lading, purchase orders, invoices, etc. It enables firms to access the information systems of suppliers, customers, and carriers in order to determine up-to-the minute status of inventory, orders, and shipments. It eliminates reams of paperwork for channel members, as well as gives them faster and more accurate status on their orders.

Demand Planning

Demand planning includes both forecasting and production planning. It is associated with the manufacturers, retailers, and consumers components of the supply chain. Manufacturers do the bulk of the work in both forecasting and production planning. However, in forecasting, retailers often provide manufacturers with point-of-sale (POS)

https://www2.supplychainacademy.com/Courses/Uploaded/1000003173/transcript.htm

2011/02/03

Transcript

Page 10 of 22

data. In production planning, manufacturers must work closely with suppliers to ensure that the right materials are delivered, so all planned production can occur. And consumers? Well, the tastes and demands of consumers are what drive the overall demand planning process in the first place. Starting with the first process, forecasting involves estimating customer demand. Forecasts indicate the sales amount the manufacturer expects for each item and the time period over which the sales are projected. As you would expect, accurate and timely information is needed to do accurate forecasting. Forecasting inventory requirements for materials and parts accurately is a key to effective inventory management.

Demand Planning (continued)

Production planning is closely related to forecasting. It involves coordinating product supply with product demand. After a forecast is developed and the current inventory at hand and usage rate is determined, production managers can determine how many units of a specific product should be produced to meet consumer demand. Their main concerns are as follows: Number of units of a specified product to be produced Time intervals over which production will occur Availability of materials and machines to produce the number of units required within the specified time frame This might seem fairly easy, but think about firms that produce multiple products. This makes it more complicated. Lines within a manufacturing plant have to changeover for different products, requiring additional time during which no products at all can be produced. Thus, having precise product planning is essential to minimize this downtime and reduce costs per unit.

Inventory Management

Inventory management is the process of trading off the amount of inventory needed to achieve high levels of customer service with the cost of holding this inventory. Inventories are managed at all levels in the supply chain, although those positioned nearer to the customer/consumer are among the more critical. Therefore, it is mainly associated with the manufacturers, distributors, retailers and consumers components of the supply chain. Effectively controlling a company's inventory is necessary for the financial survival of the company. Companies can have millions or even billions of dollars tied up in on-hand inventory. Not only do they risk on-hand inventory becoming obsolete, but more importantly, the money invested in inventory represents capital which could be used in other areas of the company. The carrying cost of inventory - just the cost of holding the product - has been estimated at 25 - 40% of the value of the inventory itself, on an annual basis. The cost of holding inventory is even higher when products can devalue over time. What kind of products would this be? Well, not a frozen pizza. But definitely products like computers and other high technology items.

https://www2.supplychainacademy.com/Courses/Uploaded/1000003173/transcript.htm

2011/02/03

Transcript

Page 11 of 22

Inventory Management (continued)

What are supply chain managers at progressive companies doing about this problem? They have incorporated flexibility and quick response into their processes and practices. In other words, they have begun to pay attention to time. For example, a seat manufacturer within the automotive industry receives seat order releases from a car/truck manufacturer. Within four hours, the seat manufacturer will assemble and deliver the components to the automotive manufacturer. Why so quickly? It provides high value to the auto manufacturers supply chain. The automotive manufacturer puts the seats into new cars as soon as they are delivered to the plant, reducing its on-hand seat inventory. So, why do all this? Companies can achieve higher return on assets, return on invested capital, and improved return on sales by focusing on shorter, more consistent cycle times, and thus, on their inventory levels. Reducing inventory levels can impact a company's income statement, as well as its balance sheet. The following are three growing initiatives/philosophies within inventory management: Just-in-Time (JIT) JIT is defined by Coyle, Bardi, and Langley (1996) as "an inventory control system that attempts to reduce inventory levels by coordinating demand and supply to the point where the desired item arrives just in time for use." This initiative does not indicate, as some may think, that no inventory is held. That would be next to impossible. What JIT does is to use the goal of zero inventory to concentrate on finding and eliminating waste in the supply chain, getting as close as possible to having no inventory. This is a far cry from what was done in the past, when companies stockpiled large inventories so as to have the right quantities on hand when customers requested them. As you might guess, JIT requires significant changes in the relationship between suppliers and buyers. Vendor-managed inventory This involves the manufacturer using information from its customers to replenish inventory to agreed- upon stock levels in a retail facility (usually a DC) without intervention by the retailer. This information is obtained with the help of EDI. In other words, the manufacturer figures out what the retailer needs and then sends it out. Thus, no orders from the retailer are necessary. Continuous Replenishment Program (CRP) The general concept of Continuous Replenishment Programs is "sell one - make one." In other words, products shouldn't be produced and delivered until a customer sells one, indicating that they need a replacement. However, as you can imagine this is not reality. Like JIT, CRP is simply a philosophy. It would never be possible to instantly replace every product that is sold, without having any inventory at all. Having this end goal, though, helps maintain low inventories.

Handfield, and Nichols, Introduction to Supply Chain Management, (Upper Saddle River, New Jersey: Prentice Hall, 1999), p. 8.

Warehousing

https://www2.supplychainacademy.com/Courses/Uploaded/1000003173/transcript.htm

2011/02/03

Transcript

Page 12 of 22

What is warehousing linked to? That's easy. It's associated with the distributors components of the supply chain. They are the ones storing products for manufacturers and retailers. There are three major functions in warehousing: Movement Consists of: Receiving. Encompasses unloading products from whatever type of transport carrier was used, updating warehouse inventory records to reflect the newly arrived products, inspecting for damage, and verifying merchandise type and count against actual orders and shipping records. Transfer and putaway. Movement of the product from receiving dock to storage location. Order picking/selection. Involves collecting different products and compiling them into pre-specified customer orders, and creating packing slips. This is the focal point of movement. Shipping. Involves the actual physical movement of assembled orders onto carrier equipment, the adjustment of inventory records, and the review of orders that are meant to be shipped. This function, movement, is most scrutinized because of the focus of companies on improving inventory turns and increasing the speed of orders from manufacturing to final delivery.

Lambert, Stock, and Ellram, Fundamentals of Logistics Management, (New York, New York: Irwin McGraw-Hill, 1998), pp. 275-277.

Storage Housing of products. Can be either temporary or semi-permanent.

Lambert, Doug; Stock, and Ellram, Fundamentals of Logistics Management, (New York, New York: Irwin McGraw-Hill, 1998), pp. 275-277.

Information transfer This function of distribution is necessary for the prior two functions, movement and storage, to occur. Examples of information collected and utilized include inventory levels, throughput levels, stock-keeping locations, inbound and outbound shipments, customer data, facility space utilization, and personnel.

Lambert, Doug; Stock, and Ellram, Fundamentals of Logistics Management, (New York, New York: Irwin McGraw-Hill, 1998), pp. 275-277.

A commonly used initiative within warehousing is cross-docking. Cross-docking involves moving products from the supplier's distribution center through the customer's distribution center without putting it away to minimize storing. True cross-docking involves products being in the warehouse for less than 24 hours. In this program, merchandise is delivered to one side of a distribution center by vendors, is unloaded and immediately reloaded onto outbound trucks that deliver merchandise to the stores.

Transportation

This supply chain process involves the selection and management of both internal private fleets of carriers and external carriers (trucking companies, railroads, shipping companies,

https://www2.supplychainacademy.com/Courses/Uploaded/1000003173/transcript.htm

2011/02/03

Transcript

Page 13 of 22

and airlines). The transportation sector of our society is significant. Transportation cannot be associated with one specific component of the supply chain. Rather, it is the connection between all of them. Yes... that's how the pizza got from the manufacturer to the distributor. And how it got to the retailer. Well, it wasn't actually there when you wanted it, but someone else did get to buy it. So, transportation was used.

Transportation (continued)

There are six types of transportation modes available for companies today. Motor Dominant form of transportation today in most countries. Motor carriers are extremely flexible in the nature of their service, due to the huge network of roads, enabling them to virtually deliver directly from anywhere to anywhere. This mode of transportation is used frequently because of its ability to carry almost any product, regardless of size and weight. Motor carriers transport agricultural, manufactured, and consumer goods. Rail Used extensively globally due to highway congestion in some countries and a lack of good highways in others. As a matter of fact, it is often the dominant form of transportation in many European countries. While rail transport is less flexible and versatile than air and motor carriers, it is much less expensive. However, it is still at a disadvantage in terms of transit time, frequency of service, and equipment availability. Air Although this mode of transportation is not used often, it is a good choice for two types of shipments: High-value shipments. Shipment for products whose high cost can justify a more expensive mode of transportation, such as air. Emergency shipments. Products that need to be sent somewhere immediately. However, many progressive companies who are analyzing their transportation systems as part of supply chain management initiatives are finding that air service may represent a valuable part of their overall transportation network. This has been proven for many companies when high inventory carrying costs, associated with less time-sensitive forms of transportation, were reduced through the use of the air option. Water Although water is one of the least expensive forms of transportation, it is extremely slow. Additionally, service is limited to the origin and destination points at which port facilities are available. Despite these restrictions, water transport is a popular mode, particularly for large amounts of product coming from overseas, and bulky, low-value, high-density products such as coal. To ship by water, companies load their products into a container and then transport it by rail or motor carrier to a port. The container is then loaded onto a container ship and sent to the destination port. Once unloaded, it is again taken by rail or motor to its final destination. Pipeline This mode of transportation is used for a very narrow range of product types, such as crude oil, natural gas, chemicals, and water. Pipelines offer very inexpensive, but slow, transport of products. Intermodal This represents the simultaneous use of two modes of transport. It has developed into a frequently used option for shippers recently. While intermodal may take a variety of forms, the two most popular are:

https://www2.supplychainacademy.com/Courses/Uploaded/1000003173/transcript.htm

2011/02/03

Transcript

Page 14 of 22

Motor carriers trailer on railroad flat car ("piggyback") Container on ships ("containerized movements")

Customer Service

Successful manufacturers today are the companies who are meeting the increasing demands of retailers. Those who buy and use their products not only want them to be top quality, they also want high quality service - both before and after the sale. Customer service can primarily be defined as activities designed to reinforce total customer satisfaction and build customer loyalty. But the benefits of improved customer service are not limited to customers. Manufacturers gain as well. First, satisfied customers are loyal, increasing the firm's product, service parts, and service market share. Second, profits can actually be generated from many customer support activities such as service parts and services. Customer service is associated with almost all of the supply chain components. Mainly, however, it is linked with manufacturers, distributors, retailers and consumers. Manufacturers and distributors provide and monitor customer service. Retailers and consumers receive it.

INTEGRATED SUPPLY CHAIN

Overview

As you can see in the graphic below, three major items flow up and down the supply chain: Product, Information, and Financial Resources. We will look at all three in this topic.

https://www2.supplychainacademy.com/Courses/Uploaded/1000003173/transcript.htm

2011/02/03

Transcript

Page 15 of 22

Overview (continued)

Just as a river flows downstream, products in a supply chain are said to flow downstream from origin (raw materials) to destination (finished product sold to consumers). Alternatively, product returns and information concerning product demand, both of which originate at the point of sale or use, are thought to flow upstream. Payments by customers or consumers to retailers, distributors, manufacturers, and suppliers also flow upstream. While these two types of flows are obviously in the opposite direction, they are not in conflict and both are essential to the effective functioning of the supply chain. As can be seen below, there are other aspects of products, information, and financial resources that flow upstream and downstream in typical supply chains. Click on the terms for more information. Products. This begins with the rawest of raw materials and goes all the way to products that are purchased by customers and consumers worldwide. Products include the physical product itself, plus packaging, labels, etc. Downstream processes = Raw materials, work-in-process, and finished goods moving towards the customer or end consumer. Upstream processes = Reverse flows of damaged and returned products to be disposed of or re-sold. Also includes disposition of used packaging materials, etc. Information. Products can't be ordered, produced, or distributed without the support of accurate and detailed information. That is, data on orders, inventory levels, production schedules, shipment dates, order status, etc. Downstream processes = Information accompanying the downstream flow of product. Includes order confirmation, advance ship notices, and billing/invoicing information. Upstream processes = Information relating to product sales and usage (point-of-sale scanner information). Also includes information relating to product returns. Financial resources. And of course, products need to be paid for. Payments flow between the various links of the supply chain - manufacturers to suppliers, distributors to manufacturers, retailers to distributors, and consumers to retailers. The flow of financial resources is a function of payment terms, credit terms, return policies, and other terms of trade, all of which need to be tightly managed. Downstream processes = Credits, deductions, and promotional allowances paid to customers from upstream supply chain partners. Upstream processes = Payments by customers or consumers which flow to retailers, distributors, manufacturers, and suppliers.

Products

Take a look at a product you recently bought on a shopping expedition - say a ski jacket. Can you explain how it arrived at the sporting goods store where you purchased it? How it moved along the supply chain? How it was transformed as it traversed along the different components of the supply chain? It didn't start out as the slick, multi-colored, windrepellant, eight- zippered jacket that you purchased to swoosh down the slopes of the Swiss Alps on. If you travel back down the chain to the various suppliers that provide materials to the coat manufacturer, you would be able to see piles of zipper components, pieces of fabric, vats of dye, etc. So, how does all of that material end up as a ski jacket on the racks at a sporting goods store?

https://www2.supplychainacademy.com/Courses/Uploaded/1000003173/transcript.htm

2011/02/03

Transcript

Page 16 of 22

Starting at the beginning of a manufacturer's supply chain, consumers indicate their demand for certain amounts and types of the ski jackets. Manufacturers develop forecasts based on this demand and place corresponding orders with suppliers. Next, these suppliers produce a variety of different items, ranging from raw materials to assembled components. Suppliers then ship the amount of material that has been requested by the manufacturer to a specific site, most likely a manufacturing plant. Materials managers take responsibility for planning and scheduling the flow of this material. They should work closely with production schedulers to accomplish these tasks. The various materials sent by the suppliers are then assembled into a final product, packaged, and sent to a distribution center via one of a number of modes of transportation (motor, rail, water, air, pipeline, or intermodal). Manufacturers then use either their own (private) or public warehouses and distribution centers to store the products. Distributors handle and store the product, while working with their customers - normally some type of retailers - to determine when and how to get them their requested amount of product. Once the product reaches the retailer, you - the consumer - are now free to purchase it. So, why do all this? Companies can achieve higher return on assets, return on net assets, and return on sales by focusing on their cycle times, and thus, on their inventory levels. Some companies use "dock to stock" delivery systems where the products that suppliers deliver at the beginning of one day end up as finished products by the end of that same day. Anything else? Paying attention to time and cycle times can also result in less product rework. And that means savings. Which directly impacts the bottom line of a corporation.

Information

A product cannot flow smoothly or successfully from supplier to end consumer without a vast array of information to guide it along. Information links every component of the supply chain together and is bi-directional. What are some examples? There are tons. Think about the pizza. Stores record information through point-of-sales data on how many are sold. This information is often then sent to the manufacturer so they can more accurately plan demand. Also, stores have to somehow let the manufacturer know how many pizzas they want, through orders. Then, the manufacturer provides information on these orders like when they will arrive and if they're late, why they are late. Invoices. Bills of lading. Advance ship notices. So, in other words, a lot of stuff. A lot of information. The format of this information has changed drastically over the years. Before the '80s, functional areas of a company almost solely used paper-based information. Slow? Possible errors? That and worse. The type of information that travels up and down the supply chain varies widely in type and scope. The chart on the next screen shows the major categories of information normally shared, and provides some examples of each.

Information (continued)

Types of Supply Chain Information Information Category Product Information Customer Information Supplier Information Examples of Information Contained in Category Product specifications, price/cost, product sales history Customer forecasts, customer sales history Product line, product lead times, sales terms and

https://www2.supplychainacademy.com/Courses/Uploaded/1000003173/transcript.htm

2011/02/03

Transcript

Page 17 of 22

conditions, and quality Production Process Information Transportation Information Inventory Information Supply Chain Alliance Information Competitive Information Sales and Marketing Information Supply Chain Process and Performance Information Capacities, commitments, production plans Carriers, lead times, cost Inventory levels, inventory carrying costs, inventory locations Key contacts for each organization, partner roles and responsibilities, meeting schedules Benchmarking information, competitive product offering, market share information Point-of-sale information, promotional plans Process descriptions, performance measures, cost, quality, delivery, time, customer satisfaction, etc.

Handfield, and Nichols, Introduction to Supply Chain Management, (Upper Saddle River, New Jersey: Prentice Hall, 1999).

Not only does information have to be shared across the supply chain - it has to be accurate. Completely accurate? Yes, the more accurate the better. Distorted information can cause more damage than having no information at all. Incorrect information in the supply chain can lead to a number of hazards, such as too much inventory, angry customers who didnt receive their products, inefficient transportation routes and schedules, and more.

Financial Resources

Financial resources also flow up and down the supply chain. They take the form of invoices as they flow down the supply chain, and payments as they flow up the supply chain. But it's not just the manufacturer getting paid, of course. The manufacturer is paying its suppliers, the suppliers are paying their suppliers, consumers are paying retailers, etc. Order processing is the main supply chain process that involves the flow of payments. From a payment perspective, it encompasses customer credit, invoicing, and accounts receivable. Customers place orders and pay for products through order processing systems. Imagine, especially for a large manufacturer, how many different customers and different products they have... how many payments are flowing in and out of the company. Thus, out of necessity, the payment process is highly automated. Companies today use electronic data interchange (EDI) to allow for electronic funds transfer (EFT) in the payment process. Companies can order and pay for products without faxing or sending invoices through the mail. Using EDI, manufacturers and their customers can transmit information about specific invoices back and forth. Customers can also receive electronic credit for damaged merchandise that has been marked down, thrown away, or returned to the manufacturer. Payment flows are affected by terms of trade between players in the supply chain, such as payment terms, credits, return policies, consignments, etc. By changing the terms of trade, the physical flows of products can also be affected. For effective supply chain management, then, companies must define the appropriate financial flow so that the three flows (product, information, and financial resources) are well coordinated.

https://www2.supplychainacademy.com/Courses/Uploaded/1000003173/transcript.htm

2011/02/03

Transcript

Page 18 of 22

The Value of an Integrated Supply Chain

So, you've now learned what a supply chain looks like. And how it works. You can now easily describe how that missing frozen pizza traveled from one end of the supply chain to the other, even if it never did make it to the grocery store where you wanted to buy it... You have been exploring how activities within the supply chain should be performed to achieve integrated supply chain management. But why is this integrated supply chain concept so important, anyway? What is the value of having an integrated supply chain? Companies in the past didn't and even today, many dont have an integrated logistics system. So why should anyone take on this task? Isn't it a tremendous amount of effort and change? Yes, but the rewards far outweigh what companies have to put into the initiatives. Remember the reference to value in the beginning of this course? Here's where it comes into play. Companies can obtain high amounts of value from having an integrated supply chain. Think about what this course has said on supply chain management in the past. Remember? Cost savings! That's almost solely what companies thought they could obtain from supply chains. Now companies have realized that they can do more than just cut costs. They can use supply chain management to generate significant amounts of value for their customers, and in turn, themselves. With an integrated supply chain, firms gain more of a customer service focus. They also reduce waste and become faster and more flexible, while maintaining the highest of quality standards. In general, they are better than the competition, and keep implementing continuous improvements to stay in that position. Sound ideal? Most companies and their managers would vehemently agree, although the vast majority is far from achieving this state.

Business Issues of Non-Integration

Companies that have not integrated their own logistics systems are still focused on functional goals, which are departmentally-driven rather than customer-driven. Functional goals refer to objectives that are developed by and for one department, such as marketing or purchasing, versus more process-oriented type goals (i.e. improved order cycle time). These non-progressive companies have the following five main characteristics: Disconnected product and information flows Limited ability to respond to customer requests Unpredictable product delivery/fill rate Limited visibility on shipment information Performance based on functional activities

Definition of Competitive Advantage

As we've talked about several times already in this module, today's marketplace is ultracompetitive, with a proliferation of players all battling one another for a bigger share of their industry. So, what can companies do? Give up? No... but they do have to completely change the way they think and act. In the past, companies could be successful by creating a unique strategic position in the marketplace. Now that isn't enough. Competitors can easily copy their position - and then often go forth to achieve it better and more cheaply. To

https://www2.supplychainacademy.com/Courses/Uploaded/1000003173/transcript.htm

2011/02/03

Transcript

Page 19 of 22

combat this, firms must also execute well. That's the secret. Unique strategic positioning and excellent execution. If a company accomplishes both, they will have achieved competitive advantage.

Achieving Competitive Advantage

You just got the definition of competitive advantage. Companies achieve this lofty goal by creating a unique strategic position in the marketplace. And executing the stellar strategy well. But to say something is easy. To achieve it, on the other hand, is slightly tougher. Well, actually, a lot tougher. Let's talk about it. As already mentioned, the two components of competitive advantage are unique strategic positioning and excellent execution. To achieve both of these items takes a lot. First, and above all, companies need to be flexible in their planning and quick in their reactions to change. Second, they need to take advantage of all information that is available about their performance. Third, firms need to position themselves and then execute using the sum total of their organization - people, technology, processes, and culture.

CONCLUSION

Course Summary

Lets review a few key points about supply chain management. Components. A typical supply chain has five main components: suppliers, manufacturers, distributors, retailers and consumers. Others who may play a valuable role in supply chains include logistics providers, contract manufacturers, information-based service providers, and financial institutions. Activities. The basic supply chain activities performed by all channel members include: Purchasing Order processing Demand planning Inventory management Warehousing Transportation Customer service Channels and flows. Products get to stores via several possible channels that might include some or all of the following supply chain components: suppliers, manufacturers, distributors, and retailers. Certain companies, like Dell Computer and amazon.com, sell directly to consumers and use channels that avoid middlemen and retailers. These flows to the ultimate consumer include product as well as information and financial resources. Additionally, some flows go back upstream such as product returns and financial payments.

Course Summary (continued)

Integration. Departments within a company need to think about the entire supply chain, and not just their individual group, when making decisions. Changes in logistics

https://www2.supplychainacademy.com/Courses/Uploaded/1000003173/transcript.htm

2011/02/03

Transcript

Page 20 of 22

levers (i.e. purchasing, inventory control, transportation, etc.) can cause a chain reaction within a company and with its supply chain partners. For example, attempting to save money on transportation by using a slower shipping mode might require holding more inventory and delaying shipments to end customers. Benefits. Effective management of supply chain activities and processes helps to reduce costs and improve customer service for companies. Additionally, it provides a new set of capabilities which may help to increase revenues, improve profitability, and create competitive advantage. To achieve competitive advantage, a company must create a unique strategic position in the marketplace and then execute that strategy well. Examples. Only a small percentage of companies in the world have developed significant expertise in the area of supply chain management. Progress made by companies such as Procter & Gamble, Dell Computer, and Wal-Mart represent good examples of what might be termed best practices in supply chain management. After you complete the Assessment for this course, you should complete the next course in this series: Introduction to Supply Chain Pitfalls and Opportunities.

Course References

We acknowledge the following sources for content used in the Introduction to Supply Chain series. Alster. "Digital TV: What a Mess." Upside. October 1998. Accenture. Seven Principles of Integrated Demand Chain Management. Accenture. SC Guiding Principles. Anderson, Britt, and Favre. "Who Says You Cant Please Customers and Enjoy Profitable Growth From Doing So? The Seven Principles of Supply Chain Management." Sloan Management Review. Summer 1996. "Are You Listening? Record Clubs and Direct Sales." The Economist. April 29, 1995. Austin, Lee, and Kopczak. "Unlocking Hidden Value in the Supply Chain." 1997. Berry, Towill, and Wadsley. "Supply Chain Management in the Electronics Products Industry." International Journal of Physical Distribution and Logistics Management. Vol. 24, No. 10, 1994. Bilzi. "The Early Adopters are Getting a Jump on HDTV." Broadcasting and Cable. November 16, 1998. Brain. "How Compact Discs (CDs) Work." How Stuff Works. (www.howstuffworks.com/cd) Brinkley. Defining Vision: The Battle for the Future of Television. Harcourt Brace. 1998. Brinkley. "The Dawn of HDTV, Ready or Not." The New York Times. October 26, 1998. Burt. A Purchasing Managers Guide to Strategic Proactive Procurement. AMACOM. 1996. Carbone. "Supply Chain Management Gets Outsourced." Purchasing. February 11, 1999. Carson. "Survey: Manufacturing: The Tijuana Triangle." The Economist. June 20, 1998.

https://www2.supplychainacademy.com/Courses/Uploaded/1000003173/transcript.htm

2011/02/03

Transcript

Page 21 of 22

Cheng. "Music Makers (Online Music Distribution)." Adweek. March 15, 1999. Christopher, Martin. Logistics and Supply Chain Management: Strategies for Reducing Cost and Improving Service. Pitman Publishing. 1998. Copacino, William C. Supply Chain Management: The Basics and Beyond. St. Lucie Press. 1997. Coyle, Bardi, and Langley. The Management of Business Logistics. West Publishing Company. 1996. Elkin. "HDTV No Longer a Pipe Dream, But Still a Marketing, Branding Challenge." Brandweek. January 19, 1998. Fischer. "A Hard Days Night at EMI." Transportation and Distribution. March 1996. Gattorna. Strategic Supply Chain Alignment: Best Practice in Supply Chain Alignment. Gower Publishing Limited. 1998. Gibson. Telephone interview of Donavan Favre of Accenture. June 24, 1999. Grover and Lesly. "Unfortunately, Elvis is Still Dead." Business Week. September 1, 1997. Handfield, and Nichols. Introduction to Supply Chain Management. Prentice Hall. 1999. Heller. "Digital Dazzles at CES." Discount Store News. January 26, 1998. Herrick. Television Theory and Servicing. Reston Publishing Company. 1972. "Home Theater." Fortune Technology Buyers Guide Supplement. Winter 1999. Hull. The Recording Industry. Allyn and Bacon. 1998. Kronstain. "HDTV Set to Mature in 1999." Dealerscope Consumer Electronics Marketplace. February 1999. Lambert, Stock, and Ellram. Fundamentals of Logistics Management. Irwin McGraw-Hill. 1998. Lee and Billington. Managing Supply Chain Inventory: Pitfalls & Opportunities. Sloan Management Review. Spring 1991. Levitt. "Searching for Harmony." Discount Merchandiser. April 1998. Littman. "No Alternative: Reality Counters Perception in Music Distribution Biz." Marketing News. August 3, 1998. "Music in the Air." Distribution. January 1995. "1998 The Year in Music." Billboard. December 26, 1998/January 2, 1999. "Recording Industry Releases 1998 Consumer Profile." Manufacturers Shipments and Value Reports. (www.riaa.com/stats/press/consumer98.htm) Reed. "Online Sales Go Uptempo." Marketing. January 7, 1999. "Research and Statistics." NARM Programs and Services. (www.narm.com/programs/research/surv97/index97.htm)

https://www2.supplychainacademy.com/Courses/Uploaded/1000003173/transcript.htm

2011/02/03

Transcript

Page 22 of 22

Rose. "Help! They Need Somebody." Fortune. May 24, 1999. Silkos. "Can Record Labels Get Back Their Rhythm." Business Week. July 27, 1998. Since Records Began EMI The First 100 Years. Amadeus Press. 1997. Stank and Lackey. "Enhancing Performance Through Logistical Capabilities in Mexican Maquiladora Firms." Journal of Business Logistics. Vol. 18, No. 1. 1997. Stein and Sweat. "Killer Supply Chains." Informationweek. November 9, 1998. "The Retail Scene." U.S. Record Sales. (www.riaa.com/stats/stusrs.htm) Trainer. "BMGCentral Boosts Communication: Distributors New Web Site Enhances TwoWay Flow." Billboard. March 20, 1999. Witt. "Camelot Music: Climbing the Charts in Distribution." Material Handling Engineering. June 1993. Witt. "Reverse Logistics at BMG." Transportation and Distribution. August 1998. "Why the Compact Disc is Music to Businessmens Ears." The Economist. March 22, 1986.

https://www2.supplychainacademy.com/Courses/Uploaded/1000003173/transcript.htm

2011/02/03

Potrebbero piacerti anche

- Q2 SSLM3 Principles-Of-Marketing JPestanoDocumento6 pagineQ2 SSLM3 Principles-Of-Marketing JPestanoDaniel Guanzon TanNessuna valutazione finora

- SCLM NotesDocumento63 pagineSCLM NoteshinaNessuna valutazione finora

- Enterprise Supply Chain Management: Integrating Best in Class ProcessesDa EverandEnterprise Supply Chain Management: Integrating Best in Class ProcessesNessuna valutazione finora

- Supply Chain Management Research Paper OutlineDocumento4 pagineSupply Chain Management Research Paper Outlinegz7vxzyz100% (1)

- Supply Chain Management: Pre-ReadDocumento90 pagineSupply Chain Management: Pre-ReadSaad Rashid100% (1)

- Supply Chain Management: Fast, flexible Supply Chain in Manufacturing and Retailing -2nd edition-Da EverandSupply Chain Management: Fast, flexible Supply Chain in Manufacturing and Retailing -2nd edition-Valutazione: 5 su 5 stelle5/5 (6)

- Supply Chain ManagementDocumento2 pagineSupply Chain ManagementJonel BarrugaNessuna valutazione finora

- SCLM NotesDocumento43 pagineSCLM NotesJyoti SinghNessuna valutazione finora

- End-to-End Supply Chain Management - 2nd edition -: Fast, flexible Supply Chains in Manufacturing and RetailingDa EverandEnd-to-End Supply Chain Management - 2nd edition -: Fast, flexible Supply Chains in Manufacturing and RetailingNessuna valutazione finora

- SCM - Subhradeep HazraDocumento22 pagineSCM - Subhradeep HazraSubhradeep HazraNessuna valutazione finora

- Dwnload Full Principles of Supply Chain Management A Balanced Approach 4th Edition Wisner Solutions Manual PDFDocumento36 pagineDwnload Full Principles of Supply Chain Management A Balanced Approach 4th Edition Wisner Solutions Manual PDFfayaliteelectary2o3oz100% (11)

- Homeworksimchi Levidesigningandmanagingsupplychain 140401173556 Phpapp01Documento50 pagineHomeworksimchi Levidesigningandmanagingsupplychain 140401173556 Phpapp01Anish Mathew88% (32)

- 01 Primer 2nd Version 2000 PDFDocumento9 pagine01 Primer 2nd Version 2000 PDFerumshafiq9243212Nessuna valutazione finora

- IT Enabled Supply Chain Management.Documento46 pagineIT Enabled Supply Chain Management.anampatelNessuna valutazione finora

- Home Work Chapter 1 To 12Documento50 pagineHome Work Chapter 1 To 12Haha JohnNgNessuna valutazione finora

- Unit 1 - NotesDocumento8 pagineUnit 1 - NotesAnas K MakNessuna valutazione finora

- Into To Supply Graduation ProjectDocumento27 pagineInto To Supply Graduation ProjectMahmoud AhmadNessuna valutazione finora

- Faculty of Business and Management Individual AssignmentDocumento9 pagineFaculty of Business and Management Individual Assignment静思Nessuna valutazione finora

- Research Paper On Logistics and Supply Chain ManagementDocumento4 pagineResearch Paper On Logistics and Supply Chain Managementgz3ezhjcNessuna valutazione finora

- Principles of Supply Chain Management A Balanced Approach 4th Edition Wisner Solutions ManualDocumento36 paginePrinciples of Supply Chain Management A Balanced Approach 4th Edition Wisner Solutions Manualoutlying.pedantry.85yc100% (28)

- Mbaln 670 T02 PDFDocumento13 pagineMbaln 670 T02 PDFKate0% (1)

- The Internet For Distribution: Review QuestionsDocumento4 pagineThe Internet For Distribution: Review Questionsshahin317Nessuna valutazione finora

- Managing Supply Chain Inventory-LeeDocumento4 pagineManaging Supply Chain Inventory-LeeSamuel MosesNessuna valutazione finora

- Ae Aesos Learning Packet No. 1 PrelimDocumento31 pagineAe Aesos Learning Packet No. 1 Prelimsean buenaventuraNessuna valutazione finora

- Chapter 1 IntroductionDocumento19 pagineChapter 1 IntroductionNazia EnayetNessuna valutazione finora

- SCM 301Documento10 pagineSCM 301Manda simzNessuna valutazione finora

- Homework Chapter 1 Introduction To Supply Chain ManagementDocumento5 pagineHomework Chapter 1 Introduction To Supply Chain Managementbuggs1152Nessuna valutazione finora

- Retail Supply Chain ManagementDocumento9 pagineRetail Supply Chain ManagementShivatiNessuna valutazione finora

- SCM in B2BDocumento11 pagineSCM in B2Brakshaksinghai100% (1)

- A Manual for Agribusiness Value Chain Analysis in Developing CountriesDa EverandA Manual for Agribusiness Value Chain Analysis in Developing CountriesNessuna valutazione finora

- Supply Chain ManagementDocumento9 pagineSupply Chain Managementkc605711Nessuna valutazione finora

- A Literature Analysis of WalmartDocumento11 pagineA Literature Analysis of WalmartharpreetNessuna valutazione finora

- Unit 1 - Supply Chain Managemnt MeaningDocumento19 pagineUnit 1 - Supply Chain Managemnt MeaningSheela AngelNessuna valutazione finora

- Topic I - Introduction To SCMDocumento9 pagineTopic I - Introduction To SCMHobiNessuna valutazione finora

- Simchi Levi3E SMDocumento56 pagineSimchi Levi3E SMKhang HuynhNessuna valutazione finora

- Supply Chain Management of Wal-MartDocumento35 pagineSupply Chain Management of Wal-MartManik SahaNessuna valutazione finora

- Principles of Supply Chain Management A Balanced Approach 4th Edition Wisner Solutions ManualDocumento26 paginePrinciples of Supply Chain Management A Balanced Approach 4th Edition Wisner Solutions ManualRobertBlankenshipbrwez100% (28)

- Value Chain22.03.2023Documento10 pagineValue Chain22.03.2023debo0712Nessuna valutazione finora

- Solution Manual For Designing and Managing The Supply Chain 3rd Edition by David Simchi LeviDocumento56 pagineSolution Manual For Designing and Managing The Supply Chain 3rd Edition by David Simchi LeviOmnia MustafaNessuna valutazione finora

- SCE Assignment CO1Documento4 pagineSCE Assignment CO1atul953020Nessuna valutazione finora

- Important Question and AnswersDocumento7 pagineImportant Question and Answersshamal0392% (25)

- The Strategy Machine (Review and Analysis of Downes' Book)Da EverandThe Strategy Machine (Review and Analysis of Downes' Book)Nessuna valutazione finora

- Online Market VS Offline Market Comparison of Fruits & Vegetables PDF 2019 DHIRAJDocumento33 pagineOnline Market VS Offline Market Comparison of Fruits & Vegetables PDF 2019 DHIRAJDhiraj JaiswalNessuna valutazione finora

- Let's Know What Supply Chain IsDocumento8 pagineLet's Know What Supply Chain IsRafia TasnimNessuna valutazione finora

- 1-Introduction To Supply Chain ManagementDocumento20 pagine1-Introduction To Supply Chain ManagementMae JamolinNessuna valutazione finora

- Name: ID: COURSE: Operations Management Course Teacher: Dr. Di LingDocumento16 pagineName: ID: COURSE: Operations Management Course Teacher: Dr. Di LingTawsif Shafayet AliNessuna valutazione finora

- Warehouse ManagementDocumento31 pagineWarehouse ManagementMageswariNessuna valutazione finora

- Global Supply Chain Management Research PaperDocumento5 pagineGlobal Supply Chain Management Research Paperhyz0tiwezif3100% (1)

- SCM in B2BDocumento11 pagineSCM in B2Bmimi ChudiNessuna valutazione finora

- Supply Chain Management: Name-Diksha Patial CLASS-MBA (4sem) ROLL-NO-1710 Submitted To-Mr. Sachin SharmaDocumento16 pagineSupply Chain Management: Name-Diksha Patial CLASS-MBA (4sem) ROLL-NO-1710 Submitted To-Mr. Sachin SharmaShivani KakkerNessuna valutazione finora

- Chapter 3Documento12 pagineChapter 3samiulctg01Nessuna valutazione finora

- Om Unit IvDocumento24 pagineOm Unit IvMiyonNessuna valutazione finora

- Wal-Mart Stores, Inc., Global Retailer case study, the GUIDE editionDa EverandWal-Mart Stores, Inc., Global Retailer case study, the GUIDE editionNessuna valutazione finora

- Aspects of Supply Chain ManagementDocumento7 pagineAspects of Supply Chain ManagementKamal SanguriNessuna valutazione finora

- Links Supply Chain Management Fundamentals Simulation: Randall G. Chapman, PHDDocumento92 pagineLinks Supply Chain Management Fundamentals Simulation: Randall G. Chapman, PHDkwandy9298Nessuna valutazione finora

- Supply Chain Executive SummaryDocumento6 pagineSupply Chain Executive Summarya3san100% (6)

- Acfrogaddhvtlsahyai7-Jrohywtxa Wy6cswalgcmcmap3azd Xqyaey7rvu81jhixqwwq9b95i G3dbfbrmifv7c4kqnkr3jlwkbtr2abugdpik82rpq6xmkyxho3574xseoywo6udeikakjhuDocumento8 pagineAcfrogaddhvtlsahyai7-Jrohywtxa Wy6cswalgcmcmap3azd Xqyaey7rvu81jhixqwwq9b95i G3dbfbrmifv7c4kqnkr3jlwkbtr2abugdpik82rpq6xmkyxho3574xseoywo6udeikakjhuJoanna Mæ Nuñez SaysønNessuna valutazione finora

- Book Channel ManagementDocumento117 pagineBook Channel ManagementParisa Asgari SabetNessuna valutazione finora

- Rationale Behind Doing This ProjectDocumento60 pagineRationale Behind Doing This Projectarun060283shukla7692Nessuna valutazione finora

- The Top Ten Supply Chain MistakesDocumento6 pagineThe Top Ten Supply Chain Mistakesfelipeangeles77Nessuna valutazione finora

- MNGPL & Sharnagat - 18-19Documento67 pagineMNGPL & Sharnagat - 18-19Chulbul PandeyNessuna valutazione finora

- New Regime Vs Old Regime AY 2024-25 - CA Sai Pratap KopparapuDocumento1 paginaNew Regime Vs Old Regime AY 2024-25 - CA Sai Pratap Kopparapuviswa081Nessuna valutazione finora

- Maqsood Bibi W/O Rasheed Peter Abbas Nagar SHD LHR: Web Generated BillDocumento1 paginaMaqsood Bibi W/O Rasheed Peter Abbas Nagar SHD LHR: Web Generated BillAzmat SoniNessuna valutazione finora

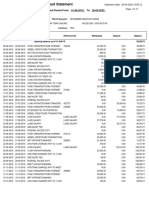

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocumento13 pagineStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceakhalikNessuna valutazione finora

- 555Documento2 pagine555HANGUKKWAN SEOULBULGOGINessuna valutazione finora

- Fatura Pag. ZoomDocumento3 pagineFatura Pag. ZoomMarcoNessuna valutazione finora

- Chigozie David Sunday 1518525449 20230213070845Documento12 pagineChigozie David Sunday 1518525449 20230213070845Sunday DavidNessuna valutazione finora

- Proforma Invoice TemplateDocumento2 pagineProforma Invoice TemplateMICHAELNessuna valutazione finora

- 1716524Documento4 pagine1716524Kamal KhuranaNessuna valutazione finora

- Chapter 07Documento11 pagineChapter 07Ram SskNessuna valutazione finora

- Bangalore Traffic Solution - PDF VersionDocumento22 pagineBangalore Traffic Solution - PDF Versiondas_gv0% (1)

- MashoodnasirDocumento17 pagineMashoodnasirmashood nasirNessuna valutazione finora

- Statement of Account: No 8 Lorong 9 Taman Sutera Sungai Petani 08000 KEDAH, KEDAHDocumento9 pagineStatement of Account: No 8 Lorong 9 Taman Sutera Sungai Petani 08000 KEDAH, KEDAHTvyan RaajNessuna valutazione finora

- HIVDocumento299 pagineHIVJhonrie PakiwagNessuna valutazione finora

- Resume 040110Documento2 pagineResume 040110beautiful_bmaNessuna valutazione finora

- Accounting For Manufacturing ActivitiesDocumento27 pagineAccounting For Manufacturing ActivitiesGerald B. Garcia100% (2)

- Motivation Sticker & Stamp Catalog: Quality UpgradedDocumento6 pagineMotivation Sticker & Stamp Catalog: Quality UpgradedABEELEEPEICHINGNessuna valutazione finora

- Slice Account Statement - Feb '22Documento3 pagineSlice Account Statement - Feb '22Roopa RooNessuna valutazione finora

- Circular No. 7 - 2007, Dated 23-10-2007Documento2 pagineCircular No. 7 - 2007, Dated 23-10-2007god gov9950Nessuna valutazione finora

- Wallet StatementDocumento308 pagineWallet StatementHarikrishna NerusuNessuna valutazione finora

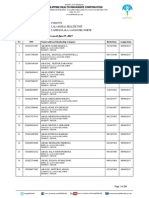

- Database Calon PegawaiDocumento12 pagineDatabase Calon PegawainadyaNessuna valutazione finora

- Chapter 11Documento26 pagineChapter 11Jack Huseynli100% (2)

- Provincial Government of Bataan: Class DDocumento2 pagineProvincial Government of Bataan: Class Dclaire50% (2)

- Pre CloseStatementDocumento2 paginePre CloseStatementMadhu BalaNessuna valutazione finora

- Egov Urban Portal-Water Tax PDFDocumento2 pagineEgov Urban Portal-Water Tax PDFPadmavathi Putra LokeshNessuna valutazione finora

- LGU NGAS Ch3 AcctgSystemVol1Documento46 pagineLGU NGAS Ch3 AcctgSystemVol1Pee-Jay Inigo UlitaNessuna valutazione finora

- Plan Amsterdam 2014Documento32 paginePlan Amsterdam 2014gustavocaneloNessuna valutazione finora

- Facture Acc MicrosoftDocumento2 pagineFacture Acc MicrosoftAbolo CyrilledonaldNessuna valutazione finora

- 2020 IFCPC Nations Championships - Technical Information 2Documento18 pagine2020 IFCPC Nations Championships - Technical Information 2Alfredo CastañoNessuna valutazione finora

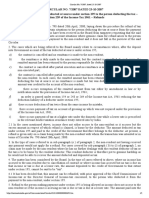

- R - e ND : Republic of The Philippines Court of Tax Appeals Quezon City Special Second DivisionDocumento68 pagineR - e ND : Republic of The Philippines Court of Tax Appeals Quezon City Special Second DivisionEugene SardonNessuna valutazione finora