Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Glucose

Caricato da

big johnCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Glucose

Caricato da

big johnCopyright:

Formati disponibili

225.

PROFILE ON PRODUCTION OF GLUCOSE

225-2

TABLE OF CONTENTS

PAGE

I.

SUMMARY

225-3

II.

PRODUCT DESCRIPTION & APPLICATION

225-3

III.

MARKET STUDY AND PLANT CAPACITY A. MARKET STUDY B. PLANT CAPACITY & PRODUCTION PROGRAMME

225-4 225-4 225-6

IV.

RAW MATERIALS AND INPUTS A. RAW & AUXILIARY MATERIALS B. UTILITIES

225-6 225-6 225-7

V.

TECHNOLOGY & ENGINEERING A. TECHNOLOGY B. ENGINEERING

225-8 225-8 225-9

VI.

MANPOWER & TRAINING REQUIREMENT A. MANPOWER REQUIREMENT B. TRAINING REQUIREMENT

225-10 225-10 225-10

VII.

FINANCIAL ANALYSIS A. TOTAL INITIAL INVESTMENT COST B. PRODUCTION COST C. FINANCIAL EVALUATION D. ECONOMIC BENEFITS

225-11 225-12 225-13 225-13 225-14

225-3

I.

SUMMARY

This profile envisages the establishment of a plant for the production of glucose with a capacity of 6,000 tones per annum.

The present demand for the proposed product is estimated at 6020 tones per annum. The demand is expected to reach at 10781 tones by the year 2017.

The plant will create employment opportunities for 45 persons.

The total investment requirement is estimated at about Birr 27.49 million, out of which Birr 12 million is required for plant and machinery.

The project is financially viable with an internal rate of return (IRR) of 15 % and a net present value (NPV) of Birr 6.49 million discounted at 8.5%.

II.

PRODUCT DESCRIPTION AND APPLICATION

Glucose, also known as corn syrup or starch syrup, is a concentrated water solution of partially hydrolyzed starch. It contains dextrose, maltose and other higher oligosaccharides derived from starch by acid or enzyme hydrolysis.

Glucose and glucose syrup have many uses, industrial as well as non industrial. The primary field of utilization is in the manufacture of confectionery, caramel coloring, brewing and wine making, infant foods, canning, baking and dairy factories and pharmaceutical products besides being used as humectants in tobacco and tanning industries. It is also used as raw material in the paper and adhesives industry.

225-4 III. MARKET STUDY AND PLANT CAPACITY

A.

MARKET STUDY

1.

Past supply and present demand

Glucose and glucose syrup has wide applications in the manufacturing sector. Among the users of the product are pharmaceuticals, breweries, tobacco producers, paper factories, adhesive industries and food processing and canning industries. Due to unavailability of domestic production the countrys requirement for the product is met through import. Import of glucose and glucose syrup for the past 10 years is shown in Table 3.1

Table 3.1 IMPORT OF GLUCOSE & GLUCOSE SYRUP (TON)

Year 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006

Quantity 253.5 437.2 273.8 1507.2 505.6 794.1 2217.1 3079.1 3290.8 8750.2

Source: Customs Authority

Table 3.1 reveals that the country's requirement of glucose and glucose syrup has been growing in the last 10 years. The yearly average supply during the period 1997-1999 has been about 321 tons. During the next consecutive years i.e. 2000-2002 it grew to a yearly average of 935 tons. A substantial growth of import has been registered in the recent four years. During year 2003

225-5 Ethiopia imported 2217 tons and increased to more than 3000 tons by the year 2004 and 2005. The quantity imported in year 2006 was exceptionally very high which amounts to 8750 tons. This substantial increase is believed as a result of the expansion and establishment of new factories in the country.

Although the quantity imported in the year 2006 was 8750 tons the current demand estimation has relied on the average import level of the recent two years. Accordingly, current effective demand is estimated at 6020 tons.

2.

Demand Projection

Demand for the product will grow with the expansion and development of the user industries. Annual growth of 6% is applied to forecast the demand assuming the manufacturing sector to grow as in the previous periods. The demand projection based on this assumption is presented in Table 3.2 Table 3.2 PROJECTED DEMAND FOR GLUCOSE & GLUCOSE SYRUP (TON)

Year 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017

Quantity 6381 6764 7170 7600 8056 8539 9052 9595 10170 10781

225-6

3.

Pricing and Distribution

Based on the import price obtained from Customs Authority a factory gate price of Birr 4,670 is adopted for sales revenue projection. The product can be directly sold to the user industries.

B.

PLANT CAPACITY AND PRODUCTION PROGRAMME

1.

Plant Capacity

Based on the market study the envisaged plant will have annual production capacity of 6000 tons. The plant will operate in a single shift of 8 hours a day, and for 300 days a year.

2.

Production Programme

Production will commence at 60%, and then will grow to 75%, 90% and 100% in the second year, third year and the fourth year and then after, respectively. Detail production programme is shown in Table 3.3 below.

Table 3.3 PRODUCTION PROGRAMME

Year Capacity utilization (%) Production (tons)

1 65 3900

2 75 4500

3 90 5400

3-10 100 6000

225-7 IV. MATERIALS AND INPUTS

A.

RAW AND AUXILIARY MATERIALS

The major raw material used to produce glucose and glucose syrup is starch which can be obtained locally. Other raw materials required in small amount to produce Glucose and

Glucose syrup are hydrochloric acid, soda ash and activated carbon. Annual consumption of raw and auxiliary materials at full production capacity is given in Table 4.1 below. The total cost of raw material is estimated at Birr 27,382,500.

Table 4.1 RAW AND AUXILIARY MATERIALS REQUIREMENT AND COST

Sr. No. 1 2 3 4 Description Starch [tones] HCl (30%)[tones] Soda ash[tones] Activated carbon[tones] 5 Packing material[pcs] Grand Total lump sum 26,295 Qty 7,500 75 30 150 LC 26,250 45 -

Cost, ['000 Birr] FC 337.5 750 TC 26,250 337.5 45 750

600 1,687.5

600 27,382.5

B.

UTILITIES

Electricity, water and fuel oil are the utilities required by the envisaged plant. Details of utilities are shown in Table 4.2. The total cost of utilities is estimated at Birr 1,079,720.

225-8 Table 4.2 UTILITIES REQUIREMENT AND COST

Sr. No. 1

Description

Quantity

Unit price (Birr)

Total Cost, Birr

Electricity (kWh) Water (m3) Furnace oil (lt.) Grand Total

450,000

0.4736 213,120

2 3

10,000 150,000

5.51 5.41

55,100 811,500 1,079,720

V.

TECHNOLOGY AND ENGINEERING

A.

TECHNOLOGY

Starch is converted into ordinary glucose and glucose syrup through a process called hydrolysis. In this process, the wet starch is mixed with a weak solution of hydrochloric acid and is heated under pressure. The hydrochloric acid and heat breakdown the starch molecules and convert them into a sugar. The hydrolysis can be interrupted at different key points to produce glucose syrup of varying sweetness. The longer the process is allowed to proceed, the sweeter the resulting syrup. This syrup is then filtered or otherwise clarified to remove any objectionable flavour or colour by adding activated carbon. It is further refined and evaporated to reduce the amount of water. To produce a glucose syrup powder, the liquid glucose syrup is passed through a vacuum drum or spray dryer to remove 97% of the water. This produces a crystalline corn syrup powder. Then the final product is cooled and packed.

2.

Source of Technology

The technology for the production of glucose and glucose syrup can be obtained from china, India, and European countries. The following Indian company can be contacted for technology supply:-

225-9 PRAJ Industries Limited PRAJ House, Bavdhan Pune 411021, India Tel: +912022905000 Fax: +912022951718 E mail: info@praj.net Web: www.praj.net

B.

ENGINEERING

1.

Machinery and Equipment

The list of machinery and equipment required by the envisaged plant is given in Table 5.1 below. The total cost of machinery and equipment with the envisaged capacity is estimated at Birr 12 million.

Table 5.1 MACHINERY AND EQUIPMENT REQUIREMENT

Sr. No. 1 2 3 4 5 6 7 8 9 10

Description

Qty. (No.)

Hydrochloric acid tank Blender/mixer Hydrolysis tank Wooden neutralization vat Filter Centrifuge Vacuum dryer Cooling tower Baby boiler Vessels and tanks

1 1 1 1 1 1 1 1 1 1

225-10

2.

Land, Building and Civil Works

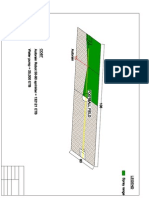

The total land requirement, including provision for open space is 5000 m2, of which 3000 m2 will be covered by building. Estimating unit building construction cost of Birr 2,800 per m2, keeping into consideration the buildings will be constructed from EGA sheet roof, prefab steel wall and cement tile floor. The total cost of building will be Birr 8,400,000. The cost of land leasing is Birr 0.2 per m2, and for 80 years land holding will be Birr 80,000. Thus, the total investment cost of land, building and civil works will be Birr 8,480,000.

3.

Proposed Location

Glucose and glucose syrup factory should be located at an area where there is sufficient raw material, market for its finished product and basic infrastructure like road, electricity and water are available. It would be, therefore, advisable to locate the plant in Alaba special woreda, Alaba Kulito town.

VI.

MANPOWER AND TRAINING REQUIREMENT

A.

MANPOWER REQUIREMENT

The plant requires workers, and their annual expenditure, including fringe benefits, is estimated at Birr 429,120. For details see Table 6.1 below.

B.

TRAINING REQUIREMENT

The production operators will be trained on the operation and maintenance of machinery for about four weeks during commissioning by the expert of machinery supplier. The total cost of training is estimated at Birr 50,000.

225-11 Table 6.1 MANPOWER REQUIREMENT AND ANNUAL LABOUR COST

Sr. No. 1 2 3

Description

Req. No.

Salary, Birr Monthly 2500 700 2000 24,000 Annual 30,000 8,400

Plant manager Secretary Production manager and technical

1 1 1

Finance manager

and

administration

1800 21,600

5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

Commercial manager Accountant Purchaser Sales man Production supervisor Mechanic Electrician Chemists Operators labourers personnel Time keepers Clerk Store keeper Driver Guard Cleaner Sub total Employee benefit (20% BS) Total

1 3 2 1 1 2 2 2 4 6 1 2 3 2 3 3 3 45 -

1800 2700 1800 900 900 1200 1200 1800 2000 1800 900 900 1050 1000 1350 900 600

21,600 32,400 21,600 10,800 10,800 14,400 14,400 21,600 24,000 21,600 10,800 10,800 12,600 12,000 16,200 10,800 7,200 357,600

71,520 429,120

225-12

VII.

FINANCIAL ANALYSIS

The financial analysis of the glucose project is based on the data presented in the previous chapters and the following assumptions:-

Construction period Source of finance

1 year 30 % equity 70 % loan

Tax holidays Bank interest Discount cash flow Accounts receivable Raw material local Raw material, import Work in progress Finished products Cash in hand Accounts payable

3 years 8% 8.5% 30 days 30days 90days 5 days 30 days 5 days 30 days

A.

TOTAL INITIAL INVESTMENT COST

The total investment cost of the project including working capital is estimated at million, of which 57 per cent will be required in foreign currency.

Birr 27.49

The major breakdown of the total initial investment cost is shown in Table 7.1.

225-13

Table 7.1 INITIAL INVESTMENT COST

Sr. No. 1 2 3 4 5 6 7 Cost Items Land lease value Building and Civil Work Plant Machinery and Equipment Office Furniture and Equipment Vehicle Pre-production Expenditure* Working Capital Total Investment cost Foreign Share

Total Cost (000 Birr) 80 8,400.00 12,000.00 150 250 1,321.29 5290.69 27,492.0 57

* N.B Pre-production expenditure includes interest during construction (Birr 1.12 million) training (Birr 50 thousand) and Birr 150 thousand costs of registration, licensing and

formation of the company including legal fees, commissioning expenses, etc.

B.

PRODUCTION COST

The annual production cost at full operation capacity is estimated at Birr 31.82 million (see Table 7.2). The material and utility cost accounts for 89.43 per cent, while repair and

maintenance take 0.47 per cent of the production cost.

225-14

Table 7.2 ANNUAL PRODUCTION COST AT FULL CAPACITY ('000 BIRR)

Items Raw Material and Inputs Utilities Maintenance and repair Labour direct Factory overheads Administration Costs Total Operating Costs Depreciation Cost of Finance Total Production Cost

Cost 27,382.50 1079.72 150 214.56 89.4 143.04 29,059.22 1725

% 86.03 3.39 0.47 0.67 0.28 0.45 91.30 5.42

1043.65 3.28 31,827.87 100

C.

FINANCIAL EVALUATION

1.

Profitability

According to the projected income statement, the project will start generating profit in the first year of operation. Important ratios such as profit to total sales, net profit to equity (Return on equity) and net profit plus interest on total investment (return on total investment) show an increasing trend during the life-time of the project.

The income statement and the other indicators of profitability show that the project is viable.

225-15

2.

Break-even Analysis

The break-even point of the project including cost of finance when it starts to operate at full capacity (year 3) is estimated by using income statement projection.

BE =

Fixed Cost Sales Variable Cost

= 30 %

3.

Payback Period

The investment cost and income statement projection are used to project the pay-back period. The projects initial investment will be fully recovered within 6 years.

4.

Internal Rate of Return and Net Present Value

Based on the cash flow statement, the calculated IRR of the project is 15 % and the net present value at 8.5% discount rate is Birr 6.49 million.

D.

ECONOMIC BENEFITS

The project can create employment for 45 persons.

In addition to supply of the domestic

needs, the project will generate Birr 7.62 million in terms of tax revenue. The establishment of such factory will have a foreign exchange saving effect to the country by substituting the current imports.

Potrebbero piacerti anche

- Maize StarchDocumento15 pagineMaize StarchpadhaiNessuna valutazione finora

- Dairy FarmDocumento14 pagineDairy FarmTESFALEWATEHENessuna valutazione finora

- Moringa Oil Business Plan and BudgetDocumento15 pagineMoringa Oil Business Plan and BudgetMoringaidNessuna valutazione finora

- Candy Manufacturing South Invest EthiopiaDocumento16 pagineCandy Manufacturing South Invest EthiopiaAbey Doni100% (4)

- Macaroni and SpagheriDocumento29 pagineMacaroni and Spagheriyenealem AbebeNessuna valutazione finora

- Small Scale-Paper MakingDocumento17 pagineSmall Scale-Paper MakingGnana SS100% (1)

- Baking PowderDocumento29 pagineBaking PowderTed Habtu Mamo AsratNessuna valutazione finora

- Corrugated Paper BoxDocumento13 pagineCorrugated Paper BoxhibadaNessuna valutazione finora

- Coff. RoastingDocumento31 pagineCoff. Roastingyenealem Abebe100% (1)

- Profile On The Production of VinegarDocumento28 pagineProfile On The Production of VinegarTed Habtu Mamo Asrat100% (1)

- Animal FeedDocumento27 pagineAnimal FeedYem Ane100% (1)

- Whole Wheat FlourDocumento4 pagineWhole Wheat FlourSHRUTI AGRAWALNessuna valutazione finora

- Ground NutDocumento19 pagineGround Nutabel_kayel100% (1)

- Semeli Business PlanDocumento17 pagineSemeli Business PlanSintayhuNessuna valutazione finora

- Profile On Sheep and Goat FarmDocumento14 pagineProfile On Sheep and Goat FarmFikirie MogesNessuna valutazione finora

- EPHIIIDocumento35 pagineEPHIIITesfaye DegefaNessuna valutazione finora

- Sesame FarmDocumento16 pagineSesame Farmvusi_zwe28100% (1)

- Produce Poultry FeedDocumento26 pagineProduce Poultry FeedMOHIT KHATWANINessuna valutazione finora

- Tin Containers Making-PlantDocumento26 pagineTin Containers Making-PlantEsayas Mekonnen100% (1)

- Cocoa Project ProposalDocumento3 pagineCocoa Project ProposalGAWII0% (1)

- Avocado Farm and Processing PlantDocumento14 pagineAvocado Farm and Processing Plantsamuel teferi100% (1)

- Jam & MarmaladeDocumento29 pagineJam & Marmaladeyenealem AbebeNessuna valutazione finora

- Avocado - Processing PlantDocumento48 pagineAvocado - Processing PlantTesfaye Kibret TesfayeNessuna valutazione finora

- Wet Coffee PupingDocumento21 pagineWet Coffee PupingJemalNessuna valutazione finora

- Honey ProcessingDocumento29 pagineHoney Processingyenealem Abebe100% (1)

- Chewing Gum, Chocolate and Hard CandyDocumento30 pagineChewing Gum, Chocolate and Hard Candyyenealem AbebeNessuna valutazione finora

- Dairy Prod.Documento29 pagineDairy Prod.yenealem Abebe100% (1)

- Model Project ProfilesDocumento13 pagineModel Project Profilesabhisek guptaNessuna valutazione finora

- Composite FLourDocumento27 pagineComposite FLouryenealem AbebeNessuna valutazione finora

- Producing Peanut Butter ProfitablyDocumento27 pagineProducing Peanut Butter Profitablyyenealem AbebeNessuna valutazione finora

- Profile On The Production of Tomato Sauce & KetchupDocumento29 pagineProfile On The Production of Tomato Sauce & Ketchupnidhi100% (1)

- Profile On The Production of Weighing ScaleDocumento26 pagineProfile On The Production of Weighing ScaleDagim GBZNessuna valutazione finora

- Shyam JVL Submitted ProjectDocumento66 pagineShyam JVL Submitted ProjectRaj Kishore Goswami100% (1)

- Showarobit Flour Mill Project B PlanDocumento30 pagineShowarobit Flour Mill Project B PlanWubshet Birke100% (1)

- Enjera Business PlanDocumento30 pagineEnjera Business PlanEndegNessuna valutazione finora

- Guyiti Tengi FULL PROJECT FinalDocumento51 pagineGuyiti Tengi FULL PROJECT FinalJemalNessuna valutazione finora

- Ethiopia's Growing Feed Industry and Training NeedsDocumento60 pagineEthiopia's Growing Feed Industry and Training NeedsAndnet Assefa100% (2)

- BiscuitDocumento27 pagineBiscuitPrabin MedhiNessuna valutazione finora

- Fdocuments - in Investment Office Anrs Embassy of Kraft Paper Company Name Maanshan HudongDocumento26 pagineFdocuments - in Investment Office Anrs Embassy of Kraft Paper Company Name Maanshan HudongSuleman100% (1)

- House Hold Plastic ManufacturingDocumento65 pagineHouse Hold Plastic ManufacturingNebiyu ZerihunNessuna valutazione finora

- Business Proposal PaperDocumento22 pagineBusiness Proposal Paperhayder nuredinNessuna valutazione finora

- Profile On Avocado OilDocumento19 pagineProfile On Avocado Oiltadiyos100% (1)

- Loundary Soap Processing PlantDocumento28 pagineLoundary Soap Processing PlantLakew50% (2)

- Market Potential for Bakery Ovens in IndiaDocumento7 pagineMarket Potential for Bakery Ovens in IndiaNikhil KediaNessuna valutazione finora

- Niger Seed OilDocumento16 pagineNiger Seed Oilbig johnNessuna valutazione finora

- Cleaning and PackagingDocumento17 pagineCleaning and PackagingDawod AbdieNessuna valutazione finora

- Candle Production Profile: Market Study and Financial AnalysisDocumento18 pagineCandle Production Profile: Market Study and Financial Analysistadiyos100% (1)

- Ambo University: Sebeta Milk Supply Section 7Documento13 pagineAmbo University: Sebeta Milk Supply Section 7Falmeta EliyasNessuna valutazione finora

- Plastic Cont.Documento25 paginePlastic Cont.John100% (1)

- KECHEMA POULTRY PRODUCTION PROJECT PROPOSALDocumento22 pagineKECHEMA POULTRY PRODUCTION PROJECT PROPOSALmulubrhan mebratuNessuna valutazione finora

- 2 Feasibility Study On DairyDocumento40 pagine2 Feasibility Study On DairyAdefrisNessuna valutazione finora

- Detail Project Report of Wheat FDocumento27 pagineDetail Project Report of Wheat FYogesh PatilNessuna valutazione finora

- Business Plan Graceland Farm and Animal Feed StoreDocumento37 pagineBusiness Plan Graceland Farm and Animal Feed StoreINformi William Ngenge100% (1)

- Food Outlook: Biannual Report on Global Food Markets May 2019Da EverandFood Outlook: Biannual Report on Global Food Markets May 2019Nessuna valutazione finora

- Detergent PowderDocumento16 pagineDetergent PowderJan Benner50% (2)

- Sodium SilicateDocumento15 pagineSodium SilicateAnonymous v5uipHNessuna valutazione finora

- Everything You Need to Know About Bleaching Powder ProductionDocumento19 pagineEverything You Need to Know About Bleaching Powder ProductionKroya Hun100% (1)

- Nitrogen PlaffdntDocumento17 pagineNitrogen PlaffdntardianalimNessuna valutazione finora

- Alcohol From Yam CassavaDocumento15 pagineAlcohol From Yam Cassavadinba123Nessuna valutazione finora

- Profile On Production of KaolinDocumento15 pagineProfile On Production of KaolinAmir FadzilNessuna valutazione finora

- Nursery Manual For Native Plants PDFDocumento309 pagineNursery Manual For Native Plants PDFbig john100% (1)

- The Date Palm Journal PDFDocumento240 pagineThe Date Palm Journal PDFbig johnNessuna valutazione finora

- Tea and IrrigationDocumento14 pagineTea and Irrigationbig johnNessuna valutazione finora

- Jam and JellyDocumento28 pagineJam and Jellybig johnNessuna valutazione finora

- Chewaka Store ModelDocumento1 paginaChewaka Store Modelbig johnNessuna valutazione finora

- Lowland OilcropsDocumento14 pagineLowland Oilcropsbig johnNessuna valutazione finora

- Co-Op Bulk Spice List in Order by Alphabetic Spice NameDocumento3 pagineCo-Op Bulk Spice List in Order by Alphabetic Spice Namebig johnNessuna valutazione finora

- Tea and IrrigationDocumento14 pagineTea and Irrigationbig johnNessuna valutazione finora

- Herb Production OrganicDocumento20 pagineHerb Production OrganicShoshannah33% (3)

- Football Field Layout1Documento1 paginaFootball Field Layout1big johnNessuna valutazione finora

- PomegranatesDocumento5 paginePomegranatesbig johnNessuna valutazione finora

- OrangeDocumento23 pagineOrangebig john100% (1)

- FCKupload File FAO Syria Crisis Report enDocumento106 pagineFCKupload File FAO Syria Crisis Report enbig johnNessuna valutazione finora

- BS Year1 No14 - Apr.02 1925Documento4 pagineBS Year1 No14 - Apr.02 1925big johnNessuna valutazione finora

- Grape JuiceDocumento16 pagineGrape Juicebig johnNessuna valutazione finora

- Tomato Paste and JuiceDocumento14 pagineTomato Paste and JuiceRamanathan Meyyappan100% (1)

- Horticulture Report FinalDocumento57 pagineHorticulture Report Finalbig john100% (1)

- Commodity TeaDocumento4 pagineCommodity Teabig johnNessuna valutazione finora

- 36 Tomato Sauce, Ketchup and PureesDocumento9 pagine36 Tomato Sauce, Ketchup and Pureesbig johnNessuna valutazione finora

- CIB, ContractDocumento89 pagineCIB, Contractbig johnNessuna valutazione finora

- Final EgyptDocumento258 pagineFinal Egyptbig johnNessuna valutazione finora

- CIB, ContractDocumento89 pagineCIB, Contractbig johnNessuna valutazione finora

- Tuta AbsolutaDocumento25 pagineTuta Absolutabig johnNessuna valutazione finora

- Participatory Irrigation Management in AlbaniaDocumento25 pagineParticipatory Irrigation Management in Albaniabig johnNessuna valutazione finora

- Tomato MarketingDocumento8 pagineTomato Marketingbig johnNessuna valutazione finora

- Dried Spray FruitDocumento130 pagineDried Spray Fruitbig john100% (2)

- Ethiopia Irrigation Diagnostic July 2010 2Documento59 pagineEthiopia Irrigation Diagnostic July 2010 2big john100% (1)

- Agribusiness Organization and Management SeminarDocumento24 pagineAgribusiness Organization and Management Seminarbig john100% (2)

- Unu Strategic Plan 2011-2014 enDocumento20 pagineUnu Strategic Plan 2011-2014 enbig johnNessuna valutazione finora

- 101 Iced Tea RecipesDocumento109 pagine101 Iced Tea RecipesNessa Santiago100% (3)