Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Corporate Safety & Environmental Inspection Report

Caricato da

Pang Lee ChingDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Corporate Safety & Environmental Inspection Report

Caricato da

Pang Lee ChingCopyright:

Formati disponibili

Corporate Safety & Environmental Inspection Report

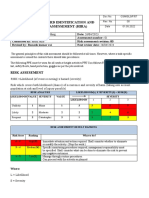

Management Safety & Environmental Walk Inspection

Participants Name Designation Signature

Item

Date:

: : :

Description

A

N A

Location

Completion Date

Part A. Safety Issues

1) Housekeep ing

1.1 1.2 1.3 1.4 1.5 1.6

Maintain proper access/ prevent obstruction Sufficient lighting at workplaces & emergency access Protruding objects (nails and/or etc.) Proper storage/ stacking of materials Control of mosquito breeding/ prevent stagnant water Remove construction waste / tidy up workplace Dust suppression measures /watering / cover stockpiles or excavated soil by tarpaulins/ wheel washing Prevent mud, oily or slippery floor Noise control / noise enclosures / use quite

1.7

1.8

1.9

equipment

1.10

Proper tray for diesel drums / generator Protection for power cable /power cable properly

1.11

hang up 2) Public

2.1

Safety / Road Work 3) Use of

3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8 2.2

Protection for road driver (e.g. traffic cones, barriers, lantern, signage & etc. ) replace damage lanterns Protection for pedestrian (e.g. hoarding, fences, safe access, signage & etc. )

Display of competent electrician & telephone number Warning notice for electrical hazards Outlet of generator / distribution switch board locked Earthing / ELCB provision/ test record Hand tools properly earthed or double insulated Use low voltage electric hand tools ( portable) Switch board should be provided with proper shelter Use water proof type socket and cable and plugs Fire fighting equipment at site office Fire fighting equipment at work areas / diesel drums Examination certificates

Electricity / Electric Hand Tools

4)

Fire

4.1 4.2 5.1

Prevention 5) Lifting

Legend A: B: C: NA:

Satisfactory at time of inspection Needs improvement Needs immediate follow-up action Not applicable or not found at time of inspection

Date:

05-12-2012

-1-

Item

Description

N A

Location

Completion Date

Appliances

5.2 5.3 5.4 5.5 5.6 5.7

Weekly inspection Form 1 Provide slinger / lookout-man for lifting operation Qualified crane operator Safe positioning of crane / outriggers fully extended Use of rings or shackles for multiple slings Safety latch of hook / safety catch device Examination of lifting gears Color code (wire ropes/ chain/ shackles / blocks etc.) Marking of safe working load :SWL Lifting gears checked without visible defect or worn

6)

Lifting

6.1 6.2 6.3

Gears

6.4

out

6.5

Chain hooks should be equipped with safety latch Examination certificates of excavator Setting position of excavator Audible signals or alarm Competent excavator operator Emergency exit / front window Weekly inspection Form 1 Proper shoring / temporary support to prevent soil

7)

Earth

7.1 7.2 7.3 7.4 7.5 7.6

Moving Plant (excavator etc.)

8)

8.1

Excavation / Earthwork

8.2 8.3 8.4 8.5 8.6 8.7 8.8

collapse in excess 1.2m Provide adequate height of barriers/ toe-board Temporary access / ladder Weekly inspection Form 4 Protection for underground utilities / warning notice Removal of pond water / prevent flooding Plant or material to be stacked away from edges of excavation Prevent soil erosion / avoid vertical cutting Proper stopper or barriers to prevent falling of

8.9

vehicles 9) Gas

9.1 9.2 9.3 9.4 9.5

Competent flame cutting operator Proper storage of gas cylinders/ use of trolley Provided with flash back arrestor Maintenance of hoses / regulators Fire extinguishers / fire fighting equipment

Welding & Flame Cutting

Legend A: B: C: NA:

Satisfactory at time of inspection Needs improvement Needs immediate follow-up action Not applicable or not found at time of inspection

Date:

05-12-2012

-2-

Item

Description

N A

Location

Completion Date

Protection of gas hoses from damage or tripping

9.6

hazard

9.7 9.8 9.9

Clear from flammable substances/ materials Protective screen to prevent fire slag Proper personal protective equipment Blowpipe equipped with non-return value Examination certificates form 2 Hose / connector properly clamped/ safety device Use of double lock couples EPD noise label Labeling / MSDS Proper storage in container Proper chemicals and /or wastes storage Store area / good ventilation

10)

Air

10.1 10.2 10.3 10.4 11.1 11.2 11.3 11.4

Receiver/ Compresso r 11) Hazard /Flammabl e substance (e.g. diesel,

11.5

gasoline) 12) Electric Arc Welding

12.1 12.2 12.3 12.4 12.5 12.6 12.7 12.8 12.9 12.10

Use of PPE when handling of hazard substances Competent welder Cable connection / prevent electrical hazards Electrode in good condition Proper earth or return Protection of cable / connector Fire extinguishers Clear from flammable substance/ materials Protective screen to prevent spark Step down voltage transformer Proper personal protective equipment Inspected by competent person : Form 5 Proper access /ladder Rigid railing ( upper & middle ) and toe board Closely board Stability / positioning / securely tie Securely covered or provided with rigid barriers Provide toe-boards or nets

13) Scaffold/ Working Platform

13.1 13.2 13.3 13.4 13.5 13.6

14)

Floor

14.1

Edge/Open

14.2

ing 15)

Legend A: B: C: NA:

Bar

15.1

Emergency stop device

Satisfactory at time of inspection Needs improvement Needs immediate follow-up action Not applicable or not found at time of inspection

Date:

05-12-2012

-3-

Item

Description

N A

Location

Completion Date

Bending Machine 16) Personal Protective Equipment

15.2 15.3 16.1 16.2 16.3 16.4 16.5 16.6

Guarding of dangerous parts Enclosure for bar bending machine Safety helmet/ reflective vest Safety footwear Use dust mask/ respirators Eye protection Ear protection when noisy environment Wearing safety harness when working platform is not practicable where person may fall from high level Drink water/ washing / toilet facilities Shelter for workers First aid facilities

17) Welfare Facilities 18)

17.1 17.2 17.3

18.1

Others

Part B. Environmental Issues

19)

Environmental Issues

19.1 19.2 19.3 19.4 19.5 19.6 19.7 19.8

Dust Control Measures Air Pollution Control Measures Noise Protection Measures Surface Runoff Waste Water Treatment Ecological Protection Measures Tree Protection Measures Chemical Waste Treatment

20)

20.1

Others

General Comment / Remark by Safety & Environment Manager/xxxxxxxxxx

Signature:

Date:

Legend A: B: C: NA:

Satisfactory at time of inspection Needs improvement Needs immediate follow-up action Not applicable or not found at time of inspection

Date:

05-12-2012

-4-

Item

Description

N A

Location

Completion Date

Legend A: B: C: NA:

Satisfactory at time of inspection Needs improvement Needs immediate follow-up action Not applicable or not found at time of inspection

Date:

05-12-2012

-5-

Potrebbero piacerti anche

- Monthly Inspection Report For Cranes and HoistsDocumento2 pagineMonthly Inspection Report For Cranes and HoistsGrace PassiniNessuna valutazione finora

- Daily report for Smiths Detection Malaysia upgrading worksDocumento2 pagineDaily report for Smiths Detection Malaysia upgrading worksMustaffa HoodMus100% (1)

- Office EHS Audit ChecksheetDocumento3 pagineOffice EHS Audit ChecksheetPanbarasan GanapathyNessuna valutazione finora

- Office Safety ManualDocumento8 pagineOffice Safety ManualtonywhNessuna valutazione finora

- Annex A - Safety Walk Report FormDocumento4 pagineAnnex A - Safety Walk Report FormwvolpeNessuna valutazione finora

- Employee Safety Inspection ChecklistDocumento2 pagineEmployee Safety Inspection ChecklistEvert W. VanderBerg100% (1)

- Osha PpeDocumento39 pagineOsha PpeIrawan AliNessuna valutazione finora

- Monitoring and Measurement RegisterDocumento12 pagineMonitoring and Measurement RegisterGcinumuzi SibandaNessuna valutazione finora

- Garment Factory Health and Safety Audit ReportDocumento23 pagineGarment Factory Health and Safety Audit ReportArefeen HridoyNessuna valutazione finora

- JSA - Doc Job Safety Analysis NewDocumento3 pagineJSA - Doc Job Safety Analysis NewKali MuthuNessuna valutazione finora

- Baseline Health and Safety Audit ResultsDocumento3 pagineBaseline Health and Safety Audit ResultsvrymanNessuna valutazione finora

- Monthly Safety PPE Report - SEP 2019Documento1 paginaMonthly Safety PPE Report - SEP 2019razambaNessuna valutazione finora

- Hira - 01Documento3 pagineHira - 01Angw BasumataryNessuna valutazione finora

- Workplace Safety ChecklistDocumento5 pagineWorkplace Safety ChecklistRavikant PandeyNessuna valutazione finora

- COMPRESSED GAS CYLINDER CHECKLISTDocumento2 pagineCOMPRESSED GAS CYLINDER CHECKLISTPerwez21100% (1)

- OHS Workplace Inspection WorkshopDocumento5 pagineOHS Workplace Inspection WorkshopRustam36Nessuna valutazione finora

- Monthly ladder checklistDocumento1 paginaMonthly ladder checklistJohn Rey AbarcaNessuna valutazione finora

- Nebosh Igc1 Lesson Plan Day 1Documento2 pagineNebosh Igc1 Lesson Plan Day 1KarenNessuna valutazione finora

- Toolbox Talk 5 Eye ProtectionDocumento2 pagineToolbox Talk 5 Eye ProtectionSajid HussainNessuna valutazione finora

- 9 Safety Inspection Report (Daily and Weekly) 01-12-14Documento3 pagine9 Safety Inspection Report (Daily and Weekly) 01-12-14Saboor KabierNessuna valutazione finora

- Personal Protective Equipment Policy - FinalDocumento6 paginePersonal Protective Equipment Policy - FinalmarkalvinbonNessuna valutazione finora

- Inspection ChecklistsDocumento6 pagineInspection Checklistsmegaspice0% (1)

- Induction Format BHELDocumento1 paginaInduction Format BHELMOJIBNessuna valutazione finora

- 6.DOSH Reporting An Accident 17Documento1 pagina6.DOSH Reporting An Accident 17alexcus1539Nessuna valutazione finora

- Osha3151 PPEDocumento57 pagineOsha3151 PPESayed Saad Shehata100% (2)

- Checklist On PpeDocumento3 pagineChecklist On PpeNikka LopezNessuna valutazione finora

- Check-List Hse: Evaluation (+) : Ok (-) : Not Ok ( ) : N/ADocumento3 pagineCheck-List Hse: Evaluation (+) : Ok (-) : Not Ok ( ) : N/AKouroufia Diaby GassammaNessuna valutazione finora

- 2020 Calendar PDFDocumento12 pagine2020 Calendar PDFHaneef ShaikNessuna valutazione finora

- Employee Training Record FormDocumento1 paginaEmployee Training Record FormAine GatdulaNessuna valutazione finora

- Training Matrix SampleDocumento4 pagineTraining Matrix SampleMaurice Avicor CoccusNessuna valutazione finora

- Excavator Inspection ChecklistDocumento2 pagineExcavator Inspection ChecklistSiyadarakkalmajeed ArakkalmajeedNessuna valutazione finora

- RPE Monthly Inspection ChecklistDocumento2 pagineRPE Monthly Inspection ChecklistOussama Ouardani100% (2)

- PPE InventoryDocumento2 paginePPE InventoryJowel MercadoNessuna valutazione finora

- Lockout Tagout FormDocumento1 paginaLockout Tagout FormSrinivas MurthyNessuna valutazione finora

- Occupational Safety and Legal Obligations: Property of STIDocumento8 pagineOccupational Safety and Legal Obligations: Property of STIKharylle P. Rivera100% (1)

- STA Audit Format-EditableDocumento1 paginaSTA Audit Format-EditableDeepu ChandranNessuna valutazione finora

- Then List Each Risk IdentifiedDocumento2 pagineThen List Each Risk IdentifiedShelby RedfernNessuna valutazione finora

- Office Ergonomics Checklist - OHCOWDocumento3 pagineOffice Ergonomics Checklist - OHCOWMarcus BragaNessuna valutazione finora

- HSE Hot Work PermitDocumento3 pagineHSE Hot Work PermitCSD shakthiNessuna valutazione finora

- Construction Safety Checklist RevisedDocumento2 pagineConstruction Safety Checklist Revisedariftajee100% (1)

- Appointment of Health and Safety Committee MembersDocumento3 pagineAppointment of Health and Safety Committee MembersmimiNessuna valutazione finora

- OSH Chapter 1 Introduction To Occupational Safety and HealthDocumento38 pagineOSH Chapter 1 Introduction To Occupational Safety and HealthEida HidayahNessuna valutazione finora

- Health & Safety On SiteDocumento4 pagineHealth & Safety On SiteshaukatNessuna valutazione finora

- Daily Toolbox Meeting Attendance SheetDocumento2 pagineDaily Toolbox Meeting Attendance SheetRaymondGomezBlancoNessuna valutazione finora

- KBR It It Sti InstructionsDocumento2 pagineKBR It It Sti InstructionsbotahraNessuna valutazione finora

- EHS Audit ReportDocumento9 pagineEHS Audit ReportMinhDũngNessuna valutazione finora

- Employee Safety Training Plan RecordDocumento1 paginaEmployee Safety Training Plan Recordsenorcojonazos100% (1)

- Njqs Core Audit Module - Rev1.6cDocumento14 pagineNjqs Core Audit Module - Rev1.6cNene UmohNessuna valutazione finora

- Violations & Penalties (Aug 6, 2017)Documento6 pagineViolations & Penalties (Aug 6, 2017)yagnamoid_21Nessuna valutazione finora

- Saf 113 A Daily She Inspection Report 1Documento4 pagineSaf 113 A Daily She Inspection Report 1saravana3kumar3ravic100% (1)

- Mifa Safety Regulations UKDocumento2 pagineMifa Safety Regulations UKnqh2009Nessuna valutazione finora

- Safe Work Method Statement (SWMS) Customising Instructions: Download and Save Your Documents Customising Your SWMSDocumento10 pagineSafe Work Method Statement (SWMS) Customising Instructions: Download and Save Your Documents Customising Your SWMSgaNessuna valutazione finora

- PPE TrainingDocumento23 paginePPE TrainingShadeed SalemNessuna valutazione finora

- Control Copy Issue RegisterDocumento30 pagineControl Copy Issue Registerpundir_vineetNessuna valutazione finora

- PPE MatrixDocumento4 paginePPE Matrixb_chiradipNessuna valutazione finora

- Safe System Of Work A Complete Guide - 2020 EditionDa EverandSafe System Of Work A Complete Guide - 2020 EditionNessuna valutazione finora

- Workplace Vocabulary for Esl Students: With Exercises and TestsDa EverandWorkplace Vocabulary for Esl Students: With Exercises and TestsNessuna valutazione finora

- Daily Site Inspection List - ExampleDocumento3 pagineDaily Site Inspection List - ExampleSeNNinhA031Nessuna valutazione finora

- Risk Assessment FormDocumento5 pagineRisk Assessment Formoadipphone7031Nessuna valutazione finora

- Drilling Rig Checklist Rev1Documento29 pagineDrilling Rig Checklist Rev1Abdulsani3357Nessuna valutazione finora

- Monitoring Locations Figure 1Documento1 paginaMonitoring Locations Figure 1Pang Lee ChingNessuna valutazione finora

- Payment of Wages Declaration MemoDocumento1 paginaPayment of Wages Declaration MemoPang Lee ChingNessuna valutazione finora

- Risk Assessment - Erection of Temporary Shoring System at Valve Chamber No. 1 & No. 2rev1.1Documento14 pagineRisk Assessment - Erection of Temporary Shoring System at Valve Chamber No. 1 & No. 2rev1.1Pang Lee ChingNessuna valutazione finora

- Emergency drill reportDocumento7 pagineEmergency drill reportPang Lee Ching40% (5)

- The Elijah Challenge Training Manual 2012Documento233 pagineThe Elijah Challenge Training Manual 2012Oliver Ortiz Quiero100% (1)

- Iceberg: 2012 Build King Group Brief Summary On Accident & ProsecutionDocumento1 paginaIceberg: 2012 Build King Group Brief Summary On Accident & ProsecutionPang Lee ChingNessuna valutazione finora

- Aed DrillDocumento9 pagineAed DrillPang Lee ChingNessuna valutazione finora

- Safe Working ProceduresDocumento2 pagineSafe Working ProceduresPang Lee ChingNessuna valutazione finora

- DSD Safety Steering GP Ad-Hoc Meting - Appendix I Action List DraftDocumento7 pagineDSD Safety Steering GP Ad-Hoc Meting - Appendix I Action List DraftPang Lee ChingNessuna valutazione finora

- Drill Report On ElectricDocumento4 pagineDrill Report On ElectricPang Lee ChingNessuna valutazione finora

- Drill Report On Emergency Treatment of Electric ShockDocumento7 pagineDrill Report On Emergency Treatment of Electric ShockPang Lee Ching60% (5)

- Risk Assessment - Working Adjacent To Water-NuaalhDocumento3 pagineRisk Assessment - Working Adjacent To Water-NuaalhPang Lee ChingNessuna valutazione finora

- Risk Assessment - Erection of Temporary Shoring System at Valve Chamber No. 1 & No. 2rev1.1Documento14 pagineRisk Assessment - Erection of Temporary Shoring System at Valve Chamber No. 1 & No. 2rev1.1Pang Lee ChingNessuna valutazione finora

- Action Plan For Uplifting Electrical Safety at WorkDocumento2 pagineAction Plan For Uplifting Electrical Safety at WorkPang Lee Ching100% (1)

- HK Institute VOC Ed Construction EMPDocumento86 pagineHK Institute VOC Ed Construction EMPPang Lee ChingNessuna valutazione finora

- Revival and Church HistoryDocumento64 pagineRevival and Church HistoryPang Lee ChingNessuna valutazione finora

- Contingency Plan For Hot WeatherDocumento11 pagineContingency Plan For Hot WeatherPang Lee Ching100% (1)

- Action Plan For Operational Control ProcedureDocumento6 pagineAction Plan For Operational Control ProcedurePang Lee ChingNessuna valutazione finora

- Revival Lifestyle e Book Chapter 1Documento9 pagineRevival Lifestyle e Book Chapter 1Pang Lee ChingNessuna valutazione finora

- A Water Tank Was Under Construction On The Ground Level of A BuildingDocumento2 pagineA Water Tank Was Under Construction On The Ground Level of A BuildingPang Lee ChingNessuna valutazione finora

- 4 Safety Training - Safety PlanDocumento7 pagine4 Safety Training - Safety PlanPang Lee ChingNessuna valutazione finora

- Derek Prince Osas ' Falling AwayDocumento30 pagineDerek Prince Osas ' Falling AwayPat Ruth Holliday100% (6)

- Is 110Documento49 pagineIs 110OlteanuNessuna valutazione finora

- Anilkumar Gopinathan Nair: Phone: +91-6380325363Documento2 pagineAnilkumar Gopinathan Nair: Phone: +91-6380325363Anilkumar GNessuna valutazione finora

- Welding A Cra-Lined Pipeline: Two "Bugs" Simultaneously Weld JointDocumento9 pagineWelding A Cra-Lined Pipeline: Two "Bugs" Simultaneously Weld JointYan FerizalNessuna valutazione finora

- Cable To Cable - TAC2Q2GDocumento2 pagineCable To Cable - TAC2Q2GedwraulNessuna valutazione finora

- Welded Pipes For CRH Line-SummaryDocumento1 paginaWelded Pipes For CRH Line-SummaryAnonymous gr5Pr9AVNessuna valutazione finora

- List of PracticalsDocumento5 pagineList of PracticalsSakil K SNessuna valutazione finora

- Section 2-Design Codes, Standards & ReferencesDocumento10 pagineSection 2-Design Codes, Standards & ReferencesMorteza alizadehNessuna valutazione finora

- The ABC's of Nondestructive Weld ExaminationDocumento10 pagineThe ABC's of Nondestructive Weld Examinationlethanhhai0306Nessuna valutazione finora

- Instruction Manual For Portable CompressorsDocumento84 pagineInstruction Manual For Portable CompressorsPopovici Alexandru100% (1)

- Ia - Gas Metal Arc Welding (Gmaw) NC IIDocumento17 pagineIa - Gas Metal Arc Welding (Gmaw) NC IIWilmerNessuna valutazione finora

- Gas WeldingDocumento17 pagineGas WeldingMostafizur Rahman SobujNessuna valutazione finora

- Method of Statement: Fit Up and ToolsDocumento1 paginaMethod of Statement: Fit Up and ToolsAmul PontingNessuna valutazione finora

- Welded and Seamless Carbon Steel and Austenitic Stainless Steel Pipe NipplesDocumento4 pagineWelded and Seamless Carbon Steel and Austenitic Stainless Steel Pipe NipplesLakesh AtwalNessuna valutazione finora

- Container inspection manual repair guideDocumento35 pagineContainer inspection manual repair guideImpresora MillantuNessuna valutazione finora

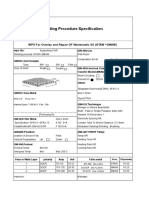

- Welding Procedure Specification: WPS For Overlay and Repair OF Martenzetic SS (GTAW +SMAW)Documento1 paginaWelding Procedure Specification: WPS For Overlay and Repair OF Martenzetic SS (GTAW +SMAW)Lipika GayenNessuna valutazione finora

- Duties of The RWCDocumento3 pagineDuties of The RWCbluegalago100% (1)

- ASME Sec VIII Div 1Documento120 pagineASME Sec VIII Div 1kanchanabalaji96% (23)

- QW 381Documento1 paginaQW 381Waqas WaqasNessuna valutazione finora

- 2021 Section VIII, Div. 1 ChangesDocumento10 pagine2021 Section VIII, Div. 1 ChangesSantoshNessuna valutazione finora

- MSC Container Inspection Criteria and Repair Guidelines - April 2023Documento15 pagineMSC Container Inspection Criteria and Repair Guidelines - April 2023romeobianco1989Nessuna valutazione finora

- Inspection of Unfired Pressure Vessel Std-128Documento34 pagineInspection of Unfired Pressure Vessel Std-128dyke_engg100% (1)

- C57.12.28-2005 Pad-Mounted Equipment-Enclosure IntegrityDocumento28 pagineC57.12.28-2005 Pad-Mounted Equipment-Enclosure IntegrityPedro Luis YanezNessuna valutazione finora

- WeldComm Stair SpecDocumento16 pagineWeldComm Stair Specsks_242Nessuna valutazione finora

- Impact Tested or Normalized - Boiler and Pressure Vessel Engineering - Eng-TipsDocumento5 pagineImpact Tested or Normalized - Boiler and Pressure Vessel Engineering - Eng-TipsNikunj KNessuna valutazione finora

- 336D2 L Excavator ZCT00001-UP (MACHINE) POWERED BY C9 Engine (SEBP6532 - 27) - Documentation PDFDocumento11 pagine336D2 L Excavator ZCT00001-UP (MACHINE) POWERED BY C9 Engine (SEBP6532 - 27) - Documentation PDFGeovanny SanjuanNessuna valutazione finora

- JOB OPPORTUNITY Internal Advert - Artisan BoilermakerDocumento2 pagineJOB OPPORTUNITY Internal Advert - Artisan BoilermakernormanNessuna valutazione finora

- Gaussian Pulsed Current Waveform Welding For Aluminum AlloysDocumento8 pagineGaussian Pulsed Current Waveform Welding For Aluminum AlloysmeleileiwangNessuna valutazione finora

- Technical Section RYCO HydraulicDocumento50 pagineTechnical Section RYCO Hydraulicedhy_03100% (1)

- 2954 2150 02 - XAS 67 DD - XATS 67 DD - XAS 77 DD - XAS 97 DD - PDFDocumento72 pagine2954 2150 02 - XAS 67 DD - XATS 67 DD - XAS 77 DD - XAS 97 DD - PDFHữu Dũng Nguyễn100% (1)

- ME workshop and statics fundamentalsDocumento20 pagineME workshop and statics fundamentalsbilal shabirNessuna valutazione finora