Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Stack Spec

Caricato da

Honey TiwariTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Stack Spec

Caricato da

Honey TiwariCopyright:

Formati disponibili

05-11 SECTION 23 51 00 BREECHINGS, CHIMNEYS, AND STACKS SPEC WRITER NOTES: 1. Delete between //---// if not applicable to project.

Also delete any other item or paragraph not applicable in the section and renumber the paragraphs. 2. This section does not include freestanding chimneys. PART 1 GENERAL: 1.1 DESCRIPTION: This section specifies flue gas exhaust system and all accessories from the boiler outlet to the stack outlet to the atmosphere. Flue gas recirculation (FGR) ductwork (if required by burners furnished) is also specified. 1.2 RELATED WORK: A. Section 07 60 00, FLASHING and SHEET METAL: Roof Penetrations. B. Section 13 05 41, SEISMIC RESTRAINT REQUIREMENTS FOR NON-STRUCTURAL COMPONENTS, C. Section 23 05 11, COMMON WORK RESULTS FOR HVAC and STEAM GENERATION. D. Section 23 05 51, NOISE and VIBRATION CONTROL FOR BOILER PLANT. E. Section 23 07 11, HVAC, PLUMBING, and BOILER PLANT INSULATION. F. Section 23 08 00, COMMISSIONING OF HVAC SYSTEMS. Requirements for commissioning, systems readiness checklists, and training //G. Section 23 52 39, FIRE-TUBE BOILERS: Economizers// //H. Section 23 52 33, WATER-TUBE BOILERS: Economizers// //I. Section 23 09 11, INSTRUMENTATION and CONTROL FOR BOILER PLANT: Boiler Draft Control System.// 1.3 QUALITY ASSURANCE: A. Provide scale drawings showing nominal dimensions and weight of the systems. B. Boiler and burner manufacturer shall review complete system from boiler flue gas outlet to stack outlet to atmosphere and advise the Government of any changes required to meet boiler and burner performance requirements. Note the altitude of plant site. C. If a double wall, factory-fabricated, positive pressure breeching and stack system is provided, the manufacturer shall completely engineer the entire system and provide all components. Manufacturers

23 51 00 - 1

05-11 representative shall provide installation instructions prior to start of construction, train the installers and certify in writing to the Resident Engineer (RE) that the entire installation complies with the official standards of the manufacturer and with the project specifications. D. Flue gas recirculation ductwork shall be designed and provided by the burner manufacturer. E. Conform to NFPA 54 and NFPA 31 for installation of fuel burning equipment and appliances. 1.4 SUBMITTALS: A. Submit in accordance with Section 01 33 23, SHOP DRAWINGS, PRODUCT DATA, and SAMPLES. B. Design, materials, weights, construction, pressure and temperature limitations of breeching and stack systems, flue gas recirculation system. //Seismic design data. // C. Drawings showing all components, system arrangement and dimensions. D. Design, construction, allowable movements, movement forces, pressure and temperature limitations of expansion joints. E. Damper design, construction, pressure and temperature limitations, pressure loss at design flow, and leakage of closed damper. F. Support designs, locations and loads for entire assembly. //Seismic design data. // G. Written statement from boiler/burner manufacturer that the design of the system is satisfactory to achieve the required boiler/burner performance. 1.5 APPLICABLE PUBLICATIONS: A. The publications listed below form a part of this specification to the extent referenced. The publications are referenced in the text by the basic designation only. B. American Institute of Steel Construction (AISC): Steel Construction Manual, Thirteenth Edition C. ASTM International (ASTM): A36/A36M-08.............Standard Specification for Carbon Structural Steel A242/A242M-04(2009).....Standard Specification for High-Strength LowAlloy Structural Steel

23 51 00 - 2

05-11 A307-07b................Standard Specification for Carbon Steel Bolts and Studs, 60,000 psi Tensile Strength A563-07a................Standard Specification for Carbon and Alloy Steel Nuts A568/A568M-09a..........Standard Specification for Steel, Sheet, Carbon, and High-Strength, Low-Alloy, HotRolled and Cold-Rolled, General Requirements For D. American Welding Society (AWS): Dl.l/D1.1M-2010.........Structural Welding Code-Steel E. Manufacturers Standardization Society of the Valves and Fittings Industry (MSS): SP-58-2009..............Pipe Hangers and Supports Materials, Design, Manufacture, Selection, Application, and Installation F. National Fire Protection Association: NFPA 54-2006............National Fuel Gas Code NFPA 31-2006............Standard for the Installation of Oil-Burning Equipment PART 2 PRODUCTS: 2.1 BREECHING, STACKS, FGR DUCTWORK: SPEC WRITER NOTES: 1. Coordinate the breeching and stack design (diameter and height) with the draft requirements of the boiler/burner. The contract drawings must show breeching and stacks in plan and sections and show diameters and heights. 2. The stack height must be sufficient to avoid flue gas being entrained into the boiler room make-up air or impinging on nearby buildings. 3. Where multiple boilers are connected to a common breeching and stack, the design should be based on boilers operating at the required steam output to serve peak load conditions plus a standby boiler in the pre-purge cycle. In this situation, the media in the breeching and stack is a mixture of hot flue gas and relatively cool purge air. A. Refer to drawings for arrangement and dimensions, except FGR ductwork shall be designed by the burner manufacturer. Connections to boilers

23 51 00 - 3

05-11 and economizers must comply with the written recommendations of the boiler and economizer manufacturers. Ninety-degree tee sections are not permitted. Intersections must be made with lateral tees. SPEC WRITER NOTE: Add wind-loading information. Edit out seismic requirements in non-seismic zones. B. Service: Design for continuous 315 C (600 F), 12 kPa (50 inches WC) positive and negative internal pressure, wind-loading for outside stacks _________________. //Design system and supports for seismic loads in accordance with Section 13 05 41, SEISMIC RESTRAINT REQUIREMENTS FOR NON-STRUCTURAL COMPONENTS.// SPEC WRITER NOTES: 1. Only UL-listed pre-engineered doublewall systems should be utilized in the building beyond the perimeter of the boiler plant. 2. Select pre-engineered, pre-fabricated double-wall system (Par. C) or custom designed single wall system (Par. D) for the boiler plant. Design details for the custom-designed single wall system must be shown on the drawings. C. Pre-engineered, Pre-Fabricated, Double-Wall System: 1. Complete factory-built system, all components and installation engineered and provided by manufacturer of system. SPEC WRITER NOTE: Allow air space with no insulation on outside stack only if the stack gas cooling and consequent reduction in draft will allow specified burner performance. 2. Provide double wall metal stacks, tested to [UL 103] [UL 127] [UL 641] and UL listed, for use with building heating equipment, in compliance with NFPA 211. 3. Corrosion-resistant steel, double-wall, circular cross section, positive pressure, blanket insulation between walls. //For stack sections outside the building, air space with no insulation between walls is allowed.//

23 51 00 - 4

05-11 4. Factory-built standard sections, connected in the field with joining system designed and provided by system manufacturer. Designed to be pressure and vacuum-tight, no deformation, at the service conditions specified. 5. System manufacturers engineered support system, attached to structural members of the building, with expansion joints between rigid supports. Thermal expansion shall be handled by expansion joints and variable spring hangers. Thermal expansion and weight of system shall not impose loads in excess of that allowed by manufacturer of boiler, economizer, or any other equipment, or exceed capabilities of building structure. Spring hangers shall conform to MSS SP-58, Type 51, variable spring. SPEC WRITER NOTE: Specify UL-listing and clearances to combustibles and noncombustibles only if necessary because of the location of the stack or breeching. //6. UL-listed for _____mm (______ inches) clearance to combustible materials and ______mm (_______ inches) clearance to non-combustible materials.// SPEC WRITER NOTE: Specify steel for natural gas and burner fuels. Specify 316 heavy fuel oil (No. 4, 5, 304 stainless No. 2 oil stainless on 6).

7. Inner Wall: Stainless steel, Type // 304 // 316 //, 0.9 mm (0.035-inch) minimum thickness for diameters 900 mm (36 inches) and smaller and 1.2 mm (0.048 inches) minimum thickness for diameters greater than 900 mm (36 inches) and 1200 mm (48 inches) and less. 8. Outer Wall: Aluminized or galvanized steel except // 304 // 316 // stainless steel outside of building, 0.6 mm (0.025 inch) minimum thickness for inner wall diameter 800 mm (32 inches) and less, 0.9 mm (0.034 inch) minimum thickness for inner wall diameter over 800 mm (32 inches) and 1200 mm (48 inches) and less. //9. Uninsulated Air Space between Inner and Outer Walls (Outside the Building Only): 25 mm (one inch) minimum. // 10. Insulation Between Walls: Fiberglass or mineral wool, 315 C (600 F). Minimum thickness 50 mm (2 inches). 11. Bands for Joining Sections: Same material as section being joined. Utilize sealant provided by system manufacturer.

23 51 00 - 5

05-11 12. Roof and wall penetrations shall be manufacturers standard ventilated thimble. Conform to Section 07 60 00, FLASHING and SHEET METAL. 13. Stack Outlet: Provide as shown, double cone rain cap or other type termination designed by manufacturer of the stack system. 14. Drain Section: Provide inside building below roof to drain rain water from stack. Extend drain pipe to floor drain. 15. Guys: Provide stack guy wires above roof, with spring-loaded tensioners, in accordance with printed instructions of stack manufacturer. D. Custom-Designed, field-fabricated, steel single wall system: 1. Breeching and stack walls, carbon steel, ASTM A568, thickness 3.4 mm (0.1345 inch). 2. Fabricate in welded sections with angle terminations for bolted connection of sections. Shapes and plate shall be ASTM A36. 3. Welding shall comply with AWS Dl.l. 4. Comply with AISC Manual of Steel Construction, "Design, Fabrication, and Erection of Structural Steel." Design to be pressure and vacuum-tight, no deformation, at the service conditions specified. 5. Provide 3.2 mm (l/8 inch) thick high temperature, non-asbestos gaskets between sections. 6. Heavy hex ASTM A307 Grade B machine bolts. Heavy hex ASTM A563 Grade C nuts. Provide washers under bolts and nuts. washers cadmium plated. 7. Provide angle clips for attachment of insulation. 8. Roof penetrations shall conform to Section 07 60 00, FLASHING and SHEET METAL. 9. Rain cap shall be double cone arrangement, welded, supported by angles. 10. Support with rigid and spring supports attached to the building structure. Supports shall be designed to completely support the system without overloading the connecting equipment or the building structure. necessary). 11. Provide guy wires on stacks with spring-loaded tensioners as shown on the drawings. Thermal expansion shall be accommodated by expansion joints and MSS SP-58, Type 51 variable spring hangers (if Bolts, nuts and

23 51 00 - 6

05-11 12. Clean all surfaces of rust, mill scale, and apply prime coat of heat and corrosion resistant paint. Apply finish coats of heat and corrosion-resistant paint to all exposed uninsulated surfaces. Select paint system compatible with maximum surface temperature. Refer to Section 09 91 00, PAINTING. SPEC WRITER NOTES: Provide outlet dampers and draft control system only on boilers that are connected to a common breeching and tall stack or chimney. 2.2 BOILER OUTLET DAMPERS AND ACCESSORIES A. Type: Multi-blade, opposed horizontal blades, automatically controlled. Open-shut operation. Also, modulating operation on systems requiring automatic draft control. Locate at the outlets of the // boilers // economizers //. //Boiler outlet draft control is specified in Section 23 09 11, INSTRUMENTATION and CONTROL FOR BOILER PLANT.// B. Service: Design for 315 C (600 F), 1.2 kPa (5 inches W.C.) positive and negative pressure. Maximum leakage, when closed, shall be ten percent of maximum required flow. Maximum pressure loss at maximum boiler steam output, 0.01 kPa (0.05 inches WC). C. Construction: 1. Blades: ASTM A242 carbon steel, air foil, dowelled to shafts. 2. Shafts: Stainless steel. Provide seals at casing penetrations. 3. Bearings: External to flow stream, carbon, self-contained, bushing, packing-gland assemblies, self-lubricating. 4. Linkages: Control arms dowelled to shafts. All control arms linked to drive motor. External to flow stream. All steel construction. D. Accessories: 1. Interlock Switch Mounting: Rigid mounting located to allow switch to sense damper linkage position. Switch is connected to burner control system specified in Section 23 09 11, INSTRUMENTATION and CONTROL FOR BOILER PLANT 2. Damper Drive Unit: Electric type that shall operate damper without overload. Provide 100 percent duty cycle maintenance-free motors that never overheat or burnout under stalled conditions. Constant speed coordinated with the controlled process so that performance parameters remain within requirements. For systems without draft control, the drive unit shall automatically open damper 90 degrees on boiler purge and firing cycle; close damper on boiler shut down.

23 51 00 - 7

05-11 For systems with draft control, the drive unit shall automatically open damper 90 degrees on boiler purge cycle, position damper as required for proper burner ignition, modulate damper during boiler firing to maintain constant outlet draft, close damper on boiler shut down. 2.3 EXPANSION JOINTS A. Provide sufficient types, quantities, and locations of expansion joints to completely absorb all thermal expansion of the system without imposing excessive loads on equipment or building structure. Fabric joints shall be used on single-wall stack and breeching system. On factory-fabricated double wall stack or breeching system, use slip-type, bellows-type, or fabric expansion joints engineered by designer of the stack and breeching system. B. Service: Design for 300 C (575 F), 5 kPa (20 inches) WC positive and negative internal pressure, continuous duty. C. Construction, Fabric Joints: 1. Fabric: High strength, designed for dewpoint service. 2. Internal Baffles: Carbon steel with stiffeners. Designed to protect interior surfaces of fabric from wiping action of the flue gases. 3. Welded frame, 6 mm (1/4 inch) thick ASTM A568 steel with 100mm (4 inch) minimum flange height, flat-belt design, fabricated by expansion joint manufacturer. Fabric element bolting, 9 mm (3/8 inch) diameter, 150 mm (6 inch) maximum centers. D. Construction, Factory-Fabricated Double-Wall System Joints: 1. Materials: Same as factory-fabricated breeching system. 2. Packing Gland: High temperature rating. Provide seal between sliding and fixed portions of joint. 2.4 ACCESSORIES A. Drains: Provide threaded pipe connection to allow drainage at all low points and drain connections in stack and breeching systems. Slope piping system to the drain. Pipe size shall be 25 mm (1 inch) minimum. B. Instrument Ports: Locate on individual stack or breeching serving each boiler. Locate in non-turbulent zone within 3600 mm (12 feet) of boiler room floor between boiler and economizer (when economizer is provided) or locate accessible from platform. Provide separate ports for the following: 1. Flue gas oxygen analyzer: Coordinate with analyzer furnished.

23 51 00 - 8

05-11 2. Opacity monitor (if required): Coordinate with sensor furnished. Locate downstream from oxygen analyzer. 3. Stack temperature sensor: Coordinate with sensor furnished. 4. Draft gauge: 25 mm (1 inch) diameter coupling, plugged. 5. Test instruments: 25 mm (1 inch) diameter coupling, plugged. C. Access Doors: Bolted, gasketed, insulated, with handles. Provide where shown. Minimum opening 400 mm x 400 mm (16 inches x 16 inches). 2.5 TYBE B DOUBLE WALL GAS VENTS A. Fabrication: Inner pipe of sheet aluminum, and outer pipe of galvanized sheet steel, tested in compliance with UL 441. PART 3 - EXECUTION SPEC WRITER NOTE: Select Par. 3.1 or 3.2, depending on the type of system specified. 3.1 INSTALLATION - PRE-ENGINEERED, PRE-FABRICATED DOUBLE WALL SYSTEM A. Supports: Completely support all systems from the building structure without overloading the building structure or the connected equipment. Support system shall be engineered by the system manufacturer and shall accommodate thermal expansion. //Refer to seismic requirements in Section 13 05 41, SEISMIC RESTRAINT REQUIREMENTS FOR NON-STRUCTURAL COMPONENTS.// B. Factory-Fabricated Stack or Breeching System: 1. Install in accordance with manufacturer's printed instructions, NFPA 54 and NFPA 31. 2. Deliver a copy of the instructions to the RE/COTR prior to commencing the installation. 3. Representative of manufacturer shall provide field training on all installation techniques to all installers. C. Connect 25 mm (1 inch) minimum pipes with ball valves to breeching and stack drains. Extend to floor drain. D. Boiler or Economizer Outlet Dampers: Locate so that there is no restriction in the flow of flue gas recirculation (if provided). E. Pitch breechings with positive slope up from fuel-fired equipment to chimney or stack. 3.2 INSTALLATION - CUSTOM-DESIGNED, FIELD-FABRICATED, STEEL SINGLE WALL SYSTEM SPEC WRITER NOTE: Verify that supports are shown on the contract drawings.

23 51 00 - 9

05-11 A. Supports: Completely support all systems from the building structure without overloading the building structure or the connected equipment. Support system shall be as shown on the drawings. //Refer to seismic requirements in Section 13 05 41, SEISMIC RESTRAINT REQUIREMENTS FOR NON-STRUCTURAL COMPONENTS.// B. Joints: Provide continuous weld between boiler outlet and connecting transition, breeching or stub stack and at connections to economizers, when recommended by manufacturer of economizer or boiler. Securely bolt all remaining joints and provide gaskets rated for service at 315 C (600 F). C. Field-Applied Insulation: Refer to Section 23 07 11, HVAC, PLUMBING, AND BOILER PLANT INSULATION. D. Connect 25 mm (1 inch) minimum pipes with ball valves to breeching and stack drains. Extend to floor drain. E. Boiler or Economizer Outlet Dampers: Locate so that there is no restriction in the flow of flue gas recirculation (if provided). F. Pitch breechings with positive slope up from fuel-fired equipment to chimney or stack. G. Install in accordance with NFPA 54 and NFPA 31. 3.3 COMMISSIONING A. Provide commissioning documentation in accordance with the requirements of Section 23 08 00 COMMISSIONING OF HVAC SYSTEMS for all inspection, start up, and contractor testing required above and required by the System Readiness Checklist provided by the Commissioning Agent. B. Components provided under this section of the specification will be tested as part of a larger system. Refer to Section 23 08 00 COMMISSIONING OF HVAC SYSTEMS and related sections for contractor responsibilities for system commissioning. - - - E N D - - -

23 51 00 - 10

Potrebbero piacerti anche

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDa Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsValutazione: 4 su 5 stelle4/5 (1)

- E20s HAP50 - Manual HAP PDFDocumento144 pagineE20s HAP50 - Manual HAP PDFAnonymous XhkjXCxxsT100% (1)

- Check List - Basic Engineering Package (BEP) Information Input/ ReviewDocumento4 pagineCheck List - Basic Engineering Package (BEP) Information Input/ ReviewssgentisNessuna valutazione finora

- Chimney Sizing PDFDocumento13 pagineChimney Sizing PDFtitieNessuna valutazione finora

- BPVC I p-2Documento2 pagineBPVC I p-2Ingeniería Thermo PressionNessuna valutazione finora

- 53 - Butt-Weld Pipe FittingsDocumento13 pagine53 - Butt-Weld Pipe Fittingsjoni_capelletoNessuna valutazione finora

- Equipment DesignDocumento146 pagineEquipment DesignhuyNessuna valutazione finora

- Heat Load CalculationsDocumento6 pagineHeat Load CalculationsHoney Tiwari0% (1)

- Tranfer Line Exchangers PDFDocumento28 pagineTranfer Line Exchangers PDFNaveen MeenaNessuna valutazione finora

- FSO-SU-5157-A - FPSO Marine Steam Plants - GeneralDocumento54 pagineFSO-SU-5157-A - FPSO Marine Steam Plants - GeneralMinh Hong Pham100% (1)

- Damper TorqueDocumento3 pagineDamper TorqueNguyễn LinhNessuna valutazione finora

- Boiler Furnace Design and DutyDocumento6 pagineBoiler Furnace Design and Dutyأمير حارث100% (1)

- Basic PipingDocumento48 pagineBasic Pipingmackoi BalaresNessuna valutazione finora

- Separator CalcsDocumento20 pagineSeparator CalcsHoney Tiwari100% (3)

- Chapter 8 Steam PipingDocumento14 pagineChapter 8 Steam PipingChen WsNessuna valutazione finora

- Boiler: Heat Sources Materials Energy Boiler EfficiencyDocumento10 pagineBoiler: Heat Sources Materials Energy Boiler EfficiencyrpercorNessuna valutazione finora

- Sulfur Tail Gas Thermal Oxidizer Systems Pickard Callidus Technologies SRU League City 2010Documento6 pagineSulfur Tail Gas Thermal Oxidizer Systems Pickard Callidus Technologies SRU League City 2010Navneet KumarNessuna valutazione finora

- 5822 2004 PDFDocumento19 pagine5822 2004 PDFSuresh CNessuna valutazione finora

- Boiler Drum DesignDocumento3 pagineBoiler Drum Designtsrinivasan508350% (2)

- Hvac Load Calculations of A VillaDocumento72 pagineHvac Load Calculations of A VillaKhalil YoussefNessuna valutazione finora

- Procedure For Recondition of Convection Coil 11 E 203 1 LowerDocumento9 pagineProcedure For Recondition of Convection Coil 11 E 203 1 LowerHaseeb BokhariNessuna valutazione finora

- Coulson& Richardson - Cap.10 Gas-Liquid Separation PDFDocumento6 pagineCoulson& Richardson - Cap.10 Gas-Liquid Separation PDFHoney TiwariNessuna valutazione finora

- Erection Procedure Rev 0Documento5 pagineErection Procedure Rev 0Arturo Suarez VillaoNessuna valutazione finora

- Data Sheets PDFDocumento58 pagineData Sheets PDFRamy MahmoudNessuna valutazione finora

- Engineering Services by KBR Technical Services, IncDocumento3 pagineEngineering Services by KBR Technical Services, IncswatkoolNessuna valutazione finora

- 6684-EQS-101-CA-0001 - 000 - 03 - Contractor's Scope of Work - Static EquiDocumento15 pagine6684-EQS-101-CA-0001 - 000 - 03 - Contractor's Scope of Work - Static EquiAvinash ShuklaNessuna valutazione finora

- Manual For Duct Work SpecificationsDocumento18 pagineManual For Duct Work SpecificationsAmos OchienoNessuna valutazione finora

- Pi Ups 1007Documento30 paginePi Ups 1007JOEL ARNAO CORTEGANANessuna valutazione finora

- Glaxo Vol IDocumento164 pagineGlaxo Vol IPrakash WarrierNessuna valutazione finora

- Condensate Flash Vessel HandbookDocumento3 pagineCondensate Flash Vessel HandbookHari Gunawan NugrahaNessuna valutazione finora

- Engineering Group: Kuwait Oil Company (K.S.C.)Documento14 pagineEngineering Group: Kuwait Oil Company (K.S.C.)Aravindan Ganesh KumarNessuna valutazione finora

- Boiler CirculationDocumento7 pagineBoiler CirculationaruntpeNessuna valutazione finora

- Compress Report For Pressure VesselDocumento394 pagineCompress Report For Pressure VesselgaurangNessuna valutazione finora

- TRB Conf Report Ec128Documento404 pagineTRB Conf Report Ec128jleboNessuna valutazione finora

- Fired Heaters: Esteem Projects Pvt. Ltd. The Fired Heater CompanyDocumento21 pagineFired Heaters: Esteem Projects Pvt. Ltd. The Fired Heater CompanySoumitra GuptaNessuna valutazione finora

- Steam BookDocumento98 pagineSteam BooklightsonsNessuna valutazione finora

- Spec BoilerDocumento9 pagineSpec BoilerAchmad MakmuriNessuna valutazione finora

- Bridge Superstructure DesignDocumento278 pagineBridge Superstructure Designmikefara100% (3)

- Metro Urban Design & Streetscape ManualDocumento268 pagineMetro Urban Design & Streetscape Manualnikhilnagpal2121994100% (1)

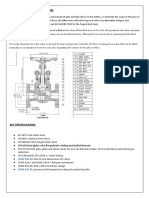

- Globe Valve Bs 1873 and Api 602: ASME B16.10Documento7 pagineGlobe Valve Bs 1873 and Api 602: ASME B16.10swapnil PATILNessuna valutazione finora

- Shellmax Boiler Design CalculationDocumento2 pagineShellmax Boiler Design Calculationrahult19Nessuna valutazione finora

- Technical Specification - Patratu-3LPE CoatingDocumento24 pagineTechnical Specification - Patratu-3LPE CoatingAJAY PatilNessuna valutazione finora

- Engineering Unit Conversion PDFDocumento5 pagineEngineering Unit Conversion PDFBarcepandoNessuna valutazione finora

- Mazzella WireRopeAtAGlance 0919Documento5 pagineMazzella WireRopeAtAGlance 0919Tarek HareedyNessuna valutazione finora

- 3.2 Big Block Assembly 3.2.1 Work Shop Assembly Pre-RequisitionsDocumento14 pagine3.2 Big Block Assembly 3.2.1 Work Shop Assembly Pre-RequisitionsEur-Ing Nicola GalluzziNessuna valutazione finora

- Earthquake Resistant Structure - NOTES 3rd YR V SEMDocumento12 pagineEarthquake Resistant Structure - NOTES 3rd YR V SEMrutuja100% (1)

- C. Specifications For Cone Roof TKDocumento21 pagineC. Specifications For Cone Roof TKFajar Sidiq AliwiyonoNessuna valutazione finora

- Cable Laying SpecificationDocumento16 pagineCable Laying SpecificationdavidgarciavazquezNessuna valutazione finora

- Compressor Capacity CalculationDocumento4 pagineCompressor Capacity CalculationHoney Tiwari100% (1)

- Technical Notes and Specifications Part CDocumento29 pagineTechnical Notes and Specifications Part Cهيمنت بيلوديا100% (1)

- SUR - Erection BOQ - ST & Geno - Rev ADocumento5 pagineSUR - Erection BOQ - ST & Geno - Rev Ashaikhsajid242Nessuna valutazione finora

- Chapter 3 PDFDocumento64 pagineChapter 3 PDFMuhammad Asyraf Bin RusliNessuna valutazione finora

- Superheater Problems in Steam GeneratorsDocumento11 pagineSuperheater Problems in Steam GeneratorsMarcus BaltesNessuna valutazione finora

- FW Utility Boiler PDFDocumento12 pagineFW Utility Boiler PDFChandan AulakhNessuna valutazione finora

- Natural Circulation in BoilerDocumento9 pagineNatural Circulation in BoilerSajjad AhmedNessuna valutazione finora

- Thrust Bearing OrientationDocumento1 paginaThrust Bearing Orientationmbueno1180Nessuna valutazione finora

- Sulphuric Acid PlantsDocumento16 pagineSulphuric Acid PlantsSekar.SNessuna valutazione finora

- Design and BuildDocumento10 pagineDesign and BuildBluesinhaNessuna valutazione finora

- Boilers Basic Components (Att. VIII)Documento28 pagineBoilers Basic Components (Att. VIII)Vijay RajNessuna valutazione finora

- Chap 28 PDFDocumento30 pagineChap 28 PDFnelson escuderoNessuna valutazione finora

- Shop Fabricated Furnace SteelDocumento7 pagineShop Fabricated Furnace SteelswatkoolNessuna valutazione finora

- ACI 318-11 Appedix DDocumento2 pagineACI 318-11 Appedix DJonathan SchauderNessuna valutazione finora

- 1) Tube & Pipe Comparison TableDocumento2 pagine1) Tube & Pipe Comparison Tablevalli rajuNessuna valutazione finora

- Modulating Control (Operating Procedure)Documento32 pagineModulating Control (Operating Procedure)goodgranitNessuna valutazione finora

- Air Cooled Condensors: General DescriptionDocumento7 pagineAir Cooled Condensors: General DescriptionRajeev MaheshwariNessuna valutazione finora

- 3s Steam BoilerDocumento13 pagine3s Steam BoilertahirNessuna valutazione finora

- Sa 423Documento6 pagineSa 423Widya widyaNessuna valutazione finora

- Boiler: Sabari Girish N Sr. Engineer (O)Documento37 pagineBoiler: Sabari Girish N Sr. Engineer (O)Deepak SinghNessuna valutazione finora

- Boiler Material and Typical ApplicationsDocumento1 paginaBoiler Material and Typical Applicationsmtbecerrap100% (1)

- Chapter 2 FiretubeDocumento18 pagineChapter 2 FiretubeWael Abdel-MageedNessuna valutazione finora

- Nickel Alloys For Sulfuric Acid ProductionDocumento5 pagineNickel Alloys For Sulfuric Acid ProductionHeanjiaAlloysNessuna valutazione finora

- How To Boost HRSG Performance and Increase Your Plant's Bottom LineDocumento28 pagineHow To Boost HRSG Performance and Increase Your Plant's Bottom Lineabdulyunus_amir100% (1)

- Curriculam Vitae: - Since Aug 2011 To Till DateDocumento6 pagineCurriculam Vitae: - Since Aug 2011 To Till DatechetanmaleNessuna valutazione finora

- Butterfly Valve Catalogue PDFDocumento25 pagineButterfly Valve Catalogue PDFPriyanka rajpurohitNessuna valutazione finora

- Working Principle of Shell and Tube Heat ExchangerDocumento8 pagineWorking Principle of Shell and Tube Heat ExchangersanjayNessuna valutazione finora

- Chap 34 PDFDocumento16 pagineChap 34 PDFnelson escuderoNessuna valutazione finora

- Boiler Types and Classifications - WikiDocumento21 pagineBoiler Types and Classifications - WikiKarthik ChillaNessuna valutazione finora

- Duct Accessories - RevDocumento5 pagineDuct Accessories - RevLuis Gabriel BautistaNessuna valutazione finora

- Graphs RE Source Platform PDFDocumento7 pagineGraphs RE Source Platform PDFHoney TiwariNessuna valutazione finora

- SAUDI-EDB Rank World Bank PDFDocumento1 paginaSAUDI-EDB Rank World Bank PDFHoney TiwariNessuna valutazione finora

- PRESS RELEASE Round3 RFQ PDFDocumento2 paginePRESS RELEASE Round3 RFQ PDFHoney TiwariNessuna valutazione finora

- Editorial Board - 2018 - Technological Forecasting and Social Change PDFDocumento1 paginaEditorial Board - 2018 - Technological Forecasting and Social Change PDFHoney TiwariNessuna valutazione finora

- PPP Prospectus 8 12 19 1Documento18 paginePPP Prospectus 8 12 19 1Honey Tiwari100% (1)

- Morocco Noor AF Project Paper P164288 May17 Clean 05212018 PDFDocumento87 pagineMorocco Noor AF Project Paper P164288 May17 Clean 05212018 PDFHoney TiwariNessuna valutazione finora

- ACCIONA, A Pioneer in The Hybridization of Solar Panels With Wind Power TowersDocumento3 pagineACCIONA, A Pioneer in The Hybridization of Solar Panels With Wind Power TowersHoney TiwariNessuna valutazione finora

- Sizing of SeparatorDocumento2 pagineSizing of SeparatorHoney TiwariNessuna valutazione finora

- Eleccostsum PDFDocumento4 pagineEleccostsum PDFHoney TiwariNessuna valutazione finora

- Air Cooled HX Data SheetDocumento1 paginaAir Cooled HX Data SheetHoney TiwariNessuna valutazione finora

- Fluor Daniel India Private LimitedDocumento1 paginaFluor Daniel India Private LimitedHoney Tiwari100% (1)

- As On 31.01.2014 Target For 31.03.2017: 1. Facts & FiguresDocumento2 pagineAs On 31.01.2014 Target For 31.03.2017: 1. Facts & FiguresHoney TiwariNessuna valutazione finora

- PEC Fund Cook IslandsDocumento3 paginePEC Fund Cook IslandsHoney TiwariNessuna valutazione finora

- Air Cooled Heat Exchanger SUMMARYDocumento1 paginaAir Cooled Heat Exchanger SUMMARYHoney TiwariNessuna valutazione finora

- Design Certification Offshore FRPDocumento10 pagineDesign Certification Offshore FRPHoney TiwariNessuna valutazione finora

- Seal Gas Conditioning Skid To Solar Tie-In DWG No. 3P961-149446 / SHEET 8 OF 20 Rev BDocumento1 paginaSeal Gas Conditioning Skid To Solar Tie-In DWG No. 3P961-149446 / SHEET 8 OF 20 Rev BHoney TiwariNessuna valutazione finora

- Ventilation Calculation For Inverter RoomDocumento1 paginaVentilation Calculation For Inverter RoomHoney TiwariNessuna valutazione finora

- Rules of Thumb PDFDocumento2 pagineRules of Thumb PDFHoney Tiwari100% (1)

- Pump Seal PlanDocumento25 paginePump Seal PlanHoney TiwariNessuna valutazione finora

- Emission Standards Diesel Engin Upto 800 PDFDocumento4 pagineEmission Standards Diesel Engin Upto 800 PDFHoney TiwariNessuna valutazione finora

- Plant NitrogenDocumento4 paginePlant NitrogenyogacruiseNessuna valutazione finora

- CPCB DG Set Noise Emission NormsDocumento6 pagineCPCB DG Set Noise Emission NormsRSNessuna valutazione finora

- CPCB DG Set Noise Emission NormsDocumento6 pagineCPCB DG Set Noise Emission NormsRSNessuna valutazione finora

- Ple-02 VSL Brian LimDocumento22 paginePle-02 VSL Brian LimAsep SummitNessuna valutazione finora

- SPECAA22421Documento4 pagineSPECAA22421SURJIT SINGHNessuna valutazione finora

- Typical Specifications: Model: Description: CertificationsDocumento1 paginaTypical Specifications: Model: Description: CertificationsLeo2pbNessuna valutazione finora

- Consolidation Settlement Examples 3 - Solutions (2) - 2Documento6 pagineConsolidation Settlement Examples 3 - Solutions (2) - 2Sujani MaarasingheNessuna valutazione finora

- Cons Accident Monthly 1218Documento68 pagineCons Accident Monthly 1218rosa gNessuna valutazione finora

- Christopher Lyon ResumeDocumento2 pagineChristopher Lyon Resumeapi-353696827Nessuna valutazione finora

- Lesson 1Documento6 pagineLesson 1Angela M. AdoracionNessuna valutazione finora

- DBB Gate Valve CatalogDocumento11 pagineDBB Gate Valve CatalogVipul PanchalNessuna valutazione finora

- Bowles J. E. - FDN - Analysis & DSNDocumento2 pagineBowles J. E. - FDN - Analysis & DSNharishNessuna valutazione finora

- Water Pipe Sizing Flow L/s Flow m3/s Flow m3/hr Area Velosity M/s Pipe Size (MM)Documento2 pagineWater Pipe Sizing Flow L/s Flow m3/s Flow m3/hr Area Velosity M/s Pipe Size (MM)saroat moongwattanaNessuna valutazione finora

- WMCAUS2017 Book PDFDocumento843 pagineWMCAUS2017 Book PDFEmre ILGINNessuna valutazione finora

- Bronzeystrainer - Kvs 200 TDocumento1 paginaBronzeystrainer - Kvs 200 TTiến Lý NhậtNessuna valutazione finora

- Asco Valves Series T298Documento2 pagineAsco Valves Series T298OceanexNessuna valutazione finora

- Measurement of in Situ Shear Strength of Rock Mass: Rajbal SinghDocumento12 pagineMeasurement of in Situ Shear Strength of Rock Mass: Rajbal SinghManish Kumar SinghNessuna valutazione finora

- Dorma FloorspringDocumento4 pagineDorma FloorspringrezaNessuna valutazione finora

- WO Mechanical Car ParkDocumento27 pagineWO Mechanical Car ParkrohanbagadiyaNessuna valutazione finora

- Lay-Out or Assemble Scaffolds and BracesDocumento37 pagineLay-Out or Assemble Scaffolds and BracesagtwtcNessuna valutazione finora

- CorbelsDocumento5 pagineCorbelsRakesh HarahNessuna valutazione finora