Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Biomass

Caricato da

nasir608100%(1)Il 100% ha trovato utile questo documento (1 voto)

356 visualizzazioni24 paginebiomass

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentobiomass

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

100%(1)Il 100% ha trovato utile questo documento (1 voto)

356 visualizzazioni24 pagineBiomass

Caricato da

nasir608biomass

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 24

1

ecMee 1&c~cLccv ecMee 1&c~cLccv ecMee 1&c~cLccv ecMee 1&c~cLccv

5umer 5umer 5umer 5umer . 0rbude . 0rbude . 0rbude . 0rbude

ABSTRACT

The World is facing grave problems energv crisis, environment pollution. This made peoples to

focus their attentions on the sustainable energv resources. Biomass Technologv is a right option in

this regard, because of its renewable, abundant, environment friendlv nature, etc.

Available Literature shows that there are various biomass conversion technologies available

such as biogas formation, briquetting, pvrolvsis, direct combustion and Gasification. Because of

relative advantages associated with Gasification, the biomass conversion technologies for gasification

such as updraft, downdraft gasifiers are discussed in this seminar. This Gas can be used to generate

electricitv / shaft power, which is shown with the help of case studv. This also indicates that utili:ation

of biomass with diesel saves the considerable amounts of diesel.

INTRODUCTION 1

'The main concern in all scientific work must be the human being himself. This, one should never

forget among all those diagrams and equations.`

- Albert Einstein

The human race has set itselI apart Irom the animal kingdom by its intensive thirst Ior

knowledge, its inventiveness and imagination, and its ability to survive such catastrophic events as

war, oIten accompanied by pestilence and Iamine. Today, we are Iaced with a grave problem, the

energy crisis, which iI unresolved will certainly have dire consequences Ior civilization in the not too

distant Iuture.

Biomass resources have perennially met a very wide spectrum oI human needs- Iood, Iodder,

Ieedstock, Iiber and energy (amongst others). Development during the last couple oI centuries (with

2

the discovery oI coal and the beginning oI industrial revolution) have resulted in increased use oI

synthetic materials and Iossil Iuels (Iollowed by nuclear energy) as substitute Ior bio-resources in

some important areas oI application. Thus, there was diversiIication Irom biomass technology and less

priority was given toward technology development Ior eIIicient and convenient utilization oI bio-

resources. But, the biomass technology is attracting the mankind. The driving Iorce behind such move

covers a wide range oI human concern about energy crisis problems.

LOOK OVER CONVENTIONAL ENERGY:

World Production and Resources

Many estimates have been made regarding the amount oI coal still available in the earth.

Estimates oI the world`s coal resources ranges Irom 6.9 x 10

6

to 11.8 x

10

6

Mt.While proved reserves

have been estimated to range Irom 0.65 x10

6

to1.16 x10

6

Mt.Nearly 70 oI the reserves lies in the

USA, Russia and China. The general agreement is that the peak value is likely to attain somewhere

between AD 2030 and AD 2060 and that 80 oI the amount available would be consumed by AD

2250.

Estimates oI the world`s resources oI oil have ranged Irom 1450 to2685 billions barrels. The

best estimate one can make today is that most oI the resources oI oil are likely to be consumed in

another 20 years.

World`s resources oI Uranium are estimated to lie in the range oI 3.5 Mt to 6.6 Mt.OI

this, 2.315 Mt. is classiIied as reasonably assured reserves. A nuclear power plant uses 0.15 to 0.2 Mt

oI Iuel per year Ior every megawatt oI capacity. Thus, the reserves would be adequate Ior running the

present installed capacity oI 350,000 MW Ior a period oI only about 35 years. It is evident that

diIIicult situation will arise by 200 years Irom now, iI the present technology continues to be used.

The rate oI production oI economic commodity oI which a Iinite quantity exists is governed by

the laws oI supply and demand. As the amount available depletes the commodity becomes costlier, its

production rate goes through maximum and its use gradually declines.

Consequently, it is now increasingly recognized that a sustainable path Ior energy development

is necessary the world over. A gathering eIIect oI this kind can readily be seen that the transition to a

sustainable energy base will have to move on two legs: one by improving the eIIiciency oI energy and

materials use and the other by developing renewable energy resources. An attempt is: The Biomass

Technology.

3

BIOMASS: What Is It? 2

Biomass is natural product oI solar energy and thereIore, a renewable source oI carbon and

hydrogen which are the basic constituents oI energy and chemical products.

Following is an attempt to deIine Biomass:

1) Total amount oI animal and plant liIe.

2) Biomass is an organic matter i.e. photochemical approach to harness solar energy can

be converted into other Iorms oI energy like heat, electricity etc. using available conversion

processes.

3) Biomass energy in the context oI the present day industrialized

World means the use oI natural organic resources to manuIacture Iuel.

|2|

4) Biomass is the organic matter derived Irom plants as a result oI photosynthesis.

Photosynthesis is the process by which solar energy is converted into chemical energy by the

plants with the help oI the pigment called chlorophyll.

6CO

2

6H

2

O Sunlight chlorophyll C

6

H

12

O

6

6O

2

chlorophyll

This process uses carbon dioxide and water in the presence oI sunlight to produce glucose.

The term Biomass includes all plant liIe trees, agriculture plants, bush, grass and algae, and their

residues aIter processing. Biomass may be obtained Irom Iorest, woods, and agricultural lands. It may

be obtained in a planned or unplanned manner. The term is also generally understood to include

animal and human waste.

4

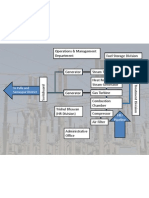

Fig (1): Biomass conversion and its applications.

ADVANTAGES WITH

BIOMASS SYSTEMS 2.1

Stored energy Ior use at will.

Renewable.

Dependent on technology already available, with minimum capital input.

Can be developed with present manpower and material sources.

Reasonably priced.

When we burn the biomass, the oxygen Irom the atmosphere combines with the carbon in

the plants to produce CO

2

and water. This CO

2

and water are again available Ior the plant

growth and hence the cyclic process continues making the biomass, a renewable source oI

energy.

Biomass Energy is unique because

- It is available in majority oI the geographical locations

- It eIIectively stores solar energy and

- It is a renewable source oI energy in the Iorm oI carbon which

can be processed into solid, liquid and gaseous Iuels

The vast majority oI the rural population oI the world is totally dependent on biomass as

Iuel. Some sources oI biomass

- Agricultural Wastes

- Crop Residues

HEAT

FUEL

PREPERATION

GAS

CLEANING

GAS

COOLLING

FURNACE

I.C.

ENGINE

S

GAS

TURBINE

S

BIOMASS

POWER

HEAT

HEAT

POWER

5

- Wood & Woody Wastes

- Organic Wastes etc,

Biomass does not contribute to global warming. Low levels oI sulphur and ash in biomass

prevent acid rain Iormation. Biomass energy brings in numerous beneIits. To name a Iew,

- Reduction in usage oI conventional Iuels.

- Reduction in environment pollution.

- Improving the nations Economy.

- Meets the basic needs oI the rural poor

- Land use competition and land tenure

The environmental beneIits include reduction in air and water pollution reducing CO

2

emission, greenhouse gases like SO

2

.

Availability oI biomass in almost all geographical locations.

Electrical energy can be produced in large scale at low cost.

Low gestation period.

Rural employment generation.

Results in less ash production minimizing ash disposal cost.

APPLICATIONS OF BIOMASS 2.2

Direct thermal application

-Boiler

-Institutional cooking and other thermal applications.

Production oI producer gas used as Iuel in

- IC Engines, vehicles

- Irrigation water pumping / village water supply

Bio Iuels applications

6

- Ethanol Ior transport application

Generation oI electricity

BIOMASS: An Energy Source

From India Point Of view

3]

2.3

India is a large country, with total land area oI 328.8 million hectare (mha). It has an estimated human

population oI about 911 million and a livestock population oI about 450 million, mainly living in

about 587,000 villages. The annual production oI Iood grains is about 130 million tones (mt). Though

there is no authentic data available with regard to the quantity oI agricultural and agro-industrial

residues, it is estimated to be about 320 mt per annum.It is also estimated that the total cattle dung

available is about 240 mt. per year. About twenty percent oI the total land area is under Iorest cover,

which produces about 40 mt oI Iuel wood and 4 mt oI sawdust.

As per the ministry oI Non-conventional energy sources (MNES), several thousand megawatts

oI power can be generated Irom biomass alone. The total amount oI Biomass produced annually is

about 1249 million tonnes.It is estimated that 1000 hectares oI land can generate 3 MW oI power.

Energy plantation should, thereIore, be coupled with power generating units based on gasiIier and

Stirling engines to Iorm integrated energy cum power projects which can provide Iuel wood as well as

power. It is estimated that 2000 MW oI power can be generated only Irom sugar bagasse. Power can

also be made available Irom systems based on agricultural waste yielded by sugar, rice, pulses and

similar crops, through newer techniques at competitive costs.Futhermore, the 93 million hectares oI

woodlands that India has can be eIIiciently put to use Ior raising bioenergy plantation, thereby

generating employment in the process. According to MNES, there is a potential oI 17000MW

equivalent biomass/Bioenergy in the country, out oI which 3500MW is Irom cogeneration. In addition

there is a potential oI 1000MW that can be realized Irom urban and Industrial waste, out oI which only

a very small portion has been tapped so Iar Ior commercial applications.

7

Table 1: Potential/ availability of agricultural and agro-Industrial waste

5]

Types of residue Potential(MW) Availability(MW) Quantity required

to realize the

potential(mt)

Agricultural residues

Agro-industrial residues

Energy plantation

9500

4500

3000

320

50

93(mha)

90

45

1(mha)

Total 17000

Table 2: Break up of different biomass sources

4]

Biomass sources percentage

Wheat straw

Bagasse

Rice husk

Cotton stalks

Ragi and Bajara straw

Coconut and groundnut shell

33.5

32.0

12.0

8.1

77.0

6.7

Biomass contributes about 40 oI the total energy supply in India. In rural India, Biomass

contributes about 84 oI the energy in the domestic sector.

BIOMASS CONVERSION TECHNOLOGY 3

There are varieties oI ways oI obtaining energy Irom biomass. These may be broadly classiIied

into:

1) Direct Methods: The direct way oI utilizing a biomass resource is to burn it, the Iuel most

commonly used being wood.

8

An interesting approach Ior the large scale planned use oI wood is the energy plantation`

approach. In this scheme, selected species oI trees are planted and harvested over regular intervals oI

time in a phased manner so that wood is continuously available Ior cooking or allied purposes. Some

oI the trees grown in India Ior this purpose are eucalyptus, babool and casuarinas.

2) Indirect Methods: These methods are classiIied into:

i) Biological conversion:

- Anaerobic Digestion

ii) Thermo chemical conversion:

- Pyrolysis

- GasiIication

ANAEROBIC DIGESTION 3.1

Anaerobic digestion has been extensively used in our country Ior high moisture organic materials,

particularly dung. Major application has been Ior domestic and institutional cooking through a Iew

installations Ior industrial heat as well as shaIt power/ electricity have also been made. The basic

process is also used Ior treatment oI industrial and municipal wastes and eIIluents with number oI

installations Ior distillery eIIluents and human excreta having been made in various part oI the

country. Being based on bacterial activity, the process has a long cycle time (running into 4 to 6 weeks

at a time) and the long retention time and high moisture / water content also results in relatively large

plant size with associated capital intensity. Total energy available on a daily basis is obviously

restricted to the average gas production level and additional 'on demand generation cannot be

attempted (even iI additional Ieed is available) because oI long retention / cycle times.

PYROLYSIS 3.2

Pyrolysis could be largely used Ior production oI various gaseous, liquid and solid Iuels Irom biomass

with the most common example being conventional charcoal making. Though the conventional

techniques suIIer Irom low energy eIIiciency and high environmental pollution, well designed

charcoal kilns can overcome these drawbacks. Production oI liquid Iuels etc., through pyrolysis has

not been used on any signiIicant scale.

9

GASIFICATION CONVERSION TECHNOLOGY 3.3

Biomass (Iirewood, agricultural residue, and dung) is one oI the main Iuels in India, particularly in the

energy-starved rural sector. Traditionally, biomass use is characterized by the low eIIiciencies oI end-

use devices. Today, gasiIication is probably the most important and eIIicient energy-conversion

technology Ior a wide variety oI biomass Iuels. The large-scale deployment oI eIIicient technology

along with interventions to enhance the sustainable supply oI biomass Iuels can transIorm the energy

supply situation in rural areas. It has the potential to become the growth engine Ior rural development

in the country.

HISTORICAL BACKGROUND 3.3.1:

GasiIication has been an important part oI energy supply earlier; namely at coal gasiIication plants

whereIrom the gas was distributed through gas pipes and used in gas cookers, and the residue product,

coke, was used Ior heating in solid Iuel stoves. During World War II wood by means oI a gasiIier was

used as petrol Ior cars.

Thus, gasiIication is not a new phenomenon, but the technology was Iorgotten Ior many years because

oI cheaper and more handy ways oI getting energy.

The renewed interest in gasiIication oI biomass, Iirst oI all straw and wood/chips, is due to the wish to

utilize the residue products Irom agriculture and Iorestry, and encourage a more environmental

conscious energy use. Here is mainly thought oI the CO

2

impact in the atmosphere.

As part oI the new direction was made a study, at the beginning oI 1992, on how Iar the development

oI gasiIications plants is abroad . A Iew companies in Europe and North America have developed

gasiIiers; but the study shows that it is impossible to buy Iully automatic and reliable gasiIiers

designed Ior cogeneration. Another characteristic oI the examined plants is that none oI them are

capable oI utilizing straw, and there is no technology to utilize the waste heat. Up till now the

technology development abroad has mainly been directed towards third world applications, where

abundant labor is available, and heat production is not that interesting.

DEFINITION 3.3.2:

GasiIication is deIined as biomass or any other solid Iuel combustion through partial oxidation at high

temperature.

10

WHY GASIFICATION? 3.3.3

I) Solid biomass Iuels are usually inconvenient, have low eIIiciency oI utilization and can only be

used Ior certain limited applications. Combustion is the normal conversion process and while direct

thermal use in cooking, heating space and water or cogeneration oI steam is possible (usually with low

eIIiciencies), generation oI power, e.g. Require high, medium pressure steam boilers with steam

engine / turbine with accessories. For small power needs (a Iew kW to Iew 100 kW), this conversion

technology is not only capital intensive and complex but also very ineIIicient.

Conversion oI same biomass to combustible gas mixture like producer gas removes most oI these

problems associated with the solid biomass Iuels.

ii) In 1980`s grate Iired combustion systems were replaced by more eIIicient Iluidized bed. Combustor

Iluidized bed technology has certain shortcomings such as

a) limited Iuel Ilexibility,

b) limited environmental perIormance, with regard to emissions oI sulpher and nitrogen oxides and

particulates.

GasiIication process helps to overcome many oI these limitations.

PRINCIPLE OF GASIFICATION 3.3.4

Biomass Iuels such as Iirewood and agro-residues essentially contain carbon, hydrogen, and oxygen

along with some moisture. Under controlled conditions, characterized by low(sub-stoichiometric)

oxygen supply and high temperatures(700 to1000

0

C), most biomass materials can be converted into a

gaseous Iuel known as producer gas, which consists oI carbon monoxide, hydrogen, carbon dioxide,

methane and nitrogen. This thermo-chemical conversion oI solid biomass into gaseous Iuel is called

biomass gasiIication. The producer gas so produced has low a caloriIic value 4190-5028 KJ/m

3

, but

can be burnt with a high eIIiciency and a good degree oI control without emitting smoke. Each

kilogram oI air-dry biomass (10 moisture content) yields about 2.5 m

3

oI producer gas. In energy

terms, the conversion eIIiciency oI the gasiIication process is in the range oI 60-70.

11

GASIFICATION TECHNOLOGY 3.3.5

The gasiIication process is oIten called thermal gasiIication, because the biomass is heated in a

chamber with controlled air supply. It is important to control the air supply; otherwise, there may

easily appear a complete combustion without gas production. During the heating, that usually is part oI

the process, the volatile gasses, which make up the main part oI energy in straw and wood, are

liberated.

Components Wood Gas( vol. )

Nitrogen 50-54

Carbon monoxide 17-22

Carbon dioxide 9-15

Hydrogen 12-20

Methane 2-3

Gas heating value(KJ/m

3

) 5000-5900

Table 3:

The most interesting part oI the gas according to energy are carbon monoxide, hydrogen, and methane.

It is a very poor gas (the heating value is lower) compared to natural gas.

TYPES OF GASIFIERS 3.3.6

Typically the gasiIier is a vertical cylindrical vessel oI varying cross section. The chemical reactions,

the Iuel has to undergo beIore it is gasiIied, are: drying, pyrolysis, combustion (oxidation), and

reduction

1he Countercurrent ( Up draft )Casifier 3.3..1

Special features:

Solid moves down and gas moves up

Tolerates variation in the Iuel quantity and size

Simple and robust in construction

Practically no ash

12

Low exit gas temperature with heavy tar content. ThereIore, suitable Ior tar Iree Iuels like

charcoal

High thermal eIIiciency and good turn down ratio

Good scale up potential

Figure(2) shows a schematic picture oI a countercurrent gasiIier including the most important reaction

zones, temperature levels, main chemical reactions, and Ilow.

In the combustion (oxidation) zone carbon Irom the Iuel bums and Iorms carbon dioxide with the

oxygen in the air. Heat is emitted during the reaction and the temperature rises until a balance between

heat supply and heat loss occurs.

Reaction: C O

2

-~ CO

2

Q (393,800 kJ/kmol)

AIter the oxidation zone the hot gas passes through the reduction zone. There is no Iree oxygen in this

zone which causes that carbon dioxide - an nonIlammable gas - reacts with the carbon in the Iuel and

Iorms carbon monoxide which is a Ilammable gas. This reaction is endothermic (demands heat) and

does not happen beIore the temperature exceeds 900C. Carbon monoxide is the most important

Ilammable compound in the produced gas.

Reaction:

C CO

2

Q (172,600 KJ / kmol) -~ 2CO

Another important endothermic reaction in the reduction zone is the reaction oI water vapour and

carbon to carbon monoxide and hydrogen. The reaction is oIten called the water gas reaction (known

Irom the old coal gasiIication plants). Both gasses are Ilammable, and the heating value oI the gas is

increased.

Reaction:

C H

2

O Q (13,400 kJ/kmol) ~ CO H

2

During the endothermic reactions the gas temperature decreases and other reactions occur. One oI

these is the reaction between carbon and water vapour, which Iorms carbon dioxide and hydrogen.

13

Reaction:

C 2H

2

O Q (88,000 kJ/kmol) -~ CO: 2H

2

II there is a surplus oI water in the reduction zone, then carbon monoxide may react with water

vapour and Iorm carbon dioxide and hydrogen. This reaction is exothermic (emits heat) and decreases

the heating value oI the produced gas.

Reaction:

CO H

2

O - Q(41,200 kJ/kmol) ~ CO

2

H

2

By gasiIication oI biomass, the water content in the Iuel is usually that big, that some part oI the

evaporated water passes through the gasiIier and Iorms part oI the outgoing gas Ilow.

In the pyrolysis zone a thermal decomposition oI the Iuel takes place at temperatures over 400

0

C.

Water vapour, methane, tar, etc., are Iormed in the pyrolysis zone. AIter the pyrolysis the Iuel has

changed to charcoal.

In the drying zone in the upper part oI the gasiIier water is separated Irom the Iuel as water vapour.

The heating value oI the gas depends to a great extent on, iI the oxygen needed Ior the gasiIication is

supplied by the air. The nitrogen in the air (app. 78) passes through the gas generator and makes up

the dominant compound oI the produced gas. Another important compound is the water vapour that

decreases the heating value oI the gas. II very wet Iuel is gasiIied, there is a risk that the produced gas

is nonIlammable.

The countercurrent gasiIier has several advantages. First oI all it is very simple in its construction and

Iunction. Second it is able to gasiIy a material with relatively high humidity; as the processes in the

reduction zone show, water/humidity exactly take part in the process.

The drawback is that the gas contains a lot oI tar which makes it impossible to use the gas directly in

engines. ThereIore it is necessary to remove the tar - or even better to crack it to Ilammable substances

in order to utilize the energy as good as possible.

14

Fig(2) Up-draft

Fig(3) Down Draft

Distillation zone

Drying zone

Grate

Feed

Gas

Drying zone

Ash zone

Air

Hearth zone

Distillation zone

Hearth zone

Air

Air

Gas

Ash pit

Reduction zone

Reduction zone

Feed

15

Parallel( Down Draft ) gasifier 3.3..2

Special features:

Both solid Ieed and gas move down

Simple in construction

Low moisture and narrow Iuel size is required

Clean gas at high exit temperature is produced

Requires high solid residence time

Ash Iusion and clinker Iormation on grate occurs

Very limited scale up potential

Figure (3) shows a schematic picture oI a parallel gasiIier. It is mainly the same chemical

reactions in this type oI gasiIier as described Ior the countercurrent gasiIier.

Unlike the countercurrent gasiIier the gas outlet is placed at the bottom oI the gasiIier and the

reduction zone is under the combustion (oxidation) zone. These two modiIications cause that tar, etc.,

which is Iormed in the pyrolysis zone, has to pass the hot combustion zone beIore it leaves the

gasiIier. By this passage the tar takes part in the combustion or is decomposed to light hydrocarbons,

and the outgoing gas is under ideal circumstances tar-Iree. In practice the tar content will be

approximately. 0.1-0.2 g/Nm.

A special kind oI parallel gasiIier has been developed at the Technical University oI Denmark. In this,

the pyrolysis is separated as a process by itselI where Ior example co-generators exhaust gasses can be

used as heating source. This way proIit is achieved. But the reason is Iirst oI all that the pyrolysis gas

can be utilized in the Iurther process taking place in the combustion chamber, in the cavity over the

Iuel. In this way, the process is optimized and a total combustion and Iormation oI cinders are avoided.

When using this gasiIication technology, the gas is directly usable Ior running engines aIter soot and

ash particles have been washed out. On the other hand the parallel gasiIier demands that the biomass

do not have too large water content.

16

COMPARISION OF BIOMASS GASIFIER 3.3.7

Down DraIt

Up DraIt

1. Small scale (up to 250KW)

2. Low heating value gas

3. Low tar and particulate content

4. UniIorm and large particles

5. Only woody biomass has been used

successIully

1. Large scale (up to 15 MW)

2. High heating value gas

3. High tar and particulate contents

4. Mixed particulate size

5. Coal, lignite, peat wood , straw has

been used

Conversion oI solid biomass into combustible gas has all the advantages associated with using gaseous

and liquid Iuels such as clean combustion, compact burning equipment, high thermal eIIiciency and a

good degree oI control. In locations, where biomass is already available at reasonable low prices (e.g.

rice mills) or in industries using Iuel wood, gasiIier systems oIIer deIinite economic advantages.

Biomass gasiIication technology is also environment-Iriendly, because oI the Iirewood savings and

reduction in CO

2

emissions. Biomass gasiIication technology has the potential to replace diesel and

other petroleum products in several applications, Ioreign exchange.

A diesel engine will typically will produce up to 3 kW-hr Irom a litre oI diesel. Thus a Iive hp diesel

engine pump set will consume about 1.25 liters oI diesel every hour. When operating in ' duel Fuel

mode with 65 replacement oI diesel by gas, it is likely to consume 0.44 liters oI diesel and 2.4 to3

kg oI woody biomass every hour.

ADVANTAGES OF GASIFICATION 3.3.8

17

A 20 kW power generation system running at about 80 load is likely to consume close to 6 liters oI

diesel every hour and so on. But, when operated under duel Iuel mode with 65 replacement will

consume 2.1 litre oI diesel and 12 to 16 kg oI wood every hour. When a gasiIier is coupled to a diesel

engine, diesel consumption is reduced by the amount deIined as diesel replacement with wood

substituting Ior such diesel reduction. In general, 3 to 4 kg. oI wood result in saving oI one litre oI

diesel.

Some useful numbers with biomass gasification

3 to 4 kg oI biomass saves litre oI diesel

65 to 85 replacement oI diesel in C.I. Engines

100 gas operation with S.I. Engines

5 H.P. pump set operating 1000 hours needs only 3.5 tones oI biomass

1 MW Ior 4000 Hrs. requires 4000 t oI biomass

For irrigation 3-4 oI land Ior tree growing 25 oI residues. Typical plantation yields are 10

to 60 tons per hectares.

APPLICATIONS 3.3.9

Producer gas can be used Ior a variety oI applications:

1. Thermal applications: cooking, water boiling, steam generation, drying etc.

2. Motive power applications: Using producer gas as a Iuel in IC engines Ior applications such as

water pumping.

3. Electricity generation: Using producer gas in dual-Iuel mode in diesel engines/as the only Iuel in

spark ignition engines/in gas turbines.

4. Irrigation pumping

18

CASE STUDY 4

__________________________________________________________________________________

ELECTRICITY/SHAFT POWER APPLICATIONS:

In case oI shaIt power/ electricity, the gas is basically burnt inside an engine. The engine can be

either diesel based or a petrol based .given that the producer gas air mixture does not auto ignite

at normal engine pressure and temperature, running diesel engine solely on gas is not possible and

pilot diesel injection is needed to start combustion. In case oI S.I. engines, spark plug initiates

combustion and hence such engine can be run totally on gas. Wherever diesel engines are used,

'diesel replacement thereIore becomes a key parameter as economics largely depends on what

percent oI total normal diesel consumption can be replaced by gas.

CASE I :

ISLAND VILLAGE ELECTRIFICATION IN SUNDERBANS( WEST BENGAL) USING

~ ANKUR ~ BIOMASS GASIFIER SYSTEMS

West Bengal renewable energy development agencies (WBREDA) have implemented a project Ior

electriIication oI an island village (village Gosaba) in Sunderbans area. The village had no

electricity. In addition to supply, installation and commissioning oI the system which has an

installed capacity oI 500kW (consisting oI Iive modules oI 100kW each), Ankur scientiIic has also

agreed to over see operation and maintenance Ior a period oI two years. The project has

completely taken over by the village co-operative society which was very enthusiastic about the

project and local youth is used to operate the system under Ankur`s supervision.

19

Fig(4) Ankur biomass gasifier (Schematic)

System description

The system has an installed capacity oI 500 kW in stand alone mode through Iive modules oI 100 kW

each. The sets are being synchronized through a semiautomatic synchronizer with the local grid being

planned by WBREDA. A normal Iiltering system is also used and three Ankur`s cutters are used Ior

biomass preparation. The Ankur biomass gasiIier is as shown in Iig.(4).

MGV MAIN GAS VALVE

RUBBER

RING

ENGINE

Diesel

Tank

HOPPER

BIOMASS

AIR

GASIFIER

Cyclone

Ventury

Scrubber

SPRAY

NOZZLE

VIBRATOR

FEED

DOOR

BLO-

WER

TO FLARE

SPARATER

FILTER

PSV

AV

DISTRIBUTION

TANK

AIR FILTER

ALTERNATOR

MGV

GAS LINE

WATER LINE

DIESEL LINE

AV AIR VALVE

PSV PRESET VALVE

ASH POND

20

The biomass is Ied through the Ieed door and is stored in the hopper. Limited and controlled amount

oI air Ior partial combustion enters through nozzles. The ash removed manually through ash Iloor. In

Case oI larger models, automatic ash disengagement through a water seal is built-in. For gasiIier , two

gas outlets are given- one Ior start up and the other normal gas outlets which deliver hot gas to the

cooling-cleaner sub-system. The cooling-cleaner sub-system consists oI scrubber, a separator box

with a Iilter and a drain tub and cyclones. Movement oI biomass Ieed stocks, charcoal and

disengagement oI ash is accomplished through low amplitude vibrations imparted to the gasiIier.An

electrically operated vibrator is used.

Total Installed capacity : 500 kW ( 5 x 100 kW)

GasiIier : Five units oI Ankur GasiIier Model AG-100 with rated biomass

consumption oI 100 kg/hr and suitable to support power generation 100 kW level in duel

Iuel mode.

SpeciIic consumption : Upper limit oI 100 cc/kWh Ior diesel and 1 kg/kWh oI biomass

Fuel cost oI generation : Rs 1.60 per kWh

CONCLUSIONS 5

____________________________________________________________________________

Biomass, a broad term Ior all organic matter oI plants, trees and crops, is currently regarded as a

renewable energy source which can contribute substantially to the world's energy supply in the Iuture.

Various scenarios Ior the development oI energy supply and demand, such as compiled by the World

Energy Council (WEC), the Intergovernmental Panel on Climate Change (IPCC), Shell and the

Stockholm Environmental Institute (SEI), indicate that biomass has the potential to make a large

contribution to the world's energy supply. Estimates oI this potential in the year 2050 vary Irom 14

to 50 oI the total supply, or Irom 100 to about 300 EJ/yr. It is estimated that currently biomass

contributes 10-14 oI the energy supply, which is equivalent to about 40-55 EJ/yr. The use oI

Iirewood in developing countries makes up a large part oI this 40-55 EJ, but there it is Ior a large part

non-commercial and non-sustainable use oI biomass.

II biomass is to make a substantial contribution to the world's energy supply it will have to include not

only biomass residues - such as Irom commercial Iorestry (e.g. thinning) and agriculture (e.g. straw) -

and organic wastes, but also energy crops. Perennial crops seem to be a particularly promising energy

21

source. Crops like Short Rotation Coppice (e.g. Willow and Eucalyptus) and grasses (e.g. Miscanthus)

give a relatively high net energy yield per hectare, have a low environmental impact and produce

relatively cheap energy. The use oI such crops in a Biomass Integrated GasiIier/Combined Cycle

(BIG/CC) plant to produce electricity or combined heat and power, and the gasiIication oI these crops

to produce Iuels like methanol and hydrogen appear to be promising routes Ior achieving high energy

conversion eIIiciency at relatively low cost.

There has been a steady research interest over many years into the use oI alternative biomass Iuels in

I.C. engines, including biogas, wood gas, biodiesel and ethanol. Both practical and theoretical work

has also been done on other engine cycles, such as the Stirling and Atkinson cycles, as alternative

means oI using a range oI Iuels and also improving eIIiciency oI the combustion oI conventional Iuels.

There is strong interest in the increasing opportunity Ior the use oI thermal and biological means to

gasiIy biomass materials, such as wood and municipal solid waste Ior power production. This seminar

had a basic aim oI making aware about presently available conversion technologies, especially

biomass gasiIication. Although we have seen up draIt and down draIt technologies, some other types

may be available in near Iuture. As we have seen the gasiIication system is suitably used to generate

shaIt power / electric power. However, independent use oI gas in engines is not Ieasible, it is necessary

to blend it with diesel as an example.Also the use oI producer gas, iI not handeled properly, may lead

to toxic hazards, Iire hazards, explosion hazards and environmental hazards.

Also, despite the promising outlook, various barriers are hampering the large scale development and

implementation oI commercial biomass energy systems. Currently, the commercial use oI biomass to

generate electricity is limited mainly to the utilization oI zero- or low-cost biomass waste or residues.

At the moment specially cultivated biomass is too expensive an option. However, biomass is able to

compete on a signiIicant scale in countries, like Sweden, Denmark and Brazil, where government

policies support its use Iinancially or have actively discouraged the use oI Iossil Iuels (such as by the

introduction oI a carbon tax). The complexity oI large scale bioenergy systems is also a barrier.

Furthermore, biomass has a relatively low energy density. The production oI biomass is bound up

with seasons and makes high demands on organization and logistics. Furthermore, it involves many

diIIerent Iactors involved in the production and utilization oI energy crops: Iarmers, utilities,

industries, governments, etc. DiIIiculties concerning public acceptability and uncertainties concerning

the ecological eIIects oI the large scale production oI use oI biomass are Iorming another problem.

Last but not least, the availability oI land may be a major problem iI the large scale production oI

energy crops is being considered. II agriculture is not modernized, especially in developing countries,

22

there might be very little room leIt Ior alternative crops. Energy Iarming may then conIlict with Iood

production, a situation which is highly undesirable.

REFERENCES 6

_____________________________________________________________________________

1. Nicholas P. Cheromisinoff, Paul N. Chermishinoff, et. al., application, technologv and

production, Marcel Dekker, Inc., New York and Basel.

2. Edward S. Cassedy, Prospects for sustainable energv a critical assessment, Cambridge

university press-2000

3. M. Kalshrestha, MVS Iyer et. al., energv from biomass. Prospects in India, Biomass energy

system, proceedings oI the international conIerence, 1996,TERI,pg.no.124

4. O.P.Rao, R&D requirements in biomass combustion and gasification , ibid., pg.no.259-269

5. N.P.Singh, Biomass programme in India. An overview, ibid.,pg.no.65-72

6. Sukhatme S.P., Solar energv.Principal of thermal collection and storage, TMH, second edition.

7. B.C.1ain, Biomass gasification technologv and its role in Indian industrv, Renewable Energy

applications to industries, Narosa publishing House, 1997, pg.no.9-17

8. V.N.G. Rao et al, power generation using Biomass combustion/ Gasification,ibid.,pg.no.119-134

9. www.wgbis.ces.iisc.ernet.in/ energy/paper/ Se Handbook

23

APPEADIX

BIOMASS MATERIALS AND THEIR TYPICAL CHARACTERISTICS

Biomass materials and biomass based industry residues are very important renewable energy sources. The importance oI

these materials as alternate Iuels has been well recognized Ior use in power generation. While the characteristics oI

biomass vary Irom diIIerent geographical regions, the values Ior typical biomass materials are indicated Ior general

guidance.

Biomass Grade

Bulk Density

Kgs/M

3

Ash

Content

C

H

N

O

CaloriIic

Value

Kcal/Kg.

Castor stick 5.40 45.97 6.65 1.28 40.70 4300

Castor Seed Shell 8.00 44.25 5.65 0.16 41.94 3860

Corn cobs 11 moisture 304 1.20 41.44 5.96 0.14 51.26

Cotton pods 5.01 41.49 6.20 1.81 45.49 4200

Cotton stalk 3.01 41.49 6.20 1.81 47.49 4200

Saw dust Loose 177 1.20 52.28 5.20 0.47 40.85 4400

Straw Loose 80 15.50 35.97 5.28 0.17 43.08 3700

Straw Bales

320

Wood (hard) --- 330 1.50 52.30 5.20 0.50 42.00 4400

Bagasse 0.12 74 4.00 47.00 6.50 0.0 42.50 4200

Coir pith 0.12 47 13.60 41.27 4.02 1.51 39.60 4100

Cotton shell 0.21 79 4.60 44.19 5.87 0.73 44.61 4200

Coconut Wastes 6.31 46.69 5.89 0.07 41.04 3720

CoIIee Husk 11.61 46.46 6.26 0.72 34.95 3745

Eucalyptus Saw dust 0.12 239 0.21 49.37 6.39 2.02 42.01 4400

Ground nut shell 0.15 165 3.10 33.90 1.97 1.10 59.93 4500

Mulberry stick 2.49 44.23 6.61 0.51 46.25 4380

Rice husk 0.12 235 22.20 36.42 4.91 0.59 35.88 3200

Sun Ilower stalk 0.12 93 4.30 44.20 5.50 0.50 45.50 4300

Sugar cane leaves 0.13 167 7.71 39.75 5.55 0.17 46.82 4200

Saw dust 0.12 165 1.20 52.28 5.20 0.47 40.85 4500

24

Subabul 1.20 42.76 5.68 1.07 49.29 3980

Sweet sorghum stalk 7.40 41.83 5.90 0.53 44.34 4100

Tobacco dust 0.18

586

49.40 19.94 1.63 4.35 24.68 1164

Tea waste 0.17

100

6.70 45.97 5.40 2.76 39.17 4000

Tobacco stem 20.6 28.30 4.50 1.00 45.60 3041

Source: Book titled "BIOMASS, Thermo-chemical characterisation" Published by IIT, New Delhi

Potrebbero piacerti anche

- Analytical Methods for Biomass Characterization and ConversionDa EverandAnalytical Methods for Biomass Characterization and ConversionNessuna valutazione finora

- A Thermodynamic Analysis of Solid Waste Gasification in The Plasma Gasification Melting ProcessDocumento9 pagineA Thermodynamic Analysis of Solid Waste Gasification in The Plasma Gasification Melting ProcessArik AprilliyantoNessuna valutazione finora

- Recent Advances in Thermochemical Conversion of BiomassDa EverandRecent Advances in Thermochemical Conversion of BiomassNessuna valutazione finora

- Biomass - Power PlantDocumento16 pagineBiomass - Power PlantVinay MishraNessuna valutazione finora

- Micro Fuel Cells: Principles and ApplicationsDa EverandMicro Fuel Cells: Principles and ApplicationsTim ZhaoNessuna valutazione finora

- Fuel BatteryDocumento17 pagineFuel BatteryHarsha Vardhan SakalaNessuna valutazione finora

- Biomass Gasification For Hydrogen ProductionDocumento9 pagineBiomass Gasification For Hydrogen ProductionCris CrisNessuna valutazione finora

- Green ChemistryDocumento35 pagineGreen Chemistryalia nasirNessuna valutazione finora

- Green FuelsDocumento19 pagineGreen FuelsMayura Gk100% (1)

- Investigation of Technical and Economic Aspects For Methanol Production Through CO2 Hydrogenation PDFDocumento13 pagineInvestigation of Technical and Economic Aspects For Methanol Production Through CO2 Hydrogenation PDFCarlosNessuna valutazione finora

- Hydrogen Fuel Cell Tech ExplainedDocumento61 pagineHydrogen Fuel Cell Tech ExplainedSyed Ñąveed HąįdeŕNessuna valutazione finora

- Wind Turbine Blade Recycling Experiences, Challenges and Possibilities in A Circular EconomyDocumento12 pagineWind Turbine Blade Recycling Experiences, Challenges and Possibilities in A Circular EconomySunil Ranjan Mohapatra100% (1)

- Biofuels-The Next Great Source of Energy?Documento4 pagineBiofuels-The Next Great Source of Energy?Rizwan NadeemNessuna valutazione finora

- Gasification of Municipal Solid Waste in The Plasma Gasification Melting ProcessDocumento23 pagineGasification of Municipal Solid Waste in The Plasma Gasification Melting ProcessArjuncv100% (3)

- InTech-Algal Biorefinery For Biodiesel ProductionDocumento34 pagineInTech-Algal Biorefinery For Biodiesel Productionchelsea_fc43100% (1)

- Hidrogeno Revision PDFDocumento6 pagineHidrogeno Revision PDFtunja1Nessuna valutazione finora

- Green ChemistryDocumento3 pagineGreen Chemistrymanbirsshowdown48Nessuna valutazione finora

- Seminar Report On Hydrogen As The Future FuelDocumento63 pagineSeminar Report On Hydrogen As The Future FuelMOHIT MGMNessuna valutazione finora

- Review On Available Technologies For Hydrogen ProductionDocumento9 pagineReview On Available Technologies For Hydrogen ProductionAnura BandaraNessuna valutazione finora

- CO2 Methanation for Renewable Energy Storage in Gas GridsDocumento6 pagineCO2 Methanation for Renewable Energy Storage in Gas GridszirimiaNessuna valutazione finora

- Waste To EnergyDocumento37 pagineWaste To EnergyCheng PasionNessuna valutazione finora

- 3 - Catalysts and CatalysisDocumento25 pagine3 - Catalysts and Catalysisshan0214Nessuna valutazione finora

- Non-Thermal Plasma Pyrolysis of Organic WasteDocumento14 pagineNon-Thermal Plasma Pyrolysis of Organic WasteMai OsamaNessuna valutazione finora

- Hydrogen ProductionDocumento31 pagineHydrogen ProductionSajid Ali100% (1)

- Utilization of Keratin-Containing Biowaste To Produce BiohydrogenDocumento7 pagineUtilization of Keratin-Containing Biowaste To Produce BiohydrogenAnjali BoseNessuna valutazione finora

- Conversion of Plastic Wastes in To FuelsDocumento6 pagineConversion of Plastic Wastes in To FuelsannuunakiNessuna valutazione finora

- Biomass Pyrolysis: Salman ZafarDocumento5 pagineBiomass Pyrolysis: Salman ZafarSalman Zafar100% (2)

- Masters Thesis-MethanolDocumento115 pagineMasters Thesis-MethanolUmesh DeshNessuna valutazione finora

- Hydrogen Production Via Cpv/soec Electrolysis Integrated As Stage I Reactor in The Haber-Bosch Ammonia SynthesisDocumento7 pagineHydrogen Production Via Cpv/soec Electrolysis Integrated As Stage I Reactor in The Haber-Bosch Ammonia SynthesisKabolobari BenakoleNessuna valutazione finora

- E Book HydrogenDocumento133 pagineE Book Hydrogenbao_ngoc_trinhNessuna valutazione finora

- Optimization of Conversion of Waste Cooking Oil Into BiodieselDocumento80 pagineOptimization of Conversion of Waste Cooking Oil Into Biodieselcxmzsw100% (5)

- Pyrolysis OilDocumento36 paginePyrolysis OilPrabhakara Rao Thanikonda100% (1)

- Fuel Cells NPTEL Full Course PDFDocumento184 pagineFuel Cells NPTEL Full Course PDFRiki MandolNessuna valutazione finora

- Hydrolysis of Lignocellulosic Materials For Ethanol ProductionDocumento56 pagineHydrolysis of Lignocellulosic Materials For Ethanol Productionajali1957Nessuna valutazione finora

- Converting Waste Plastics Into Liquid Fuel by Pyrolysis Developments in China - Yuan XingzhongDocumento27 pagineConverting Waste Plastics Into Liquid Fuel by Pyrolysis Developments in China - Yuan Xingzhongvuongcoi102Nessuna valutazione finora

- Fuel ConsumptionDocumento11 pagineFuel ConsumptionMerick Diamante Jr.Nessuna valutazione finora

- Steam Reforming of Biodiesel By-Product GlycerolDocumento81 pagineSteam Reforming of Biodiesel By-Product GlycerolAquared LexusNessuna valutazione finora

- Episode 3: Production of Synthesis Gas by Steam Methane ReformingDocumento31 pagineEpisode 3: Production of Synthesis Gas by Steam Methane ReformingSAJJAD KHUDHUR ABBASNessuna valutazione finora

- FLASH PYROLYSIS FOR BIO-OIL PRODUCTIONDocumento19 pagineFLASH PYROLYSIS FOR BIO-OIL PRODUCTIONerkiruthiraj100% (1)

- Hydrogen The Fuel For 21st Century PDFDocumento12 pagineHydrogen The Fuel For 21st Century PDFAlex CoțNessuna valutazione finora

- Plasma GasificationDocumento6 paginePlasma GasificationIntan Permata LaksmiNessuna valutazione finora

- Optimised switched reluctance motors for hybrid electric vehiclesDocumento6 pagineOptimised switched reluctance motors for hybrid electric vehiclesgeerhardusvosNessuna valutazione finora

- Chapter No. 1: Catalytic Steam Gasification of MSWDocumento79 pagineChapter No. 1: Catalytic Steam Gasification of MSWMUh Ammar100% (1)

- Industrial Production of ALCOHOLDocumento5 pagineIndustrial Production of ALCOHOLaarashya KashyapNessuna valutazione finora

- Biomass Conversion PDFDocumento8 pagineBiomass Conversion PDFVivek Rajkumar GNessuna valutazione finora

- Hydrogenics Selected References: Fueling StationsDocumento20 pagineHydrogenics Selected References: Fueling StationsSaradhi Medapureddy100% (1)

- Biomass Gasification SearchDocumento680 pagineBiomass Gasification SearchgengadharanNessuna valutazione finora

- Bio-Diesel Paper PresentationDocumento13 pagineBio-Diesel Paper PresentationJigar Mevada50% (2)

- BIOFUELSDocumento9 pagineBIOFUELSGeorgette RepunteNessuna valutazione finora

- Manufacturing Methods: 1. Methanol Carbonylation 2. Acetaldehyde Oxidation 3. Ethylene Oxidation 4. Anerobic FermentationDocumento39 pagineManufacturing Methods: 1. Methanol Carbonylation 2. Acetaldehyde Oxidation 3. Ethylene Oxidation 4. Anerobic Fermentationkumari svgNessuna valutazione finora

- Power Plants Lab: Assignment 2Documento7 paginePower Plants Lab: Assignment 2Faseeh GhaziNessuna valutazione finora

- Perovskite Solar Cell PDFDocumento7 paginePerovskite Solar Cell PDFHuzaif RahimNessuna valutazione finora

- Interface Design and Software Development For PEM Fuel Cell Modeling Based On Matlab/Simulink EnvironmentDocumento5 pagineInterface Design and Software Development For PEM Fuel Cell Modeling Based On Matlab/Simulink EnvironmentAuraNessuna valutazione finora

- h2 From BiomassDocumento11 pagineh2 From BiomassrajaWoodNessuna valutazione finora

- Tribhuvan University Institute of Engineering Thapathali Campus Presentation On Hydrogen Energy Prepared byDocumento18 pagineTribhuvan University Institute of Engineering Thapathali Campus Presentation On Hydrogen Energy Prepared byRashmi DhunganaNessuna valutazione finora

- Pyrolysis 2014017017 ChelseaDocumento24 paginePyrolysis 2014017017 ChelseaerkiruthirajNessuna valutazione finora

- Kinetics of Propylene Glycol HydrochlorinationDocumento4 pagineKinetics of Propylene Glycol HydrochlorinationWidya Isti AriantiNessuna valutazione finora

- Plasma Technology For Solid Waste ManagementDocumento12 paginePlasma Technology For Solid Waste Managementup4allNessuna valutazione finora

- Corrosion Metallic Bipolar Plates PEM Fuel CellsDocumento17 pagineCorrosion Metallic Bipolar Plates PEM Fuel CellsDeni ShidqiNessuna valutazione finora

- Optimization of Synthesis Gas (Autothermal) Reactor in Methanol Production Process Using Natural Gas As Feed StockDocumento18 pagineOptimization of Synthesis Gas (Autothermal) Reactor in Methanol Production Process Using Natural Gas As Feed StockainmnrhNessuna valutazione finora

- FGHBNVBVDFN FKBNSSD K LFBKNSFBJ GKBJSNFB SFKNB SKFBNKDocumento1 paginaFGHBNVBVDFN FKBNSSD K LFBKNSFBJ GKBJSNFB SFKNB SKFBNKnasir608Nessuna valutazione finora

- VNVDF XVVNBGNB NFBVJBNBGV D NDFJ NFDKFV VDSJDVNDocumento1 paginaVNVDF XVVNBGNB NFBVJBNBGV D NDFJ NFDKFV VDSJDVNnasir608Nessuna valutazione finora

- BKPL OBC Form PDFDocumento1 paginaBKPL OBC Form PDFPriyatham GangapatnamNessuna valutazione finora

- BiomassDocumento24 pagineBiomassnasir608100% (1)

- Detection of Copy-Move Forgery in Digital ImagesDocumento10 pagineDetection of Copy-Move Forgery in Digital ImagesJunel HerreraNessuna valutazione finora

- Vocational Training Report On NTPC FaridabadDocumento46 pagineVocational Training Report On NTPC Faridabadnasir608Nessuna valutazione finora

- Mechanical Placement QuestionsDocumento2 pagineMechanical Placement QuestionsHarshit AgarwalNessuna valutazione finora

- Mechanical Interview Questions and Answers - Fluid MechanicsDocumento2 pagineMechanical Interview Questions and Answers - Fluid MechanicsannukiitNessuna valutazione finora

- Insights Into Biomass Gasification TechnologyDocumento6 pagineInsights Into Biomass Gasification Technologytamizhan1987Nessuna valutazione finora

- Vocational Training Report On NTPC FaridabadDocumento46 pagineVocational Training Report On NTPC Faridabadnasir608Nessuna valutazione finora

- (WWW - Entrance-Exam - Net) - TCS Placement Sample Paper 6Documento11 pagine(WWW - Entrance-Exam - Net) - TCS Placement Sample Paper 6nasir608Nessuna valutazione finora

- Summer Training at NTPC Faridabad Power PlantDocumento3 pagineSummer Training at NTPC Faridabad Power Plantnasir608Nessuna valutazione finora

- (WWW - Entrance-Exam - Net) - TCS Placement Sample Paper 3Documento6 pagine(WWW - Entrance-Exam - Net) - TCS Placement Sample Paper 3nasir608Nessuna valutazione finora

- TCS Placement Sample Paper 5Documento9 pagineTCS Placement Sample Paper 5sanjeevka08Nessuna valutazione finora

- TCS 2004 exam questions for Anna UniversityDocumento12 pagineTCS 2004 exam questions for Anna Universitysaranya_gupta_2Nessuna valutazione finora

- TCS Placement Paper 1Documento15 pagineTCS Placement Paper 1anoos04Nessuna valutazione finora

- Vedanta - A Journey With A Vision: MissionDocumento3 pagineVedanta - A Journey With A Vision: Missionnasir608Nessuna valutazione finora

- Https Campus - TcsDocumento5 pagineHttps Campus - Tcsnasir608Nessuna valutazione finora

- Touchless TechnologyDocumento9 pagineTouchless TechnologyKrishna KarkiNessuna valutazione finora

- Layout NTPCDocumento1 paginaLayout NTPCnasir608Nessuna valutazione finora

- Biomass Gasification Country Reports Oct 2004Documento178 pagineBiomass Gasification Country Reports Oct 2004Yiannis AntonopoulosNessuna valutazione finora

- L&T Annual Report 2012-13Documento316 pagineL&T Annual Report 2012-13Niyati VaidyaNessuna valutazione finora

- LUT Thesis Examines MBM Energy UseDocumento80 pagineLUT Thesis Examines MBM Energy UseUgiNessuna valutazione finora

- Thermal Conversion Technologies For Solid WastesDocumento19 pagineThermal Conversion Technologies For Solid Wastesraowaleedahmad100% (1)

- D20b - European Workshop Sept 2009Documento229 pagineD20b - European Workshop Sept 2009arsalanrabbanianNessuna valutazione finora

- Automotive TransmissionDocumento6 pagineAutomotive TransmissionAditya ShuklaNessuna valutazione finora

- Gerbilnow: PH: (02) 6242 0124 Email: Web SiteDocumento4 pagineGerbilnow: PH: (02) 6242 0124 Email: Web SiteColin DunstanNessuna valutazione finora

- Production of AmmoniaDocumento29 pagineProduction of AmmoniaBhavna Bajpai83% (6)

- The Foster Wheeler Gasification Technology For Biofuels: Refuse-Derived Fuel (RDF) Power GenerationDocumento17 pagineThe Foster Wheeler Gasification Technology For Biofuels: Refuse-Derived Fuel (RDF) Power Generationib4uNessuna valutazione finora

- KTH Doctoral Student in Bioenergy and Negative Emission TechnologiesDocumento4 pagineKTH Doctoral Student in Bioenergy and Negative Emission TechnologiesLeynard NatividadNessuna valutazione finora

- A Review of Hydrogen Production Using Coal Biomass and Other Solid FuelsDocumento22 pagineA Review of Hydrogen Production Using Coal Biomass and Other Solid FuelsBamrung SungnoenNessuna valutazione finora

- Technology Converting Waste Agriculture To EnergyDocumento229 pagineTechnology Converting Waste Agriculture To EnergyAdhi ErlanggaNessuna valutazione finora

- 3rd I-CIPEC Babcock & Wilcox VolundDocumento5 pagine3rd I-CIPEC Babcock & Wilcox VolundMatias MancillaNessuna valutazione finora

- Combustion and Incineration Processes PDFDocumento708 pagineCombustion and Incineration Processes PDFLarry StanfordNessuna valutazione finora

- Bevae 181 AssignmentDocumento16 pagineBevae 181 AssignmentRajni KumariNessuna valutazione finora

- DX189647 PDFDocumento257 pagineDX189647 PDFNguyenHuanNessuna valutazione finora

- Thermochemical Ethanol Via Direct Gasification and Mixed Alcohol Synthesis of Lignocellulosic BiomassDocumento144 pagineThermochemical Ethanol Via Direct Gasification and Mixed Alcohol Synthesis of Lignocellulosic BiomassCristina Garcia RamosNessuna valutazione finora

- Products Brochure PDFDocumento2 pagineProducts Brochure PDFGuna RajNessuna valutazione finora

- Gwf-Int 01 2011 ArtikelDocumento12 pagineGwf-Int 01 2011 ArtikelPetra Margot PedrazaNessuna valutazione finora

- Operating Plasma Gasification PlantsDocumento7 pagineOperating Plasma Gasification PlantsRaviNessuna valutazione finora

- Comparison of Technologies To Serve Waste To Energy ConversionDocumento5 pagineComparison of Technologies To Serve Waste To Energy ConversionABDUL RAFEYNessuna valutazione finora

- Fischer Tropsch ProcessDocumento19 pagineFischer Tropsch ProcessKeenan Agape100% (1)

- Biomass Gas Fire StoveDocumento89 pagineBiomass Gas Fire StoveTamru gebregeorgisNessuna valutazione finora

- Assessing The Feasibility of Using The Heat Demand-Outdoor Temperature Function For A Long-Term District Heat Demand ForecastDocumento5 pagineAssessing The Feasibility of Using The Heat Demand-Outdoor Temperature Function For A Long-Term District Heat Demand ForecastmohammedelamenNessuna valutazione finora

- Assignment Waste ManagementDocumento5 pagineAssignment Waste ManagementMuhammadHafizul Zaki BinYusofNessuna valutazione finora

- Cinetica PaperDocumento15 pagineCinetica PaperCarlos Alberto Ubillas AlcaldeNessuna valutazione finora

- FanusDocumento19 pagineFanusfanusNessuna valutazione finora

- Teri Retreat PDFDocumento8 pagineTeri Retreat PDFArchitecture M05100% (1)

- Biomass Gasification Process for Hydrogen SynthesisDocumento51 pagineBiomass Gasification Process for Hydrogen Synthesisnisa methildaarNessuna valutazione finora

- Sustainable Solutions For The 21 CenturyDocumento86 pagineSustainable Solutions For The 21 Centuryandik_yNessuna valutazione finora

- Why We Die: The New Science of Aging and the Quest for ImmortalityDa EverandWhy We Die: The New Science of Aging and the Quest for ImmortalityValutazione: 3.5 su 5 stelle3.5/5 (2)

- When the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisDa EverandWhen the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisValutazione: 3.5 su 5 stelle3.5/5 (2)

- The Molecule of More: How a Single Chemical in Your Brain Drives Love, Sex, and Creativity--and Will Determine the Fate of the Human RaceDa EverandThe Molecule of More: How a Single Chemical in Your Brain Drives Love, Sex, and Creativity--and Will Determine the Fate of the Human RaceValutazione: 4.5 su 5 stelle4.5/5 (515)

- A Brief History of Intelligence: Evolution, AI, and the Five Breakthroughs That Made Our BrainsDa EverandA Brief History of Intelligence: Evolution, AI, and the Five Breakthroughs That Made Our BrainsValutazione: 4.5 su 5 stelle4.5/5 (4)

- This Is Your Brain On Parasites: How Tiny Creatures Manipulate Our Behavior and Shape SocietyDa EverandThis Is Your Brain On Parasites: How Tiny Creatures Manipulate Our Behavior and Shape SocietyValutazione: 3.5 su 5 stelle3.5/5 (31)

- The Other Side of Normal: How Biology Is Providing the Clues to Unlock the Secrets of Normal and Abnormal BehaviorDa EverandThe Other Side of Normal: How Biology Is Providing the Clues to Unlock the Secrets of Normal and Abnormal BehaviorNessuna valutazione finora

- The Consciousness Instinct: Unraveling the Mystery of How the Brain Makes the MindDa EverandThe Consciousness Instinct: Unraveling the Mystery of How the Brain Makes the MindValutazione: 4.5 su 5 stelle4.5/5 (93)

- Crypt: Life, Death and Disease in the Middle Ages and BeyondDa EverandCrypt: Life, Death and Disease in the Middle Ages and BeyondValutazione: 4 su 5 stelle4/5 (3)

- Masterminds: Genius, DNA, and the Quest to Rewrite LifeDa EverandMasterminds: Genius, DNA, and the Quest to Rewrite LifeNessuna valutazione finora

- The Lives of Bees: The Untold Story of the Honey Bee in the WildDa EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildValutazione: 4.5 su 5 stelle4.5/5 (44)

- 10% Human: How Your Body's Microbes Hold the Key to Health and HappinessDa Everand10% Human: How Your Body's Microbes Hold the Key to Health and HappinessValutazione: 4 su 5 stelle4/5 (33)

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldDa EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldValutazione: 4.5 su 5 stelle4.5/5 (18)

- Why We Sleep: Unlocking the Power of Sleep and DreamsDa EverandWhy We Sleep: Unlocking the Power of Sleep and DreamsValutazione: 4.5 su 5 stelle4.5/5 (2083)

- The Mind & The Brain: Neuroplasticity and the Power of Mental ForceDa EverandThe Mind & The Brain: Neuroplasticity and the Power of Mental ForceNessuna valutazione finora

- All That Remains: A Renowned Forensic Scientist on Death, Mortality, and Solving CrimesDa EverandAll That Remains: A Renowned Forensic Scientist on Death, Mortality, and Solving CrimesValutazione: 4.5 su 5 stelle4.5/5 (396)

- Undeniable: How Biology Confirms Our Intuition That Life Is DesignedDa EverandUndeniable: How Biology Confirms Our Intuition That Life Is DesignedValutazione: 4 su 5 stelle4/5 (11)

- The Dragons of Eden: Speculations on the Evolution of Human IntelligenceDa EverandThe Dragons of Eden: Speculations on the Evolution of Human IntelligenceValutazione: 4 su 5 stelle4/5 (632)

- Superlative: The Biology of ExtremesDa EverandSuperlative: The Biology of ExtremesValutazione: 4.5 su 5 stelle4.5/5 (51)

- Human Errors: A Panorama of Our Glitches, from Pointless Bones to Broken GenesDa EverandHuman Errors: A Panorama of Our Glitches, from Pointless Bones to Broken GenesValutazione: 3.5 su 5 stelle3.5/5 (56)

- Darwin's Dangerous Idea: Evolution and the Meaning of LifeDa EverandDarwin's Dangerous Idea: Evolution and the Meaning of LifeValutazione: 4 su 5 stelle4/5 (523)

- Lymph & Longevity: The Untapped Secret to HealthDa EverandLymph & Longevity: The Untapped Secret to HealthValutazione: 4.5 su 5 stelle4.5/5 (13)

- Inside of a Dog: What Dogs See, Smell, and KnowDa EverandInside of a Dog: What Dogs See, Smell, and KnowValutazione: 4 su 5 stelle4/5 (390)

- Fearfully and Wonderfully: The Marvel of Bearing God's ImageDa EverandFearfully and Wonderfully: The Marvel of Bearing God's ImageValutazione: 5 su 5 stelle5/5 (40)

- Mitochondria and the Future of Medicine: The Key to Understanding Disease, Chronic Illness, Aging, and Life ItselfDa EverandMitochondria and the Future of Medicine: The Key to Understanding Disease, Chronic Illness, Aging, and Life ItselfValutazione: 4.5 su 5 stelle4.5/5 (98)

- Gathering Moss: A Natural and Cultural History of MossesDa EverandGathering Moss: A Natural and Cultural History of MossesValutazione: 4.5 su 5 stelle4.5/5 (347)

- The Dog Who Couldn't Stop Loving: How Dogs Have Captured Our Hearts for Thousands of YearsDa EverandThe Dog Who Couldn't Stop Loving: How Dogs Have Captured Our Hearts for Thousands of YearsNessuna valutazione finora

- Younger for Life: Feel Great and Look Your Best with the New Science of AutojuvenationDa EverandYounger for Life: Feel Great and Look Your Best with the New Science of AutojuvenationValutazione: 4 su 5 stelle4/5 (1)