Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

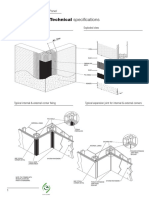

Hipertec Wall Details

Caricato da

amadeus_x64Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Hipertec Wall Details

Caricato da

amadeus_x64Copyright:

Formati disponibili

WALL F I R E R E S I S TA N C E

Hipertec Wall

Profiled wall system, insulated with fire resistant rockwool insulation

IN: I PO TALY RTU GA L

Resistance to fire

The fire-resistance of a product is measured by means of a furnace brought up to a temperature of more than 1000C in accordance with a given standardised curve. The test measures the products capacity to conserve through time certain significant parameters, such as: MECHANICAL STRENGHT (R) IMPERMEABILITY TO GAS (E) THERMAL INSULATION (I) The HIPERTEC WALL panel was tested at the Instituto Giordano S.p.A. on an unloaded structure in compliance with circular no. 91 of 14/9/61 and the following results were obtained: HIPERTEC WALL thickness 100 REI 120 certificate n 108394 / 1664 RF HIPERTEC WALL thickness 80 REI 60 certificate n 108395 / 1665 RF HIPERTEC WALL thickness 50 REI 30 certificate n 108396 / 1666 RF Test have been also made at foreign institutes with the following results: HIPERTEC WALL thickness 120 F-120 Germany, certificate M.P.A. 3713/4891 HIPERTEC WALL thickness 100 F-90 Germany, certificate M.P.A. 3713/4891 HIPERTEC WALL thickness 100 F-90 Austria, certificate IBS 3811/98 HIPERTEC WALL thickness 100 120 Holland, certificate T.N.O. 2000-CVB-R01872 HIPERTEC WALL thickness 80 30 France, certificate C.S.T.B. RS 99 - 069 HIPERTEC WALL thickness 80 F-60 Germany, certificate M.P.A. 3713/4891 HIPERTEC WALL panels have been tested at the RINA Institute for conformity with EN 1364-1, obtaining the following results: HIPERTEC WALLthickenss 150 EI 120 n 11314/05 RINA MAJOR PRODUCT TECHNICAL APPROVALS Agrment Tecnico ICITE 518 / 98 Zulassung DIBT Z - 10.4 - 237

PROD

UCED

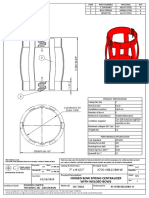

Self-supporting metal panel system insulated with rockwool for wall and partition applications, which require a high degree of fire resistance and acoustic insulation. The HIPERTEC WALL panel, manufactured in accordance with a system patented by Metecno, consists of two micro-ribbed steel sheets, with an insulation core of orientated fibre high density rockwool, arranged perpendicularly to the plane of the panel and positioned in strips, laid longitudinally with off-set joints and transversely compacted, in such a way as to completely fill the space between the metal facings. Maximum panel lenght: 15,500 mm. For additional technical information, before to the HIPERTEC WALL technical manual.

1000 Side 1 62,5

Reaction to fire

Reaction to fire is the degree in which a material resists combustion. With regard to this, materials are assigned a class (0, 1, 2, 3, 4, and 5): the higher the class, the higher the degree of combustion. HIPERTEC WALL panels, thicknesses 50 - 80 -100 mm, tested: At the Istituto Giordano S.p.A., pursuant to the Ministerial Decree of 50 26/6/84, were classified 0/1 for reaction to fire in the wall position. 45 At the MPA Dresden according to EN 13823 and EN 11925-2 40 for reaction to fire, have been classified, according to 35 EN 13501-1 as A2 S1 D0 .Since the panel consists of two steel sheets 30 25 with a layer of rockwool inbetween, the class 0 refers to the external 20 parameter and the class 1 to the insulation. Tests have been also made 15 at foreign Institutes with the following results: 10 Germany: Panel class B1, insulation class A1 - France: class M0. 5

Sound Insulation Capacity "R" [dB]

HIPERTEC WALL

62,5 Side 2 1017 62,5 62,5

Thickness 100 mm Thickness 80 mm Thickness 50 mm 400 500 630 800 1000 1250 1600 2000 2500 3150

Sound insulation

0 100 125 160 200 250 315

The sound insulation of a material (for example, a panel) is given by the ability to reduce the passage of sound energy between two places. The HIPERTEC WALL panel has been tested to UNI 140/3/78 and ISO 717/82 standards and, for the thicknesses 50 - 80 - 100 mm, obtained valuation indices of Rw = 30-30.5 dB.

Frequencies [Hz]

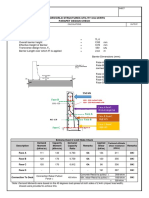

Table of safe spans

Values guaranteed with 0.6 + 0.6 mm thick steel sheets. l spans (in meters) relevant to a uniformly distributed overload p (daN/m2) were taken from structural tests that were carried out at ITC laboratories for 50, 80, 100, and 120 mm thick panels, and at our laboratories for 150 mm thick panels. Spans were calculated in such a way as to guarantee simultaneously: max. deflection: f = l/200; working stress: 1/25 of the limit moment and 1/2.5 of the limit shear.

IMPORTANT: In the assembly stage, attention to the correct positioning of the painted side: the side marked with INTERNAL must face the internalside.

S

mm

K

Kcal m2h C 0,65 0,42 0,34 0,29 0,23 Watt m2 C 0,75 0,49 0,40 0,34 0,27

Panel weight kg/m2

0,6 + 0,6

Color group of external metal sheet I I I I I

l

p = (daN/m )

2

l

60 3,75 5,33 5,33 5,33 5,33 80 2,84 4,50 5,33 5,33 5,33 100 2,31 3,65 4,55 5,33 5,33

l

120 1,94 3,08 3,82 4,58 4,66 150 1,57 2,48 3,09 3,71 3,77 40 4,75 6,17 6,92 7,60 8,44 60 3,97 5,05 5,65 6,17 6,89 80 3,33 4,38 4,89 5,34 5,97

l

100 2,67 3,91 4,38 4,80 5,34 120 2,24 3,54 3,99 4,38 4,87 150 1,81 2,88 3,56 3,92 4,34

40 5,33 5,33 5,33 5,33 5,33

50 80 100 120 150

16,05 19,05 21,05 23,05 26,05

l= l= l= l= l=

70

The values in red have been limited for manufacturing reasons.

71

Potrebbero piacerti anche

- Heraklith C ENG 2012 11Documento2 pagineHeraklith C ENG 2012 11Calin AncutaNessuna valutazione finora

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Da EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Nessuna valutazione finora

- POLYFOAMDATASHEETDocumento8 paginePOLYFOAMDATASHEETvinodNessuna valutazione finora

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesDa EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesValutazione: 3.5 su 5 stelle3.5/5 (3)

- KS1000 RW Roof Panel Product DataDocumento4 pagineKS1000 RW Roof Panel Product DataIvanSmithNessuna valutazione finora

- Kooltherm K5 External Wall BoardDocumento6 pagineKooltherm K5 External Wall BoardShaneNessuna valutazione finora

- Construction Recommendations: Construction Examples For Roof, Wall, Floor and CeilingDocumento60 pagineConstruction Recommendations: Construction Examples For Roof, Wall, Floor and Ceilingapi-233915538Nessuna valutazione finora

- Armaflex Insulation + Fire Rated DuctworkDocumento7 pagineArmaflex Insulation + Fire Rated DuctworkGiải Pháp Cơ ĐiệnNessuna valutazione finora

- KS1200 AB Product Data NordicDocumento4 pagineKS1200 AB Product Data NordicDirt FilterNessuna valutazione finora

- PAL Polyurethane Panel Spec 31102008Documento4 paginePAL Polyurethane Panel Spec 31102008Mohd Fahmie Bin MustapaNessuna valutazione finora

- Geolan CatalogueDocumento20 pagineGeolan CataloguelajharkaNessuna valutazione finora

- Heraklith-C ENG 2012-11 PDFDocumento2 pagineHeraklith-C ENG 2012-11 PDFCalin AncutaNessuna valutazione finora

- Metecnopanel Information Guide NZDocumento8 pagineMetecnopanel Information Guide NZbassouadNessuna valutazione finora

- Atlas Nailable Insulation GuideDocumento31 pagineAtlas Nailable Insulation Guidenumber_25100% (1)

- U-Boot Silence Mantle For Sound InsulationDocumento8 pagineU-Boot Silence Mantle For Sound InsulationDaliform GroupNessuna valutazione finora

- ITCC in Riyadh Residential Complex J10-13300 09510-1 Acoustical TilesDocumento5 pagineITCC in Riyadh Residential Complex J10-13300 09510-1 Acoustical TilesuddinnadeemNessuna valutazione finora

- External Thermal Insulation Composite Systems EticsDocumento34 pagineExternal Thermal Insulation Composite Systems EticsAlket DhamiNessuna valutazione finora

- Euro Therma TR27 2ppDocumento2 pagineEuro Therma TR27 2ppbakkakraljNessuna valutazione finora

- Cellecta Sound Proofing Solutions GuideDocumento24 pagineCellecta Sound Proofing Solutions Guidejamiecellecta2012Nessuna valutazione finora

- Insulation Application GuideDocumento33 pagineInsulation Application GuideNath BoyapatiNessuna valutazione finora

- IIG Mineral Wool Spec SheetDocumento2 pagineIIG Mineral Wool Spec SheetNaresh PaneruNessuna valutazione finora

- Ward Product SelectorDocumento32 pagineWard Product SelectorvgchgchgcNessuna valutazione finora

- WB 3 - Fireproofing IntumescentDocumento2 pagineWB 3 - Fireproofing Intumescentwafik.bassily100% (1)

- Polyiso InsulationDocumento2 paginePolyiso Insulationarbor02Nessuna valutazione finora

- Product Data Sheet: Product: Ks1000 SF EcosafeDocumento4 pagineProduct Data Sheet: Product: Ks1000 SF EcosafeSamuel RICEANNessuna valutazione finora

- Isocop Rev 07-11-2012 - ENGLDocumento15 pagineIsocop Rev 07-11-2012 - ENGLAlexandru RucareanuNessuna valutazione finora

- Proflex CatalogueDocumento8 pagineProflex Catalogueapi-291585305Nessuna valutazione finora

- Chapter 3 Datasheets Roof PanelsDocumento16 pagineChapter 3 Datasheets Roof PanelsMladen BilincNessuna valutazione finora

- PDA Compliance ReportDocumento4 paginePDA Compliance ReportScribdTranslationsNessuna valutazione finora

- Hygiene Wall: Workspace CreationDocumento5 pagineHygiene Wall: Workspace CreationDivyang241088Nessuna valutazione finora

- Technopanel en 20141023Documento39 pagineTechnopanel en 20141023GeorgiStoyanovNessuna valutazione finora

- Vanpanel Wall: External and Internal SheetDocumento3 pagineVanpanel Wall: External and Internal SheetMl JainNessuna valutazione finora

- Firestop Polyester: Problem 1Documento2 pagineFirestop Polyester: Problem 1FelalqNessuna valutazione finora

- 7-Tontine Wall Ceiling BlanketDocumento2 pagine7-Tontine Wall Ceiling BlanketAdrian Law PangNessuna valutazione finora

- Separating Function of Light Timber Frame Assemblies Exposed To FireDocumento8 pagineSeparating Function of Light Timber Frame Assemblies Exposed To FirecasanovavnNessuna valutazione finora

- TROSTEN Mechanical Specification - AHUDocumento6 pagineTROSTEN Mechanical Specification - AHUBalaji JenarthananNessuna valutazione finora

- Isopan Man Tecnico GBDocumento76 pagineIsopan Man Tecnico GBSergiu StanciuNessuna valutazione finora

- 1.4 Advanced PFP Seminar 11 2011 PDFDocumento94 pagine1.4 Advanced PFP Seminar 11 2011 PDFfredo405Nessuna valutazione finora

- Fire Barrier & Cavity Systems Stop Fires!: KillerDocumento4 pagineFire Barrier & Cavity Systems Stop Fires!: KillerMedhat ElhagrasiNessuna valutazione finora

- Tehnicki List ROOFROCK-C ENG PDFDocumento2 pagineTehnicki List ROOFROCK-C ENG PDFStudeer BogdanNessuna valutazione finora

- BR SpecificationDocumento6 pagineBR SpecificationqamerilyasNessuna valutazione finora

- Ecozero PDFDocumento12 pagineEcozero PDFvranceanu.ovidiu-1Nessuna valutazione finora

- Climaver Ductwork System BrochureDocumento12 pagineClimaver Ductwork System BrochureFredoMari LCNessuna valutazione finora

- Sectional Pipe InsulationDocumento2 pagineSectional Pipe InsulationjackwpsoNessuna valutazione finora

- Airrock HD EngDocumento2 pagineAirrock HD EnggccontraNessuna valutazione finora

- ITCC in Riyadh Residential Complex J10-13300 07200-1 Building InsulationDocumento5 pagineITCC in Riyadh Residential Complex J10-13300 07200-1 Building InsulationuddinnadeemNessuna valutazione finora

- Kooltherm k8Documento8 pagineKooltherm k8slik0013Nessuna valutazione finora

- Technical Specifications of EXIN Lightweight Building PanelDocumento6 pagineTechnical Specifications of EXIN Lightweight Building Panelandrewb20050% (1)

- Styrofoam (English)Documento21 pagineStyrofoam (English)Krish DoodnauthNessuna valutazione finora

- Spaceloft Technical Guide 1 1-EU LowresDocumento64 pagineSpaceloft Technical Guide 1 1-EU LowresraeggaemanNessuna valutazione finora

- ETICS Details SubmissionDocumento11 pagineETICS Details SubmissionbarunNessuna valutazione finora

- Enquiry - Passive Fire Protection SystemDocumento6 pagineEnquiry - Passive Fire Protection Systemrkpatel40Nessuna valutazione finora

- CSI Rev 2011 Nov-2Documento6 pagineCSI Rev 2011 Nov-2Lloyd R. PonceNessuna valutazione finora

- E85 Catalogue TC 1616Documento285 pagineE85 Catalogue TC 1616atalayyNessuna valutazione finora

- Hilti Firestop Submittal - Balamand UniversityDocumento32 pagineHilti Firestop Submittal - Balamand UniversitybasbousrNessuna valutazione finora

- Jabfloor JabliteDocumento10 pagineJabfloor JabliteAshik ShahNessuna valutazione finora

- Ecobatt GuideDocumento8 pagineEcobatt GuideTheOne YasirNessuna valutazione finora

- Insulation Gide BookDocumento3 pagineInsulation Gide Bookjoshimanan01Nessuna valutazione finora

- GUTEX en BR Construction 2014-09Documento48 pagineGUTEX en BR Construction 2014-09Ioana BarsanNessuna valutazione finora

- The Best - How To Install GitLab On Debian 12 Step-by-StepDocumento21 pagineThe Best - How To Install GitLab On Debian 12 Step-by-Stepamadeus_x64Nessuna valutazione finora

- SelfsignedDocumento3 pagineSelfsignedamadeus_x64Nessuna valutazione finora

- About Javascript EventsDocumento17 pagineAbout Javascript Eventsamadeus_x64Nessuna valutazione finora

- Beginners Guide To PHP in WordpressDocumento57 pagineBeginners Guide To PHP in Wordpressamadeus_x64Nessuna valutazione finora

- Geoserver 2.8.0 User Manual PDFDocumento1.213 pagineGeoserver 2.8.0 User Manual PDFamadeus_x64Nessuna valutazione finora

- Macromedia Fireworks MX Basic Tutorial: Creating A New DocumentDocumento6 pagineMacromedia Fireworks MX Basic Tutorial: Creating A New Documentamadeus_x64Nessuna valutazione finora

- Edge Box User Manual 50Documento272 pagineEdge Box User Manual 50Nisrine HassaniNessuna valutazione finora

- WAP54G-EU-LA-UK V3 User Guide Rev NC WebDocumento75 pagineWAP54G-EU-LA-UK V3 User Guide Rev NC Webjohnalex_prado3Nessuna valutazione finora

- Motorworld Structures Utility Culverts Parapet Design Check: MM MM 1070 TL-5 1330Documento1 paginaMotorworld Structures Utility Culverts Parapet Design Check: MM MM 1070 TL-5 1330Jemicah YumenaNessuna valutazione finora

- ACU DDD - TNT Phase 2 PLDT Cauayan ME Plan 17may2021 - JEHAN - UpdatedDocumento8 pagineACU DDD - TNT Phase 2 PLDT Cauayan ME Plan 17may2021 - JEHAN - UpdatedMark Roger II HuberitNessuna valutazione finora

- Ps 0700 0812obh WDocumento1 paginaPs 0700 0812obh WLoreleiNessuna valutazione finora

- ANSI-AISC 358-20 - C7SA - InglésDocumento7 pagineANSI-AISC 358-20 - C7SA - InglésmanuelNessuna valutazione finora

- LEED ZeroDocumento16 pagineLEED ZeroDaniel Nuñez HernandezNessuna valutazione finora

- Design of Combined FootingDocumento23 pagineDesign of Combined Footingsameed malik100% (1)

- Design For Manufacturability For CNC MachiningDocumento4 pagineDesign For Manufacturability For CNC Machiningviorelu99Nessuna valutazione finora

- Axially Loaded Compression MembersDocumento19 pagineAxially Loaded Compression MembersAnjielo AusaNessuna valutazione finora

- Sekisui GRP Water Tank CatalogueDocumento28 pagineSekisui GRP Water Tank CatalogueFathyNessuna valutazione finora

- Napa Air Compressor ENDocumento26 pagineNapa Air Compressor ENTenny SupNessuna valutazione finora

- APS Hydro Private LimitedDocumento14 pagineAPS Hydro Private LimitedHema LathaNessuna valutazione finora

- Safety Requirements For ScaffoldsDocumento17 pagineSafety Requirements For ScaffoldsRackie Enriquez83% (6)

- Mod MC Premium PM Installation Manual: Automatic Horizontal Sliding Car DoorDocumento60 pagineMod MC Premium PM Installation Manual: Automatic Horizontal Sliding Car DoorCoil98Nessuna valutazione finora

- Is 3495 - 1 2019Documento8 pagineIs 3495 - 1 2019srinivasa annamayyaNessuna valutazione finora

- 03-2 PSME Code On Fire ProtectionDocumento23 pagine03-2 PSME Code On Fire ProtectionDessa GuditoNessuna valutazione finora

- Sub Grade Modulus and Relation To Bearing Capacity of SoilDocumento3 pagineSub Grade Modulus and Relation To Bearing Capacity of SoilPrantik Adhar SamantaNessuna valutazione finora

- Hydromechanical Work Tools CPH v1.1 03.13.14Documento53 pagineHydromechanical Work Tools CPH v1.1 03.13.14Joshwa SimamoraNessuna valutazione finora

- Basf Masterroc Sa 190 TdsDocumento3 pagineBasf Masterroc Sa 190 TdsHalit Baris SertbakanNessuna valutazione finora

- Cooling Fan Belt TensionerDocumento13 pagineCooling Fan Belt Tensionerakuncbm.hillconNessuna valutazione finora

- 1.Chiều dài ống gió mềm-SMACNA 1995Documento4 pagine1.Chiều dài ống gió mềm-SMACNA 1995Long MaiNessuna valutazione finora

- Symphony 303: Project SpecificationDocumento588 pagineSymphony 303: Project SpecificationJen MasNessuna valutazione finora

- Vidyasagar Setu Kolkata: Under The Guidance of Prof. Dibya Jivan PatiDocumento7 pagineVidyasagar Setu Kolkata: Under The Guidance of Prof. Dibya Jivan PatisonakshiNessuna valutazione finora

- Dubai Municipality Exam - G+1Documento32 pagineDubai Municipality Exam - G+1rabia bano60% (5)

- Why Don't We Deduct The Steel Volume While Calculating The Concrete Volume in RCC StructuresDocumento5 pagineWhy Don't We Deduct The Steel Volume While Calculating The Concrete Volume in RCC StructuressitaracommercialcomplexNessuna valutazione finora

- 13012022031306157Documento4 pagine13012022031306157Shah FaisalNessuna valutazione finora

- RX Screw CataloguesDocumento2 pagineRX Screw CataloguesPuppala Laxmana PrasadNessuna valutazione finora

- Cyclic Behaviour of A Full Scale RC Structural WallDocumento11 pagineCyclic Behaviour of A Full Scale RC Structural WallAzhar PLNessuna valutazione finora

- NTN Bearings CatalogueDocumento412 pagineNTN Bearings Cataloguemfulgosi1231Nessuna valutazione finora

- Purlin DESIGN Car ParkDocumento8 paginePurlin DESIGN Car ParkNasrul Torres0% (1)

- Refresher - Ground Engineering MethodsDocumento2 pagineRefresher - Ground Engineering MethodsHazel Joy SorianoNessuna valutazione finora