Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

TECHNICAL REQUIREMENTS FOR DHCS OPERATION

Caricato da

ameeri143Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

TECHNICAL REQUIREMENTS FOR DHCS OPERATION

Caricato da

ameeri143Copyright:

Formati disponibili

GENERAL This document contains the basic technical information for Architectural, Civil & Structural and M&E

Building Services as required by supplier to achieve optimum DHCS operation. The time frame required for the completion of the DHCS customer station works is six(6) months prior to the official date of turn on of the chilled/hot water supply.

1.0 1.1 1.1.1

CONDITIONS FOR CHILLED WATER SUPPLY (PRIMARY SIDE BY DHCS SUPPLIER) CHILLED WATER TEMPERATURE AND PRESSURE Chilled Water Supply Temperature The averaging temperature of supply chilled water measured at the sensing point on the supply side of the measuring unit shall be as followings: Standard Temp Chilled Water 7.0 C Allowable Range 7.0 1C

1.1.2

Chilled Water Return Temperature The averaging temperature of return chilled water measured at the sensing point on the return side of the measuring unit shall be as followings: Standard Temp Chilled Water 14.0 C Allowable Range 14.0 1 C

1.1.3

Chilled Water Pressure Generally, the pressure in the distribution pipe will be varied from 5.0 kg/cmG to 10.0 kg/cmG (Plants setting value) depending on distance run and geographical position of underground pipes.

1.2 1.2.1

CONTROL Cooling Demand Load Management In order to maintain stable chilled water supply to all customers, when the DHCS sense a customer demand load exceeding the declared demand beyond a preset limit, the chilled water flow may be restricted by operating a control valve. This is to minimize overused of chilled water load beyond the declared load.

1.2.2

Return Chilled Water Temperature Control The return chilled water will be restricted by operating a control valve so that the temperature of the water can be maintained at 13C and above, measured at the sensing point on the return side of the measuring unit.

2.0

DESIGN CRITERIA FOR CUSTOMERS AIR-CONDITIONING SYSTEM (SECONDARY SIDE BY CUSTOMER) TEMPERATURE AND PRESSURE Supply Chilled Water Temperature Secondary supply chilled water temperature after heat exchangers shall be maintained by CUSTOMER at 8.01C.

2.1 2.1.1

2.1.2

Return Chilled Water Temperature Secondary return chilled water temperature shall be maintained by CUSTOMER to 151C.

2.1.3

Pressure of Chilled Water Secondary distribution chilled water system by CUSTOMER connected to DHCS after heat exchanger shall not exceed 10 kg/cmG.

2.2

AHU/FCU AND CONTROLS SETTINGS Supply chilled water temperature : 8.01C Return : 151C Chilled water control : 2-way valve control 2-way valve shall be closed during shut-down of AHU/FCU operation

To prevent the in rush of chilled water from the heat exchangers when all AHUs / FCUs are turn on simultaneously, it is necessary to implement daily timed sequential start-up operation strategy for all AHUs / FCUs. This would reduce the chance of chilled water consumption exceeding the declared peak cooling demand. 3.0 3.1 3.1.1 CONDITIONS FOR HOT WATER SUPPLY (PRIMARY SIDE BY DHCS SUPPLIER) HOT WATER TEMPERATURE AND PRESSURE Hot Water Supply Temperature The averaging temperature of hot water supply measured at the sensing point on the supply side of the measuring unit shall be as followings: Supply Temperature Hot Water 80 C Tolerance 1C

3.1.2

Hot Water Return Temperature The averaging temperature of hot water return measured at the sensing point on the return side of the measuring unit shall be as followings: Return Temperature Hot Water 60 C Tolerance 1 C

3.1.3

Hot Water Pressure Generally, the operating pressure in the distribution pipe will be varied from 5.0 kg/cmG to 10.0 kg/cmG (Plants setting value) depending on distance run and geographical position of

underground pipes. 3.2 3.2.1 CONTROL Hot Water Demand Load Management In order to maintain stable hot water supply to all customers, when the DHCS sense a customer demand load exceeding the declared demand beyond a preset limit, the hot water flow may be restricted by operating a control valve. This is to minimize overused of hot water load beyond the declared load. 3.2.2 Return Hot Water Temperature Control The return hot water will be restricted by operating a control valve so that the temperature of the water can be maintained at 50C and below, measured at the sensing point on the return side of the measuring unit. 4.0 DESIGN CRITERIA FOR CUSTOMERS SPACE HEATING SYSTEM (SECONDARY SIDE BY CUSTOMER) TEMPERATURE AND PRESSURE Hot Water Supply Temperature Secondary hot water supply temperature after heat exchangers shall be maintained by CUSTOMER at 60.01C. 4.1.2 Hot Water Return Temperature Secondary hot water return temperature shall be maintained by CUSTOMER at 501C. 4.1.3 Pressure of Hot Water Secondary distribution hot water system by CUSTOMER connected to DHCS after heat exchanger shall not exceed 10 kg/cmG. 4.2 RADIATOR/ DUCT COIL CONTROLS SETTINGS * * * * Supply Hot water temperature : 60.01C Return : 50.01C Hot water control : 2-way valve control 2-way valve shall be closed during shut-down of Radiator/Duct coil operation

4.1 4.1.1

To prevent the in rush of hot water from the heat exchangers when all Radiator/Duct Coils are turn on simultaneously, it is necessary to implement daily timed sequential start-up operation strategy for all Radiators / Duct Coils. This would reduce the chance of hot water consumption exceeding the declared peak heating demand load.

5.0

CHILLED/HOT WATER PUMP In order to maintain return chilled/hot water temperature within the tolerance, variable water flow control with constant water temperature shall be provided. A variable speed pump system is required to achieve this operation. The variable speed pump system shall be calibrated to deliver optimum flow to prevent energy wastage. CUSTOMER is required to size up the variable speed pump(s) to take care of the minimum cooling/heating load requirement during off-peak hours (which should be made known to the DHCS supplier during the design stage).

6.0

DHCS CUSTOMER STATION LAYOUT Room space requirement to be advised by DHCS.

7.0

SCOPE OF WORKS BETWEEN DHCS SUPPLIER (DHCS) AND CUSTOMER

The Developer shall officially hand-over the DHCS customer station to the DHCS SUPPLIER six (6) months prior to the official date of turn on of the chilled/hot water. The DHCS customer station shall fulfill the requirements under the scope of works by Developer as specified below, prior to the official hand-over to the DHCS SUPPLIER.

Item 1 2 3 4 5 6 DHCS customer station structure and finish work Chilled/Hot water pipe-work up to the DHCS customer station Ditto support work Ditto penetration galvanized steel pipe sleeves & sleeve external water tight work Secondary pipework & support DHCS Instruments panels, remote transmission cabinets & power distribution cabinets Concrete plinth work Carry-in & installation Terminals installation for instruments Branch off valve Measuring meters Thermal insulation/painting equipment work for

Constructed By Developer DHCS DHCS Developer Developer DHCS

Paid by Developer DHCS DHCS Developer Developer DHCS

Remarks Refer to Note 1 Refer to Fig. 1 & Fig. 2

Refer to Fig. 3

7 8 9 10 11 12 13

Developer DHCS DHCS DHCS DHCS DHCS Developer

Developer DHCS DHCS DHCS DHCS DHCS Developer

Refer to Note 1

Electric power supply equipment for DHCS customer station and lighting fixture (eg. Distribution board, control panels, isolator & etc.)

Refer to Note 4

Item 14 2 nos of metal clad switch socket with RCCB Emergency Power Requirement Black Out Signal and power recovery signal DHCS customer pressure test DHCS customer flushing/cleaning up station equipment pipe

Constructed By Developer

Paid by Developer

Remarks Refer to Fig. 4

15 16 17 18 19 20 21 22 23

Developer Developer DHCS DHCS Developer Developer Developer Developer Developer

Developer Developer DHCS DHCS Developer Developer Developer Developer Developer

Refer to Note 5 Refer to Note 6

station

Primary side only Refer to Note 2 Refer to Note 3

Ventilation in the DHCS customer station Facilities for water supply/drainage in the DHCS customer station Fire alarm/fire fighting system of DHCS customer station room Two direct telephone line for DHCS metering terminated inside room DHCS Equipment Lifting Hooks, Anchor Bolted Hooks. Each hook shall be designed to carry 1 no. of heat exchanger loading Temporary lifting in opening to facilitate movement of heat exchangers into customer station

24

Developer

Developer

Opening size to be advised by DHCS. Patching of opening by the Developer Refer to Note 7

25

A normally closed by-pass pipe connecting the secondary chilled/hot water supply and return piping. This pipe shall be installed in secondary pump room for secondary side water flushing purpose. Secondary pumps on/off signal On/off motorized valves at secondary chilled/hot water circuit & interfacing cables if common header pipe is installed inside secondary pump room. Chilled/Hot Water Quality treatment at secondary side & Water

Developer

Developer

26 27

Developer Developer

Developer Developer

Refer to Note 8 Refer to Note 9

28

Developer

Developer

Refer to Note 10

Note 1:

Requirements on architectural works

Internal finish schedule in the DHCS customer station Standard finish schedule is shown below. Reasonable finish schedule used by Developer for other machine rooms (such as secondary pump station) can be considered. Floor Baseboard Wall Ceiling Door size : : : : : Mortar smooth finish with dust proof epoxy paints Ditto Mortar smooth finish with resin paint Insulation coating required if condensation occurred 1,500mm (W) double leaf door x 2,500mm (H) with key lock

If there is a room underneath the DHCS customer station, floor water proofing shall be required. Concrete plinth (with rein-bar) for equipment Dust proof epoxy paint required for concrete plinth. Details to be provided by DHCS Coordination will be required during detailed design and construction stage.

Note 2:

Requirements for DHCS customer station ventilation Ventilation rate: 8 air change per hour Fresh air shall be supplied directly from outdoor through fresh air duct to the DHCS customer station (by Developer) Fresh air duct shall be installed up to inside of the wall opening (by Developer) For exhaust from DHCS customer station to the outdoor, exhaust fan, ductwork and wall openings shall be provided by Developer. No ductwork shall be run within room, wall grilles shall be provided to terminate on room wall. Air grilles shall be sized to not exceeding 3 m/s air velocity. Coordination will be necessary during detailed design and construction stage.

Note 3:

Requirements on water supply and drainage in the DHCS customer station The DHCS customer station shall be provided with adequate drainage facilities to convey water out of the room. If a sump pit is provided, it shall be furnished with submersible sump pump for quick draining of water. The sump pit shall be covered with galvanized steel grating. Sump pump operation shall be controlled automatically by float switches and manual activation. The alarm signal shall be monitored by the Building Automation System. Floor mounted mop sink (minimum size 500 mm x 600 mm x 300 mm high) of either stainless steel or tiled concrete with diameter 15mm hose tap and bib shall be provided. Sink drain 50 mm diameter shall be fitted with stainless steel mesh strainer and drain stopper completes with stainless steel chain. A water meter shall be provided to monitor consumption of water. Drain hoppers or micro-sumps with grating cover shall be provided for heat exchangers

draining. Coordination shall be required during detailed design and construction stage. Water proofing of floor slab, insulation of drainage pipe will be required if there is any basement floor below the DHCS customer station. Note 4: Requirements on electricity & Lighting Electricity shall be supplied to DHCS customer station with distribution / isolating switchboard by Developer. A electricity sub meter shall be provided by developer to monitor electricity consumption. Specifications: 3 phase 4 wire 50A. Refer to Fig. 4 for a typical wiring diagram. Room shall be illuminated to at least 500 lux level. Internal lighting fixtures, receptacles, ventilation fans and sump pumps shall be provided by Developer. Coordination will be required during detailed design and construction stage. Note 5: Requirements on emergency electricity supply Emergency power supply of minimum 1000VA shall be provided by the Developer. This emergency electricity supply shall kick in upon power failure to sustain the operation of the controls and instrumentation in the DHCS customer station. The emergency power supply shall supply to a distribution board, control panel or isolator. Please refer to Fig. 4 for a typical wiring diagram. Note 6: Black-Out Signal and power recovery signal The Developer shall provide a black-out and power recovery signal(s) to notify DHCS in the event of power failure and power recovery. Please refer to Fig. 4 for a typical blackout/recovering signal circuit diagram. The Developer shall provide similar or equivalent circuit for monitoring power in the DHCS customer station. Note 7: By-pass Pipes for Flushing Developer shall install by-pass pipes at their secondary side chilled/hot water piping system to prevent contamination of heat exchangers during chemical flushing. The by-pass pipe shall be installed near to the flange installed by DHCS. The water quality shall be within a reasonable quality acceptable by DHCS before water is allowed to enter into the heat exchangers. Side stream water filtration devices are recommended to install by developer.

Note 8:

Secondary Pumps on/off Signal To ensure proper interlocking between the chilled/hot water demand by Developer and the supply by DHCS, Developer shall provide pump (s) operation signal to DHCS, so as to trigger the supply of chilled/hot water at the primary side of the heat exchanger(s). This signal shall tap from a non-voltage dry contact, when pump(s) operates the contact shall be closed. The signal wiring shall be wired and terminated at the DHCS room control panel as provided by DHCS.

Note 9:

On/Off motorized valves Developer shall install on/off motorized valves at secondary side chilled/hot water circuit if common header pipe is provided inside secondary chilled/hot water pump room due to space constraint (or) pumps configuration. This is to ensure chilled/hot water supply temperature at secondary side is maintained within the specification while only one unit of heat exchanger is operating during the low cooling/heating load. Respective On/off motorized valves shall react according to the feedback signal receive from DHCS. The developer shall connect all interfacing cables to the automatic control panel located inside DHCS room.

Note 10: Water Quality Standard In order to prevent corrosion and fouling to the piping and heat exchanger systems, customer must ensure proper flushing, passivation and water treatment to be carried out by water treatment specialist on the secondary chilled/hot water pipe work system to meet the following water quality control parameters, and the water quality test report must be at least 3 days prior to turn on of DHCS chilled/hot water. Developer shall engage competent water treatment specialist to maintain the water quality throughout the live operation of air conditioning & space heating system. Scheduled circulation of chilled/hot water and monitoring of water quality will be required during fit-out (tenant) work before the building is in full operation: Affect to Corrosion =<50 Chilled/Hot =<50 Chilled/Hot =<70 Chilled/Hot =<30 Chilled/Hot <5.0 Chilled/Hot Chilled/Hot Chilled/Hot >5 >500(Hot), >190(Chilled) <20 Scaling

Essential Items PH (25C) Electrical conductivity C Chloride ion (mgCL/l) Sulfuric acid ion (mgSO4/l) Acid consumption PH 4.8 (mgCaCO3/l) Calcium Hardness (mgCaCO3/l) Silica (mgSiO2/l) Fe (mgFe/l) Total Phosphate (PO4) Nitrite Ion (mg/l as NO2) Turbidity (Degree)

Application Chilled/Hot Chilled/Hot Chilled/Hot

Range of Index 7 - 10.0 <2500 <50

Chilled/Hot

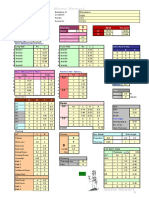

FIGURE 1: Chilled Water System Flow Sheet for DHCS customer station and CUSTOMER Building (Recommended)

DHCS

FIGURE 2: Hot Water System Flow Sheet for DHCS customer station and CUSTOMER Building (Recommended)

Secondary Hot Water Pump (VSD)

: Interface of DHCS and Customer station works

A flange will be provided to Customer by Supplier and flange shall be welded to the secondary pipes at customer side

10

FIGURE 3. STANDARD DETAIL FOR DHCS PIPE PENETRATION

DHCS Room / INTERNAL

DHCS Room / INTERNAL

11

13

FIGURE 4. Sample Electrical Wiring for DHCS customer station

Potrebbero piacerti anche

- Standard Operating Procedure - HVAC - V01 - 29082010Documento10 pagineStandard Operating Procedure - HVAC - V01 - 29082010Karthik MandyaNessuna valutazione finora

- MEP Design Report - Rev-1 - 30thjuneDocumento33 pagineMEP Design Report - Rev-1 - 30thjuneonspsnons71% (7)

- Distric Cooling Connection RegulationDocumento10 pagineDistric Cooling Connection RegulationJobin JosephNessuna valutazione finora

- Advanced Temperature Measurement and Control, Second EditionDa EverandAdvanced Temperature Measurement and Control, Second EditionNessuna valutazione finora

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingDa EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingValutazione: 5 su 5 stelle5/5 (3)

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersDa EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersValutazione: 4 su 5 stelle4/5 (13)

- Water Cooled Chiller - SOPDocumento13 pagineWater Cooled Chiller - SOParunceedee100% (4)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDa EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsValutazione: 3.5 su 5 stelle3.5/5 (3)

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ADa EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANessuna valutazione finora

- Chilled Water Dist I But I OnDocumento44 pagineChilled Water Dist I But I OnVineeth MuraleedharanNessuna valutazione finora

- Water Cooled Water Chillers, Condenserless Water Chillers, Water-to-Water Reverse Cycle Heat Pumps. Models CWP-A, CWP-A/RC & CWP-A/HP 02 To 35Documento28 pagineWater Cooled Water Chillers, Condenserless Water Chillers, Water-to-Water Reverse Cycle Heat Pumps. Models CWP-A, CWP-A/RC & CWP-A/HP 02 To 35jeromeduytscheNessuna valutazione finora

- ETS Connection Requirements-IndirectDocumento8 pagineETS Connection Requirements-IndirectAhm AnNessuna valutazione finora

- DFW Airport Design Criteria Manual HVAC SystemsDocumento16 pagineDFW Airport Design Criteria Manual HVAC SystemsambuenaflorNessuna valutazione finora

- PSU Campus Chilled Water SequenceDocumento8 paginePSU Campus Chilled Water SequenceAshNessuna valutazione finora

- Chilled Water Distribution SystemDocumento5 pagineChilled Water Distribution SystemThiru AnanthNessuna valutazione finora

- Cooling Water System ProceduresDocumento8 pagineCooling Water System ProceduresBoiler Scrubber50% (2)

- 1 C-ME-HM-009R3-Calculation Sheet For Main Transformer and HAVC Equipments Cooling Water System R3Documento17 pagine1 C-ME-HM-009R3-Calculation Sheet For Main Transformer and HAVC Equipments Cooling Water System R3rotimi olalekan fataiNessuna valutazione finora

- WHZ 2005 PDFDocumento8 pagineWHZ 2005 PDFΓεώργιος ΠαπαδόπουλοςNessuna valutazione finora

- VariableDocumento2 pagineVariableThan NaingooNessuna valutazione finora

- DB DCLC-R134a-50HzDocumento36 pagineDB DCLC-R134a-50Hzrahimi mohamad100% (2)

- DPU, Two-Stage Titanium Plate Type Fresh Water GeneratorDocumento4 pagineDPU, Two-Stage Titanium Plate Type Fresh Water GeneratorIvana SeputNessuna valutazione finora

- Refrigeration Laboratory Unit R715: P.A.Hilton LTDDocumento5 pagineRefrigeration Laboratory Unit R715: P.A.Hilton LTDvineet SinghNessuna valutazione finora

- Cooling Tower1Documento66 pagineCooling Tower1Er Bali Pandhare100% (1)

- Multistack ASP X OMDocumento16 pagineMultistack ASP X OMRudy HerreraNessuna valutazione finora

- Reliance Energy Sea Water FGD DesignDocumento17 pagineReliance Energy Sea Water FGD DesignsuparnabhoseNessuna valutazione finora

- Engineering Manual Evaporative CondensersDocumento16 pagineEngineering Manual Evaporative Condenserstulamst100% (2)

- 15545-Chilled Water SystemDocumento5 pagine15545-Chilled Water Systemenlightened1718Nessuna valutazione finora

- 4TH Class Part B Review QuestionsDocumento14 pagine4TH Class Part B Review QuestionsCalvin Jude GoveiaNessuna valutazione finora

- Linea 24 and 28 Installation and Servicing InstructionsDocumento64 pagineLinea 24 and 28 Installation and Servicing InstructionsdragonbeardNessuna valutazione finora

- Report Technical Vol41 - 3Documento8 pagineReport Technical Vol41 - 3rojanmathewNessuna valutazione finora

- A New Era of Free CoolingDocumento7 pagineA New Era of Free CoolingmajortayNessuna valutazione finora

- Kencana Square Water-Cooled Chiller GuideDocumento11 pagineKencana Square Water-Cooled Chiller Guidejames_chan2178Nessuna valutazione finora

- 021-29501-000-REP-001 - Report Pryme Cooling Water System RedesignDocumento8 pagine021-29501-000-REP-001 - Report Pryme Cooling Water System Redesignbarun1977Nessuna valutazione finora

- HP Heater Performance and Spray System PresentationDocumento16 pagineHP Heater Performance and Spray System PresentationDhiraj KumarNessuna valutazione finora

- Converting Primary/Secondary Chilled Water Systems To All Variable FlowDocumento4 pagineConverting Primary/Secondary Chilled Water Systems To All Variable Flowpitong_manningNessuna valutazione finora

- ASHRAE Journal - How To Design & Control Waterside Economizers-TaylorDocumento7 pagineASHRAE Journal - How To Design & Control Waterside Economizers-TaylorsajuhereNessuna valutazione finora

- CTV Eb 84Documento8 pagineCTV Eb 84btgottlieb100% (3)

- Technical Ycre YcseDocumento18 pagineTechnical Ycre Ycsenairam2003Nessuna valutazione finora

- ASHRAE Chilled Water Systems GuideDocumento4 pagineASHRAE Chilled Water Systems Guidecoolth2Nessuna valutazione finora

- Mechanical and Electrical Technical Specification: For TheDocumento117 pagineMechanical and Electrical Technical Specification: For TheKo Pauk100% (1)

- Closed Cooling Water SystemDocumento8 pagineClosed Cooling Water SystemtheoNessuna valutazione finora

- Hydro Test Procedure - REV 02Documento14 pagineHydro Test Procedure - REV 02Amitava Pal100% (1)

- Design GuideDocumento36 pagineDesign GuideDaniel A. NorbergNessuna valutazione finora

- CSRH.c-y Water Cooled Chiller - R134aDocumento12 pagineCSRH.c-y Water Cooled Chiller - R134antt_121987Nessuna valutazione finora

- Module 3 - Chiller SystemDocumento45 pagineModule 3 - Chiller Systemmadan karkiNessuna valutazione finora

- DDC System Commissioning Acceptance Procedure: Example Project/Building DescriptionDocumento21 pagineDDC System Commissioning Acceptance Procedure: Example Project/Building DescriptionAbdul Mohid SheikhNessuna valutazione finora

- Energy Efficiency On Chilled Water SystemDocumento56 pagineEnergy Efficiency On Chilled Water Systembalraj100% (1)

- VALVE SELECTION GUIDEDocumento12 pagineVALVE SELECTION GUIDEAnonymous R23prjoKnoNessuna valutazione finora

- Heating and Cooling Generation and Distribution Systems: Central Vs Decentralized SystemsDocumento15 pagineHeating and Cooling Generation and Distribution Systems: Central Vs Decentralized SystemsRakesh RanjanNessuna valutazione finora

- Chilleri Rhoss Tcee 105 140Documento20 pagineChilleri Rhoss Tcee 105 140Sorin DiaconuNessuna valutazione finora

- Sample Mechanical Basis of Design For UW - Chiller SystemsDocumento4 pagineSample Mechanical Basis of Design For UW - Chiller SystemsdaveleyconsNessuna valutazione finora

- District Heating Substation Guidelines PresentationDocumento38 pagineDistrict Heating Substation Guidelines Presentationjrri16Nessuna valutazione finora

- HVAC Chilled Water Distribution SchemesDocumento56 pagineHVAC Chilled Water Distribution SchemesJenson Joy100% (5)

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsDa EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNessuna valutazione finora

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesDa EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNessuna valutazione finora

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDa EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNessuna valutazione finora

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Da EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Valutazione: 3.5 su 5 stelle3.5/5 (3)

- Report For Design Problems002Documento2 pagineReport For Design Problems002ameeri143Nessuna valutazione finora

- Pre Feb Bluding Iqbal SHB 313-Model - pdf03Documento1 paginaPre Feb Bluding Iqbal SHB 313-Model - pdf03ameeri143Nessuna valutazione finora

- 4 - Wsfu To GPM TableDocumento2 pagine4 - Wsfu To GPM Tableameeri143Nessuna valutazione finora

- EstimateDocumento40 pagineEstimateMuhammad Al-ShaibahNessuna valutazione finora

- Pre Feb Bluding Iqbal SHB 313-Model - pdf02Documento1 paginaPre Feb Bluding Iqbal SHB 313-Model - pdf02ameeri143Nessuna valutazione finora

- 3.0 Prequalification Process For Health Facility Design ConsultantsDocumento6 pagine3.0 Prequalification Process For Health Facility Design Consultantsameeri143Nessuna valutazione finora

- Muhammad Khalil: Cell: +92 334 9771235Documento1 paginaMuhammad Khalil: Cell: +92 334 9771235ameeri143Nessuna valutazione finora

- Service Block Ws 002 Ws 002Documento1 paginaService Block Ws 002 Ws 002ameeri143Nessuna valutazione finora

- Sewerage Pipe & Fittings Measurement SummaryDocumento1.167 pagineSewerage Pipe & Fittings Measurement Summaryameeri143Nessuna valutazione finora

- Room Numbering GuidelineDocumento3 pagineRoom Numbering Guidelineameeri143Nessuna valutazione finora

- Split AC SpecsDocumento1 paginaSplit AC Specsameeri143Nessuna valutazione finora

- Pre Feb Bluding Iqbal SHB 313-Model - pdf01Documento1 paginaPre Feb Bluding Iqbal SHB 313-Model - pdf01ameeri143Nessuna valutazione finora

- Metric to Imperial Conversion Table for Area MeasurementsDocumento1 paginaMetric to Imperial Conversion Table for Area MeasurementsMuhammad SharifNessuna valutazione finora

- Procurement JDDocumento1 paginaProcurement JDameeri143Nessuna valutazione finora

- WISE Reference GuideDocumento20 pagineWISE Reference Guideameeri143Nessuna valutazione finora

- 373 CXDocumento16 pagine373 CXameeri143Nessuna valutazione finora

- Package Hygienic Units ManualDocumento24 paginePackage Hygienic Units Manualameeri143Nessuna valutazione finora

- Hygienic AHU ComponentsDocumento1 paginaHygienic AHU Componentsameeri143Nessuna valutazione finora

- Dse711020 DiagramDocumento3 pagineDse711020 Diagramameeri143Nessuna valutazione finora

- Setup: Deep Sea Electronics Dse855 Usb - Ethernet Converter Installation InstructionsDocumento28 pagineSetup: Deep Sea Electronics Dse855 Usb - Ethernet Converter Installation Instructionsameeri143Nessuna valutazione finora

- Eurovent Certification Part 1 PDFDocumento54 pagineEurovent Certification Part 1 PDFameeri143Nessuna valutazione finora

- RS 6 C 011 2016 - Hygienic - AHUDocumento22 pagineRS 6 C 011 2016 - Hygienic - AHUameeri143Nessuna valutazione finora

- Series18946 Catalogue Page Doc5322 v1 en-EUDocumento1 paginaSeries18946 Catalogue Page Doc5322 v1 en-EUameeri143Nessuna valutazione finora

- Monday: 21 November, 2016: Kan-Therm Press System by Kan-Term GMBH 1Documento10 pagineMonday: 21 November, 2016: Kan-Therm Press System by Kan-Term GMBH 1ameeri143Nessuna valutazione finora

- Manchester CCGs plan for single hospital commissioningDocumento5 pagineManchester CCGs plan for single hospital commissioningameeri143Nessuna valutazione finora

- Mx11922 The Big 5 Dubai Online Practical Guide v10Documento1 paginaMx11922 The Big 5 Dubai Online Practical Guide v10ameeri143Nessuna valutazione finora

- Organization Charts: Buildings & PropertiesDocumento3 pagineOrganization Charts: Buildings & Propertiesameeri143Nessuna valutazione finora

- Watt / SF Area (SF) Total KW Div. Factor Total KW HR DayDocumento2 pagineWatt / SF Area (SF) Total KW Div. Factor Total KW HR Dayameeri143Nessuna valutazione finora

- Guide to designing electrical networks for buildings and small areasDocumento2 pagineGuide to designing electrical networks for buildings and small areasameeri143Nessuna valutazione finora

- Electrical Thumb Rules - Useful Equations and FormulasDocumento15 pagineElectrical Thumb Rules - Useful Equations and Formulasameeri143100% (1)

- Lesson 5: Cultural Relativism: Learning OutcomesDocumento4 pagineLesson 5: Cultural Relativism: Learning OutcomesGanda GandaNessuna valutazione finora

- Meinrad 2018 All Symbols With NumbersDocumento4 pagineMeinrad 2018 All Symbols With NumbersXer N. AcostaNessuna valutazione finora

- Temp Gradient For Warping Stress in Rigid PavementDocumento9 pagineTemp Gradient For Warping Stress in Rigid PavementAmul KotharkarNessuna valutazione finora

- Reynaers Product Overview CURTAIN WALLDocumento80 pagineReynaers Product Overview CURTAIN WALLyantoNessuna valutazione finora

- Installation Procedure for Castwel Supercast-II CastableDocumento3 pagineInstallation Procedure for Castwel Supercast-II CastableRAJKUMARNessuna valutazione finora

- Pengaruh Komunikasi DGN KinerjaDocumento15 paginePengaruh Komunikasi DGN KinerjaTitHa AwallunnisaNessuna valutazione finora

- Suggested For You: 15188 5 Years Ago 20:50Documento1 paginaSuggested For You: 15188 5 Years Ago 20:50DeevenNessuna valutazione finora

- Shell Donax TA Transmission Fluid TDS PDFDocumento1 paginaShell Donax TA Transmission Fluid TDS PDFirwanbahrudin117134Nessuna valutazione finora

- 10 - The Geological Interpretation of Well LogsDocumento292 pagine10 - The Geological Interpretation of Well LogsLorenza LorenzanaNessuna valutazione finora

- Series Portable Oscilloscopes: Keysight DSO1000A/BDocumento15 pagineSeries Portable Oscilloscopes: Keysight DSO1000A/BNestor CardenasNessuna valutazione finora

- "Smart Attendance Using F Ttendance Management Using Face Recognition" Anagement SystemDocumento13 pagine"Smart Attendance Using F Ttendance Management Using Face Recognition" Anagement Systemamer HNessuna valutazione finora

- A Pilot's Guide To ILS PRM ApproachesDocumento4 pagineA Pilot's Guide To ILS PRM ApproachesgregmNessuna valutazione finora

- Prologue - Life InsuranceDocumento4 paginePrologue - Life InsuranceCamila Andrea Sarmiento BetancourtNessuna valutazione finora

- Chapter 6 (Latest) - Value Orientation and Academic AchievementDocumento21 pagineChapter 6 (Latest) - Value Orientation and Academic AchievementNur Khairunnisa Nezam IINessuna valutazione finora

- Properties of Skeletal MuscleDocumento72 pagineProperties of Skeletal MuscleAakash GohilNessuna valutazione finora

- Non-Permanence Risk Report Template (Short Form) : Instructions For Completing TheDocumento5 pagineNon-Permanence Risk Report Template (Short Form) : Instructions For Completing Theferrian prabowoNessuna valutazione finora

- How many times do clock hands overlap in a dayDocumento6 pagineHow many times do clock hands overlap in a dayabhijit2009Nessuna valutazione finora

- HydrodynamicsDocumento122 pagineHydrodynamicsIustin Cristian100% (2)

- Elon Musk: AI Is A Fundamental Risk To The Existence of Human CivilizationDocumento19 pagineElon Musk: AI Is A Fundamental Risk To The Existence of Human CivilizationBDApp StarNessuna valutazione finora

- MMA Electrode ClassificationDocumento3 pagineMMA Electrode ClassificationRathnakrajaNessuna valutazione finora

- The Housekeeping Department: Learning Activity #1Documento4 pagineThe Housekeeping Department: Learning Activity #1Limar Geoff G. RosalesNessuna valutazione finora

- Six Sigma MotorolaDocumento3 pagineSix Sigma MotorolarafaNessuna valutazione finora

- Ice-Cream ProductionDocumento65 pagineIce-Cream ProductionMujtaba HaseebNessuna valutazione finora

- Technical Specifications For Construction Tower Support 113-Shc-Ta-001 and 113-Sch-Ta-002 at The Coke Handling SystemDocumento12 pagineTechnical Specifications For Construction Tower Support 113-Shc-Ta-001 and 113-Sch-Ta-002 at The Coke Handling SystemAna RojasNessuna valutazione finora

- METRO Otherscape PlaytestDocumento101 pagineMETRO Otherscape PlaytestthomasNessuna valutazione finora

- Beamware 2: Users ManualDocumento14 pagineBeamware 2: Users ManualAdi FaizinNessuna valutazione finora

- HP t410 Smart Zero Client: Zero Management. Zero Configuration. Zero CompromiseDocumento5 pagineHP t410 Smart Zero Client: Zero Management. Zero Configuration. Zero Compromisekonan09Nessuna valutazione finora

- Tos Template Arpan 1Documento25 pagineTos Template Arpan 1florence s. fernandezNessuna valutazione finora

- Chapter 2 - Cross-Cultural Management SkillsDocumento26 pagineChapter 2 - Cross-Cultural Management Skillsfatematuj johoraNessuna valutazione finora

- t640 - Parts CatalogDocumento69 paginet640 - Parts CatalogSattittecInfomáticaNessuna valutazione finora