Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Iwip

Caricato da

kishoreardentDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Iwip

Caricato da

kishoreardentCopyright:

Formati disponibili

INTERNATIONAL WELDING INSPECTION PERSONNEL

The Indian Institute Of Welding has been accredited by IIW as its only Authorised National Body (ANB) in India (To be referred to as ANB-India) to operate its above international scheme and award various International Welding Diplomas including the International Welding Inspector Diplomas to welding personnel at Basic (IWI-B), Standard (IWI-S) and Comprehensive (IWE-C) level respectively of increasing knowledge, skill & responsibility as per guideline IAB-041r3-08 July 2008 for the education of International Welding Inspection Personnel

1. Role of the Welding Inspector

The Inspector's role begins well before welding starts, continues during welding operation, involves action after welding is completed, and is finished only when the results are properly reported. As a part of quality system, inspection activities are defined in an inspection and test plan, which clearly describes what, is required. The inspector is frequently responsible for producing documents that ensure traceability of the components and related fabricating action. Prior to welding, the inspector must be assured that the base materials and consumables are correct and the shop has approved welding procedures and appropriately qualified welders. Written procedures and competent operators are important to the production of a quality welded product, but the actual execution of the weld is also critical point for the inspector. Once the inspector is satisfied that all is in order for welding to proceed, the task becomes one of witnessing and monitoring. There are two basic interests at this point, ensuring that written procedures are followed and of course, watching for any physical sign of non-conformance of the final product. The inspector must verify that the base material and consumables are correct and observe the fitup and preparation for weld. Once the welding is completed a new series of inspection tasks begin according to an approved procedure, keeping track of the status of examination and testing and selecting specific welds for further NDT or ,mechanical testing. Heat treatment (such as preheating, post heating and post weld heat treatment) can be a critical parameter in a welding operation and the inspector is often required to ensure that it has been done properly. Heat treatment must be carried out according to an approved written procedure. The inspector must know enough about the technique, the equipment and the reports to have confidence in the result.

2. Benefit

2.1 Industry: The IWIP qualification system, administered by ANB India will provide a pool of welding inspectors at all levels, trained to international standard for industry. This will also enable industry to fulfil the overall future requirements of ISO 3834 (Quality Requirement for Welding) as well as ISO 14731 (Welding Co-ordination Task and Responsibilities) and NDT inspectors requirement as per ISO-9712 and which will be particularly relevant for export-oriented industries. 2.2 Career for Inspector: Qualified personnel with knowledge of both welding technology and Welding Inspection are not readily available so far in India in the absence of any proper curriculum and recognised certification system satisfying the essence of both Welding Co-ordination under ISO-14371 & NDT under ISO-9712 respectively for following ISO 1763540, ISO-13916 etc. The demand for such qualified persons will be felt increasingly with globalisation and scope to obtain overseas appointment at all levels. The IWIP qualification at various levels more than fulfils the requirements of all above & also SNT-TC-1A & IS:13805 - for welding Inspection personnel.

2. International Welding Inspector (Curriculum)

For the International Welding Inspection course: International Welding Inspector Diplomas are at three levels i.e. Basic (IWI-B), Standard (IWI-S) and Comprehensive (IWE-C) respectively of increasing knowledge, skill & responsibility. The guideline divides the syllabus in two main modules as below with 3 levels of depth. Welding Technology (WT) in three levels of I, II & III Welding Inspection (WI) in three levels of I, II & III

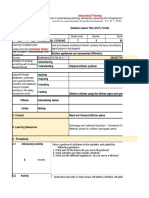

(Figures against the subject heads are minimum lesson hours)

2.1

1 2 3 4

Welding Technology Module

Subject Heading Welding Process & Equipment Materials & their behaviour during Welding Construction & design Fabrication, Application Engineering Total Recommended Hours for Technology Module Subject Heading General Introduction to Welding Inspection Testing Weld Imperfections Testing Method Quality Assurance Management of Inspection Function Practical Work Total Recommended Hours for Inspection Module WT - III 25 52 21 24 122 WI - III 3 1 7 31 3 3 49 97 WT - II 13 41 17 23 94 WI - II 3 1 5 25 3 3 23 63 WT - I 11 25 12 17 65 WI - I 2 1 3 18 1 0 15 40

2.2 Welding Inspection Module

1 2 3 4 5 6 7

Exemptions allowed from attending some modules for 'prior learning' after ATB/ANB Check. 2.3 Theoretical education: Basic Technology "Module 0" (40 hrs) may apply to certain candidates without requisite education & industry metal working background who want to engage in Standard level. The course comprises Introduction, Measurement Units, Technical Calculation, Technical Drawing, Basics of Electro-technology, Basic Chemistry, Basics of Materials, Metal Products, Machining of Materials, Technical Mechanics & Calculation of Strength.

3. International Welding Inspection Personnel (Access/Eligibility)

The entry to the International Welding Inspectors course at various levels could be by Standard Route or by Transition Route. Access condition/Eligibility for entry for each method is specified against each level by ANB with the authorisation of IAB 3.1 Access by Standard Route is as per IAB Guideline IAB-041r3-08 July 2008 3.2 Alternative routes for IWIP-B, IWIP-S & IWIP-C are for qualified experienced persons already engaged in responsible position and having relevant experience having IWP, IWS or IWT Diplomas respectively or qualification satisfying condition for access to same. On production of evidence and ANB Check & professional + technical Interview by ANB may be entered at appropriate level.

4.0 International Welding Inspector's Examination

The intermediate examinations are mandatory unless exempted and is the responsibility of the ATB to ensure that those entering the next stage have acquired required level of knowledge. The final examination to assess student performance, in accordance with the relevant IIW guideline and those rules is conducted by the Board of Examiners appointed by ANB-India. This examination is mandatory and is independent of any assessment procedure conducted by ATB.

Page 2 of 3

5.0 International Welding Inspection Personnel : Diploma

Examination procedures are designed to simulate the different situations of a welding inspector active in industry. The examination will be in three parts, Part 1: Professional interview to test the ability to understand standards, codes and quality documentation. This is conducted individually. Part 2: Theoretical Written Examination covering both Welding technology and Inspection. Part 3: Practical Examination is to test competence in undertaking a range of inspection tasks and will include both oral examination to assess comprehension and written reporting of test result. The appropriate Diploma as Basic (IWI-B), Standard (IWI-S) and Comprehensive (IWE-C) respectively is awarded after successful finish of all the required modules. The Certification does not form part of the Guideline and is normally the subject of an independent Certification Scheme.

6.0 Procedure for Enrolment, Registration & Training

The candidate may go through this website to get details of the course. In case the candidate is interested further, he/she may collect the course details & relevant application available at cost from the IIW-ANB office or from a conveniently located ATB in the process of being appointed.The duly filled in "Application Form" along with all enclosures etc. have to be submitted along with application fees as per chart below to ANB-India or through the Approved Training Body (ATB) for final approval by ANB-India. ANB India controls admission to all IIW courses as per eligibility requirements of the Access Conditions and subsequent registration process, examination, testing and final award of International Welder Diploma and Certification on practical welding skill. After successful theoretical and practical examination, the Authorized National Body awards an 'International Inspector' Diploma to the candidate of the appropriate level.

7.0 Transition Route

Transition Route is open to suitably qualified and experienced candidates only as per "Transition Criteria", during initial window of 3 years.. and are required to apply through an "Application Form for Transition" subject to their passing a professional interview, without having to go through a formal training or examination. This golden opportunity is open to existing professionals for a period of three years up-to December 2012. 8. Fees & Charges Payable by the Candidates to ANB (In Rupees)

Sl. No.

Description Information brochure Course details & Application Form Application Fee Registration Fee (For All Routes) Assessment Professional Interview Fees for Certification Total

IWIP - C Free 250 1,000.00 1,000.00 6,000.00 12,000.00 20,000.00

IWIP - S Free 250 1,000.00 1,000.00 6,000.00 10,000.00 18,000.00

IWIP - B Free 250 1,000.00 1,000.00 6,000.00 7,000.00 15,000.00

1. 2. 3. 4. 5. 6 7

The above Fees are payable by DD to The Indian Institute of Welding-ANB for transition only and subject to revision from time to time. The candidates may contact ANB - India for the list of Approved Training Bodies (ATBs) in the process of being appointed Prospective candidates following Standard route are required to refer to ATB (When available) for details of course fees and other charges payable to ANB. Standard Route through lessons at ATB is yet to start.

Page 3 of 3

Potrebbero piacerti anche

- Pmi-Acp Exam Prep Study Guide: Extra Preparation for Pmi-Acp Certification ExaminationDa EverandPmi-Acp Exam Prep Study Guide: Extra Preparation for Pmi-Acp Certification ExaminationNessuna valutazione finora

- BGAS-CSWIP Welding and Coating Inspection: Certification, Process, Exam Preparation and Q&ADa EverandBGAS-CSWIP Welding and Coating Inspection: Certification, Process, Exam Preparation and Q&ANessuna valutazione finora

- Sub BinderDocumento29 pagineSub BinderSabrina BordenNessuna valutazione finora

- ICE3001A RoutestoMembership WebDocumento20 pagineICE3001A RoutestoMembership Websam_antony2005Nessuna valutazione finora

- Static Equipment InspectorDocumento6 pagineStatic Equipment InspectorNorman MoralesNessuna valutazione finora

- Iiw Welding GuidelinesDocumento95 pagineIiw Welding Guidelinestomychalil100% (2)

- IAB-041-02 (IW Inspection Personnel)Documento43 pagineIAB-041-02 (IW Inspection Personnel)Teddy TP100% (1)

- Proposal For Training On VDA 6.3process AuditDocumento2 pagineProposal For Training On VDA 6.3process AuditAnkurNessuna valutazione finora

- Part A - CWI - Fundamental Orignal 2017Documento588 paginePart A - CWI - Fundamental Orignal 2017Husseinallawi banderNessuna valutazione finora

- CSWIP-WI-6-92 12th Edition May 2012Documento17 pagineCSWIP-WI-6-92 12th Edition May 2012Shaju ShamsudheenNessuna valutazione finora

- ESO 3 Present PerfectDocumento7 pagineESO 3 Present PerfectVane YesteNessuna valutazione finora

- API653 Feb12Documento4 pagineAPI653 Feb12Amair CoolNessuna valutazione finora

- API510 Nov13Documento6 pagineAPI510 Nov13vkumaranNessuna valutazione finora

- Global: Personnel Certification SchemeDocumento36 pagineGlobal: Personnel Certification SchemeJadson FerreiraNessuna valutazione finora

- Audit Risk Alert: Government Auditing Standards and Single Audit Developments: Strengthening Audit Integrity 2018/19Da EverandAudit Risk Alert: Government Auditing Standards and Single Audit Developments: Strengthening Audit Integrity 2018/19Nessuna valutazione finora

- Cswip 692Documento27 pagineCswip 692shrikantajitNessuna valutazione finora

- Prepare Evidence Gathering ToolsDocumento43 paginePrepare Evidence Gathering Toolsjonellambayan100% (1)

- Cswip DocumentDocumento23 pagineCswip DocumentAmit KumarNessuna valutazione finora

- The Indian Institute of WeldingDocumento11 pagineThe Indian Institute of WeldingNnamdi Celestine NnamdiNessuna valutazione finora

- ICE 3001A Routes To MembershipDocumento20 pagineICE 3001A Routes To MembershiprosavascoNessuna valutazione finora

- Cae 10 Writing Tests 2015Documento42 pagineCae 10 Writing Tests 2015franosullivanNessuna valutazione finora

- CSWIP-PW-6-96 7th Edition February 2017 Calificacion PolietilenoDocumento18 pagineCSWIP-PW-6-96 7th Edition February 2017 Calificacion PolietilenoyecerosuNessuna valutazione finora

- IIW Guidance For 3834Documento20 pagineIIW Guidance For 3834Necati Dayı80% (5)

- API653 Training Application 170610 UpdateDocumento4 pagineAPI653 Training Application 170610 UpdateesamhamadNessuna valutazione finora

- ATB BrochureDocumento2 pagineATB BrochureAbu Dzulqornain Tulus100% (1)

- IIW-India ANB Brochure JulyDocumento6 pagineIIW-India ANB Brochure JulyMahesh JetuNessuna valutazione finora

- Brochure IWCP Standard-Alternate April 2013Documento4 pagineBrochure IWCP Standard-Alternate April 2013Sadhasivam VeluNessuna valutazione finora

- Brochure IWCP ALL Routes July - 2011Documento5 pagineBrochure IWCP ALL Routes July - 2011kumarvizayinNessuna valutazione finora

- INFO IWCP Transition Online - 2021 M5Documento2 pagineINFO IWCP Transition Online - 2021 M5tauqeer salimNessuna valutazione finora

- Brochure Iwcp STD, Alt, TR - 27-Jan 2020Documento4 pagineBrochure Iwcp STD, Alt, TR - 27-Jan 2020pratap biswasNessuna valutazione finora

- IIW-India ANB Announces: Welding Coordination PersonnelDocumento2 pagineIIW-India ANB Announces: Welding Coordination PersonnelBalkishan DyavanapellyNessuna valutazione finora

- Corporate Partner No: 203112Documento8 pagineCorporate Partner No: 203112FirozeNessuna valutazione finora

- Cswipws 190Documento17 pagineCswipws 190Vin BdsNessuna valutazione finora

- CSWIP-WI-1-91 9th Edition November 2010Documento8 pagineCSWIP-WI-1-91 9th Edition November 2010Thamaraikani ManiNessuna valutazione finora

- DASH Training ProgramsDocumento16 pagineDASH Training ProgramsdashNessuna valutazione finora

- Cswip 2Documento8 pagineCswip 2heartbreakkid132Nessuna valutazione finora

- CSWIP-WI-6!92!11th Edition September 2011Documento16 pagineCSWIP-WI-6!92!11th Edition September 2011JiminYoo0419Nessuna valutazione finora

- Api InfoDocumento12 pagineApi InfoRamu NallathambiNessuna valutazione finora

- ICE Standards Information BookletDocumento18 pagineICE Standards Information BookletRony Prayitno SimeonNessuna valutazione finora

- Api Info PDFDocumento12 pagineApi Info PDFarvindzdenNessuna valutazione finora

- IWCP Alternative Route How To Apply r10 May 2021Documento4 pagineIWCP Alternative Route How To Apply r10 May 2021tauqeer salimNessuna valutazione finora

- Pakistan 1113 Visual Welding Inspector - January 2016Documento1 paginaPakistan 1113 Visual Welding Inspector - January 2016Adnan RanaNessuna valutazione finora

- CP3 - 1-09 Tube Welding 2nd Edition July 2015 PDFDocumento19 pagineCP3 - 1-09 Tube Welding 2nd Edition July 2015 PDFAdnan RanaNessuna valutazione finora

- Cswipdiv 903Documento16 pagineCswipdiv 903anand060589Nessuna valutazione finora

- CSWIP PW 6 96 Plastics Welder 8th Edition March 2021Documento21 pagineCSWIP PW 6 96 Plastics Welder 8th Edition March 2021Saravana kumar NagarajanNessuna valutazione finora

- Cswip Visual Welding Inspector 3.0 BrochureDocumento1 paginaCswip Visual Welding Inspector 3.0 BrochureNasfauzan100% (2)

- Technician (Techweldi) : CriteriaDocumento1 paginaTechnician (Techweldi) : Criteriapavi32Nessuna valutazione finora

- AWS CWI Training Program BrochureDocumento4 pagineAWS CWI Training Program BrochureDeepakNessuna valutazione finora

- CSWIP-WI-1-91 Part 1 12th Edition March 2016Documento7 pagineCSWIP-WI-1-91 Part 1 12th Edition March 2016هيمنت بيلودياNessuna valutazione finora

- Info Dec 13Documento13 pagineInfo Dec 13Malik Uzair ZafarNessuna valutazione finora

- Qa QC PDFDocumento2 pagineQa QC PDFVijay SekharNessuna valutazione finora

- SS 01 - Dec 2012Documento10 pagineSS 01 - Dec 2012Manish WaghareNessuna valutazione finora

- Cswip Div 9 03 General Inspector 4th Edition Jan 2008Documento12 pagineCswip Div 9 03 General Inspector 4th Edition Jan 2008obinnaNessuna valutazione finora

- TUV Welders Training LetterDocumento2 pagineTUV Welders Training LetterMagudeeswaran ThirumurthyNessuna valutazione finora

- Cswip 3.1 Q1Documento2 pagineCswip 3.1 Q1Mustafa ElfatihNessuna valutazione finora

- CSWIP Plant Inspectors 5th Edition, May 2012Documento13 pagineCSWIP Plant Inspectors 5th Edition, May 2012Er Faiyaz AhmedNessuna valutazione finora

- Visual Welding Inspector - Cswip 3.0: Mermaid Training & Technical Services LTDDocumento1 paginaVisual Welding Inspector - Cswip 3.0: Mermaid Training & Technical Services LTDsheikjasmohammed85Nessuna valutazione finora

- Cswip Div 7 95 Underwater Diver Inspectors Part 1 6th Edition April 2019 1Documento18 pagineCswip Div 7 95 Underwater Diver Inspectors Part 1 6th Edition April 2019 1Satendra kumarNessuna valutazione finora

- DOCUMENT NO. CSWIP-DIV-7-95 - Part 1 Requirements For The Certification of Underwater (Diver) InspectorsDocumento18 pagineDOCUMENT NO. CSWIP-DIV-7-95 - Part 1 Requirements For The Certification of Underwater (Diver) InspectorsOke Adesina GaniyuNessuna valutazione finora

- Abdullah Alshaghab - CV - March 2016Documento3 pagineAbdullah Alshaghab - CV - March 2016Ahmad fayyazNessuna valutazione finora

- CP2 Part 3 Plate Welding Practical 2nd Edition July 2015Documento20 pagineCP2 Part 3 Plate Welding Practical 2nd Edition July 2015sathishvpNessuna valutazione finora

- CSWIP QCC 20 08 Requirements For The Certification of A Welding Quality Control Co Ordinator 3rd Edition January 2021Documento7 pagineCSWIP QCC 20 08 Requirements For The Certification of A Welding Quality Control Co Ordinator 3rd Edition January 2021Ho-Rim JUNessuna valutazione finora

- Navigating Professional Paths: A Guide to CA, MBA, UPSC, SSC, Banking, GATE, Law, and UGCDa EverandNavigating Professional Paths: A Guide to CA, MBA, UPSC, SSC, Banking, GATE, Law, and UGCNessuna valutazione finora

- Music Describes Three Interrelated Uses of The Term "Music Theory"Documento1 paginaMusic Describes Three Interrelated Uses of The Term "Music Theory"R.A. GregorioNessuna valutazione finora

- Syllabus-ME 31100 ECE31200Documento3 pagineSyllabus-ME 31100 ECE31200DavidVizcaínoNessuna valutazione finora

- Course Outline - Introduction To Business Grade 10: Napanee District Secondary SchoolDocumento7 pagineCourse Outline - Introduction To Business Grade 10: Napanee District Secondary SchoolNDSSBIzNessuna valutazione finora

- Lbs 400 Lesson Plan 2Documento2 pagineLbs 400 Lesson Plan 2api-315590585Nessuna valutazione finora

- Europass CV 120131 PedrosaSaladoDocumento2 pagineEuropass CV 120131 PedrosaSaladoantonioescohotadoNessuna valutazione finora

- Seanewdim Ped Psy VII 80 Issue 198Documento70 pagineSeanewdim Ped Psy VII 80 Issue 198seanewdimNessuna valutazione finora

- Teacher Training For Low ProficiencyDocumento4 pagineTeacher Training For Low Proficiencyiin hermiyantoNessuna valutazione finora

- T 134 Syllabusfall 2014 Section 17781Documento9 pagineT 134 Syllabusfall 2014 Section 17781api-251069635Nessuna valutazione finora

- GENL0250Documento3 pagineGENL0250PabloAndrésVilaVomieroNessuna valutazione finora

- Open LearningDocumento19 pagineOpen LearningErika ClaudNessuna valutazione finora

- TylerDocumento11 pagineTylerSharla DimaculanganNessuna valutazione finora

- Form 137 - E: Pagunlad Sa Mababang PaaralanDocumento3 pagineForm 137 - E: Pagunlad Sa Mababang PaaralanHanna VillamorNessuna valutazione finora

- Newsflash MagazineDocumento64 pagineNewsflash MagazineIan LuoNessuna valutazione finora

- Functions of Everyday Situations r1Documento27 pagineFunctions of Everyday Situations r1api-333583911Nessuna valutazione finora

- Nwanosike, Oba F. & Onije, Liverpool Eboh 2011 'Colonialism and Education' Proceedings of The International Conference On Teaching, Learning and Change, IATEL (Pp. 624 - 631)Documento8 pagineNwanosike, Oba F. & Onije, Liverpool Eboh 2011 'Colonialism and Education' Proceedings of The International Conference On Teaching, Learning and Change, IATEL (Pp. 624 - 631)voxpop88Nessuna valutazione finora

- Essential Worksheets 05Documento2 pagineEssential Worksheets 05Daniela MedinaNessuna valutazione finora

- Contest Acrostic Rubric 2014updateDocumento3 pagineContest Acrostic Rubric 2014updateCacai GariandoNessuna valutazione finora

- Key Understan Ding To Be Developed Learning ObjectivesDocumento118 pagineKey Understan Ding To Be Developed Learning ObjectivesJaymar Tuatis100% (1)

- Job Resume in SpanishDocumento7 pagineJob Resume in Spanishcprdxeajd100% (2)

- Manuscript For EditingDocumento14 pagineManuscript For EditingAbdul Aziz MuhammadNessuna valutazione finora

- DLP Interpret Kitchen SymbolsDocumento6 pagineDLP Interpret Kitchen SymbolsWilma S. Bentayao100% (1)

- Training Evaluation Form TemplatesDocumento2 pagineTraining Evaluation Form TemplatesahmadNessuna valutazione finora

- Winsome Hin-Shin LEE CV (Jul 2017)Documento6 pagineWinsome Hin-Shin LEE CV (Jul 2017)Winsome LeeNessuna valutazione finora

- SALA - FLA 1 Understanding The MATATAG Curriculum An InfographicDocumento1 paginaSALA - FLA 1 Understanding The MATATAG Curriculum An InfographicJel VemberNessuna valutazione finora

- Jessica A. Carter: ObjectiveDocumento1 paginaJessica A. Carter: ObjectiveJessica Carter MooreNessuna valutazione finora