Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

PDS 1994

Caricato da

htopaven4340Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

PDS 1994

Caricato da

htopaven4340Copyright:

Formati disponibili

Polymer Degradationand Stability 45 (1994) 71-76

ELSEVIER

~) 1994 ElsevierScience Limited Printed in Northern Ireland. All rights reserved 0141-3910/94/$07.00

The recovery of photodegraded low density polyethylene from green houses and solars (S-LD-PE). III. Rheological properties of the melts of certain blends based on S-LD-PE

D o i n a Staicu & Horia Paven

Institute for Chemical Research, Research Center for Plastics Materials, SPL. lndependentei, NR. 202, 77208, Bucharest 6, Romania

(Received 3 December 1993; revised version received 3 February 1994; accepted 8 February 1994)

In order to reuse photodegraded low density polyethylene from green houses and solars, it has been physically modified with EPDR, bitumen atactic polypropylene. Thermodynamically compatible blends, selected by DSC and dielectric spectroscopy studies, were moulded into hydroinsulating sheets, which exhibit useful properties. The influence of the degree of miscibility of the components at the molecular level on the rheological properties of melts of certain blends based on S-LD-PE is presented.

INTRODUCTION

EXPERIMENTAL

In order to reuse photodegraded low density polyethylene (S-LD-PE) from green houses and solars, it was physically modified with ethylene propylene diene monomer rubber (EPDR), bitumen (B), or atactic polypropylene (APP), after grinding, separation, washing and drying.t-7 Since the useful properties of the polymeric blends depends on the degree of miscibility of the components at the molecular level, attempts must be directed towards obtaining thermodynamically compatible blends. These were selected by DSC 1 and dielectric spectroscopy studies,2 which were assessed on the basis of their transition temperatures. Thus the blends studied, based on S-LD-PE, were analysed through DSC 1 measurements to obtain their melting characteristics and through dielectric spectroscopy their o~-relaxation. Thermodynamically compatible blends were extruded into hydroinsulating sheets which had good utilization properties. 3"7 The influence of the degree of miscibility of the components on the melt flow properties of the blends based on S-LD-PE is presented.

71

Work performed in order t o obtain compatible blends has already been described. 1-7 The influence of the degree of miscibility on the melt flow properties of the blends based on S-LD-PE, was studied by determining the influence of the blend composition on the kinematic viscosity, v, activation energy of viscous flow, E, and the non-Newtonian index values, n, and the comparison of these results with those obtained from the compatibility study presented. 1,2 The rheological properties studied were calculated from melt flow indices8-t using the following formulae:

v = r/= 5 10 5 G p MFI(T, G) E=R T~T2 InMFI(T~' G) T2- T~ MFI(T2, G) (stokes) (1)

(kJ/mol)

(2)

~(/ n = In

MFI(G;, T) In MFI(G/, T)

(3)

72

Doina Staicu, Horia Paven

Table 1. The theological properties of raw and photodegraded low density polyethylene

where n is the non-Newtonean index, v is the kinematic viscosity (stokes),/9 is the melt density (g/cm3), MFI is the melt flow index (g/10 min), Gi,/ are the weights upon the plastomer piston (kg), r/ is the dynamic viscosity (poise), TL2 are the operating plastomer temperatures (K) and E is the activation energy of viscous flow (kJ/mol). The melt flow indices were measured on a ' P O L I R E O ' capillary plastometer at 4 length/ diameter ratio, TI.2=190C and 200C and Gi,/= 2, 5, 10 kg. The results were presented in ternary diagrams, plotting the dependence of rheological properties as a function of the blends composition where P represents the difference between the modified and non-modified polymer properties. The physical and mechanical properties of S-LD-PE show that during its useful life, a degradation process takes place involving chain breaking, cross-linking and oxidation. That is why all the S-LD-PE properties including the rheological properties, differ from those of the primary polyethylene. 3 The change in the rheological properties of S-LD-PE is mainly due to the chain breaking and cross-linking processes (Table 1). Therefore, the MFI values are lower than those of the primary LD-PE. The flow activation energies of the S-LD-PE melt are higher than those of the primary polymer melt. Consequently, the nonNewtonian character of the flow is much more pronounced (the non-Newtonian index, n, of S-LD-PE is much lower).

Binary blends with E P D R

Property (unit) Raw 1. Melt flow index (g/10 min) T = 190Cwith 2.16 kg 5 kg 10 kg 2000C with 2.16 kg 5 kg 10 kg 2. Non-Newtonianindex T = 190Cwith 2.16 kg 5 kg 10 kg 2000C with 2.16 kg 5 kg 3. Kinematicviscosity (104 stokes) T = 190Cwith 2.16 kg 5 kg 10 kg 200C with 2.16 kg 4. The melt flow activation energy (kJ/mol), heating from 190Cto 200C 2.16 kg 5 kg 1.86 8.0 20.85 2.38 0.72 23.36 0-57 0.62 0.62 0.59 0.77

LD-PE Secondary 0.28 1.0 3.75 0.22 1.28

0.66 0.63 0.59 0.47 0.42

58.064 31.25 23.98 47.37

38.57 25.0 13.30 49.09

33.677 34.577

43.884 44.925

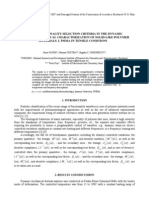

E P D R induces important changes in the rheological properties of the polymer melt as shown in Fig. 1. It is well known that the viscous flow activation energy and the melt viscosity characterize the energy consumption required for melt processing and the non-Newtonian index gives information about the melt stability for various processing conditions (i.e. ~,-shear rate, temperature).S-~ From Fig. l(a) it can be seen that every 5% of E P D R decreases the kinematic viscosity of the S-LD-PE by about 5-10stokes, the melt flow activation energy by about 7 kcal/mol (Fig. l(b)) and the non-Newtonian index by approximately 0-04 units (Fig. l(c)). This kind of change shows that this modifier reduces only the energy consumption required

for melt processing and does not increase the melt flow stability for various processing conditions. As previously demonstrated L2 the blends of S-LD-PE with E P D R are, to a great extent, thermodynamically compatible. However, the miscibility of the two components is not complete because the blend with the highest EPDR concentration (i.e. 15%) retains a small shoulder on its melting endotherm at T = 126C, the temperature of the second melting endotherm of the S-LD-PE. Thus partial miscibility of the E P D R and S-LD-PE macromolecules results in only a partial improvement in the flow properties of the melts of the blends.

Binary blends with A P P

Figure 1 also shows the influence of APP on the rheological properties of the S-LD-PE melt. Addition of 5% of the modifier reduces the kinematic viscosity of the S-LD-PE by about 10K J/tool and the non-Newtonian index by about 0.07 units. The decrease in the activation

The recovery of photodegraded, low density polyethylene

(a)

73

Percentageincrease (b) Percentage increase ([plM / lO0[p] S-LD-PE) ([pIM / lO0[pl S-LD-PE) 10 15 ~ 5 10 15

I I ~'~ 0 I 1 r/-~ _5 I

(c)

Percentage increase ([pIM/ 100[p]S-LD-PE)

5 10 15

r

-5

-10 ~ -15

~ -15 -20 -25 -30 -35 -

ii -20

-25

P -0"15 I

Fig. 1. Change in: (a) kinematic viscosity (stokes); (b) activation energy of viscous flow (kj/mol); (c) non-Newtonian index of S-LD-PE modified with EPDR, APP and bitumen.

energy of viscous flow cannot be considered a real improvement in the melt flow properties. It must be emphasized that this modifier reduces, more than E P D R , the energy consumption required for melt processing and the stability of the melt for various processing conditions. It was previously demonstrated 5 that the S-LD-PE blends with APP are not completely miscible. The melting endotherms of these blends still preserve a small shoulder at 126C, the temperature at which the S-LD-PE has its second melting endothermic maximum. Therefore, the quasi-total miscibility of S-LD-PE with APP, leads only to a decrease in the energy consumption required for melt processing.

Newtonian index (Fig. l(c)) are lower. Thus, bitumen provides a decrease in the energy required for melt processing somewhat similar to that produced by APP but also results in a pronounced reduction in the melt stability for various processing conditions. It was previously demonstrated 1 that the bitumen and S-LD-PE macromolecules are not completely miscible. The DSC thermograms of these blends still preserve two small shoulders on the melting endotherms, at temperatures recorded for the second melting maximum of S-LD-PE. Thus the quasi-total miscibility of the S-LD-PE and bitumen macromolecules results in only a partial improvement in the melt flow properties.

Binary blends with bitumen Ternary S-LD-PE, E P D R , bitumen blends

The influence of bitumen on the rheological properties of S-LD-PE is also shown in Fig. 1. The melts of these blends of S-LD-PE and B show similar rheological behaviour to S-LD-PE blends with APP. The bitumen also induces a decrease in the three rheological studied properties. Compared with the influence of APP, the extent of decrease in the kinematic viscosity is similar (Fig. l(a)) while the viscous flow activation energy (Fig. l(b)) and the non-

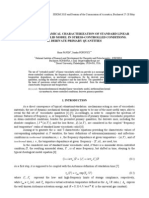

The results of studies of the influence of bitumen on the rheological properties of binary blends of S-LD-PE and E P D R are shown in Fig. 2. The presence of bitumen also decreases the kinematic viscosity and the activation energy of viscous flow of these blends (Figs 2(a) and 2(b)), but it is very interesting that the non-Newtonian index increased (Fig. 2(c)) with higher quantities of modifier. Thus, compared with blends of S-LD-PE and

74

Doina Staicu, Horia Paven

0

++%-+,

o

o= .+

+

<

I

+o

(uv) x~pm tre.mol~0N-UON

t,,-

5 ~ +..+e

~

u,ff

A ["~ ~I

zl

"

I I

~Z l,.t.1 o

++ ,---T

+~~., >

i

I

A~OU m O ~ S ~ JO .~OUO uo.n~^.rlov

,.~,=

.+~

o

.u

o

0 o ~ ~1", ~ ~ I,~ ~m, 0 v 0 ~ ml

The recovery of photodegraded, low density polyethylene

75

...,Z"

(uV) x~m. tm!uo1~N-UON

~"

~:

og, g

/I

~:~l/

<Z

{ ~-

,~

---"%,

z, "~

t~ m

(lOre / f~l) a3~ -

~

J

"-'

~o[I snoas!AJO ,(~au~uo.rlI~Ag3V ~

~a

.--

.~--o_~ .---

. . z -e

_ -

~.

.~,

~0

(s-x4ms)^V ~,.0[

[.d~

,{l!so~!^a.n~au.DI

~

,

76

Doina Staicu, Horia Paven

E P D R , the additional presence of bitumen in ternary blends results in lower energy for melt processing and a better stability for various processing conditions. Thus, increased miscibility at the molecular level between the S-LDoPE and E P D R molecules, due to the presence of bitumen, results in an important improvement in the rheological properties of the melts of these kinds of blends.

HYDROINSULATING SHEETS FROM COMPATIBLE BLENDS BASED ON S-LD-PE

The compatible blends of S-LD-PE with bitumen and E P D R or APP ~-6 were moulded into hydroinsulating sheets which proved to have good properties under site conditions. 7

CONCLUSIONS Ternary S-LD-PE, APP, bitumen blends

Thermodynamically compatible blends of S-LDPE with bitumen and E P D R or APP have improved melt flow properties. Thus the energy necessary for melt processing is lower and the stability of the melts for various processing conditions is much better.

The presence of bitumen in the blends of S-LD-PE with APP results in a strong decrease in the kinematic viscosity (Fig. 3(a)) of the activation energy of viscous flow (Fig. 3(b)), and a significant increase in the non-Newtonian index (Fig. 3(c)). It was previously demonstrated I that because the DSC thermograms show only one endothermic melting maximum and no additional shoulders at the values of temperature specific to the individual components (as happened with the binary blends) the ternary blends of S-LD-PE with APP and bitumen are thermodynamically compatible. Consequently, these blends have better rheological properties. Thus the energy required for melt processing is lower and the stability of the melts for various processing conditions is much better.

REFERENCES

1. Staicu, D., Polym. Deg. Stab. (in press). 2. Staicu, D., Revue Roumaine de Chimie, Romania (in press). 3. Staicu, D., Materiale Plastice, Romania (in press). 4. Staicu, D., (ICECHIM But.), Ro. Pat. 86376 (January 5, 1985); Chem. Abstr., 18 (1986) 154741. 5. Staicu, D., (ICECHIM Buc.), Ro. Pat. 97231 (February 13, 1987); Chem. Abstr., 113 (1990). 6. Staieu, D., (ICECHIM Buc.), Ro. Pat. 97232 (February 13, 1987); Chem. Abstr., 113 (1990). 7. Staieu, D., Hidrotehnica, 36 (1991) 160. 8. Jinescu, V. V., Physical and Thermodynamic Properties of the Plastics Materials. Ed. Tehnica, Bucuresti, 1972. 9. Tudose, R. Z., Macromolecular Compounds Rheology. Ed. Tehnica, Bucuresti, 1973. 10. Paul, D. R., Polym. Engng. Sci., 13 (1973) 307.

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- FCC Catalyst Fluidization: Theory & PracticeDocumento22 pagineFCC Catalyst Fluidization: Theory & Practiceccnew3000Nessuna valutazione finora

- How To Heat LoadDocumento63 pagineHow To Heat LoadJonnelFuertezNessuna valutazione finora

- Steam Pipe Failure Investigation ReportDocumento21 pagineSteam Pipe Failure Investigation ReportMohd Saiful Izwan100% (1)

- Design Calculation Sheet For Fire Lift Well Pressurisation S.NO. DescriptionDocumento1 paginaDesign Calculation Sheet For Fire Lift Well Pressurisation S.NO. DescriptionpsjjoshiNessuna valutazione finora

- Rock & Rock-Fluid Properties: Permeability & Relative PermeabilityDocumento43 pagineRock & Rock-Fluid Properties: Permeability & Relative PermeabilityJorge Jiménez100% (1)

- ME 331 Thermo II Steam Cycle 2Documento81 pagineME 331 Thermo II Steam Cycle 2Mimo Ammar90% (10)

- Isr 2000Documento3 pagineIsr 2000htopaven4340Nessuna valutazione finora

- Iupac Macro'83Documento2 pagineIupac Macro'83htopaven4340Nessuna valutazione finora

- Joam 2004Documento4 pagineJoam 2004htopaven4340Nessuna valutazione finora

- NASA Transl. 1974Documento10 pagineNASA Transl. 1974htopaven4340Nessuna valutazione finora

- Upbsb 2013Documento14 pagineUpbsb 2013htopaven4340Nessuna valutazione finora

- Polimerice: ReologiaDocumento7 paginePolimerice: Reologiahtopaven4340Nessuna valutazione finora

- Icr 84Documento8 pagineIcr 84htopaven4340Nessuna valutazione finora

- ECCM9 2kDocumento10 pagineECCM9 2khtopaven4340Nessuna valutazione finora

- MP2011 176Documento7 pagineMP2011 176htopaven4340Nessuna valutazione finora

- PB80Documento4 paginePB80htopaven4340Nessuna valutazione finora

- PSS 1975Documento14 paginePSS 1975htopaven4340Nessuna valutazione finora

- 2010D25Documento5 pagine2010D25htopaven4340Nessuna valutazione finora

- MP2010 121Documento5 pagineMP2010 121htopaven4340Nessuna valutazione finora

- 2011 D19 XDocumento8 pagine2011 D19 Xhtopaven4340Nessuna valutazione finora

- 2012D33Documento6 pagine2012D33htopaven4340Nessuna valutazione finora

- RC 05Documento13 pagineRC 05htopaven4340Nessuna valutazione finora

- Multifunctionality Selection Criteria in The Dynamic Thermorheological Characterization of Solid-Like Polymer Materials. I. Pmma in Tensile CondtionsDocumento6 pagineMultifunctionality Selection Criteria in The Dynamic Thermorheological Characterization of Solid-Like Polymer Materials. I. Pmma in Tensile Condtionshtopaven4340Nessuna valutazione finora

- Explicit Analytical Relations For Strain-ControlledDocumento4 pagineExplicit Analytical Relations For Strain-Controlledhtopaven4340Nessuna valutazione finora

- Explicit Analytical Relations For Stress-Controlled Rheodynamical Quantities in The Case of Zener-Arrhenius ModelDocumento4 pagineExplicit Analytical Relations For Stress-Controlled Rheodynamical Quantities in The Case of Zener-Arrhenius Modelhtopaven4340Nessuna valutazione finora

- ICR13 2kDocumento3 pagineICR13 2khtopaven4340Nessuna valutazione finora

- 2012D32Documento6 pagine2012D32htopaven4340Nessuna valutazione finora

- 2010D26Documento5 pagine2010D26htopaven4340Nessuna valutazione finora

- MP2007 138Documento6 pagineMP2007 138htopaven4340Nessuna valutazione finora

- RC 04Documento15 pagineRC 04htopaven4340Nessuna valutazione finora

- 2009D33Documento5 pagine2009D33htopaven4340Nessuna valutazione finora

- 2009D32Documento5 pagine2009D32htopaven4340Nessuna valutazione finora

- 2004D26Documento8 pagine2004D26htopaven4340Nessuna valutazione finora

- 2004D27Documento8 pagine2004D27htopaven4340Nessuna valutazione finora

- 2007D14Documento8 pagine2007D14htopaven4340Nessuna valutazione finora

- Donikian Et Al (2012) 3D Ssi Analysis of Cut and Cover Tunnel Doyle Drive SF, CaDocumento10 pagineDonikian Et Al (2012) 3D Ssi Analysis of Cut and Cover Tunnel Doyle Drive SF, CaYuamar BasarahNessuna valutazione finora

- Gas - in - Place - A - Volumetrics - I. KocabasDocumento31 pagineGas - in - Place - A - Volumetrics - I. KocabasTadeo ChoqueNessuna valutazione finora

- 385C Excavator Hydraulic System (Attachment) : Fluid Power SymbolsDocumento4 pagine385C Excavator Hydraulic System (Attachment) : Fluid Power SymbolsLuis Valencia100% (1)

- Losses of Prestress: Elastic Shortening, Friction, Anchorage Slip, Creep, Shrinkage, RelaxationDocumento29 pagineLosses of Prestress: Elastic Shortening, Friction, Anchorage Slip, Creep, Shrinkage, RelaxationLalitha Krishna MoorthyNessuna valutazione finora

- Fluid Mechanics My Book PDFDocumento38 pagineFluid Mechanics My Book PDFAniket BabutaNessuna valutazione finora

- Nzee Storage TanksDocumento13 pagineNzee Storage Tanksvttrlc100% (1)

- Concrete Design I Chapter Three Shear Analysis and Design of BeamsDocumento7 pagineConcrete Design I Chapter Three Shear Analysis and Design of BeamsamyarNessuna valutazione finora

- SimCentral Simulation Platform Thermodynamics Reference GuideDocumento113 pagineSimCentral Simulation Platform Thermodynamics Reference GuideBelmederNessuna valutazione finora

- Lecture Six - Two Dimensional Fluid Flow and Seepage: 6.1. IntroducionDocumento21 pagineLecture Six - Two Dimensional Fluid Flow and Seepage: 6.1. IntroducionAhmed AlmayaliNessuna valutazione finora

- Brizzolara CFD Planing HullsV5 LibreDocumento9 pagineBrizzolara CFD Planing HullsV5 LibrehiguelNessuna valutazione finora

- Topic 3 - Flexible Pavement Stress AnalysisDocumento22 pagineTopic 3 - Flexible Pavement Stress AnalysisWelly Pradipta bin Maryulis100% (1)

- Modelling of Secondary Petroleum Migration Using Invasion Percolation TechniquesDocumento17 pagineModelling of Secondary Petroleum Migration Using Invasion Percolation TechniquesYash GuptaNessuna valutazione finora

- FM 3e SI Chap09 LectureDocumento78 pagineFM 3e SI Chap09 LectureUmIe AhmadNessuna valutazione finora

- Shuttle Valve - Tuscon - 5-710Documento2 pagineShuttle Valve - Tuscon - 5-710Rajan BediNessuna valutazione finora

- KENR7618KENR7618-02 Cargador 924HDocumento2 pagineKENR7618KENR7618-02 Cargador 924HEliceo PalominoNessuna valutazione finora

- 01 Dynamic Modelling For Vapour Compression Systems - RasmussenDocumento23 pagine01 Dynamic Modelling For Vapour Compression Systems - RasmussenAllyson LuizNessuna valutazione finora

- Stress Waves in Solids, Transmission, Reflection and Interaction andDocumento10 pagineStress Waves in Solids, Transmission, Reflection and Interaction andBrijeshNessuna valutazione finora

- Sistema de Riego Por Aspersores: Erick Montes BedollaDocumento6 pagineSistema de Riego Por Aspersores: Erick Montes BedollaOscar RomeroNessuna valutazione finora

- End Plate (Simple Connection)Documento10 pagineEnd Plate (Simple Connection)floi dNessuna valutazione finora

- Automotive Air Conditioning and Heating System PDFDocumento19 pagineAutomotive Air Conditioning and Heating System PDFCarl AriffNessuna valutazione finora

- PT 2023 Past QuestionDocumento7 paginePT 2023 Past QuestionTSOG MHNessuna valutazione finora

- Hydraulics and River Engineering Assignment (Submission Date: Within May 15, 2020) Long Questions, Answer in Own Words As Far As PracticableDocumento2 pagineHydraulics and River Engineering Assignment (Submission Date: Within May 15, 2020) Long Questions, Answer in Own Words As Far As PracticableNitish ShahNessuna valutazione finora

- CDTPDocumento1 paginaCDTPfauzidarmaNessuna valutazione finora

- Aerodynamics of Airfoil & WingsDocumento38 pagineAerodynamics of Airfoil & WingsaerochirishNessuna valutazione finora