Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

3.3 S-MD S en

Caricato da

Laurence SarmientoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

3.3 S-MD S en

Caricato da

Laurence SarmientoCopyright:

Formati disponibili

Product information

Stainless steel self-drilling screws

Applications

Stainless steel screws with sealing washers for fastening profile steel sheet to profile steel

sheet or for fastening profile steel sheet to steel framing.

Fastening profile aluminium sheet to profile aluminium sheet or for fastening profile aluminium sheet to steel framing.

Screws without sealing washers for framing fastenings (not exposed to weather).

Product description

The screw is made from two different materials:

Stainless steel (part B) and hardened carbon steel (part A)

The drill point and thread start are made from hardened carbon steel. This

ensures trouble-free screw fastening even in the hardest construction steel.

The screw first drills the required hole in the part to be fastened and in

the framing (A). Then the thread is cut (B).

A watertight seal is formed at the fastening when the screw with sealing washer is driven.

The surface of the screw is galvanized. This protects the screw from corrosion and lubricates

the drilling and thread-cutting operation.

Hilti

MPA

Several screw programs have been awarded approval by the public building

NRW

inspection authorities in Germany.

Please note the approval mark shown for each of the applicable screw programs.

All screws can be ordered with coloured heads and washers in colours according to the RAL

colour chart.

Z-14.1-4

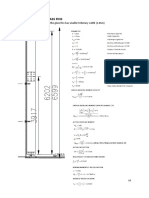

Screw designations

e.g.: S-MD 51 S 5.5x45

S

M

D

5

for screw fastening

for metal construction

for self-drilling screw

2 pressed-on steel flange 15 mm

4 sealing washer 14 mm

5 sealing washer 16 mm

6 sealing washer 19 mm

7 sealing washer 22 mm

0 without sealing washer

1

1 drill point # 1 = 1.25 to 4 mm drilling thickness

3 drill point # 3 = 2.1 to 6 mm drilling thickness

5 drill point # 5 = 4.6 to 12 mm drilling thickness

Please refer to the screw program for the specific max.

drilling thickness for each screw.

S

stainless steel 1.4301 (S for stainless steel)

5.5x45 screw dimensions ( x length)

Further designations:

S-MD 51Z 4.8x19 PB15 PB15 screw head in the colours listed in the RAL colour chart

S-MD 51LS 5.5x25

L extended drill point

S-MD 01Z 4.8x19 M

M collated

11 / 2009

3.63

S-MD 51S / S-MD61S

S-MD 51 S 4.8L + 5.5L / S-MD 61 S 4.8L

stainless steel self-drilling screw

Product data

General information

Material specification:

with hardened carbon steel drill point and

thread start, reduced-diameter drill point for

higher pull-out values and fitted EPDM

sealing washer 16 or 19 mm.

Coloured screws available on request.

Fastening tools

Screwdriver:

Drive using depth

gauge set:

Nut set driver

S-NSD 8:

Approvals

Hilti ST 2500,

Hilti ST 1800

Item no. 304611

Item no. 308901

Hilti

Z-14.1-4

MPA

NRW

Dimensions

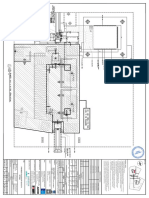

Uses:

Fastening sheet metal to sheet metal, with or without intermediate insulation layer.

For corrosion-resistant and watertight joints.

MF

DC

SW

mm

Applications

Examples

3.64

11 / 2009

S-MD 51S 4.8 / S-MD 61S 4.8

Load data

Design data

Drilling capacity t

max. 2,0 mm

Tightening torque (Recommendation)

Screw in end-stop oriented

Tightening torque:

5 Nm

Component II steel with tll [mm]

S235J according to DIN EN 10025-2

S280GD or S320GD (DIN EN 10326)

0.63

0.75

0.88

1.00

1.13

1.25

Component I

steel with tl [mm]

S280GD or S320GD

(DIN EN 10326)

Shear force VR,k [kN]

0.63

1.00

1.50

1.80

2.00 a

2.00 a

2.00 a

0.75

1.00

1.80

2.10

2.40

2.40 a

2.40 a

0.88

1.20

1.90

2.30

2.80

2.80

1.00

1.40

2.10

2.60

3.10

1.13

1.40

2.10

2.60

1.25

1.40

2.10

Tension force NR,k [kN]

0.50

0.43

0.54

0.65

0.76 a

0.92 a

1.08 a

0.55

0.55

0,68

0.82

0.95 a

1.16 a

1.36 a

0.63

0.80

1.00

1.20

1.40 a

1.70 a

2.00 a

0.75

0.80

1.00

1.20

1.40

1.70 a

2.00 a

0.88

0.80

1.00

1.20

1.40

1.70

1.00

0.80

1.00

1.20

1.40

1.13

0.80

1.00

1.20

1.25

Additional provisions:

0.80

1.00

For steel grade S320GD characteristic loads can be increased by 8%.

11 / 2009

3.65

S-MD 51S 4.8 / S-MD61S 4.8

(a)

single

(b)

side lap

(c)

end overlap

(d)

side lap and end overlap

Safety factors according to EN 1993-1-3 and CUAP 06.02/07

Tension

Shear

M = 1.33

Influence of cyclic loading

cyclic = 1.0

M = 1.33

Design load

NRd = 1.0 NRk / 1.33

VRd = VRk / 1.33

Global safety concept

Global safety factor *

GLOB = 2.0

GLOB = 2.0

Recommended load

NRd = 1.0 NRk / 2.0

VRd = VRk / 2.0

Partial safety concept

Partial safety factor

* Note: The global safety factor of 2.0 includes a partial safety factor of F = 1.5 for wind load. For other loads safety

factors should be applied in accordance with the appropriate standards.

Screw selection

Screw program

Drilling thickness

DC

mm

Fastening thickness

MF

max. mm

Dimensions

(dxL)

mm

Sealing washer

mm

Head size

AF

Package

contents

Ordering

designation

1.25-2.0

6.0

4.8 x 22

16

500

S-MD 51S 4.8 x 22 375228

1.25-2.0

9.0

4.8 x 25

16

500

S-MD 51S 4.8 x 25 375229

1.25-2.0

6.0

4.8 x 22

19

500

S-MD 61S 4.8 x 22 283052

3.66

Item no.

11 / 2009

S-MD 51S 5.5

Load data

Design data

Drilling capacity t

max. 3,0 mm

Tightening torque (Recommendation)

Screw in end-stop oriented

Tightening torque:

5 Nm

Component II steel with tll [mm]

S235J according to DIN EN 10025-2

S280GD or S320GD (DIN EN 10326)

0.63

0.75

0.88

1.00

1.13

1.25

1.50

2.00

Component I

steel with tl [mm]

S280GD or S320GD

(DIN EN 10326)

Shear force VR,k [kN]

0.63

1.00

1.30

1.70

2.00

2.40

2.80 ac 3.00 ac 3.00 a

0.75

1.30

1.80

2.10

2.40

2.70

3.00

3.80

3.80 a

0.88

1.30

1.80

2.10

2.70

2.70

3.00

3.80

4.50

1.00

1.30

1.80

2.40

3.00

3.00

3.00

3.80

5.20

1.13

1.30

1.80

2.40

3.40

3.40

3.40

4.40

1.25

1.40

1.80

2.80

3.80

3.90

4.10

5.00

1.50

1.40

1.80

2.80

3.80

3.90

4.70

5.00

Tension force NR,k [kN]

0.50

0.38

0.49

0.59

0.76

0.92

1.03

1.24

1.24

0.55

0.48

0.61

0.75

0.95

1.16

1.30

1.57

1.57

0.63

0.70

0.90

1.10

1.40

1.70

1.90

2.30

2.30

0.75

0.70

0.90

1.10

1.40

1.70

1.90

2.50

3.30

0.88

0.70

0.90

1.10

1.40

1.70

1.90

2.50

3.70

1.00

0.70

0.90

1.10

1.40

1.70

1.90

2.50

3.70

1.13

0.70

0.90

1.10

1.40

1.70

1.90

2.50

1.25

0.70

0.90

1.10

1.40

1.70

1.90

2.50

1.50

Additional provisions:

0.70

0.90

1.10

1.40

1.70

1.90

2.50

For steel grade S275J and S350GD characteristic loads can be

increased by 10%.

11 / 2009

3.67

S-MD 51S 5.5

(a)

single

(b)

side lap

(c)

end overlap

(d)

side lap and end overlap

Safety factors according to EN 1993-1-3 and CUAP 06.02/07

Partial safety concept

Partial safety factor

Tension

Shear

M = 1.33

M = 1.33

Influence of cyclic loading

cyclic = 1.0

Design load

NRd = 1.0 NRk / 1.33

Global safety concept

/

VRd = VRk / 1.33

Global safety factor *

GLOB = 2.0

GLOB = 2.0

Recommended load

NRd = 1.0 NRk / 2.0

VRd = VRk / 2.0

* Note: The global safety factor of 2.0 includes a partial safety factor of F = 1.5 for wind load. For other loads safety

factors should be applied in accordance with the appropriate standards.

Screw selection

Screw program

Drilling thickness

DC

mm

Fastening thickness

MF

max. mm

1.25-3.0

8.0

5.5 x 25

16

500

S-MD 51S 5.5 x 25 378257

1.25-3.0

15.0

5.5 x 32

16

250

S-MD 51S 5.5 x 32 375230

1.25-3.0

21.0

5.5 x 38

16

250

S-MD 51S 5.5 x 38 375231

1.25-3.0

33.0

5.5 x 50

16

250

S-MD 51S 5.5 x 50 375232

3.68

Dimensions

(dxL)

mm

Sealing washer

mm

Head size

AF

Package

contents

Ordering

designation

Item no.

11 / 2009

S-MD 51LS / S-MD 61LS /

S-MD 71LS

S-MD 51 LS 5.5L / S-MD 61 LS 5.5L / S-MD 71 LS

5.5L stainless steel self-drilling screw

Product data

General information

Material specification:

with hardened carbon steel drill point and

thread start, with fitted EPDM sealing

washer 16, 19 or 22 mm.

Coloured screws available on request.

Fastening tools:

Screwdriver:

Drive using depth

gauge set:

Nut set driver

S-NSD 8:

Approvals:

Hilti ST 2500,

Hilti ST 1800

Item no. 304611

Item no. 308901

Hilti

Z-14.1-4

MPA

NRW

Dimensions

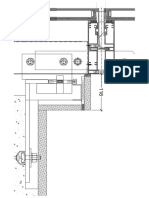

Uses:

Fastening trapezoidal metal sheets to liner trays.

For corrosion-resistant and watertight joints.

HS

d

DC

MF

SW

mm

Applications

Examples

11 / 2009

3.69

S-MD 51LS / S-MD61LS /

S-MD 71LS

Load data

Design data

Drilling capacity t

max. 4,0 mm

Tightening torque (Recommendation)

Screw in end-stop oriented

Tightening torque:

5 Nm

Component II steel with tll [mm]

S235J according to DIN EN 10025-2

S280GD or S320GD (DIN EN 10326)

0.63 2

0.75 2

0.88 2

1.00 2

1.13 2

1.25 2

1.50

2

Component I

steel with tl [mm]

S280GD or S320GD

(DIN EN 10326)

Shear force VR,k [kN]

0.63

2.20

2.70

2.70

2.70

2.90

3.10

3.10

0.75

2.40

3.10

3.10

3.10

3.30

3.60

3.60

0.88

2.70

3.10

3.10

3.10

3.50

4.00

4.00

1.00

3.10

3.20

3.20

3.20

3.80

4.40

4.40

1.13

3.40

3.40

3.80

4.20

4.50

4.90

1.25

3.70

3.70

4.40

5.10

5.30

5.40

1.50

3.70

3.70

4.40

5.10

5.30

5.40

Tension force NR,k [kN]

0.50

1.03

1.13

1.24

1.24

1.24

1.24

1.24

0.55

1.30

1.43

1.57

1.57

1.57

1.57

1.57

0.63

1.90

2.10

2.30

2.30

2.30

2.30

2.30

0.75

1.90

2.10

2.40

2.80

3.30

3.30

3.30

0.88

1.90

2.10

2.40

2.80

3.30

3.80

4.30

1.00

1.90

2.10

2.40

2.80

3.30

3.80

4.80

1.13

1.90

2.10

2.40

2.80

3.30

3.80

1.25

1.90

2.10

2.40

2.80

3.30

3.80

1.50

Additional provisions:

1.90

2.10

2.40

2.80

3.30

3.80

For steel grade S275J and S350GD characteristic loads can be

increased by 10%.

3.70

11 / 2009

S-MD 51LS / S-MD 61LS /

S-MD 71LS

Safety factors according to EN 1993-1-3 and CUAP 06.02/07

Tension

Shear

M = 1.33

Influence of cyclic loading

cyclic = 1.0

M = 1.33

Design load

NRd = 1.0 NRk / 1.33

VRd = VRk / 1.33

Global safety concept

Global safety factor *

GLOB = 2.0

GLOB = 2.0

Recommended load

NRd = 1.0 NRk / 2.0

VRd = VRk / 2.0

Partial safety concept

Partial safety factor

* Note: The global safety factor of 2.0 includes a partial safety factor of F = 1.5 for wind load. For other loads safety

factors should be applied in accordance with the appropriate standards.

Screw selection

Screw program

Drilling thickness

DC

mm

Fastening thickness

MF

max. mm

Dimensions

(dxL)

mm

Sealing washer

mm

Head size

AF

Package

contents

Ordering

designation

1.8-4.0

5.0

5.5 x 25

16

500

S-MD 51LS 5.5 x 25 378258

1.8-4.0

5.0

5.5 x 25

19

500

S-MD 61LS 5.5 x 25 283058

1.8-4.0

5.0

5.5 x 25

22

500

S-MD 71LS 5.5 x 25 285596

11 / 2009

Item no.

3.71

S-MD 53S / S-MD63S /

S-MD 73S

S-MD 53 S / S-MD 63 S / S-MD 73 S 5.5L +

6.3L stainless steel self-drilling screw

Product data

General information

Material specification:

with hardened carbon steel drill point and

thread start, with fitted EPDM sealing

washer 16, 19 or 22 mm.

Coloured screws available on request.

Fastening tools

Screwdriver:

Drive using depth

gauge set:

Nut set driver

S-NSD 8:

Approvals

Hilti ST 2500,

Hilti ST 1800

Item no. 304611

Item no. 308901

Hilti

Z-14.1-4

MPA

NRW

Dimensions

Uses:

Fastening sheet metal to steel framing, with or without intermediate insulation layers.

For corrosion-resistant and watertight joints.

without insulation

DCmin

with insulation

DCmin

DC

SW

mm

MF

L

DCmax

DCmax / MFmax

MFmax

Applications

Examples

3.72

11 / 2009

S-MD 53S 5.5

Load data

Design data

Drilling capacity t

max. 5,50 mm

Tightening torque (Recommendation)

Screw in end-stop oriented

Tightening torque:

5 Nm

Component II steel with tll [mm]

S235J according to DIN EN 10025-2

S280GD or S320GD (DIN EN 10326)

1.50

2.00

2.50

3.00

4.00

Component I

steel with tl [mm]

S280GD or S320GD

(DIN EN 10326)

Shear force VR,k [kN]

0.63

2.10 ac

2.60 ac

3.00 ac

3.40 ac

3.40 ac

0.75

2.50 ac

3.00 ac

3.50 ac

4.00 ac

4.00 ac

0.88

2.70

3.40 ac

4.00 ac

4.60 ac

4.60 a

1.00

2.90

4.80 ac

5.00 ac

5.20 ac

5.20 a

1.13

3.30

5.10

5.40

6.00

6.00

1.25

3.60

5.30

5.80

6.80

6.80

1.50

4.40

5.90

6.60

7.20

7.20

1.75

4.40

5.90

6.60

7.20

2.00

5.40

6.50

6.60

7.20

Tension force NR,k [kN]

0.50

0.92 ac

1.35 ac

1.35 ac

1.35 ac

1.35 ac

0.55

1.16 ac

1.71 ac

1.71 ac

1.71 ac

1.71 ac

0.63

1.70 ac

2.50 ac

2.50 ac

2.50 ac

2.50 ac

0.75

1.70 ac

2.60 ac

3.30 ac

3.30 ac

3.30 ac

0.88

1.70

2.60 ac

3.60 ac

4.10 ac

4.10 a

1.00

1.70

2.60 ac

3.60 ac

4.60 ac

4.70 a

1.13

1.70

2.60

3.60

4.60

5.40

1.25

1.70

2.60

3.60

4.60

5.90

1.50

1.70

2.60

3.60

4.60

6.00

1.75

1.70

2.60

3.60

4.60

2.00

1.70

2.60

3.60

4.60

11 / 2009

3.73

S-MD 53S 5.5

Additional provisions:

(a)

single

For steel grade S275J and S350GD characteristic loads can be

increased by 10%.

(b)

side lap

(c)

end overlap

(d)

side lap and end overlap

Safety factors according to EN 1993-1-3 and CUAP 06.02/07

Tension

Shear

M = 1.33

Influence of cyclic loading

cyclic = 1.0

M = 1.33

Design load

NRd = 1.0 NRk / 1.33

VRd = VRk / 1.33

Global safety concept

Global safety factor *

GLOB = 2.0

GLOB = 2.0

Recommended load

NRd = 1.0 NRk / 2.0

VRd = VRk / 2.0

Partial safety concept

Partial safety factor

* Note: The global safety factor of 2.0 includes a partial safety factor of F = 1.5 for wind load. For other loads safety

factors should be applied in accordance with the appropriate standards.

3.74

11 / 2009

S-MD 53S 6.3

Load data

Design data

Drilling capacity t

max. 6,00 mm

Tightening torque (Recommendation)

Screw in end-stop oriented

Tightening torque:

5 Nm

Component II steel with tll [mm]

S235J according to DIN EN 10025-2

S280GD or S320GD (DIN EN 10326)

1.50

2.00

2.50

3.00

4.00

Component I

steel with tl [mm]

S280GD or S320GD

(DIN EN 10326)

Shear force VR,k [kN]

0.63

2.20

2.50 ac

2.80 ac

3.00 ac

2.00 ac

0.75

2.70

3.20 ac

3.60 ac

4.10 ac

4.10 ac

0.88

3.00

3.70 ac

4.50 ac

5.30 ac

5.30 ac

1.00

3.30

4.00 ac

5.20 ac

6.40 ac

6.40 ac

1.13

3.70

4.70

5.70

6.70

6.70

1.25

4.10

5.10

6.00

6.90

6.90

1.50

5.00

6.30

6.90

7.50

8.10

1.75

5.00

6.30

6.90

7.50

8.10

2.00

6.70

6.70

6.90

7.50

8.10

Tension force NR,k [kN]

0.50

0.76

1.46 ac

1.62 ac

1.62 ac

1.62 ac

0.55

0.95

1.84 ac

2.05 ac

2.05 ac

2.05 ac

0.63

1.40

2.70 ac

3.00 ac

3.00 ac

3.00 ac

0.75

1.40

2.70 ac

3.90 ac

3.90 ac

3.90 ac

0.88

1.40

2.70 ac

4.00 ac

4.80 ac

4.80 ac

1.00

1.40

2.70 ac

4.00 ac

5.40 ac

5.60 ac

1.13

1.40

2.70

4.00

5.40

6.20

1.25

1.40

2.70

4.00

5.40

6.80

1.50

1.40

2.70

4.00

5.40

7.20

1.75

1.40

2.70

4.00

5.40

7.20

2.00

1.40

2.70

4.00

5.40

7.20

11 / 2009

3.75

S-MD 53S / S-MD63S /

S-MD 73S

Additional provisions:

(a)

single

For steel grade S275J and S350GD characteristic loads can be

increased by 10%.

(b)

side lap

(c)

end overlap

(d)

side lap and end overlap

Safety factors according to EN 1993-1-3 and CUAP 06.02/07

Partial safety concept

Tension

Shear

M = 1.33

cyclic = 1.0

M = 1.33

Influence of cyclic loading

Design load

NRd = 1.0 NRk / 1.33

VRd = VRk / 1.33

Partial safety factor

Global safety concept

Global safety factor *

GLOB = 2.0

GLOB = 2.0

Recommended load

NRd = 1.0 NRk / 2.0

VRd = VRk / 2.0

* Note: The global safety factor of 2.0 includes a partial safety factor of F = 1.5 for wind load. For other loads safety

factors should be applied in accordance with the appropriate standards.

3.76

11 / 2009

S-MD 53S / S-MD 63S /

S-MD 73 S

Screw selection

Screw program

Drilling thickness

DC

mm

Fastening thickness

MF

max. mm

Dimensions

(dxL)

mm

Sealing washer

mm

Head size

AF

Package

contents

Ordering

designation

2.1-5.5

5.5 x 25

16

500

S-MD 53 S 5.5 x 25 375233

2.1-5.5

15

5.5 x 32

16

250

S-MD 53 S 5.5 x 32 375234

2.1-5.5

21

5.5 x 38

16

250

S-MD 53 S 5.5 x 38 375235

2.1-5.5

33

5.5 x 50

16

250

S-MD 53 S 5.5 x 50 375236

2.1-5.5

46

5.5 x 63

16

100

S-MD 53 S 5.5 x 63 375237

2.1-5.5

5.5 x 25

19

500

S-MD 63 S 5.5 x 25 283059

2.1-5.5

15

5.5 x 32

19

250

S-MD 63 S 5.5 x 32 283060

2.1-5.5

21

5.5 x 38

19

250

S-MD 63 S 5.5 x 38 283061

2.1-5.5

33

5.5 x 50

19

250

S-MD 63 S 5.5 x 50 283062

2.1-5.5

46

5.5 x 63

19

100

S-MD 63 S 5.5 x 63 283063

2.1-5.5

5.5 x 25

22

500

S-MD 73 S 5.5 x 25 285597

2.1-5.5

15

5.5 x 32

22

250

S-MD 73 S 5.5 x 32 285598

2.1-5.5

21

5.5 x 38

22

250

S-MD 73 S 5.5 x 38 285599

2.1-5.5

33

5.5 x 50

22

250

S-MD 73 S 5.5 x 50 285600

2.1-5.5

46

5.5 x 63

22

100

S-MD 73 S 5.5 x 63 285601

2.1-6.0

6.3 x 25

16

500

S-MD 53 S 6.3 x 25 375238

2.1-6.0

6.3 x 25

19

500

S-MD 63 S 6.3 x 25 283064

2.1-6.0

6.3 x 25

22

500

S-MD 73 S 6.3 x 25 285602

11 / 2009

Item no.

3.77

S-MD 43S

S-MD 43 S 5.5L stainless steel self-drilling

screw

Product data

General information

Material specification:

with hardened carbon steel drill point and

thread start, with fitted EPDM sealing

washer 14 mm.

Coloured screws available on request.

Fastening tools

Screwdriver:

Drive using depth

gauge set:

Nut set driver

S-NSD 8:

Approvals

Hilti ST 2500,

Hilti ST 1800

Item no. 304611

Item no. 308901

Hilti

Z-14.1-4

MPA

NRW

Dimensions

Uses:

Fastening sheet metal to steel framing, with or without intermediate insulation layers.

For corrosion-resistant and watertight joints.

DC

SW

mm

MF

L

Applications

Examples

3.78

11 / 2009

S-MD 43S 5.5

Load data

Design data

Drilling capacity t

max. 5,50 mm

Tightening torque (Recommendation)

Screw in end-stop oriented

Tightening torque:

5 Nm

Component II steel with tll [mm]

S235J according to DIN EN 10025-2

S280GD or S320GD (DIN EN 10326)

1.50

2.00

2.50

3.00

4.00

Component I

steel with tl [mm]

S280GD or S320GD

(DIN EN 10326)

Shear force VR,k [kN]

0.63

2.50

2.50 ac

2.60 ac

2.70 ac

2.70 ac

0.75

2.80

2.80 ac

2.80 ac

2.80 ac

3.70 ac

0.88

3.00

3.00 ac

3.00 ac

3.00 ac

3.70 a

1.00

3.30

3.70 ac

4.30 ac

4.90 ac

4.90 a

1.13

3.50

3.90

4.60

5.30

5.30

1.25

3.80

4.10

4.90

5.80

5.80

1.50

3.80

5.30

5.60

5.90

6.40

1.75

3.80

5.30

5.60

5.90

2.00

5.60

5.60

5.60

5.90

Tension force NR,k [kN]

0.63

1.90

2.30

2.30

2.30

2.30

0.75

1.90

2.50

3.20

3.20

3.20

0.88

1.90

2.50

3.30

4.10

4.10

1.00

1.90

2.50

3.30

4.20

4.90

1.13

1.90

2.50

3.30

4.20

5.60

1.25

1.90

2.50

3.30

4.20

5.60

1.50

1.90

2.50

3.30

4.20

5.60

1.75

1.90

2.50

3.30

4.20

2.00

Additional provisions:

1.90

2.50

3.30

4.20

For steel grade S275J and S350GD characteristic loads

can be increased by 10%.

11 / 2009

3.79

S-MD 43S 5.5

(a)

single

(b)

side lap

(c)

end overlap

(d)

side lap and end overlap

Safety factors according to EN 1993-1-3 and CUAP 06.02/07

Partial safety concept

Tension

Shear

M = 1.33

cyclic = 1.0

M = 1.33

Influence of cyclic loading

Design load

NRd = 1.0 NRk / 1.33

VRd = VRk / 1.33

Partial safety factor

Global safety concept

Global safety factor *

GLOB = 2.0

GLOB = 2.0

Recommended load

NRd = 1.0 NRk / 2.0

VRd = VRk / 2.0

* Note: The global safety factor of 2.0 includes a partial safety factor of F = 1.5 for wind load. For other loads safety

factors should be applied in accordance with the appropriate standards.

Screw selection

Screw program

Drilling thickness

DC

mm

Fastening thickness

MF

max. mm

Dimensions

(dxL)

mm

Sealing washer

mm

Head size

AF

Package

contents

Ordering

designation

2.1-5.5

5.5 x 25

14

500

S-MD 43 S 5.5 x 25 378259

2.1-5.5

15

5.5 x 32

14

500

S-MD 43 S 5.5 x 32 378260

2.1-5.5

21

5.5 x 38

14

250

S-MD 43 S 5.5 x 38 378261

2.1-5.5

33

5.5 x 50

14

250

S-MD 43 S 5.5 x 50 378262

2.1-5.5

46

5.5 x 63

14

100

S-MD 43 S 5.5 x 63 378263

3.80

Item no.

11 / 2009

S-MD 55S / S-MD 65S /

S-MD 75 S

S-MD 55 S / S-MD 65 S / S-MD 75 S 5.5L

stainless steel self-drilling screw

Product data

General information

Material specification:

with hardened carbon steel drill point and

thread start, with fitted EPDM sealing

washer 16, 19 or 22 mm.

Coloured screws available on request.

Fastening tools

Screwdriver:

Drive using depth

gauge set:

Nut set driver

S-NSD 8:

Approvals

Hilti ST 1800

Item no. 304611

Item no. 308901

Hilti

Z-14.1-4

MPA

NRW

Dimensions

Uses:

Fastening sheet metal to thick, hot-rolled steel beams, with or without intermediate

insulation layers.

For corrosion-resistant and watertight joints.

without insulation

H H

S

SW

SW

DCmin

d

DC

mm mm

with insulation

DCmin

DC

MF

L

MF

DCmax

DCmax / MFmax

MFmax

Applications

Examples

11 / 2009

3.81

S-MD 55S / S-MD65S /

S-MD 75S

Load data

Design data

Drilling capacity t

max. 12,00 mm

Tightening torque (Recommendation)

Screw in end-stop oriented

Tightening torque:

5 Nm

Component II steel with tll [mm]

S235J according to DIN EN 10025-2

4.00

5.00

6.00

8.00

10.00

Component I steel with tl [mm]

S280GD or S320GD

(DIN EN 10326)

Shear force VR,k [kN]

0.63

2.70 ac

2.70 ac

2.70 abcd 2.70 abcd 2.70 abcd

0.75

2.90 ac

2.90 ac

2.90 abcd 2.90 abcd 2.90 abcd

0.88

3.50 ac

3.50 ac

3.50 ac

3.50 ac

3.50 ac

1.00

4.00 ac

4.00 ac

4.00 ac

4.00 ac

4.00 ac

1.13

5.00

5.00

5.00 ac

5.00 ac

5.00 ac

1.25

6.00

6.00

6.00 ac

6.00 ac

6.00 a

1.50

6.00

6.20

6.50 ac

6.50

6.50 a

1.75

6.00

6.20

6.50

6.50

6.50

6.00

6.40

6.90

6.90

6.90

2.00

Tension force NR,k [kN]

0.50

1.35 ac

1.35 ac

1.35 abcd 1.35 abcd 1.35 abcd

0.55

1.71 ac

1.71 ac

1.71 abcd 1.71 abcd 1.71 abcd

0.63

2.50 ac

2.50 ac

2.50 abcd 2.50 abcd 2.50 abcd

0.75

3.30 ac

3.30 ac

3.30 abcd 3.30 abcd 3.30 abcd

0.88

4.10 ac

4.10 ac

4.10 ac

4.10 ac

4.10 ac

1.00

4.70 ac

4.70 ac

4.70 ac

4.70 ac

4.70 ac

1.13

5.40

5.40

5.40 ac

5.40 ac

5.40 ac

1.25

5.90

5.90

5.90 ac

5.90 ac

5.90 a

1.50

6.90

6.90

6.90 ac

6.90 ac

6.90 a

1.75

6.90

6.90

6.90

6.90

6.90

2.00

Additional provisions:

8.00

8.00

8.00

8.00

8.00

For steel grade S275J and S350GD characteristic loads

can be increased by 10%.

3.82

11 / 2009

S-MD 55S / S-MD 65S /

S-MD 75 S

(a)

single

(b)

side lap

(c)

end overlap

(d)

side lap and end overlap

Safety factors according to EN 1993-1-3 and CUAP 06.02/07

Partial safety concept

Tension

Shear

M = 1.33

cyclic = 1.0

M = 1.33

Influence of cyclic loading

Design load

NRd = 1.0 NRk / 1.33

VRd = VRk / 1.33

Global safety concept

Global safety factor *

GLOB = 2.0

GLOB = 2.0

Recommended load

NRd = 1.0 NRk / 2.0

VRd = VRk / 2.0

Partial safety factor

* Note: The global safety factor of 2.0 includes a partial safety factor of F = 1.5 for wind load. For other loads safety

factors should be applied in accordance with the appropriate standards.

Screw selection

Screw program

Drilling thickness

DC

mm

Fastening thickness

MF

max. mm

Dimensions

(dxL)

mm

Sealing washer

mm

Head size

AF

Package

contents

Ordering

designation

Item no.

4.6-12

12

5.5 x 45

16

250

S-MD 55 S 5.5 x 45 375239

4.6-12

17

5.5 x 50

16

250

S-MD 55 S 5.5 x 50 375240

4.6-12

30

5.5 x 63

16

100

S-MD 55 S 5.5 x 63 375241

4.6-12

47

5.5 x 80

16

100

S-MD 55 S 5.5 x 80 375242

4.6-12

67

5.5 x 100

16

100

S-MD 55 S 5.5 x 100 375243

4.6-12

12

5.5 x 45

19

250

S-MD 65 S 5.5 x 45 283065

4.6-12

17

5.5 x 50

19

250

S-MD 65 S 5.5 x 50 283066

4.6-12

30

5.5 x 63

19

100

S-MD 65 S 5.5 x 63 283067

4.6-12

47

5.5 x 80

19

100

S-MD 65 S 5.5 x 80 283068

4.6-12

67

5.5 x 100

19

100

S-MD 65 S 5.5 x 100 283069

4.6-12

12

5.5 x 45

22

250

S-MD 75 S 5.5 x 45 285603

4.6-12

17

5.5 x 50

22

250

S-MD 75 S 5.5 x 50 285604

4.6-12

30

5.5 x 63

22

100

S-MD 75 S 5.5 x 63 285605

4.6-12

47

5.5 x 80

22

100

S-MD 75 S 5.5 x 80 285606

4.6-12

67

5.5 x 100

22

100

S-MD 75 S 5.5 x 100 285607

11 / 2009

3.83

S-MD 01S / S-MD03S /

S-MD 05S

S-MD 01 S / S-MD 03 S / S-MD 05 S stainless

steel self-drilling screw

Product data

General Information

Material specification:

with hardened carbon steel drill point and

thread start.

Fastening tools

Screwdriver:

Hilti ST 1800

Torque settings:

S-MD01S 4.8

3 5

S-MD01S / S-MD01LS /

S-MD03S 5.5

6 8

S-MD03S 6.3

810

S-MD05S 5.5

810

Drive without depth gauge.

Cut-out controlled by torque clutch.

Nut set driver S-NSD 8:

Item no. 308901

Dimensions

Uses:

Fastening steel sections and sheet steel to steel framing, with or without insulating material.

without insulation

d

DCmin

DC

with insulation

DCmin

MF

SW

L

DCmax

DCmax / MFmax

3.84

MFmax

11 / 2009

S-MD 01S / S-MD 03S /

S-MD 05 S

Applications

Examples

11 / 2009

3.85

S-MD 01S 4.8

Load data

Design data

Drilling capacity t

max. 2.00 mm

Component II steel with tll [mm]

S280GD or S320GD (DIN EN 10326

0.63

0.75

0.88

1.00

1.13

1.25

Component I steel with tl [mm]

S280GD or S320GD

(DIN EN 10326)

Shear force VR,k [kN]

0.63

0.90

0.90

0.90

0.90

0.90

0.90

0.75

0.90

1.60

1.60

1.60

0.88

0.90

1.60

2.20

2.20

1.00

0.90

1.60

2.20

2.80

1.13

0.90

1.60

2.20

2.80

0.90

1.60

1.25

Tension force NR,k [kN]

0.63

0.80

0.80

0.80

0.80

0.80

0.80

0.75

1.00

1.00

1.00

1.00

1.00

1.00

0.88

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.10

1.40

1.40

1.40

1.40

1.40

1.13

1.10

1.40

1.40

1.40

1.40

1.40

1.25

1.10

1.80

1.80

2.00

2.00

2.00

3.86

11 / 2009

S-MD 01LS 5.5

Load data

Design data

Drilling capacity t

max. 4,00 mm

Component II steel with tll [mm]

S280GD or S320GD (DIN EN 10326

0.63 2

0.75 2

0.88 2

1.00 2

1.13 2

1.25 2

1.50

2

Component I steel with tl [mm]

S280GD or S320GD

(DIN EN 10326)

Shear force VR,k [kN]

0.63

2.10

2.10

2.10

2.10

0.75

2.10

3.00

3.00

3.00

0.88

2.10

3.00

3.10

3.10

1.00

2.10

3.00

3.10

3.20

1.13

2.10

3.00

3.10

1.25

2.10

3.00

1.50

2.10

Tension force NR,k [kN]

0.63

1.60

1.60

1.60

1.60

1.60

1.60

1.60

0.75

2.00

2.00

2.00

2.00

2.00

2.00

2.00

0.88

2.00

2.00

2.00

2.00

2.00

2.00

2.00

1.00

2.00

2.20

2.20

3.10

3.10

3.10

3.10

1.13

2.00

2.20

2.20

3.10

3.10

3.10

3.10

1.25

2.00

2.20

2.20

3.10

3.10

4.30

4.30

1.50

2.00

2.20

2.20

3.10

3.10

4.30

4.80

11 / 2009

3.87

S-MD 03S 5.5

Load data

Design data

Drilling capacity t

max. 5.50 mm

Component II steel with tll [mm]

S280GD or S320GD (DIN EN 10326

1.50

2.00

3.00

Component I steel with tl [mm]

S280GD or S320GD

(DIN EN 10326)

Shear force VR,k [kN]

0.63

2.30

2.30

0.75

2.30

3.00

0.88

2.30

3.00

1.00

4.80

Tension force NR,k [kN]

0.63

1.50

1.50

1.50

0.75

1.70

2.00

2.00

0.88

1.70

2.00

2.00

1.00

1.70

2.60

3.20

1.13

1.70

2.60

3.20

1.25

1.70

2.60

4.60

1.50

1.70

2.60

4.60

2.00

1.70

2.60

4.60

3.88

11 / 2009

S-MD 03S 6.3

Load data

Design data

Drilling capacity t

max. 6.00 mm

Component II steel with tll [mm]

S280GD or S320GD (DIN EN 10326

1.50

2.00

3.00

Component I steel with tl [mm]

S280GD or S320GD

(DIN EN 10326)

Shear force VR,k [kN]

0.63

2.40

2.40

0.75

2.40

3.50

0.88

2.40

3.50

1.00

3.90

Tension force NR,k [kN]

0.63

1.40

1.70

1.70

0.75

1.40

2.20

2.20

0.88

1.40

2.20

2.20

1.00

1.40

2.70

3.70

1.13

1.40

2.70

3.70

1.25

1.40

2.70

5.40

1.50

1.40

2.70

5.40

2.00

1.40

2.70

5.40

11 / 2009

3.89

S-MD 05S 5.5

Load data

Design data

Drilling capacity t

max. 12.00 mm

Component II steel with tll [mm]

S280GD or S320GD (DIN EN 10326

4.00

6.00

8.00

Component I steel with tl [mm]

S280GD or S320GD

(DIN EN 10326)

Shear force VR,k [kN]

0.75

4.10

4.10

4.10

0.88

4.80

4.80

4.80

1.00

5.40

5.40

5.40

1.13

5.40

5.40

5.40

1.25

6.70

6.70

6.70

Tension force NR,k [kN]

0.63

1.40

1.40

1.40

0.75

1.60

1.60

1.60

0.88

1.60

1.60

1.60

1.00

2.20

2.20

2.20

1.13

2.20

2.20

2.20

1.25

2.70

2.70

2.70

1.50

3.30

3.30

3.30

2.00

4.30

4.30

4.30

3.90

11 / 2009

S-MD 01S / S-MD 03S /

S-MD 05 S

Safety factors according to EN 1993-1-3 and CUAP 06.02/07

Tension

Shear

M = 1.33

Influence of cyclic loading

cyclic = 1.0

M = 1.33

Design load

NRd = 1.0 NRk / 1.33

VRd = VRk / 1.33

Global safety concept

Global safety factor *

GLOB = 2.0

GLOB = 2.0

Recommended load

NRd = 1.0 NRk / 2.0

VRd = VRk / 2.0

Partial safety concept

Partial safety factor

* Note: The global safety factor of 2.0 includes a partial safety factor of F = 1.5 for wind load. For other loads safety

factors should be applied in accordance with the appropriate standards.

Screw program

Drilling thickness

DC

mm

Fastening thickness

MF

max. mm

Dimensions

(dxL)

mm

Head size

AF

Package

contents

Ordering

designation

Item no.

1.25-2.0

4.8 x 22

500

S-MD 01 S 4.8 x 22 285608

1.8-4

5.5 x 25

500

S-MD 01 LS 5.5 x 25 285609

2.1-5.5

11

5.5 x 25

500

S-MD 03 S 5.5 x 25 285610

2.1-5.5

18

5.5 x 32

250

S-MD 03 S 5.5 x 32 285611

2.1-5.5

24

5.5 x 38

250

S-MD 03 S 5.5 x 38 285612

2.1-5.5

36

5.5 x 50

250

S-MD 03 S 5.5 x 50 285613

2.1-5.5

49

5.5 x 63

100

S-MD 03 S 5.5 x 63 285614

2.1-6.0

10

6.3 x 25

500

S-MD 03 S 6.3 x 25 285615

4.6-12

15

5.5 x 45

250

S-MD 05 S 5.5 x 45 285616

4.6-12

20

5.5 x 50

250

S-MD 05 S 5.5 x 50 285617

4.6-12

33

5.5 x 63

100

S-MD 05 S 5.5 x 63 285618

4.6-12

50

5.5 x 80

100

S-MD 05 S 5.5 x 80 285619

4.6-12

70

5.5 x 100

100

S-MD 05 S 5.5 x 100 285620

11 / 2009

3.91

S-MD 31PS 4.8

S-MD 31 PS 4.819 stainless steel

self-drilling screw

Product data

General information

Material specification:

with hardened carbon steel drill point and

thread start, with reduced drill point

= greater pull-out value, with fitted EPDM

sealing washer 12 mm.

Coloured screws available on request.

Fastening tools:

Screwdriver:

Drive using depth

gauge set:

Bit S-B TX25W:

Hilti ST 1800

Hilti ST2500

Item no. 304611

Item no. 237296

Approvals:

MF

DC

Hilti

Z-14.1-4

MPA

NRW

Dimensions

d

Uses:

MF

DC corrugated

Fastening

profiled

sheet metal with profiled corrugate sheet metal with or without

D

L

intermediate insulation

layers.

For corrosion-resistant and watertight joints.

d

MF

DC

Applications

Examples

d

DC

MF

L

3.92

11 / 2009

S-MD 31PS 4.8

Load data

Design data

Drilling capacity t

max. 2.75 mm

Screw in end-stop oriented

Component II steel with tll [mm]

S235 (DIN EN 10025-1)

S280GD, S320GD or S350GD (DIN EN 10326)

0.63 0.75 0.88 1.00 1.13 1.25 1.50 1.75 2.00

Component I

steel with tl [mm]

S280GD up to S350GD

(DIN EN 10326)

Shear force VR,k [kN]

0.63

1.12 1.12 1.12 1.12 1.12 1.12 1.12 1.12 1.12

0.75

1.12 1.31 1.31 1.31 1.31 1.31 1.31 1.31 1.31

0.88

1.12 1.31 1.92 1.92 1.92 1.92 1.92 1.92

1.00

1.12 1.31 1.92 2.53 2.53 2.53 2.53 2.53

1.13

1.12 1.31 1.92 2.53 2.53 2.53 2.53

1.25

1.12 1.31 1.92 2.53 2.53 2.53 2.53

1.50

1.12 1.31 1.92 2.53 2.53 2.53

1.75

1.12 1.31 1.92 2.53

2.00

1.12 1.31

Tension force NR,k [kN]

0.63

0.59 0.87 1.12 1.37 1.37 1.37 1.37 1.37 1.37

0.75

0.59 0.87 1.12 1.37 1.37 1.37 1.37 1.37 1.37

0.88

0.59 0.87 1.12 1.37 1.37 1.37 1.37 1.37

1.00

0.59 0.87 1.12 1.37 1.37 1.37 1.37 1.37

1.13

0.59 0.87 1.12 1.37 1.37 1.37 1.37 1.37

1.25

0.59 0.87 1.12 1.37 1.37 1.37 1.37

1.50

0.59 0.87 1.12 1.37 1.37 1.37

1.75

0.59 0.87 1.12 1.37

2.00

0.59 0.87

11 / 2009

3.93

S-MD 31PS 4.8

Component II

Solid timber S10/C24 with e 20 mm

end stop oriented

Component I

steel with tl [mm]

S280GD up to S350GD

(DIN EN 10326

0.63 0.75 0.88 1.00 1.13 1.25 1.50 1.75 2.00

Failure of component I

(bearing stress)

Shear force VR,k [kN]

1.36 2.22 2.22 2.22 2.22 2.22 2.22 2.22 2.22

Failure of component I

(pull-over)

Addition provisions:

Tension force NR,k [kN]

2.34 2.34 2.34 2.34 2.34 2.34 2.34 2.34 2.34

Calculating the resistance of the screw in timber

(Component II) according to timber standard's

3.94

11 / 2009

S-MD 31PS 4.8

Drilling capacity t

max. 2.75 mm

Screw in end-stop oriented

Component II aluminium tll [mm]

Profil sheeting with Rm 185 N/mm2 according to

DIN EN 485-2:2004-09 or substructure according to

DIN 4113-1/A1:2002-09 witht z 185 N/mm

0.50 0.60 0.70 0.80 0.90 1.00 1.10 1.20 1.30 1.40 1.50

Component I

aluminium tl [mm]

Profil sheeting with Rm

185 N/mm2 according to

DIN EN 485-2:2004-09 Shear force VR,k [kN]

0.50

0.31 0.31 0.31 00.31 0.31 0.31 0.31 0.31 0.31 0.31 0.31

0.60

0.31 0.42 0.42 0.42 0.42 0.42 0.42 0.42 0.42 0.42 0.42

0.70

0.31 0.42 0.53 0.53 0.53 0.53 0.53 0.53 0.53 0.53 0.53

0.80

0.31 0.42 0.53 0.70 0.70 0.70 0.70 0.70 0.70 0.70 0.70

0.90

0.31 0.42 0.53 0.70 0.88 0.88 0.88 0.88 0.88 0.88 0.88

1.00

0.31 0.42 0.53 0.70 0.88 1.05 1.05 1.05 1.05 1.05 1.05

1.10

0.31 0.42 0.53 0.70 0.88 1.05 1.05 1.05 1.05 1.05 1.05

1.20

0.31 0.42 0.53 0.70 0.88 1.05 1.05 1.05 1.05 1.05 1.05

1.30

0.31 0.42 0.53 0.70 0.88 1.05 1.05 1.05 1.05 1.05

1.40

0.31 0.42 0.53 0.70 0.88 1.05 1.05 1.05 1.05

1.50

0.31 0.42 0.53 0.70 0.88 1.05 1.05 1.05

Tension force NR,k [kN]

0.50

0.17 0.26 0.35 0.46 0.55 0.61 0.61 0.61 0.61 0.61 0.61

0.60

0.17 0.26 0.35 0.46 0.55 0.61 0.70 0.70 0.70 0.70 0.70

0.70

0.17 0.26 0.35 0.46 0.55 0.61 0.73 0.82 0.83 0.83 0.83

0.80

0.17 0.26 0.35 0.46 0.55 0.61 0.73 0.82 0.91 0.99 0.99

0.90

0.17 0.26 0.35 0.46 0.55 0.61 0.73 0.82 0.91 1.00 1.05

1.00

0.17 0.26 0.35 0.46 0.55 0.61 0.73 0.82 0.91 1.00 1.05

1.10

0.17 0.26 0.35 0.46 0.55 0.61 0.73 0.82 0.91 1.00 1.05

1.20

0.17 0.26 0.35 0.46 0.55 0.61 0.73 0.82 0.91 1.00 1.05

1.30

0.17 0.26 0.35 0.46 0.55 0.61 0.73 0.82 0.91 1.00

1.40

0.17 0.26 0.35 0.46 0.55 0.61 0.73 0.82 0.91

1.50

0.17 0.26 0.35 0.46 0.55 0.61 0.73 0.82

11 / 2009

3.95

S-MD 31PS 4.8

Addition provisions:

For asymmetric loading on profile sheeting with tI < 1.25 mm or

asymmetric seel profiles with tll < 5.0 mm (load values have to be

multiplied by a factor of 0.7).

Component II

Solid timber S10/C24 with e 20 mm

end stop oriented

Component I

aluminium tl [mm]

Profil sheeting with Rm

185 N/mm2 according to

DIN EN 485-2:2004-09 0.50 0.60 0.80 0.90 1.00 1.10 1.20 1.30 1.40 1.50

Failure of component I Shear force VR,k [kN]

(bearing stress)

0.79 0.93 1.06 1.28 1.49 1.71 1.71 1.71 1.71 1.71 1.71

Failure of component I Tension force NR,k [kN]

(pull-over)

0.61 0.70 0.83 0.99 1.19 1.42 1.70 2.02 2.02 2.02 2.02

Addition provisions:

Calculating the resistance of the screw in timber

(Component II) according to timber standard's

Safety factors according to EN 1993-1-3 and CUAP 06.02/07

Partial safety concept

Tension

Shear

M = 1.33

cyclic = 1.0

M = 1.33

Influence of cyclic loading

Design load

NRd = 1.0 NRk / 1.33

VRd = VRk / 1.33

Partial safety factor

Global safety concept

Global safety factor *

GLOB = 2.0

GLOB = 2.0

Recommended load

NRd = 1.0 NRk / 2.0

VRd = VRk / 2.0

* Note: The global safety factor of 2.0 includes a partial safety factor of F = 1.5 for wind load. For other loads safety

factors should be applied in accordance with the appropriate standards.

Screw selection

Screw program

Drilling thickness

DC

mm

Dimensions

(dxL)

mm

Sealing washer

mm

Drive

dimensions

Package

contents

Ordering

designation

1.002.75 5

Fastening to wood

4.8x19

12

TX 25

500

S-MD 31 PS 4.8x19 202421

1.002.75

4.8x38

12

TX25

250

S-MD31PS 4.8x38

387248

1.002.75

4.8x50

12

TX25

250

S-MD31PS 4.8x50

202422

3.96

Fastening thickness

MF

max. mm

Item no.

11 / 2009

S-MD 31PS 5.5

S-MD 31 PS 5.5 stainless steel

self-drilling screw

Product data

General information

Material specification:

with hardened carbon steel drill point and

thread start, with reduced drill point

= greater pull-out value, with fitted EPDM

sealing washer 12 mm.

Coloured screws available on request.

Fastening tools:

Screwdriver:

Drive using depth

gauge set:

Bit S-B TX25W:

Hilti ST 1800

Hilti ST2500

Item no. 304611

Item no. 237296

Approvals:

MF

DC

Hilti

Z-14.1-4

MPA

NRW

Dimensions

d

Uses:

MF

DC corrugated

Fastening

profiled

sheet metal with profiled corrugate sheet metal with or without

D

L

intermediate insulation

layers.

For corrosion-resistant and watertight joints.

d

MF

DC

Applications

Examples

d

DC

MF

L

11 / 2009

3.97

S-MD 31PS 5.5

Load data

Design data

Drilling capacity t

max. 3.0 mm

Screw in end-stop oriented

Component II steel with tll [mm]

S235 (DIN EN 10025-1)

S280GD up to S350GD (DIN EN 10326)

0.63

0.75

0.88

1.00

1.13

1.25

1.50

1.75

Component I

steel with tl [mm]

S280GD up to S350GD

(DIN EN 10326)

Shear force VR,k [kN]

0.63

1.13

1.38

1.38

1.38

1.38

1.38

1.38

1.38

0.75

1.21

1.74

1.74

1.74

1.74

1.74

1.74

1.74

0.88

1.21

1.74

2.19

2.19

2.19

2.19

2.19

2.19

1.00

1.21

1.74

2.19

2.63

2.63

2.63

2.63

2.63

1.13

1.21

1.74

2.19

2.63

2.63

2.63

2.63

2.63

1.25

1.21

1.74

2.19

2.63

2.63

2.63

2.63

2.63

1.50

1.21

1.74

2.19

2.63

2.63

2.63

2.63

1.75

1.21

1.74

2.19

2.63

2.63

2.63

2.00

1.21

1.74

2.19

2.63

Tension force NR,k [kN]

0.63

0.66

0.89

1.14

1.39

1.68

1.91

1.91

1.91

0.75

0.66

0.89

1.14

1.39

1.68

1.91

1.91

1.91

0.88

0.66

0.89

1.14

1.39

1.68

1.91

1.91

1.91

1.00

0.66

0.89

1.14

1.39

1.68

1.91

1.91

1.91

1.13

0.66

0.89

1.14

1.39

1.68

1.91

1.91

1.91

1.25

0.66

0.89

1.14

1.39

1.68

1.91

1.91

1.91

1.50

0.66

0.89

1.14

1.39

1.68

1.91

1.91

1.91

1.75

0.66

0.89

1.14

1.39

1.68

1.91

1.91

1.91

2.00

0.66

0.89

1.14

1.39

1.68

1.91

1.91

1.91

3.98

11 / 2009

S-MD 31PS 5.5

Screw in end-stop oriented

Component II steel with tll [mm]

S235 (DIN EN 10025-1)

S280GD up to S350GD (DIN EN 10326)

0.63

Component I

steel with tl [mm]

S280GD up to S350GD

(DIN EN 10326)

0.63 2

0.75 2

0.88 2

1.00 2

1.13 2

1.25 2

0.63 2

0.75 2

0.88 2

1.00 2

1.13 2

1.25 2

1.50 2

11 / 2009

0.75

0.88

1.00

1.13

Shear force VR,k [kN]

2.04

2.04

2.04

2.04

2.04

2.04

2.41

2.41

2.41

2.04

2.41

2.41

2.41

2.04

2.41

2.41

3.07

2.04

2.41

2.41

2.04

2.41

Tension force NR,k [kN]

1.37

2.15

2.34

2.34

2.34

1.37

2.15

2.34

2.34

2.34

1.37

2.15

2.34

2.34

2.34

1.37

2.15

2.34

2.34

2.34

1.37

2.15

2.34

1.37

2.15

1.37

3.99

S-MD 31PS 5.5

Screw in end-stop oriented

Component II aluminium tll [mm]

Profil sheeting with Rm 185 N/mm2 according to

DIN EN 485-2:2004-09 or substructure according to

DIN 4113-1/A1:2002-09 witht z 185 N/mm2

0.50

0.60

0.70

0.80

0.90

1.00

1.50

2.00

Component I

aluminium tl [mm]

Profil sheeting with Rm

185 N/mm2 according to

DIN EN 485-2:2004-09

Shear force VR,k [kN]

0.50

0.35

0.48

0.60

0.60

0.60

0.60

0.60

0.60

0.60

0.37

0.48

0.60

0.60

0.60

0.60

0.60

0.60

0.70

0.39

0.50

0.60

0.60

0.60

0.60

0.60

0.60

0.80

0.39

0.50

0.60

0.60

0.60

0.60

0.60

0.60

0.90

0.39

0.50

0.60

0.60

0.60

0.60

0.60

0.60

1.00

0.39

0.50

0.60

0.60

1.00

1.20

1.20

1.20

1.10

0.39

0.50

0.60

0.60

1.00

1.20

1.20

1.20

0.39

0.50

0.60

0.60

1.00

1.20

1.20

1.30

0.39

0.50

0.60

0.60

1.00

1.20

1.20

1.40

0.39

0.50

0.60

0.60

1.00

1.20

1.20

0.39

0.50

0.60

0.60

1.00

1.20

1.20

1.50

Tension force NR,k [kN]

0.50

0.23

0.31

0.39

0.53

0.61

0.61

0.61

0.61

0.60

0.23

0.31

0.39

0.53

0.64

0.69

0.70

0.70

0.70

0.23

0.31

0.39

0.53

0.64

0.69

0.83

0.83

0.80

0.23

0.31

0.39

0.53

0.64

0.69

0.99

0.99

0.90

0.23

0.31

0.39

0.53

0.64

0.69

1.19

1.19

1.00

0.23

0.31

0.39

0.53

0.64

0.69

1.25

1.25

1.10

0.23

0.31

0.39

0.53

0.64

0.69

1.25

1.20

0.23

0.31

0.39

0.53

0.64

0.69

1.25

1.30

0.23

0.31

0.39

0.53

0.64

0.69

1.25

1.40

0.23

0.31

0.39

0.53

0.64

0.69

1.25

1.50

0.23

0.31

0.39

0.53

0.64

0.69

1.25

3.100

11 / 2009

S-MD 31PS 5.5

Screw in end-stop oriented

Component II steel tll [mm]

S235 according to DIN EN 10026-2

S280GD up to S350GD as per DIN EN 10326

2 0.63

2 20.70 2 0.80

2 1.00

2 1.13

Component I

aluminium tl [mm]

Profil sheeting with Rm

185 N/mm2 according to

DIN EN 485-2:2004-09

Shear force VR,k [kN]

0.50

0.94

0.94

0.94

0.94

0.94

0.60

0.94

0.94

0.94

0.94

0.94

0.70

0.94

1.21

1.21

1.21

1.21

0.80

0.94

1.21

1.21

1.21

0.90

0.94

1.21

1.21

1.21

1.00

0.94

1.21

1.21

1.21

1.10

0.94

1.21

1.21

1.20

0.94

1.21

1.21

1.30

0.94

1.21

1.40

0.94

1.21

1.50

0.94

1.21

Tension force NR,k [kN]

0.50

0.61

0.61

0.61

0.61

0.61

0.60

0.70

0.70

0.70

0.70

0.70

0.70

0.83

0.83

0.83

0.83

0.83

0.80

0.99

0.99

0.99

0.99

0.90

1.19

1.19

1.19

1.19

1.00

1.37

1.42

1.42

1.42

1.10

1.37

1.70

1.70

1.20

1.37

2.02

2.02

1.30

1.37

2.02

1.40

1.37

2.02

1.50

Addition provisions::

1.37

2.02

For asymmetric loading on profile sheeting with tl < 1.25 mm

or asymmetric seel profiles with tll < 5.0 mm (load values have

to be multiplied by a factor of 0.7).

11 / 2009

3.101

S-MD 31PS 5.5

Safety factors according to EN 1993-1-3 and CUAP 06.02/07

Tension

Shear

M = 1.33

Influence of cyclic loading

cyclic = 1.0

M = 1.33

Design load

NRd = 1.0 NRk / 1.33

VRd = VRk / 1.33

Global safety concept

Global safety factor *

GLOB = 2.0

GLOB = 2.0

Recommended load

NRd = 1.0 NRk / 2.0

VRd = VRk / 2.0

Partial safety concept

Partial safety factor

* Note: The global safety factor of 2.0 includes a partial safety factor of F = 1.5 for wind load. For other loads safety

factors should be applied in accordance with the appropriate standards.

Screw selection

Screw program

Drilling thickness

DC

mm

Fastening thickness

MF

max. mm

Dimensions

(dxL)

mm

Sealing washer

mm

Drive

dimensions

Package

contents

Ordering

designation

Item no.

1.03.00

5.5x22

12

TX 25

500

S-MD 31 PS 5.5x22 202423

1.03.00

13

5.5x28

12

TX 25

500

S-MD 31 PS 5.5x28 202424

1.03.00

23

5.5x38

12

TX 25

250

S-MD 31 PS 5.5x38 202425

1.03.00

35

5.5x50

12

TX 25

250

S-MD 31 PS 5.5x50 202426

3.102

11 / 2009

S-MD 33PS

S-MD 33 PS stainless steel self-drilling

screw

Product data

General information

Material specification:

with hardened carbon steel drill point and

thread start, with fitted EPDM sealing

washer 12 mm.

Coloured screws available on request.

Fastening tools:

Screwdriver:

Drive using depth

gauge set:

Bit S-B TX25W:

Approvals:

Hilti ST 1800

Hilti ST2500

Item no. 304611

Item no. 237296

Hilti

Z-14.1-4

MPA

NRW

Dimensions

d

Uses:

MF

DC

D

Fastening

profiled corrugated sheet metal with steel base material with or without

L

intermediate insulation layers.

For corrosion-resistant and watertight joints.

without insulation

DCmin

DCmin

MF

DC

with insulation

DCmax

d

Applications

Examples

D

DCmax / MFmax

MFmax

MF

DC

L

DC

MF

L

11 / 2009

3.103

S-MD 33PS

Load data

Design data

Drilling capacity t

max. 5.5 mm

Screw in end-stop oriented

Component II aluminium tll [mm]

Profil sheeting with Rm 185 N/mm2 according to

DIN EN 485-2:2004-09 or substructure according to

DIN 4113-1/A1:2002-09 witht z 185 N/mm2

1.00

1.50

2.00

2,50

3.00

Component I

steel with tl [mm]

S280GD up to S350GD

(DIN EN 10326)

Shear force VR,k [kN]

0.63

1.10

1.10

1.10

1.10

1.10

0.75

1.28

1.46

1.46

1.46

1.46

0.88

1.32

1.73

1.73

1.73

1.73

1.00

1.36

1.99

1.99

1.99

1.99

1.13

1.36

1.99

1.99

1.99

1.99

1.25

1.36

1.99

1.99

1.99

1.99

1.50

1.36

1.99

1.99

1.99

1.99

1.75

1.36

1.99

1.99

1.99

1.99

2.00

1.36

1.99

1.99

1.99

1.99

Tension force NR,k [kN]

0.63

0.34

0.78

1.17

1.66

2.34

0.75

0.34

0.78

1.17

1.66

2.34

0.88

0.34

0.78

1.17

1.66

2.34

1.00

0.34

0.78

1.17

1.66

2.34

1.13

0.34

0.78

1.17

1.66

2.34

1.25

0.34

0.78

1.17

1.66

2.34

1.50

0.34

0.78

1.17

1.66

2.34

1.75

0.34

0.78

1.17

1.66

2.34

2.00

0.34

0.78

1.17

1.66

2.34

3.104

11 / 2009

S-MD 33PS

Screw in end-stop oriented

Component II steel tll [mm]

S235 according to DIN EN 10026-2

S280GD up to S350GD as per DIN EN 10326

0.75

0.88

1.00

1.25

2 0.75 2 0.88 2 1.00 2 1.25

Component I

steel with tl [mm]

S280GD up to S350GD

(DIN EN 10326)

Shear force VR,k [kN]

0.63

0.75

1.29

1.29

1.29

1.29

2.05

2.05

2.05

2.05

0.88

1.29

1.81

1.81

1.81

2.05

2.56

2.56

2.56

1.00

1.29

1.81

2.32

2.32

2.05

2.56

3.07

3.07

1.13

1.29

1.81

2.32

2.32

2.05

2.56

3.07

3.07

1.25

1.29

1.81

2.32

2.32

2.05

2.56

3.07

3.07

1.50

1.29

1.81

2.32

2.32

2.05

2.56

3.07

3.07

1.75

1.29

1.81

2.32

2.32

2.05

2.56

3.07

3.07

2.00

1.29

1.81

2.32

2.32

2.05

2.56

3.07

3.07

Tension force NR,k [kN]

0.63

0.45

0.65

0.85

1.08

0.97

1.24

1.51

1.91

0.75

0.45

0.65

0.85

1.08

0.97

1.24

1.51

1.91

0.88

0.45

0.65

0.85

1.08

0.97

1.24

1.51

1.91

1.00

0.45

0.65

0.85

1.08

0.97

1.24

1.51

1.91

1.13

0.45

0.65

0.85

1.08

0.97

1.24

1.51

1.91

1.25

0.45

0.65

0.85

1.08

0.97

1.24

1.51

1.91

1.50

0.45

0.65

0.85

1.08

0.97

1.24

1.51

1.91

1.75

0.45

0.65

0.85

1.08

0.97

1.24

1.51

1.91

2.00

0.45

0.65

0.85

1.08

0.97

1.24

1.51

1.91

11 / 2009

3.105

S-MD 33PS

Drilling capacity t

max. 5.5 mm

Screw in end-stop oriented

Component II aluminium tll [mm]

Profil sheeting with Rm 185 N/mm2 according to

DIN EN 485-2:2004-09 or substructure according to

DIN 4113-1/A1:2002-09 with z 185 N/mm2

1.00

1.50

2.00

2.50

3.00

Component I

aluminium tl [mm]

Profil sheeting with Rm

185 N/mm2 according to

DIN EN 485-2:2004-09

Shear force VR,k [kN]

0.50

0.56

0.79

0.79

0.79

0.79

0.60

0.65

0.91

0.91

0.91

0.91

0.70

0.74

1.03

1.03

1.03

1.03

0.80

0.85

1.10

1.10

1.10

1.10

0.90

0.96

1.18

1.18

1.18

1.18

1.00

1.07

1.25

1.25

1.25

1.25

1.10

1.07

1.25

1.25

1.25

1.25

1.20

1.07

1.25

1.25

1.25

1.25

1.30

1.07

1.25

1.25

1.25

1.25

1.40

1.07

1.25

1.25

1.25

1.25

1.50

1.07

1.25

1.25

1.25

1.25

Tension force NR,k [kN]

0.50

0.34

0.61

0.61

0.61

0.61

0.60

0.34

0.70

0.70

0.70

0.70

0.70

0.34

0.78

0.83

0.83

0.83

0.80

0.34

0.78

0.99

0.99

0.99

0.90

0.34

0.78

1.17

1.19

1.19

1.00

0.34

0.78

1.17

1.42

1.42

1.10

0.34

0.78

1.17

1.66

1.70

1.20

0.34

0.78

1.17

1.66

2.02

1.30

0.34

0.78

1.17

1.66

2.02

1.40

0.34

0.78

1.17

1.66

2.02

1.50

0.34

0.78

1.17

1.66

2.02

3.106

11 / 2009

S-MD 33PS

Screw in end-stop oriented

Component II steel tll [mm]

S235 according to DIN EN 10026-2

S280GD up to S350GD as per DIN EN 10326

0.75

0.88

1.00

1.25

2 0.75 2 0.88 2 1.00 2 1.25

Component I

aluminium tl [mm]

Profil sheeting with Rm

185 N/mm2 according to

DIN EN 485-2:2004-09

Shear force VR,k [kN]

0.50

0.60

0.70

0.99

0.99

0.99

0.99

0.80

0.90

0.99

0.99

0.99

0.99

0.99

0.99

0.99

0.99

1.00

0.99

0.99

1.31

1.10

0.99

0.99

1.31

1.20

0.99

0.99

1.30

0.99

1.40

1.50

1.18

1.18

1.18

1.18

1.18

1.18

1.18

1.18

1.18

1.18

1.18

1.18

1.31

1.18

1.18

1.18

1.18

1.31

1.18

1.18

1.18

1.18

1.31

1.31

1.18

1.18

1.18

1.18

0.99

1.31

1.31

1.18

1.18

1.18

1.18

0.99

0.99

1.31

1.31

1.18

1.18

1.18

1.18

0.99

0.99

1.31

1.31

1.18

1.18

1.18

1.18

Tension force NR,k [kN]

0.50

0.45

0.61

0.61

0.61

0.61

0.61

0.61

0.61

0.60

0.45

0.65

0.70

0.70

0.70

0.70

0.70

0.70

0.70

0.45

0.65

0.83

0.83

0.83

0.83

0.83

0.83

0.80

0.45

0.65

0.85

0.99

0.97

0.99

0.99

0.99

0.90

0.45

0.65

0.85

1.08

0.97

1.19

1.19

1.19

1.00

0.45

0.65

0.85

1.08

0.97

1.24

1.42

1.42

1.10

0.45

0.65

0.85

1.08

0.97

1.24

1.51

1.70

1.20

0.45

0.65

0.85

1.08

0.97

1.24

1.51

1.91

1.30

0.45

0.65

0.85

1.08

0.97

1.24

1.51

1.91

1.40

0.45

0.65

0.85

1.08

0.97

1.24

1.51

1.91

1.50

0.45

0.65

0.85

1.08

0.97

1.24

1.51

1.91

11 / 2009

3.107

S-MD 33PS

Safety factors according to EN 1993-1-3 and CUAP 06.02/07

Tension

Shear

M = 1.33

Influence of cyclic loading

cyclic = 1.0

M = 1.33

Design load

NRd = 1.0 NRk / 1.33

VRd = VRk / 1.33

Global safety concept

Global safety factor *

GLOB = 2.0

GLOB = 2.0

Recommended load

NRd = 1.0 NRk / 2.0

VRd = VRk / 2.0

Partial safety concept

Partial safety factor

* Note: The global safety factor of 2.0 includes a partial safety factor of F = 1.5 for wind load. For other loads safety

factors should be applied in accordance with the appropriate standards.

Screw selection

Screw program

Drilling thickness

DC

mm

Fastening thickness

MF

max. mm

Dimensions

(dxL)

mm

Sealing washer

mm

Drive

dimensions

Package

contents

Ordering

designation

Item no.

2.15.5

5.5x22

12

TX 25

500

S-MD 33PS 5.5x22 202427

2.15.5

11

5.5x28

12

TX 25

500

S-MD 33PS 5.5x28 202428

2.15.5

21

5.5x38

12

TX 25

250

S-MD 33PS 5.5x38 202429

2.15.5

33

5.5x50

12

TX 25

250

S-MD 33PS 5.5x50 202430

3.108

11 / 2009

S-MD 35PS

S-MD 35 PS stainless steel self-drilling

screw

Product data

General information

Material specification:

with hardened carbon steel drill point and

thread start, with fitted EPDM sealing

washer 12 mm.

Coloured screws available on request.

Fastening tools:

Screwdriver:

Drive using depth

gauge set:

Bit S-B TX25W:

Approvals:

Hilti ST 1800

Hilti ST2500

Item no. 304611

Item no. 237296

Hilti

Z-14.1-4

MPA

NRW

Dimensions

Uses:

Fastening profiled corrugated sheet metal with a thick, hot-rolled steel beams, with or

without intermediate insulation layers.

For corrosion-resistant and watertight joints.

without insulation

DCmin

DCmin

MF

DC

with insulation

DCmax

d

Applications

Examples

D

DCmax / MFmax

MFmax

MF

DC

L

d

MF

DC

11 / 2009

3.109

DC

MF

L

S-MD 35PS

Load data

Design data

Drilling capacity t

max. 12.5 mm

Screw in end-stop oriented

Component II steel with tll [mm]

S235 (DIN EN 10025-1)

S280GD up to S350GD (DIN EN 10326)

4.0

5.0

6.0

8.0

10.0

Component I

steel with tl [mm]

S280GD up to S350GD

(DIN EN 10326)

Shear force VR,k [kN]

0.63

2.69

2.93

3.16

3.16

3.16

0.75

2.95

3.11

3.27

3.27

3.27

0.88

3.46

3.73

4.01

4.01

4.01

1.00

3.97

4.36

4.74

4.74

4.74

1.13

4.97

5.16

5.35

5.35

5.35

1.25

5.97

5.97

5.97

5.97

5.97

1.50

5.97

6.23

6.49

6.49

6.49

1.75

5.97

6.33

6.69

6.69

6.69

2.00

5.97

6.43

6.89

6.89

6.89

Tension force NR,k [kN]

0.63

2.34

2.34

2.34

2.34

2.34

0.75

2.34

2.34

2.34

2.34

2.34

0.88

2.34

2.34

2.34

2.34

2.34

1.00

2.34

2.34

2.34

2.34

2.34

1.13

2.34

2.34

2.34

2.34

2.34

1.25

2.34

2.34

2.34

2.34

2.34

1.50

2.34

2.34

2.34

2.34

2.34

1.75

2.34

2.34

2.34

2.34

2.34

2.00

2.34

2.34

2.34

2.34

2.34

3.110

11 / 2009

S-MD 35PS

Screw in end-stop oriented

Component II steel with tll [mm]

S235 (DIN EN 10025-1)

S280GD up to S350GD (DIN EN 10326)

4.0

5.0

6.0

8.0

10.0

Component I

aluminium tl [mm]

Profil sheeting with Rm

185 N/mm2 according to

DIN EN 485-2:2004-09

Shear force VR,k [kN]

0.50

1.03

1.03

1.03

1.03

1.03

0.60

1.27

1.27

1.27

1.27

1.27

0.70

1.51

1.51

1.51

1.51

1.51

0.80

1.79

1.79

1.79

1.79

1.79

0.90

2.07

2.07

2.07

2.07

2.07

1.00

2.35

2.35

2.35

2.35

2.35

1.10

2.35

2.35

2.35

2.35

2.35

1.20

2.35

2.35

2.35

2.35

2.35

1.30

2.35

2.35

2.35

2.35

2.35

1.40

2.35

2.35

2.35

2.35

2.35

1.50

2.35

2.35

2.35

2.35

2.35

Tension force NR,k [kN]

0.50

0.61

0.61

0.61

0.61

0.61

0.60

0.70

0.70

0.70

0.70

0.70

0.70

0.83

0.83

0.83

0.83

0.83

0.80

0.99

0.99

0.99

0.99

0.99

0.90

1.19

1.19

1.19

1.19

1.19

1.00

1.42

1.42

1.42

1.42

1.42

1.10

1.70

1.70

1.70

1.70

1.70

1.20

2.02

2.02

2.02

2.02

2.02

1.30

2.02

2.02

2.02

2.02

2.02

1.40

2.02

2.02

2.02

2.02

2.02

1.50

2.02

2.02

2.02

2.02

2.02

11 / 2009

3.111

S-MD 35PS

Safety factors according to EN 1993-1-3 and CUAP 06.02/07

Tension

Shear

M = 1.33

Influence of cyclic loading

cyclic = 1.0

M = 1.33

Design load

NRd = 1.0 NRk / 1.33

VRd = VRk / 1.33

Global safety concept

Global safety factor *

GLOB = 2.0

GLOB = 2.0

Recommended load

NRd = 1.0 NRk / 2.0

VRd = VRk / 2.0

Partial safety concept

Partial safety factor

* Note: The global safety factor of 2.0 includes a partial safety factor of F = 1.5 for wind load. For other loads safety

factors should be applied in accordance with the appropriate standards.

Screw selection

Screw program

Drilling thickness

DC

mm

Fastening thickness

MF

max. mm

Dimensions

(dxL)

mm

Sealing washer

mm

Drive

dimensions

Package

contents

Ordering

designation

4.612

12

5.5x45

12

TX 25

250

S-MD 35 PS 5.5x45 202431

3.112

Item no.

11 / 2009

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)