Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Flanges - Standard Dim For Flanges Used in Investa

Caricato da

Bharat TailorTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Flanges - Standard Dim For Flanges Used in Investa

Caricato da

Bharat TailorCopyright:

Formati disponibili

Flanges, American standard flanges, class 150

flanges, nominal pipe size, diameter weld bevel,

depth of socket, length of threading, raised face

thickness, bolt circle, bolt holes, Mumbai

HOME

Home

ABOUT US

Flanges

FLANGES

American Standard

PIPE FITTINGS

BUSINESS ENQUIRY

CONTACT US

SITEMAP

C lass 150 Flanges

CLASS 150 FLANGES

FLANGES

American Standard

Class 150 Flanges

C lass 300 Flanges

C lass 600 Flanges

C lass 900 Flanges

C lass 1500 Flanges

C lass 2500 Flanges

Schedule of Weldneck Flanges &

Weights

Tolerance of Flanges

British Standard

BS 10 Table D & Table E

BS 10 Table F & Table H

German Standard

DIN 2502 / DIN 2503

DIN 2527

DIN 2565 / DIN 2566

DIN 2573 / DIN 2576

DIN 2627 / DIN 2628 / DIN 2629

DIN 2630 / DIN 2631 / DIN 2632

DIN 2633 / DIN 2634 / DIN 2635

DIN 2636 / DIN 2637 / DIN 2638

BS EN 1092-1:2002

PN 16 Dimensions

PN 40 Dimensions

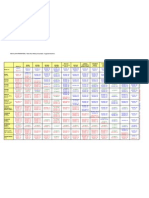

DIMENSIONS OF CLASS 150 FLANGES (ANSI B 16.5) (in mm)

Nominal

Pipe Size

Flange

Dia

'O'

Dia of

Bolt

Circle

'A'

Dia of

Thk of Diameter

Bolt No. of

Flange at Weld

Holes Holes

'C'

Bevel

'D'

Dia of

Hub

'E'

Length Through Hub

Bore 'B'

S/O &

S/W

Y

W/N

Y

L/J

Y

S/O &

S/W

B

L/J

B

Dia of

R/F

R

Depth of Length

Socket

of

F

Threading

1/2''

15

88.9

60.3

15.9

11.1

21.3

30.2

15.9

47.6

15.9

22.3

22.9

34.9

9.5

15.9

3/4''

20

98.4

69.8

15.9

12.7

26.7

38.1

15.9

52.4

15.9

27.7

28.2

42.9

11.1

15.9

1''

25

107.9

79.4

15.9

14.3

33.5

49.2

17.5

55.6

17.5

34.5

35.0

50.8

12.7

17.5

1 ''

32

117.5

88.9

15.9

15.9

42.2

58.7

20.6

57.1

20.6

43.2

43.7

63.5

14.3

20.6

1 ''

40

127.0

98.4

15.9

17.5

48.3

65.1

22.2

61.9

22.2

49.5

50.0

73.0

15.9

22.2

2''

50

152.4

120.6

19.0

19.0

60.4

77.8

25.4

63.5

25.4

62.0

62.5

92.1

17.5

25.4

2 ''

65

177.8

139.7

19.0

22.2

73.1

90.5

28.6

69.8

28.6

74.7

75.4

104.8

19.0

28.6

3''

80

190.5

152.4

19.0

23.8

88.9

107.9

30.2

69.8

30.2

90.7

91.4

127.0

20.6

30.2

3 ''

90

216.0

177.8

19.0

23.8

101.6

122.2

31.7

71.4

31.7

103.4

104.1

140.0

20.6

31.7

4''

100

228.6

190.5

19.0

23.8

114.3

134.9

33.3

76.2

33.3

116.1

116.8

157.2

23.8

33.3

5''

125

254.0

215.9

22.2

23.8

141.2

163.5

36.5

88.9

36.5

143.8

144.5

185.7

23.8

36.5

6''

150

279.4

241.3

22.2

25.4

168.4

192.1

39.7

88.9

39.7

170.7

171.4

215.9

27.0

39.7

8''

200

342.9

298.4

22.2

28.6

219.2

246.1

44.4

101.6

44.4

221.5

222.2

269.9

31.7

44.4

10''

250

406.4

361.9

25.4

12

30.2

273.0

304.8

49.2

101.6

49.2

276.3

277.4

323.8

33.3

49.2

12''

300

482.6

431.8

25.4

12

31.8

323.8

365.1

55.6

114.3

55.6

327.1

328.2

381.0

39.7

55.6

14''

350

533.4

476.2

28.6

12

34.9

355.6

400.0

57.1

127.0

79.4

359.1

360.2

412.7

41.3

57.1

16''

400

596.9

539.7

28.6

16

36.5

406.4

457.2

63.5

127.0

87.3

410.5

411.2

469.9

44.4

63.5

18''

450

635.0

577.8

31.7

16

39.7

457.2

504.8

68.3

139.7

96.8

461.8

462.3

533.4

49.2

68.3

20''

500

698.5

635.0

31.7

20

42.9

508.0

558.8

73.0

144.5

103.2

513.1

514.3

584.2

54.0

73.0

24''

600

812.8

749.3

34.9

20

47.6

609.6

663.6

82.5

152.4

111.1

615.9

615.9

692.1

63.5

82.5

Note : Thickness 'C' is inclusive of Raised Face Thickness of 1.65 MM. For Class 150

A class 150 flange can be created from various materials like stainless steel, carbon steel, ductile iron, cast iron, etc and is resistant to abrasion & corrosion with high

durability. Flanges such as American standard flanges, British standard flanges and German standard flanges created using above mentioned materials have

separate pressure ratings.

The pressure rating of flanges depends on various factors which we will look at in the following section.

Flanges are able to resist different pressure values at different & varied temperatures. With increase in temperature pressure rating of a flange decreases. Let us take an

example to illustrate what happens; Class 150 flanges rates to about 270 PSIG (in ambient conditions), at 400 F a PSIG of 180, at 600 F a PSIG of 150 & 75 PSIG at 800

F. So it all depends on the fluids operating temperature.

Different types of Class 150 Flanges:

1.

2.

3.

4.

5.

6.

Welding neck flanges

Slip on flanges

Blind flanges

Threaded flanges

Lap joint flanges

Socket weld flanges

Home

About Us

Flanges

C opyright 2010 I. P. C orporations - All rights reserved.

Pipe Fittings

Downloads

Business Enquiry

Contact Us

Sitemap

Website Designing & Web Developement by C MI

Potrebbero piacerti anche

- Bronze Ball Valves Flammable Fluid Fuel Gas Applications - TBDocumento4 pagineBronze Ball Valves Flammable Fluid Fuel Gas Applications - TBGreg FarzettaNessuna valutazione finora

- Dimensions of Butt Welding Equal Tee en 10253 2Documento1 paginaDimensions of Butt Welding Equal Tee en 10253 2aliNessuna valutazione finora

- EXP 2 Compressible Gas Flow 08-15 PDFDocumento16 pagineEXP 2 Compressible Gas Flow 08-15 PDFKamran MostajiriNessuna valutazione finora

- Gruvlok CatalogDocumento276 pagineGruvlok CatalogFerdie WakeUp FromAdversityNessuna valutazione finora

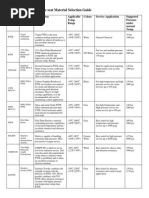

- Valve Seat Material GuideDocumento1 paginaValve Seat Material GuidewawanNessuna valutazione finora

- Advanced High Pressure Engine Study For Mixed Mode Vehicle ApplicationsDocumento318 pagineAdvanced High Pressure Engine Study For Mixed Mode Vehicle Applicationsdjeffal mohammed amineNessuna valutazione finora

- 10 Ok Leakage Rates API 6d and Iso 14313Documento0 pagine10 Ok Leakage Rates API 6d and Iso 14313ZoebairNessuna valutazione finora

- F300 Valves For API 641 TestingDocumento3 pagineF300 Valves For API 641 TestingSyed AhmedNessuna valutazione finora

- Valve World - India: 3 - 4 October 2019Documento11 pagineValve World - India: 3 - 4 October 2019aharnishaNessuna valutazione finora

- General Arrangement Drawing For Slug Catcher Rev.c IfaDocumento1 paginaGeneral Arrangement Drawing For Slug Catcher Rev.c IfaMe RahmanNessuna valutazione finora

- Valve Seat Material Selection GuideDocumento1 paginaValve Seat Material Selection Guidemurtuza5Nessuna valutazione finora

- Ai ML PDFDocumento4 pagineAi ML PDFanon_531841359Nessuna valutazione finora

- National Standard Plumbing CodeDocumento30 pagineNational Standard Plumbing CodeChristian D. OrbeNessuna valutazione finora

- BHEL TDC For FittingsDocumento9 pagineBHEL TDC For FittingsGuru KguruNessuna valutazione finora

- Supplier Quality Management A Complete Guide - 2021 EditionDa EverandSupplier Quality Management A Complete Guide - 2021 EditionNessuna valutazione finora

- ES 49BranchConnectionsDocumento7 pagineES 49BranchConnectionsrodofgodNessuna valutazione finora

- Valve Seat Seal Selection GuideDocumento2 pagineValve Seat Seal Selection Guideecovarrubias1Nessuna valutazione finora

- 12 BonnetsDocumento15 pagine12 Bonnetsfaisal84in100% (1)

- Lesson Plan Cowboys and CowgirlsDocumento2 pagineLesson Plan Cowboys and Cowgirlsapi-314832142Nessuna valutazione finora

- Lesson Plan BugsDocumento2 pagineLesson Plan Bugsapi-314832142Nessuna valutazione finora

- Trading Journal: "Buat Sampai Profit, Tuhan Jangan Lupa" "Buat Sampai Profit, Tuhan Jangan Lupa"Documento2 pagineTrading Journal: "Buat Sampai Profit, Tuhan Jangan Lupa" "Buat Sampai Profit, Tuhan Jangan Lupa"Nuryusri AimanNessuna valutazione finora

- CWB Certification ServicesDocumento7 pagineCWB Certification ServicesSaid Alauddeen FaiszNessuna valutazione finora

- Sa 299Documento3 pagineSa 299Web LogueandoNessuna valutazione finora

- JIS US316L Steel, JIS G4403 SUS316L Stainless SteelDocumento2 pagineJIS US316L Steel, JIS G4403 SUS316L Stainless Steelnguyenvandai8xNessuna valutazione finora

- Gas Flow Rate Calculation From Wellhead PressuresDocumento1 paginaGas Flow Rate Calculation From Wellhead Pressureschandramohan murugan100% (1)

- 6A E21 Addendum 1 PDFDocumento9 pagine6A E21 Addendum 1 PDFAndres FCTNessuna valutazione finora

- Trading JournalDocumento34 pagineTrading JournaltianNessuna valutazione finora

- Smith Gasket BrochureDocumento29 pagineSmith Gasket BrochureJeesan MathewNessuna valutazione finora

- C1277-15 Standard Specification For Shielded Couplings Joining Hubless Cast Iron Soil Pipe and Fittings PDFDocumento9 pagineC1277-15 Standard Specification For Shielded Couplings Joining Hubless Cast Iron Soil Pipe and Fittings PDFCarlos Guillermo Somoza AlvarengaNessuna valutazione finora

- Perrin High Pressure Valves For Hydrogen ServiceDocumento12 paginePerrin High Pressure Valves For Hydrogen ServiceKunming Wang100% (1)

- RTJ Flange Facing DimensionsDocumento3 pagineRTJ Flange Facing DimensionsMandar Nalavde0% (1)

- Catalog - Texas FlangesDocumento76 pagineCatalog - Texas FlangesVicky GautamNessuna valutazione finora

- Wps-Gtaw SmawDocumento15 pagineWps-Gtaw SmawSripathyNessuna valutazione finora

- Api600 Valve Trim ChartDocumento2 pagineApi600 Valve Trim ChartBoankNessuna valutazione finora

- ANSI ISA 75.19.01hydrostatic Testing of Control Valves (2003)Documento34 pagineANSI ISA 75.19.01hydrostatic Testing of Control Valves (2003)kikechuNessuna valutazione finora

- Cherne Catalog PDFDocumento72 pagineCherne Catalog PDFNissam SidheeqNessuna valutazione finora

- Codes TableDocumento2 pagineCodes TablejesamsonNessuna valutazione finora

- Comco Pipe Supply Company Green BookDocumento28 pagineComco Pipe Supply Company Green BookinfoNessuna valutazione finora

- BP Variable Catalog 09VDocumento52 pagineBP Variable Catalog 09VPetros IosifidisNessuna valutazione finora

- 5 Whys: Why 1 Why 2 Why 3 Why 4 Why 5 Why? Because Why? Because Why? Because Why? Because Why? BecauseDocumento2 pagine5 Whys: Why 1 Why 2 Why 3 Why 4 Why 5 Why? Because Why? Because Why? Because Why? Because Why? BecauseMony ESNessuna valutazione finora

- Global Marketing For Tube & Pipe: JIS G3457 Arc Welded Carbon Steel PipesDocumento7 pagineGlobal Marketing For Tube & Pipe: JIS G3457 Arc Welded Carbon Steel PipesNurzed MunkhbayarNessuna valutazione finora

- Sfa-5.01 Filler Metal Procurement GuidelinesDocumento10 pagineSfa-5.01 Filler Metal Procurement GuidelinesCesar Agustin LimousinNessuna valutazione finora

- IFC Series Y-Strainers: NotesDocumento30 pagineIFC Series Y-Strainers: Notesmarsha.fsdNessuna valutazione finora

- Difference Between API 5L 44th & 45th EditionDocumento7 pagineDifference Between API 5L 44th & 45th EditionPankaj ShrivastvaNessuna valutazione finora

- Extract From ISO:5211 & DIN:3337Documento1 paginaExtract From ISO:5211 & DIN:3337Fabio PersoliNessuna valutazione finora

- Avk Gate Valves PDFDocumento9 pagineAvk Gate Valves PDFDanielNessuna valutazione finora

- GB 150.2-2010 固定式压力容器 第2部分:材料(征求意见稿)Documento53 pagineGB 150.2-2010 固定式压力容器 第2部分:材料(征求意见稿)Guan WilliamNessuna valutazione finora

- Mil HDBK 695d Change 2Documento45 pagineMil HDBK 695d Change 2dhoo_babyNessuna valutazione finora

- Weld IncoDocumento1 paginaWeld IncomprabhurajalingamNessuna valutazione finora

- Written Report Six SigmaDocumento17 pagineWritten Report Six SigmaJm CruzNessuna valutazione finora

- Triple-Offset Butterflyvalves PDFDocumento8 pagineTriple-Offset Butterflyvalves PDFDiwakar NigamNessuna valutazione finora

- Materials System SpecificationDocumento13 pagineMaterials System SpecificationMoustafa Bayoumi100% (1)

- Flowserve Air To Open Standard Actuator Valtek 2112 Selection For Korting Thermocompressor ValveDocumento1 paginaFlowserve Air To Open Standard Actuator Valtek 2112 Selection For Korting Thermocompressor ValvealicardozoNessuna valutazione finora

- Q235 Steel Equivalent StandardDocumento1 paginaQ235 Steel Equivalent StandardigorNessuna valutazione finora

- DelCorte - AccesoriosDocumento56 pagineDelCorte - AccesoriosespanolasaNessuna valutazione finora

- Asme Sa 106 Grade B PipesDocumento1 paginaAsme Sa 106 Grade B PipesFerroPipENessuna valutazione finora

- FlangeDocumento7 pagineFlangeEdi YantoNessuna valutazione finora

- Plumbing or PipingDocumento7 paginePlumbing or PipingsundaramNessuna valutazione finora

- Din 2642 Flange Manufacture Din2642 PN 10 Flanges and PN 10 in IndiaDocumento3 pagineDin 2642 Flange Manufacture Din2642 PN 10 Flanges and PN 10 in Indiasayed_20004Nessuna valutazione finora

- Accessories For Pipes: FlangesDocumento7 pagineAccessories For Pipes: FlangesJbr IrvingNessuna valutazione finora

- Operational Trainers: flreguet/BAC Jaguar B (Royal Air Force)Documento1 paginaOperational Trainers: flreguet/BAC Jaguar B (Royal Air Force)Bharat TailorNessuna valutazione finora

- List, Noted That They Were Equipped With " Bull-: Incidentally It Is Now Intensely Hot in The FrontierDocumento1 paginaList, Noted That They Were Equipped With " Bull-: Incidentally It Is Now Intensely Hot in The FrontierBharat TailorNessuna valutazione finora

- List, Noted That They Were Equipped With " Bull-: Incidentally It Is Now Intensely Hot in The FrontierDocumento1 paginaList, Noted That They Were Equipped With " Bull-: Incidentally It Is Now Intensely Hot in The FrontierBharat TailorNessuna valutazione finora

- Military Aircraft: Hindustan HJT-16 Kiran in Production For The Indian Air ForceDocumento1 paginaMilitary Aircraft: Hindustan HJT-16 Kiran in Production For The Indian Air ForceBharat TailorNessuna valutazione finora

- 1970 - 2022Documento1 pagina1970 - 2022Bharat TailorNessuna valutazione finora

- 1970 - 0625Documento1 pagina1970 - 0625Bharat TailorNessuna valutazione finora

- Hawker HartDocumento1 paginaHawker HartBharat TailorNessuna valutazione finora

- 1970 - 0625Documento1 pagina1970 - 0625Bharat TailorNessuna valutazione finora

- 1970 - 0775Documento1 pagina1970 - 0775Bharat TailorNessuna valutazione finora

- Air Transport: Britishunitedstrike AvertedDocumento1 paginaAir Transport: Britishunitedstrike AvertedBharat TailorNessuna valutazione finora

- Sensor: Marut Trainerhindustanhf-24MkitDocumento1 paginaSensor: Marut Trainerhindustanhf-24MkitBharat TailorNessuna valutazione finora

- 1970 - 2022Documento1 pagina1970 - 2022Bharat TailorNessuna valutazione finora

- Defence: N A T O ' S Nuclear RetaliationDocumento1 paginaDefence: N A T O ' S Nuclear RetaliationBharat TailorNessuna valutazione finora

- 1970 - 1443Documento1 pagina1970 - 1443Bharat TailorNessuna valutazione finora

- High Flight: Military Helicopter ProgrammesDocumento6 pagineHigh Flight: Military Helicopter ProgrammesBharat Tailor100% (1)

- Military Aircraft: Hindustan HJT-16 Kiran in Production For The Indian Air ForceDocumento1 paginaMilitary Aircraft: Hindustan HJT-16 Kiran in Production For The Indian Air ForceBharat TailorNessuna valutazione finora

- Military AircraftDocumento1 paginaMilitary AircraftBharat TailorNessuna valutazione finora

- 1970 - 1005Documento1 pagina1970 - 1005Bharat TailorNessuna valutazione finora

- Helicopters Indian FinalistsDocumento3 pagineHelicopters Indian FinalistsBharat TailorNessuna valutazione finora

- 1970 - 1018Documento1 pagina1970 - 1018Bharat TailorNessuna valutazione finora

- The IAF's Trainer Mess - by GP Capt AG BewoorDocumento3 pagineThe IAF's Trainer Mess - by GP Capt AG BewoorShiv AroorNessuna valutazione finora

- Mixing It at Istres: Air Exercise Garuda'Documento2 pagineMixing It at Istres: Air Exercise Garuda'Bharat TailorNessuna valutazione finora

- Exercise Shoorveer 2012Documento4 pagineExercise Shoorveer 2012Bharat TailorNessuna valutazione finora

- Exercise Livewire 2013Documento1 paginaExercise Livewire 2013Bharat TailorNessuna valutazione finora

- Fomin A Dec 2009 MIG 29K Back On Deck Take Off MagazineDocumento4 pagineFomin A Dec 2009 MIG 29K Back On Deck Take Off MagazineBharat TailorNessuna valutazione finora

- July 2011Documento7 pagineJuly 2011Bharat TailorNessuna valutazione finora

- Andreyev V Nov 2012 MiG 29K Lands On Vikramaditya Take Off MagazineDocumento4 pagineAndreyev V Nov 2012 MiG 29K Lands On Vikramaditya Take Off MagazineBharat Tailor100% (1)

- Tigers Taming The: Force Report Sri Lanka Air ForceDocumento5 pagineTigers Taming The: Force Report Sri Lanka Air ForceBharat TailorNessuna valutazione finora

- Indian Air Force in The 21st Century: Challenges and OpportunitiesDocumento14 pagineIndian Air Force in The 21st Century: Challenges and OpportunitiesBharat TailorNessuna valutazione finora

- India's Quest For An Indigenous Aircraft CarrierDocumento3 pagineIndia's Quest For An Indigenous Aircraft CarrierBharat TailorNessuna valutazione finora

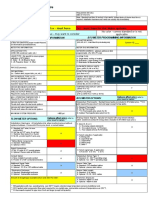

- Petronas Carigali Sdn. Bhd. Inspection Test Record (Itr) - A Piping Work Completion P01-ADocumento21 paginePetronas Carigali Sdn. Bhd. Inspection Test Record (Itr) - A Piping Work Completion P01-AWael Chouchani100% (2)

- Ej800ahfph (2016-2017) W800 PDFDocumento86 pagineEj800ahfph (2016-2017) W800 PDFAlbert DepanoNessuna valutazione finora

- Is 10135 1985 PDFDocumento16 pagineIs 10135 1985 PDFRony JoyNessuna valutazione finora

- General Specification For Welding and Weld Inspection (EIL)Documento19 pagineGeneral Specification For Welding and Weld Inspection (EIL)Mitchel Fernandes100% (6)

- Index To PTSDocumento47 pagineIndex To PTSpolaris44100% (2)

- Corrugated Steel Pipe Design Manual 2008Documento636 pagineCorrugated Steel Pipe Design Manual 2008fiercecat100% (1)

- DRP001-OUF-SPE-C-000-007-B3 (Storm Sewers & Culverts)Documento10 pagineDRP001-OUF-SPE-C-000-007-B3 (Storm Sewers & Culverts)Kannan MurugesanNessuna valutazione finora

- SSW - April 2020 - Lowres Pages 42 45 PDFDocumento4 pagineSSW - April 2020 - Lowres Pages 42 45 PDFBaher ElsheikhNessuna valutazione finora

- Catalogo Modelo AquaPoolDocumento2 pagineCatalogo Modelo AquaPoollloberasNessuna valutazione finora

- Detail DesignDocumento67 pagineDetail DesignBHAVISHA GOHILNessuna valutazione finora

- Oroflex Well BrochureDocumento8 pagineOroflex Well BrochureMoussa BANessuna valutazione finora

- Identifying Threads and ChartsDocumento4 pagineIdentifying Threads and ChartsAlvaro Gonza HuallaNessuna valutazione finora

- Btu Meter FormDocumento2 pagineBtu Meter Formtkm2004Nessuna valutazione finora

- Kanthal Af Tube - S Kaxxx Ps Eng - 0Documento2 pagineKanthal Af Tube - S Kaxxx Ps Eng - 0Chia Sze KiatNessuna valutazione finora

- A Method For Assessing The In-Place Cleanability of Food Processing EquipmentDocumento16 pagineA Method For Assessing The In-Place Cleanability of Food Processing Equipmentriza ayu putri100% (1)

- Инструкция Сервисная HAIER AB (092-182), AC (142-148), AD (092-148), AF (092-122), AS (072-222) PDFDocumento174 pagineИнструкция Сервисная HAIER AB (092-182), AC (142-148), AD (092-148), AF (092-122), AS (072-222) PDFmikeNessuna valutazione finora

- Application of Line Pipe and Hot Induction Bends in Hydrogen Gas PDFDocumento6 pagineApplication of Line Pipe and Hot Induction Bends in Hydrogen Gas PDFgagodoy20Nessuna valutazione finora

- Irrigation ToolsDocumento25 pagineIrrigation Toolsrvesesi mxxnNessuna valutazione finora

- S2K14 SBU1 PIP DOC 1003 Pipe Class SpecificationDocumento7 pagineS2K14 SBU1 PIP DOC 1003 Pipe Class SpecificationvivekpecNessuna valutazione finora

- Draft Pren 15383: European Standard Norme Européenne Europäische NormDocumento55 pagineDraft Pren 15383: European Standard Norme Européenne Europäische NormGigiNessuna valutazione finora

- Seamless - Welded Comparison Rev 1Documento6 pagineSeamless - Welded Comparison Rev 1amuihNessuna valutazione finora

- Pema News 2004 enDocumento8 paginePema News 2004 enkorky1Nessuna valutazione finora

- Itp Co DienDocumento43 pagineItp Co DienChungNguyenNessuna valutazione finora

- Snoop Leak Test LiquidDocumento6 pagineSnoop Leak Test Liquidaldi_crisNessuna valutazione finora

- Sway Bracing:: PW P P, P PDocumento3 pagineSway Bracing:: PW P P, P PShafiullah AmanNessuna valutazione finora

- Submersible Component PartsDocumento1 paginaSubmersible Component PartsFayez Al-ahmadiNessuna valutazione finora

- GB 20 & Astm 106Documento2 pagineGB 20 & Astm 106satheshNessuna valutazione finora

- Polyethylene Encasement For Ductile Iron Pipe For Water or Other LiquidsDocumento7 paginePolyethylene Encasement For Ductile Iron Pipe For Water or Other LiquidsTamil funNessuna valutazione finora

- Welded and Seamless Wrought Steel Pipe: ASME B36.10M-2004Documento2 pagineWelded and Seamless Wrought Steel Pipe: ASME B36.10M-2004Amit BansalNessuna valutazione finora

- Utilities (SUB-UTL) : Chapter 02 - SubstructureDocumento2 pagineUtilities (SUB-UTL) : Chapter 02 - Substructureجميل عبد الله الحماطيNessuna valutazione finora