Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Potash Crystallization

Caricato da

Uditha LakshanCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Potash Crystallization

Caricato da

Uditha LakshanCopyright:

Formati disponibili

INTRODUCTION

Crystal growth fundamentals

Crystals are formed by the process called nucleation. Nucleation can start either with the solute

molecules or with some solid matter which might be an impurity in the solution. The growth normally

occurs by aggregation of molecules that are attracted to each other. The number of crystals formed,

crystal sizes and shapes generally depend on properties of the solution like, saturation (solute

concentration), operating temperature and mechanical disturbances.

In solutions which the solute is near saturation promote fast crystal growth. Supersaturated solutions

tend to give crystals which are small in size. If the nucleation is low, such solutions will result in fewer

crystals each of larger size. Nucleation is certainly promoted by turbulence and thus mechanical

disturbances typically result in smaller crystals.

In general, thermal gradient methods tend to produce high quality crystals. Such methods include slow

cooling and zonal heating. The latter employs convection by creating a thermal gradient in the crystal

growing vessel. The solution becomes more saturated in the warm part of a vessel and crystal growth

occurs when the solution is slowly transferred to a cooler region.

[1]

Rest of this report will discuss about how to design a crystallizer for crystallization of aqueous solution

of potash under the following operating conditions:

Absolute pressure - 0.8 atm

Temperature - 40

o

C

Mean diameter - 2.5 m

Length of cylindrical shell - 5 m

1. Material selection

Since an aqueous solution of potash is used as the raw materials for the crystallization process, special

attention should paid in order to avoid the corrosion. Therefore its better to use Stainless Steel as the

fabricating material.

Grade 304 (SA-240) is the most widely used stainless steel which is available in a wider range of

forms. It has excellent forming and welding characteristics. Post-weld annealing is not required when

welding thin sections. Grade 304 is available in roll formed into a variety of components for

applications in the industrial, architectural & transportation fields.

Grade 304L is the low carbon version of 304, does not require post-weld annealing and so is

extensively used in heavy gauge components (over about 6mm).

SA-240 also has a excellent corrosion resistance in a wide range of atmospheric environments and

many corrosive media. But, it may subject to pitting and crevice corrosion in warm chloride

environments, and to stress corrosion cracking above about 60C. Since the crystallizer is maintained

at 40

o

C this might not be an issue.

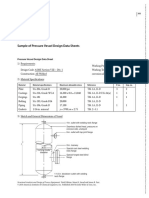

Design Pressure & Temperature

i. Design Pressure (

)

Absolute Pressure

The absolute pressure is measured relative to the absolute zero pressure. In other words, relative to the

pressure that would occur at absolute vacuum.

Under the given operating conditions, operating pressure inside the crystallizer is 0.8atm (absolute).

Therefore, this scenario falls under the category of;

&

Therefore

is given by,

Therefore;

( )

ii. Design Temperature (

)

Since the crystallizer should be operated at

it is required to be heated. Lets assume, that the

vessel is indirectly heated with using a heating coil.

Therefore;

Therefore;

2. Calculation of the wall thickness of the shell economical and safe to

Lets assume that all the welded joints are butt joints & therefore according to the section II, Part D of

ASME, welded joint efficiency () will be 0.7.

Theoretical wall thickness for the cylindrical portion of the vessel can be calculated by;

design

design

actual

D P

t

o

=

2

Thickness to resist plastic failure;

(

)

(

)

Where, L is the effective length of the vessel.

Therefore;

)

(

When the actual thickness is calculating, corrosion allowance should be added to the theoretical

thickness. Since SA-240 is used & it is a stainless steel corrosion allowance is not needed.

Therefore;

Critical pressure for elastic failure;

Where K & m are constants depends on

ratio.

D

o

/L

(effective)

K m

0.1 0.185 2.60

0.2 0.224 2.54

0.3 0.229 2.47

0.4 0.246 2.43

0.6 0.516 2.49

0.8 0.660 2.48

1.0 0.879 2.49

1.5 1.572 2.52

2.0 2.364 2.54

3.0 5.144 2.61

4.0 9.037 2.62

5.0 10.359 2.58

For this scenario;

L

h

1

h

2

Assuming linear interpolation is possible K & m were calculated as follows,

D

o

/L

(effective)

K m

0.4 0.246 2.43

0.4414 0.3019 2.4424

0.6 0.516 2.49

According to the FIG HA-1 of the page 712 in ASME section II part D, Youngs modulus of SS grade

304 (SA-240) is 193.1GPa.

Assuming t<<<D

o

& therefore

Since

is 20265Pa,

therefore, vessel could undergo elastic failure.

Now, let

& find the required wall thickness to resist the elastic failure.

Therefore, wall thickness of 5.6683mm will resist the vessel for elastic & plastic failure.

Available plate thickness will be 6mm.

Selection of suitable ends & their calculations

Here are some of available heads& closers.

Dished only

80% dished, 10%

knuckle

Flanged only

hemispherical

ASME flanged

and dished

Standard flanged

dished

Elliptical

Tori-conical

Tori-spherical Conical

When designing a pressure vessel head geometry should be selected based on the design pressure &

the fabrication cost. For this vessel, its possible to use a flat end. But it will need a thickness which is

considerably higher compare to tori-spherical head. Therefore, tori-spherical head is selected. Since

this is a crystallizer, bottom end is obviously a conical end.

- Tori-spherical head

Here; R - Crown radius,

r Knuckle radius

D Outer diameter

t Thickness of the head

h Flanged height

According to the ASME code;

R =

D

r

= 6% D

inner

There are 3 different equations available for calculate h

E

value.

) (

( ) ( ( ))

Minimum value of h

e

is 0.4233

Where; C is the stress concentration factor & given by the following table

t/D

o

h

E

/ D

o

0.00075 0.0005 0.001 0.002 0.005 0.01 0.02 0.04

0.15 5.34 5.50 5.18 4.55 2.66 2.15 1.95 1.75

0.20 2.55 2.60 2.5 2.3 1.7 1.45 1.37 1.32

0.25 1.48 1.50 1.46 1.38 1.14 1 1 1

0.30 0.98 1.00 0.97 0.92 0.77 0.77 0.77 0.77

0.40 0.59 0.59 0.59 0.59 0.59 0.59 0.59 0.59

0.50 0.55 0.55 0.55 0.55 0.55 0.55 0.55 0.55

Its reasonable to assume D

Outer

= D

Mean

since wall thickness is negligible compare to diameter of the

vessel.

Therefore;

Assuming linear interpolation is possible C value is calculated for above ratio.

t/D

o

h

E

/ D

o

0.00075 0.0005 0.001 0.002 0.005 0.01 0.02 0.04

0.15 5.34 5.50 5.18 4.55 2.66 2.15 1.95 1.75

0.1693 4.26 4.38 4.15 - - - - -

0.20 2.55 2.60 2.5 2.3 1.7 1.45 1.37 1.32

When C=4.26;

When C=4.38;

Using above four calculated values, actual C value can be calculated.

Disked section

Knuckle section

Flanged section

(cylinder)

R

C

A

O

h

B

a

R - Crown radius,

r Knuckle radius

D Outer diameter

t Thickness of the head

h Height of knuckle section

OC = R = 2.5m

BC = R - r

= ( )

AB = Din / 2 - r

= ( )

AC = (BC

2

- AB

2

)

=

Sin = AC/ BC

= 2.077/2.35 = 0.8838

= 62.1078

0

h =

=( )

=0.1326m

Dish height = OC ( AC +h)

=2.5-(2.077+0.1326)

=0.2904m

Since thickness of the wall < 25mm;

D

blank

= D

outer

+ D

outer

/42 + 2/3 r

knuckle

+ 2H

flanged

Where,

Therefore; D

blank

= 2.5 + (2.5/42) + 2/3 0.15 + 20.846 m

D

blank

= 4.3515m

- Conical bottom

t Vessel thickness of the cylindrical portion

t

r

Reinforce thickness

= 60

0

value for this bottom is

Assuming extrapolation is possible for the above set of data; corresponding value can be calculated

as 11.11

o

. Therefore the maximum value of without reinforcing is 11.11

o

. But, its not practical to

use such a small value since it will drastically increase height of the vessel. Lets assume = 60

0

.

Then t

c

is given by;

() (

)

Available plate thickness will be 1mm

Reinforce area is given by;

()

13

o

18

o

22

o

25

o

28

o

31

o

8t

8tc

tc

( ). P 6 . 0 cos 2

P

t

design

design

l theoretica

=

o o

design

D

|

.

|

\

| A

=

o

o

o

1

8

tan

2

i

D p

A

A is also given by;

[(

) (

)]

( )

Therefore;

( )

Available plate thickness will be 3mm

Fabrication procedure

Stainless steel is available in several forms & dimensions at market such as Plates, Sheets, Bars and

Forgings. Since this vessel is having moderate diameter its suitable to use stainless steel plates for the

fabrication procedure.

- Shell fabrication

Cutting the plate to obtain required diameter and height by using an Oxy-acetylene flame or

a laser beam. Then the quality of the edge can be mirror smooth, and a precision of around

0.1mm can be obtained.

Crimping this was done prior to rolling process to enhance plate rolling roundness and

efficiency. Crimping sets the correct radius on the ends of the plate and eliminates the

waste of excess material

Heating - The plate is then heated and moved to the rolling mill

Rolling- The rollers work the plate to the proper radius. Then ends of the plate meet at the

proper diameter

Welding-After the plate is formed into cylinders; many welding processes are used to

fabricate the rest of the vessel. Here we have selected that the shell should be welded by a

single grove butt welding.

Heat Treating

Testing- then magnetic particle testing was done.

- Head and End Fabrication

For both Head and bottom 10mm thick torrispherical ends has been selected

1. Select the 10 mm thickness carbon steel blank

2. It is subjected on pressing.

3. Then it is subjected to spinning using a die.

- Shell and ends are welded using single V grove butt joint

Technical drawings of the designed vessel including welding symbols

REFERENCES

http://www.math.wsu.edu/faculty/tsat/files/Potash.pdf

http://www.engineeringtoolbox.com/pressure-d_587.html

http://www.niroinc.com/evaporators_crystallizers/crystallizer_applications.asp

http://www.whiting-equip.com/media/swenson_crystallization.pdf

http://www.matweb.com/search/DataSheet.aspx?MatGUID=25bd2cee70ac40fdaae0acbf5b69dafe

http://www.matweb.com/search/DataSheet.aspx?MatGUID=21eca9c274a2473a8c3587d57d924b52

http://www.walkerep.com/products/products--capabilities/processor-vessels/whey-crystallizer.aspx

http://www.google.cm/imgres?q=crystallizer&hl=fr&sa=X&biw=1366&bih=667&tbm=isch&prmd=i

mvnsfd&tbnid=j1QepKv5xl39VM:&imgrefurl=http://www.mpi-

magdeburg.mpg.de/research/projects/1032/1044&docid=yAPDitdchjtb7M&imgurl=http://www.mpi-

magdeburg.mpg.de/research/projects/1032/1044/granulation.png&w=400&h=364&ei=jQdvT-

nFE5DxrQfJodygDg&zoom=1&iact=hc&vpx=860&vpy=195&dur=905&hovh=214&hovw=235&tx=

125&ty=141&sig=114604428543611562465&page=3&tbnh=143&tbnw=158&start=47&ndsp=26&ve

d=1t:429,r:11,s:47

Potrebbero piacerti anche

- Glycerin Purification Column: Keerthana Baskaran 130686J CH 3060 - Plant and Equipment Design Assignment - 1Documento23 pagineGlycerin Purification Column: Keerthana Baskaran 130686J CH 3060 - Plant and Equipment Design Assignment - 1Keerthana Bas100% (1)

- Chapter 6 - Mechanical DesignDocumento121 pagineChapter 6 - Mechanical DesignohoreyNessuna valutazione finora

- Component DesignDocumento32 pagineComponent Designdaniel hambissaNessuna valutazione finora

- Numerical Problems - Casting PDFDocumento14 pagineNumerical Problems - Casting PDFSubramanian Chidambaram100% (1)

- Welding Rod CalculationDocumento4 pagineWelding Rod CalculationuemaaplNessuna valutazione finora

- Riser DesignDocumento4 pagineRiser DesignJiggy Jick100% (1)

- Problems On CastingDocumento28 pagineProblems On CastingShantha Kumar G C100% (2)

- Tugas Metalurgi Las - Heat Flow in WeldingDocumento4 pagineTugas Metalurgi Las - Heat Flow in WeldingRhidiyan Waroko100% (4)

- Report Fatigue PDFDocumento21 pagineReport Fatigue PDFHassan Aero100% (1)

- CH 3 PDFDocumento20 pagineCH 3 PDFHassaan SajidNessuna valutazione finora

- Homework CastingDocumento6 pagineHomework CastingYassineZklNessuna valutazione finora

- Production Conventional Question and AnswerDocumento10 pagineProduction Conventional Question and AnswerRamesh ChandraNessuna valutazione finora

- FinalDocumento12 pagineFinalchompink6900Nessuna valutazione finora

- Tutorial CastingDocumento4 pagineTutorial CastingFaIz FauziNessuna valutazione finora

- Outokumpu Acom High Strength Stainless Steel For Storage TanksDocumento10 pagineOutokumpu Acom High Strength Stainless Steel For Storage Tankshenrideterding1988Nessuna valutazione finora

- N0174147G Manufacturing ProcessesDocumento10 pagineN0174147G Manufacturing Processesphillip chirongweNessuna valutazione finora

- 6) 6.2 SeparatorDocumento29 pagine6) 6.2 SeparatorPeet AmranNessuna valutazione finora

- FA2015 Torispherical HeadDocumento4 pagineFA2015 Torispherical HeadAshok SureshNessuna valutazione finora

- Tks 3245 Perancangan Alat ProsesDocumento38 pagineTks 3245 Perancangan Alat Prosesfadhillah ivanNessuna valutazione finora

- Watertank GSDocumento24 pagineWatertank GSjnnce420Nessuna valutazione finora

- Agenda Item: 650-569: Title: Shell Design VDP Method, Variable Corrosion Date: ContactDocumento4 pagineAgenda Item: 650-569: Title: Shell Design VDP Method, Variable Corrosion Date: ContactMuhammad ChairulNessuna valutazione finora

- Stiffening Ring Cal For Exteneral Press.Documento11 pagineStiffening Ring Cal For Exteneral Press.inspectormhp100% (1)

- Structural Analysis and Design of Process Equipment - 2018 - Jawad - Sample of Pressure Vessel Design Data SheetsDocumento13 pagineStructural Analysis and Design of Process Equipment - 2018 - Jawad - Sample of Pressure Vessel Design Data SheetsnaveenNessuna valutazione finora

- ISF Aachen Welding Technology Part II PDFDocumento140 pagineISF Aachen Welding Technology Part II PDFscott2355Nessuna valutazione finora

- Tutorial Last AnswerDocumento9 pagineTutorial Last AnswerEswaran ManakorNessuna valutazione finora

- How To Design Concrete Structures Using Eurocode 2 - (3) SlabsDocumento8 pagineHow To Design Concrete Structures Using Eurocode 2 - (3) Slabsbobbytirona566100% (1)

- DC 53 CatalogDocumento4 pagineDC 53 CatalogHonza MičkaNessuna valutazione finora

- Plasma Arc CuttingDocumento13 paginePlasma Arc CuttingSarahNessuna valutazione finora

- Examples and Answers-The Science and Engineering of MaterialsDocumento6 pagineExamples and Answers-The Science and Engineering of MaterialschutiyaNessuna valutazione finora

- Materials and Cold Work of Forming: 2.1 Steel StandardsDocumento23 pagineMaterials and Cold Work of Forming: 2.1 Steel Standardshunter8080Nessuna valutazione finora

- Metal PressworkDocumento32 pagineMetal PressworkLihle Ayabonga NcambacaNessuna valutazione finora

- Unit2B SSDocumento8 pagineUnit2B SSRahul YadavNessuna valutazione finora

- Job Knowledge 95 - Calculating Weld Volume and Weight (July 2008)Documento3 pagineJob Knowledge 95 - Calculating Weld Volume and Weight (July 2008)waleed yehiaNessuna valutazione finora

- Miet2072 C7Documento17 pagineMiet2072 C7vincent02hk_57881301Nessuna valutazione finora

- Alloy Castings: Experimental Analysis of Cylindrical Riser Design For Lm6 AluminiumDocumento10 pagineAlloy Castings: Experimental Analysis of Cylindrical Riser Design For Lm6 AluminiumvengadeshNessuna valutazione finora

- Injection Mold DesignDocumento12 pagineInjection Mold DesignbobNessuna valutazione finora

- Thickness Cal. Fo DM Water Storage Tank-API 650Documento15 pagineThickness Cal. Fo DM Water Storage Tank-API 650Jose Rodriguez50% (2)

- Lecture Mechanical Design of Heat ExchangerDocumento46 pagineLecture Mechanical Design of Heat ExchangerDawitNessuna valutazione finora

- Thin CylinderDocumento10 pagineThin Cylinderarunnical100% (3)

- Heat-Treatment of High Carbon Steel Wire - PatentingDocumento4 pagineHeat-Treatment of High Carbon Steel Wire - Patentingعزت عبد المنعم100% (1)

- Final Exam Key AnswerDocumento6 pagineFinal Exam Key Answergirma worku100% (1)

- Quay Walls - Combined - Wall - Buckling - TubesDocumento12 pagineQuay Walls - Combined - Wall - Buckling - TubesHugo LeiteNessuna valutazione finora

- Calculating Weld Volume and Weight: Welding CostsDocumento4 pagineCalculating Weld Volume and Weight: Welding CostsMehmet SoysalNessuna valutazione finora

- Nptel CombinedDocumento76 pagineNptel CombinedRADHE GRAPHICSNessuna valutazione finora

- Design For RC Flat SlabsDocumento70 pagineDesign For RC Flat SlabsAil Aafaaq100% (3)

- ManPro IJan 2020Documento5 pagineManPro IJan 2020Mansingh YadavNessuna valutazione finora

- PVD Coating-ADocumento12 paginePVD Coating-Arijoy p pNessuna valutazione finora

- Design of Cylindrical Shell Part 2Documento14 pagineDesign of Cylindrical Shell Part 2Tito FebriantoNessuna valutazione finora

- Design of Penstock Pipe For A HydroelectDocumento21 pagineDesign of Penstock Pipe For A Hydroelectjanardhana100% (1)

- Dilli Max 690Documento4 pagineDilli Max 690Fernando Alonso Troncos MendivesNessuna valutazione finora

- WeldDocumento3 pagineWeldSenthil SubramanianNessuna valutazione finora

- Cylinders, Compound Cylinders, Press & Shrink FitsDocumento9 pagineCylinders, Compound Cylinders, Press & Shrink Fitstvsaagar100% (1)

- Vessel, BS5500 Cat-3, Is Followed. The Chamber Is Designed As A Pressure VesselDocumento19 pagineVessel, BS5500 Cat-3, Is Followed. The Chamber Is Designed As A Pressure Vesselbhalchandrak1867Nessuna valutazione finora

- TS7 Unfolding Computation MethodsDocumento11 pagineTS7 Unfolding Computation MethodsNina GregorioNessuna valutazione finora

- IWE4-3 - Residual StressesDocumento16 pagineIWE4-3 - Residual StressesIrmantas ŠakysNessuna valutazione finora

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDa EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsValutazione: 4.5 su 5 stelle4.5/5 (10)

- Chem Academy: Enolate ChemistryDocumento13 pagineChem Academy: Enolate ChemistryHamit RanaNessuna valutazione finora

- Presentation: Darwisa G. Hawari Dip-Ems 1ADocumento35 paginePresentation: Darwisa G. Hawari Dip-Ems 1AZeal Alexis MontellorNessuna valutazione finora

- ARO 2019 PX20X 2 Inch Metallic Diaphragm Pump Manual Fluid SectionDocumento12 pagineARO 2019 PX20X 2 Inch Metallic Diaphragm Pump Manual Fluid Sectionduc tranNessuna valutazione finora

- Potent Antimutagenic Activity of White Tea in Comparison With Green Tea in The Salmonella AssayDocumento15 paginePotent Antimutagenic Activity of White Tea in Comparison With Green Tea in The Salmonella AssayPhan Anh TrịnhNessuna valutazione finora

- RT (Main)Documento16 pagineRT (Main)Keshav Singhal100% (1)

- NT Mat 003 - Assessment of Corrosion Protection Classes For Inorganic Coatings On Steel - Nordtest MethodDocumento7 pagineNT Mat 003 - Assessment of Corrosion Protection Classes For Inorganic Coatings On Steel - Nordtest MethodCorina StanculescuNessuna valutazione finora

- Single Phase Heat Transfer and Pressure Drop Characteristics of Micro-Fin TubesDocumento2 pagineSingle Phase Heat Transfer and Pressure Drop Characteristics of Micro-Fin TubesGerehNessuna valutazione finora

- Torsion I: Prepared By: Nash BonaventuraDocumento25 pagineTorsion I: Prepared By: Nash Bonaventuranashb96Nessuna valutazione finora

- Blueberry Fruit QualityDocumento4 pagineBlueberry Fruit Qualityolga leonNessuna valutazione finora

- Untitled PresentationDocumento10 pagineUntitled Presentationanurag singhNessuna valutazione finora

- ManometerDocumento2 pagineManometerAlexanderSorianoNessuna valutazione finora

- Bitesize Bio SDS-PAGE Cheat Sheet: Essential Buffer and Gel Recipes For Your LaboratoryDocumento4 pagineBitesize Bio SDS-PAGE Cheat Sheet: Essential Buffer and Gel Recipes For Your LaboratoryCristian RuizNessuna valutazione finora

- Coatings Formulation: Bodo Müller - Ulrich PothDocumento285 pagineCoatings Formulation: Bodo Müller - Ulrich PothAdnan HussainNessuna valutazione finora

- The Effect of Polycarboxylate Ethers As Deflocculants in CastablesDocumento4 pagineThe Effect of Polycarboxylate Ethers As Deflocculants in CastablesAmi Sa100% (1)

- Mark Scheme (Results) Summer 2016Documento31 pagineMark Scheme (Results) Summer 2016NaushinNessuna valutazione finora

- 5070 s23 QP 42 MergedDocumento100 pagine5070 s23 QP 42 MergedMuhammad QasimNessuna valutazione finora

- Flootank® Catalogue 2022Documento21 pagineFlootank® Catalogue 2022Anindra Ahmad FarrasNessuna valutazione finora

- PE6705 Water Flooding and Enhanced Oil Recovery L T P C 3 0 0 3 Objective: Unit I 9Documento6 paginePE6705 Water Flooding and Enhanced Oil Recovery L T P C 3 0 0 3 Objective: Unit I 9Prince ImmanuelNessuna valutazione finora

- Pulp Mill Odor ControlDocumento6 paginePulp Mill Odor Controlalakazum28Nessuna valutazione finora

- The Influence of Methanol Concentration To Biodiesel Yield and QualityDocumento5 pagineThe Influence of Methanol Concentration To Biodiesel Yield and QualityOniNessuna valutazione finora

- MasterEmaco S 466 PDFDocumento145 pagineMasterEmaco S 466 PDFSri KanthNessuna valutazione finora

- MSDS BenzeneDocumento3 pagineMSDS BenzeneUmair JavedNessuna valutazione finora

- Cationic and Anionic Redox in Lithium-Ion Based Batteries PDFDocumento18 pagineCationic and Anionic Redox in Lithium-Ion Based Batteries PDFLeilane Natsumi Alves KanbaraNessuna valutazione finora

- Eudragit l100 55 PDFDocumento2 pagineEudragit l100 55 PDFJohnNessuna valutazione finora

- Fish Processing HandoutDocumento1 paginaFish Processing HandoutGre ChieNessuna valutazione finora

- Solutions - Levi a.F.J. Applied Quantum Mechanics.. Solutions Manual (2ed., CUP, 2006) (ISBN 0521860962) (73s) - PQMTBDocumento73 pagineSolutions - Levi a.F.J. Applied Quantum Mechanics.. Solutions Manual (2ed., CUP, 2006) (ISBN 0521860962) (73s) - PQMTBenareshkumar23100% (1)

- Physical Chemistry - R. L. MadanDocumento1 paginaPhysical Chemistry - R. L. MadanOscar Santos EstofaneroNessuna valutazione finora

- Chapter 9 The Endocrine SystemDocumento1 paginaChapter 9 The Endocrine SystemacNessuna valutazione finora

- Class 6 Asm 1 Science Chemistry Unit 1: Sorting Separation and ChangesDocumento2 pagineClass 6 Asm 1 Science Chemistry Unit 1: Sorting Separation and Changessipdas 10a100% (1)