Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Distillation Column Design Exercise PDF

Caricato da

Hari Purwito0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

279 visualizzazioni1 paginaA distillation column needs to be designed to separate dichlorobenzene (DCB) from a high-boiling reaction product. Sieve trays and valve trays need to be designed for the 20 actual trays required. Sieve trays are best for low vapor flow rates and valve trays are best for high vapor flow rates. The column conditions including flow rates, pressures, temperatures, and material properties are provided to inform the design of the trays.

Descrizione originale:

Titolo originale

Distillation Column Design Exercise.pdf

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoA distillation column needs to be designed to separate dichlorobenzene (DCB) from a high-boiling reaction product. Sieve trays and valve trays need to be designed for the 20 actual trays required. Sieve trays are best for low vapor flow rates and valve trays are best for high vapor flow rates. The column conditions including flow rates, pressures, temperatures, and material properties are provided to inform the design of the trays.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

279 visualizzazioni1 paginaDistillation Column Design Exercise PDF

Caricato da

Hari PurwitoA distillation column needs to be designed to separate dichlorobenzene (DCB) from a high-boiling reaction product. Sieve trays and valve trays need to be designed for the 20 actual trays required. Sieve trays are best for low vapor flow rates and valve trays are best for high vapor flow rates. The column conditions including flow rates, pressures, temperatures, and material properties are provided to inform the design of the trays.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

Distillation-Tray

Selection and Design

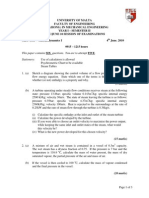

Design the trays for a distillation column separating dichlorobenzene (DCB from a high-boiling reaction product. Include design for sieve trays and valve trays, and discuss the application of each. The product is temperature-sensitive, so sump pressure should be held at about 100 mmHg (3.9 inHg or 0.13 bar). The separation requires 20 actual trays. Column Conditions in the top section are as follows: Vapor Flow Rate = 69,000 lb/h (31,300 kg/h) Liquid Flow Rate = 20,100 lb/h (9120 kg/h) Liquid Viscosity = 0.35 cP (3.5 x 10-4 Pa.s) Liquid Density = 76.7 lb/ft3 (1230 kg/m3) Surface Tension of DCB Liquid = 16.5 dyn/cm (1.65 x 10-4 N/cm) Temperature (average for top section) = 200oF (366 K) Pressure (average for top section) = 50 mmHg (6.67 kPa) Molecular Weight of DCB = 147 Note: Pressure drop for the vapor stream is assumed to be 3 mmHg (0.4 kPa) per tray; therefore, the pressure at the top of the column is set at 40 mmHg (5.3 kPa), given that the sump pressure is to be no greater than 100 mmHg (13.3 kPa).

NOTE: The pressure for the question should be changed for each person. Use the last two digits of your student number added to the pressure. For example: the pressure is 100 mmHg and your student ID number is: 1006358331. Add 31 to the 100 mmHg. Therefore the pressure becomes 131 mmHg.

Potrebbero piacerti anche

- GASES With Varying Path LengthDocumento12 pagineGASES With Varying Path LengthKristine Ann VillanuevaNessuna valutazione finora

- Distillation Column1Documento49 pagineDistillation Column1chaitanyavura0% (1)

- ME4225 Quiz #2 - SolutionDocumento2 pagineME4225 Quiz #2 - Solutionjaysonly90Nessuna valutazione finora

- Process Line Sizing Task and Solution PDFDocumento4 pagineProcess Line Sizing Task and Solution PDFKamalNessuna valutazione finora

- Guid To Design of EvaporatorDocumento40 pagineGuid To Design of Evaporatorscranderi100% (2)

- Distillation Column Design in Separating Ethanol-Water MixtureDocumento16 pagineDistillation Column Design in Separating Ethanol-Water MixtureSata Ajjam75% (4)

- Process Equipment DesignDocumento29 pagineProcess Equipment Designt_prithvi0% (1)

- Gas Dynamics and Jet PropulsionDocumento2 pagineGas Dynamics and Jet PropulsionAnonymous f1UCK4Nessuna valutazione finora

- A Centrifugal Pump Is Drawing Water From An Overhead Tank - Autosaved - AutosavedDocumento16 pagineA Centrifugal Pump Is Drawing Water From An Overhead Tank - Autosaved - AutosavedAkshat KhandelwalNessuna valutazione finora

- FCU and Flow Rates For Air, Condensate and Chilled WaterDocumento6 pagineFCU and Flow Rates For Air, Condensate and Chilled WaterAhmed Hassan100% (1)

- Cooling Tower Formulas and Tables PDFDocumento2 pagineCooling Tower Formulas and Tables PDFRoozbeh PNessuna valutazione finora

- Distillation Column Design GuideDocumento49 pagineDistillation Column Design GuideMercy John71% (7)

- Problem of Heat Exchanger DesignDocumento15 pagineProblem of Heat Exchanger DesignSumit KaushikNessuna valutazione finora

- Tutorial Problems StatementDocumento21 pagineTutorial Problems StatementAbni AbhiNessuna valutazione finora

- Tutorial QuestionsDocumento6 pagineTutorial QuestionsLadnilrebNessuna valutazione finora

- Tutorial 8Documento3 pagineTutorial 8CHANDAN RAJNessuna valutazione finora

- Bry MomentumDocumento13 pagineBry MomentumBryan ManaliliNessuna valutazione finora

- CompressibleFlow PracticeProblemsDocumento42 pagineCompressibleFlow PracticeProblemsmavilla10100% (1)

- Tutorial Questions 1111Documento6 pagineTutorial Questions 1111Fahmy Muhd100% (1)

- Problem Set 1 For All The Problems State The Assumptions You Consider ClearlyDocumento2 pagineProblem Set 1 For All The Problems State The Assumptions You Consider ClearlychandrahasNessuna valutazione finora

- HEAT TRANSFER - Heat Exchanger Design - HandoutDocumento22 pagineHEAT TRANSFER - Heat Exchanger Design - HandoutTrong PhatNessuna valutazione finora

- Worked Problems Heat ExchangersDocumento18 pagineWorked Problems Heat Exchangers521 Balaji ONessuna valutazione finora

- Set 8 AnsDocumento14 pagineSet 8 AnsMuhammad RomzuddinNessuna valutazione finora

- MEC1405 - Thermodynamics I (2009Documento3 pagineMEC1405 - Thermodynamics I (2009Maria CutajarNessuna valutazione finora

- Tutorial Slides - Internal Forced Convection & Natural ConvectionDocumento31 pagineTutorial Slides - Internal Forced Convection & Natural ConvectionVivaan Sharma75% (4)

- Double Pipe Heat Exchanger - SsDocumento72 pagineDouble Pipe Heat Exchanger - SsNathanian100% (2)

- Lesson No. 1 - Pipe Sizing HydraulicsDocumento4 pagineLesson No. 1 - Pipe Sizing Hydraulicsusaid saifullahNessuna valutazione finora

- Bubble Cap Plate For Distillation ColumnDocumento26 pagineBubble Cap Plate For Distillation Columnsanjukec100% (2)

- Mathematics - B 02/08/1999 Instructions:: Answer Any TwoDocumento4 pagineMathematics - B 02/08/1999 Instructions:: Answer Any TwoKiran Gayakwad100% (1)

- Sample Problems in Industrial Plant DesignDocumento26 pagineSample Problems in Industrial Plant DesignSdhfdh Hdfhd100% (1)

- Classroom Examples of HysysDocumento5 pagineClassroom Examples of HysysRahul TavadareNessuna valutazione finora

- ASEN3113 HW5 Solutions PART1Documento7 pagineASEN3113 HW5 Solutions PART1Jikni NobleNessuna valutazione finora

- Assignment 2 SolutionDocumento3 pagineAssignment 2 SolutionJacob Johnston100% (1)

- Basic Data & Course Rules of ThumbDocumento10 pagineBasic Data & Course Rules of Thumbburhan kathiriaNessuna valutazione finora

- CCTD101B Engineering Thermodynamics Tutorial 1 - Basic Concepts and DefinitionsDocumento2 pagineCCTD101B Engineering Thermodynamics Tutorial 1 - Basic Concepts and Definitionsgaurie50% (2)

- Boiler Drum Level Transmitter CalibrationDocumento5 pagineBoiler Drum Level Transmitter Calibrationnineapril82Nessuna valutazione finora

- 2017 06 26 ESTAD TBM Cold Model CSADocumento13 pagine2017 06 26 ESTAD TBM Cold Model CSAwillian limaNessuna valutazione finora

- 0.5 Pretest Day2Documento15 pagine0.5 Pretest Day2Janica Palangeo100% (1)

- Chapter 10: Refrigeration and Heat Pump Systems: Maae 3400: Applied Thermodynamics Problem Set 4Documento2 pagineChapter 10: Refrigeration and Heat Pump Systems: Maae 3400: Applied Thermodynamics Problem Set 4Mohd Ridzuan RozaidiNessuna valutazione finora

- Lecture 2Documento172 pagineLecture 2Ahmed ShahabiNessuna valutazione finora

- First LAw of Thermodynamics - Open SYstemDocumento12 pagineFirst LAw of Thermodynamics - Open SYstemJannineNessuna valutazione finora

- Problemas Mec Fluidos MoyDocumento6 pagineProblemas Mec Fluidos MoyKrlitos Alberto Soria OrnelasNessuna valutazione finora

- Design A Distillation Column With A Total Condenser and Partial Re Boiler For The Following SeparationDocumento41 pagineDesign A Distillation Column With A Total Condenser and Partial Re Boiler For The Following SeparationSihanu Subasingha100% (1)

- Fluid Properties (HW1)Documento4 pagineFluid Properties (HW1)Jamiel CatapangNessuna valutazione finora

- CompressibleFlow PracticeProblemsDocumento42 pagineCompressibleFlow PracticeProblemsGautam KadianNessuna valutazione finora

- ME Thermodynamics II: Vapor Power CyclesDocumento11 pagineME Thermodynamics II: Vapor Power CyclesJasmine_lai00Nessuna valutazione finora

- Q and A Problem Solving ReliefDocumento3 pagineQ and A Problem Solving ReliefCharlotte Bacani SamilinNessuna valutazione finora

- THERMO1 - 4 Control Volume PDFDocumento11 pagineTHERMO1 - 4 Control Volume PDFEdmark AldeaNessuna valutazione finora

- 619PT304Documento4 pagine619PT304arpit gargNessuna valutazione finora

- Ch03 SolutionsDocumento26 pagineCh03 Solutionsacz1234Nessuna valutazione finora

- CHE 480 Practice Questions-10Documento15 pagineCHE 480 Practice Questions-10harisjawedNessuna valutazione finora

- Ped QuestionsDocumento11 paginePed QuestionsYashPatel100% (1)

- Control Valve Sizing ExampleDocumento3 pagineControl Valve Sizing Exampleuetian729Nessuna valutazione finora

- ME3100 Solution Tut-2Documento8 pagineME3100 Solution Tut-2B V V HANUMA GAYATHRINessuna valutazione finora

- Errata SolnsDocumento14 pagineErrata SolnsnickNessuna valutazione finora

- If Time Permits Continue With The Following ExercisesDocumento3 pagineIf Time Permits Continue With The Following ExercisesGregory Eleazar D. AngelesNessuna valutazione finora

- CH 05 WEDocumento43 pagineCH 05 WEBeauponte Pouky MezonlinNessuna valutazione finora

- Tender Review Lombok 2 CFPP 2 X 50 MWDocumento6 pagineTender Review Lombok 2 CFPP 2 X 50 MWHari PurwitoNessuna valutazione finora

- PERP Program - Isoprene/Bioisoprene: Routes Via C5 StreamsDocumento3 paginePERP Program - Isoprene/Bioisoprene: Routes Via C5 StreamsHari PurwitoNessuna valutazione finora

- Plastics: The IssuesDocumento2 paginePlastics: The IssuesHari PurwitoNessuna valutazione finora

- Biomaterials: The Potential For Bio-Isoprene: Commercial StatusDocumento3 pagineBiomaterials: The Potential For Bio-Isoprene: Commercial StatusHari PurwitoNessuna valutazione finora

- Dynamic Modeling Using UniSim Design 2013engDocumento129 pagineDynamic Modeling Using UniSim Design 2013engHari PurwitoNessuna valutazione finora

- PV Newsletter - Volume 2012 Issue 7Documento8 paginePV Newsletter - Volume 2012 Issue 7Hari PurwitoNessuna valutazione finora

- Distillation Column Design Guidance PDFDocumento10 pagineDistillation Column Design Guidance PDFHari PurwitoNessuna valutazione finora

- CV EngDocumento2 pagineCV EngHari PurwitoNessuna valutazione finora

- CV EngDocumento2 pagineCV EngHari PurwitoNessuna valutazione finora

- Error CodesDocumento10 pagineError CodesAlgie ReñonNessuna valutazione finora

- Fig. 1: Clap Switch Block DiagramDocumento26 pagineFig. 1: Clap Switch Block DiagramDiljot Singh 236Nessuna valutazione finora

- Dynamic of Bow RotorDocumento20 pagineDynamic of Bow Rotormh1999Nessuna valutazione finora

- Fast Bus Changeover PDFDocumento8 pagineFast Bus Changeover PDFhussainNessuna valutazione finora

- Ground Fault Protection Expert Guide PDFDocumento54 pagineGround Fault Protection Expert Guide PDFClaudNessuna valutazione finora

- Mass Volume Density Notes PDFDocumento17 pagineMass Volume Density Notes PDFNadya PutriNessuna valutazione finora

- TN17-1003 Pruebas de NucleoDocumento6 pagineTN17-1003 Pruebas de NucleoAlonsoNessuna valutazione finora

- Engr302 - Lecture 6 - Capacitance and Laplace's EquationDocumento64 pagineEngr302 - Lecture 6 - Capacitance and Laplace's EquationNitin KathuriaNessuna valutazione finora

- SMPS & UpsDocumento22 pagineSMPS & UpsDudley Mosy ChifengaNessuna valutazione finora

- OptiCem RT SystemDocumento1 paginaOptiCem RT SystemJean CarlosNessuna valutazione finora

- Math Seminar 2022Documento9 pagineMath Seminar 2022Joefoe JalandoniNessuna valutazione finora

- Electromagnetic Field Theory Solution BTETC501 - 1Documento19 pagineElectromagnetic Field Theory Solution BTETC501 - 1College use EducationNessuna valutazione finora

- NPC Power System Protection PhilosophyDocumento60 pagineNPC Power System Protection PhilosophySellappan Muthusamy100% (3)

- Busbar Eet414Documento34 pagineBusbar Eet414yahyeNessuna valutazione finora

- Ild1, Ild2, Ild5, Ilq1, Ilq2: Vishay SemiconductorsDocumento10 pagineIld1, Ild2, Ild5, Ilq1, Ilq2: Vishay SemiconductorsTan Hung LuuNessuna valutazione finora

- SVP 917 ManualDocumento8 pagineSVP 917 ManualGalvao.endNessuna valutazione finora

- ProperDocumento21 pagineProperPhysics loverNessuna valutazione finora

- Iot Based Smart Energy Management SystemDocumento11 pagineIot Based Smart Energy Management Systeminnovative VijayawadaNessuna valutazione finora

- Cuk Trainer ManualDocumento6 pagineCuk Trainer ManualShankar ArunmozhiNessuna valutazione finora

- Application Problems 1Documento3 pagineApplication Problems 1DianaLaura AlvarezNessuna valutazione finora

- Imaginary TimeDocumento2 pagineImaginary TimeSally MoremNessuna valutazione finora

- Insulators 101 Panel Final ADocumento84 pagineInsulators 101 Panel Final ABlakeNessuna valutazione finora

- Physics ExperimentDocumento3 paginePhysics ExperimentKush Gautam0% (1)

- Schematic Diagram of 220 /132 /54 KV Traction SubstationDocumento1 paginaSchematic Diagram of 220 /132 /54 KV Traction SubstationjitendraNessuna valutazione finora

- XQ1475 Lehx0010 01Documento8 pagineXQ1475 Lehx0010 01gsantosh06Nessuna valutazione finora

- ATS48 User ManualDocumento85 pagineATS48 User Manualkythuat04 nteNessuna valutazione finora

- Revisi AnggaranDocumento11 pagineRevisi Anggaranmas udinNessuna valutazione finora

- Flare Calc Sheet API RP 521Documento9 pagineFlare Calc Sheet API RP 521Clarence AG YueNessuna valutazione finora

- Mine Environment by Prof. G.B. Mishra PDFDocumento322 pagineMine Environment by Prof. G.B. Mishra PDFsaurabh singh100% (1)

- Module 2 Dynamics Roller Coaster Depth Study 63174ef8a89d4Documento16 pagineModule 2 Dynamics Roller Coaster Depth Study 63174ef8a89d4Athul JitheshNessuna valutazione finora

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionDa EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionValutazione: 4.5 su 5 stelle4.5/5 (3)

- Bulk Material Handling: Practical Guidance for Mechanical EngineersDa EverandBulk Material Handling: Practical Guidance for Mechanical EngineersValutazione: 5 su 5 stelle5/5 (1)

- Laws of UX: Using Psychology to Design Better Products & ServicesDa EverandLaws of UX: Using Psychology to Design Better Products & ServicesValutazione: 5 su 5 stelle5/5 (9)

- Transformed: Moving to the Product Operating ModelDa EverandTransformed: Moving to the Product Operating ModelValutazione: 4 su 5 stelle4/5 (1)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDa EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedValutazione: 5 su 5 stelle5/5 (1)

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneDa EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneValutazione: 4.5 su 5 stelle4.5/5 (5)

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CDa EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CNessuna valutazione finora

- The Laws of Thermodynamics: A Very Short IntroductionDa EverandThe Laws of Thermodynamics: A Very Short IntroductionValutazione: 4.5 su 5 stelle4.5/5 (10)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsDa EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNessuna valutazione finora

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ADa EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANessuna valutazione finora

- Basic Digital Signal Processing: Butterworths Basic SeriesDa EverandBasic Digital Signal Processing: Butterworths Basic SeriesValutazione: 5 su 5 stelle5/5 (1)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tDa EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tValutazione: 4.5 su 5 stelle4.5/5 (27)

- Mechanical Vibrations and Condition MonitoringDa EverandMechanical Vibrations and Condition MonitoringValutazione: 5 su 5 stelle5/5 (1)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseDa EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseValutazione: 4.5 su 5 stelle4.5/5 (51)

- Airplane Flying Handbook: FAA-H-8083-3C (2024)Da EverandAirplane Flying Handbook: FAA-H-8083-3C (2024)Valutazione: 4 su 5 stelle4/5 (12)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisDa EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisValutazione: 4 su 5 stelle4/5 (2)

- Cyber-Physical Systems: Foundations, Principles and ApplicationsDa EverandCyber-Physical Systems: Foundations, Principles and ApplicationsHoubing H. SongNessuna valutazione finora

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionDa EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionNessuna valutazione finora

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureDa EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureValutazione: 4.5 su 5 stelle4.5/5 (2)

- Safety Theory and Control Technology of High-Speed Train OperationDa EverandSafety Theory and Control Technology of High-Speed Train OperationValutazione: 5 su 5 stelle5/5 (2)

- Electrical (Generator and Electrical Plant): Modern Power Station PracticeDa EverandElectrical (Generator and Electrical Plant): Modern Power Station PracticeValutazione: 4 su 5 stelle4/5 (9)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideDa Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideValutazione: 3.5 su 5 stelle3.5/5 (7)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDa EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsValutazione: 3.5 su 5 stelle3.5/5 (3)