Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

QSB Audit1

Caricato da

meca2aTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

QSB Audit1

Caricato da

meca2aCopyright:

Formati disponibili

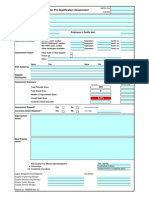

QUALITY SYSTEMS BASICS AUDIT

EVIDENCE REQUIRED LOOK FOR COMMENTS

SCORE R/Y/G

LAYERED PROCESS AUDITS

Is there a system in place to verify the documented manufacturing/assembly process through layered audits?

A defined Layered Process Audit procedure that is owned by manufacturing. 1) 2) 3) 4) Written Procedure Audit & work instructions Counter measure process Owned by Manufacturing

All levels of the organization participate in Layered Process Audits at established frequencies.

1) Audit Schedule showing level of participation and frequency. 2) Evidence that ALL layers of the organization perform regularly scheduled standardized audits. Plant Manager should be monthly, Shift Leaders and Management Support Staff - Weekly, Group Leader-Team Leaders-Daily. 3) Tracking to ensure every work station is evaluated on regular basis. Audit Check sheet includes: 1) Quality Focused checks for past customer failures. (i.e. Assigned Workstation, Quality (Customer Focus), at Fast Response, for PRR or Liaison Report issues, error-proofing and System high risk items. verification, etc...) 2) Workstation Specific check items (Review of actual work performed by Team Members to standardized work instructions, 5S-WPO, Rotation Log, Training, etc..) 3) Work Station and Quality Focused items are checked by all auditors. 4) System Specific items (Preventative Maintenance, Business Plan reviews, Shop Floor Management standards, etc..) Process specific audits are performed (CQI 9, 11, 12, Weld Audit, Chrome Audit, Paint Process Audit etc.) System to review and document the results of the audit. 1) Verification in the Layered Process Audit under system specific items that, where applicable, Audits for special processes are performed. 1) Results reviewed with team members & area supervisors 2) Evidence and documentation of immediate corrective action for nonconformance. (Items corrected immediately) All deviations are recorded on the check 3) Countermeasure list with responsibility and dates for items that sheet. could not be corrected immediately. 4) Review of counter measure process at least once per week. 5) When appropriate nonconformance is added to Fast Response or C.A.R.E. BEST PRACTICE: Check that the Audits are verified by the next level Supervisor. Addition of Layered Process Audit issues to the Lessons Learned system. Audit results are summarized and reviewed by manufacturing site leadership. 1) Lessons Learned system, documentation.

0

1) Reports or graphics that are reviewed by management.

R R

28

0

SCORE / POTENTIAL 0

QSB Audit form 07.04

1 of 1

Rev 20090213

Potrebbero piacerti anche

- IATF 16949:2016 Audit Guide and Checklist 2nd EditionDa EverandIATF 16949:2016 Audit Guide and Checklist 2nd EditionValutazione: 4.5 su 5 stelle4.5/5 (10)

- Lear-75-GM Quality System Basics Audit FormDocumento12 pagineLear-75-GM Quality System Basics Audit FormalexrferreiraNessuna valutazione finora

- Layered AuditDocumento5 pagineLayered AuditlugarxNessuna valutazione finora

- 1.1. Overview of System X: Development ProjectDocumento17 pagine1.1. Overview of System X: Development Projectmathewk000Nessuna valutazione finora

- GM 1927-30 QSB Audit Master - Final011811Documento16 pagineGM 1927-30 QSB Audit Master - Final011811Mohammad GadNessuna valutazione finora

- RS Test Plan Sample of ProjectDocumento30 pagineRS Test Plan Sample of Projectrsingh2310Nessuna valutazione finora

- GM 1927 36 Quality System Basic Marzo 2009 LpasDocumento26 pagineGM 1927 36 Quality System Basic Marzo 2009 LpasFrancisco Javier Manzo100% (1)

- The Audit ProcessDocumento21 pagineThe Audit ProcessMariale GBNessuna valutazione finora

- Layered Audit Process: Global Supply ManagementDocumento5 pagineLayered Audit Process: Global Supply Management주호돈Nessuna valutazione finora

- Layered Audit Process: PurposeDocumento8 pagineLayered Audit Process: PurposeNavnath TamhaneNessuna valutazione finora

- SAP Technical AuditDocumento5 pagineSAP Technical AuditSuryanarayana TataNessuna valutazione finora

- GM 1927 36 Quality System Basic Marzo 2009 Lpas PDFDocumento26 pagineGM 1927 36 Quality System Basic Marzo 2009 Lpas PDFmedi38Nessuna valutazione finora

- LPA - Layer Process Audit GuidelinesDocumento23 pagineLPA - Layer Process Audit GuidelinesR J100% (2)

- IATF16949+Chapter+33 +Internal+AuditsDocumento19 pagineIATF16949+Chapter+33 +Internal+AuditsSathish Kumar RockkzzNessuna valutazione finora

- 141 ISACA NACACS Auditing IT Projects Audit ProgramDocumento85 pagine141 ISACA NACACS Auditing IT Projects Audit ProgramkirwanicholasNessuna valutazione finora

- Auditoria Por CapasDocumento23 pagineAuditoria Por Capasmpedraza-1Nessuna valutazione finora

- 7-IF-QMS-07 Internal AuditDocumento6 pagine7-IF-QMS-07 Internal AuditGourav SainiNessuna valutazione finora

- BUSINESS PROCESS: Calibration Process Overview: ASISDocumento4 pagineBUSINESS PROCESS: Calibration Process Overview: ASISVikas SharmaNessuna valutazione finora

- PRC1002Documento3 paginePRC1002AlineNessuna valutazione finora

- ISO 9000 Solutions, Inc.: Free Download - 2000Documento11 pagineISO 9000 Solutions, Inc.: Free Download - 2000tlidiaNessuna valutazione finora

- Audit Checklist (ISO) Internal AuditDocumento2 pagineAudit Checklist (ISO) Internal Auditnithyachatsu100% (1)

- 141 ISACA NACACS Auditing IT Projects Audit ProgramDocumento86 pagine141 ISACA NACACS Auditing IT Projects Audit Programkautaliya100% (6)

- 01 Supplier Pre-Qualification AssessmentDocumento18 pagine01 Supplier Pre-Qualification AssessmentChinh Lê Đình100% (1)

- Process Verification Audit ChecklistDocumento5 pagineProcess Verification Audit Checklistriki3xNessuna valutazione finora

- General Process Audit QuestionsDocumento8 pagineGeneral Process Audit QuestionsTracy TreacherNessuna valutazione finora

- IRIS Top 25 QuestionsDocumento4 pagineIRIS Top 25 QuestionsAndrew KerrNessuna valutazione finora

- New Vendor System Audit Check SheetDocumento6 pagineNew Vendor System Audit Check SheetJetesh Devgun83% (6)

- ITG-Internal Control MatrixDocumento14 pagineITG-Internal Control Matrixbladexdark67% (3)

- ISO 9001 Audit Checklist in Human EnglishDocumento9 pagineISO 9001 Audit Checklist in Human EnglishBryant Castillo Gonzalez50% (2)

- ITG-Internal Control MatrixDocumento14 pagineITG-Internal Control MatrixfeesmoNessuna valutazione finora

- Audit Checklist 9001 13485 21 CFR 820Documento66 pagineAudit Checklist 9001 13485 21 CFR 820Zoli0984100% (5)

- Integrated Internal Audit ProcedureDocumento1 paginaIntegrated Internal Audit ProcedureJuan Enric ElricNessuna valutazione finora

- Process Audit ChecklistDocumento17 pagineProcess Audit ChecklistKeith Hoodless100% (1)

- QF-822-01-Internal Quality Management Audit Report PDFDocumento5 pagineQF-822-01-Internal Quality Management Audit Report PDFJAYFLOR PLANOSNessuna valutazione finora

- SAP Baseline Security Audit: Essential Technical ControlsDocumento5 pagineSAP Baseline Security Audit: Essential Technical ControlsRanjeet SinghNessuna valutazione finora

- 9001 Planning Checklist - Production ProcessDocumento14 pagine9001 Planning Checklist - Production ProcessAmer RahmahNessuna valutazione finora

- ISO/TS 16949:2009 Checklist - QWBT Issue: Ref. Question CommentsDocumento40 pagineISO/TS 16949:2009 Checklist - QWBT Issue: Ref. Question CommentsleadyourlifeNessuna valutazione finora

- Chapter 34. Business Planning & Management Review: 6.2.2.1 Quality Objectives and Planning To Achieve Them-SupplementalDocumento14 pagineChapter 34. Business Planning & Management Review: 6.2.2.1 Quality Objectives and Planning To Achieve Them-SupplementalVijayendran VijayNessuna valutazione finora

- PDCA - Appendix A PDFDocumento12 paginePDCA - Appendix A PDFcristinaNessuna valutazione finora

- 141 Auditing IT Projects Audit Report TemplateDocumento12 pagine141 Auditing IT Projects Audit Report Templatekirwanicholas100% (2)

- Software - Engg Chap 05.4Documento25 pagineSoftware - Engg Chap 05.4mylove6947Nessuna valutazione finora

- ISO 9001 - 2008 ChecksheetDocumento14 pagineISO 9001 - 2008 ChecksheetSachin KumbharNessuna valutazione finora

- Project Management Process/phases of Management Process: PlanningDocumento9 pagineProject Management Process/phases of Management Process: PlanningusmankcroadNessuna valutazione finora

- PowerPoint Presentation FAI AS9102Documento29 paginePowerPoint Presentation FAI AS9102Danny Fydm OliveiraNessuna valutazione finora

- Quality Management: GoalsDocumento3 pagineQuality Management: GoalsVasile DanNessuna valutazione finora

- Cqi 11Documento73 pagineCqi 11dwimukh360Nessuna valutazione finora

- Process Interaction Matrix ArticleDocumento4 pagineProcess Interaction Matrix Articlevasudeva yasasNessuna valutazione finora

- Audit Program ItDocumento25 pagineAudit Program ItabdulNessuna valutazione finora

- SEQA-Session-5 Software Quality AssuranceDocumento110 pagineSEQA-Session-5 Software Quality Assurance14Sarthak KarkeraNessuna valutazione finora

- Development of Quality System For Engine AssemblyDocumento55 pagineDevelopment of Quality System For Engine AssemblysvrbchaudhariNessuna valutazione finora

- Software EngineeringDocumento7 pagineSoftware Engineeringfareedullahhamdard7Nessuna valutazione finora

- Why Do We Test Software?Documento38 pagineWhy Do We Test Software?Phalguna SatishNessuna valutazione finora

- QSP 05 Internal Audits REV 1Documento7 pagineQSP 05 Internal Audits REV 1kmvimal36Nessuna valutazione finora

- Pharmaceutical Deviation Report System QMS-035 SampleDocumento9 paginePharmaceutical Deviation Report System QMS-035 SampleMostafa FawzyNessuna valutazione finora

- Software Quality Assurance: CIS 375 Bruce R. Maxim UM-DearbornDocumento36 pagineSoftware Quality Assurance: CIS 375 Bruce R. Maxim UM-DearbornSabahat HussainNessuna valutazione finora

- Free Ts 16949 Audit ChecklistDocumento8 pagineFree Ts 16949 Audit ChecklistKumaravel100% (1)

- Verification and ValidationDocumento1 paginaVerification and ValidationPhanindrasai BoyapatiNessuna valutazione finora

- GM 1927-30 QSB AuditDocumento38 pagineGM 1927-30 QSB Auditmanune01Nessuna valutazione finora

- Information Systems Auditing: The IS Audit Testing ProcessDa EverandInformation Systems Auditing: The IS Audit Testing ProcessValutazione: 1 su 5 stelle1/5 (1)

- Automatic Railway Gate Control SystemDocumento24 pagineAutomatic Railway Gate Control SystemDIPAK VINAYAK SHIRBHATE100% (12)

- Antenna PrimerDocumento14 pagineAntenna PrimerStephen Dunifer100% (3)

- ESS PASI SEISMIC CivilEngineering Seismograph CE-3SDocumento2 pagineESS PASI SEISMIC CivilEngineering Seismograph CE-3SRaydenTeuinkNessuna valutazione finora

- EMI EMC Project ReportDocumento55 pagineEMI EMC Project ReportAshish Agarwal80% (5)

- Ivd Symbols FinalDocumento14 pagineIvd Symbols FinalDennis ChenNessuna valutazione finora

- Datasheet Borne SiemensDocumento3 pagineDatasheet Borne Siemenslorentz franklinNessuna valutazione finora

- On API 650Documento52 pagineOn API 650ferdad79% (19)

- HRSG Design and Operation On Unit Reliability and Remaining LifeDocumento74 pagineHRSG Design and Operation On Unit Reliability and Remaining LifeNisal PereraNessuna valutazione finora

- SJ 9 PDFDocumento52 pagineSJ 9 PDFNicolas X FloresNessuna valutazione finora

- sw8 chp06Documento22 paginesw8 chp06api-115560904Nessuna valutazione finora

- 17118Documento5 pagine17118hairilmasonNessuna valutazione finora

- Ddal Players Guide v5Documento12 pagineDdal Players Guide v5Jakob Cherpovsky100% (1)

- Performance Measurement. The ENAPS ApproachDocumento33 paginePerformance Measurement. The ENAPS ApproachPavel Yandyganov100% (1)

- Dual Prime Source Datasheet 1Documento1 paginaDual Prime Source Datasheet 1EstebanNessuna valutazione finora

- のわる式証明写真メーカー|PicrewDocumento1 paginaのわる式証明写真メーカー|PicrewpapafritarancheraNessuna valutazione finora

- Network Design IssuesDocumento13 pagineNetwork Design IssuesMustur Raghunath ReddyNessuna valutazione finora

- UHP Water Jetting Unit: Ultrabar 10 ECDocumento1 paginaUHP Water Jetting Unit: Ultrabar 10 ECFrederik CañabiNessuna valutazione finora

- UNIC Jakarta Internship ApplicationDocumento4 pagineUNIC Jakarta Internship ApplicationMuhammad IkhsanNessuna valutazione finora

- PT 100 Operators ManualDocumento15 paginePT 100 Operators ManualSerhiiNessuna valutazione finora

- Workbook Answer Key Unit 9 Useful Stuff - 59cc01951723dd7c77f5bac7 PDFDocumento2 pagineWorkbook Answer Key Unit 9 Useful Stuff - 59cc01951723dd7c77f5bac7 PDFarielveron50% (2)

- Yamaha Acoustic GuitarsDocumento18 pagineYamaha Acoustic Guitarsrusf123100% (5)

- DORP Action PlanDocumento3 pagineDORP Action PlanSantisas Zai100% (3)

- Aksesoris PumpDocumento10 pagineAksesoris PumpDido AlexanNessuna valutazione finora

- Checkpoint R65 QoS Admin GuideDocumento220 pagineCheckpoint R65 QoS Admin GuidePradeep_KNVPNessuna valutazione finora

- Heat Load Computation Sheet: Phil. Setting DB 92°F WB 81°F RH 60% + 5%Documento2 pagineHeat Load Computation Sheet: Phil. Setting DB 92°F WB 81°F RH 60% + 5%Zubenel MaicongNessuna valutazione finora

- 3 SuperjunctionDocumento5 pagine3 SuperjunctionharibadriNessuna valutazione finora

- Topic 1 Valve and Instrumentation SymbolsDocumento8 pagineTopic 1 Valve and Instrumentation SymbolshatiniNessuna valutazione finora

- Reconfigurable Vivaldi Antenna With Improved Gain For Uwb ApplicationsDocumento5 pagineReconfigurable Vivaldi Antenna With Improved Gain For Uwb ApplicationsSubhanjali MyneniNessuna valutazione finora

- Aspen Plus Model For Moving Bed Coal GasifierDocumento30 pagineAspen Plus Model For Moving Bed Coal GasifierAzharuddin_kfupm100% (2)

- Versidrain 30: Green RoofDocumento2 pagineVersidrain 30: Green RoofMichael Tiu TorresNessuna valutazione finora