Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Approximate RT Calculation For API 650 Tank

Caricato da

jayaarnavTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Approximate RT Calculation For API 650 Tank

Caricato da

jayaarnavCopyright:

Formati disponibili

REFERENCE: WELDED TANKS FOR OIL STORAGE | API STANDARD 650 | ELEVENTH EDITION, JUNE 2007 | ADDENDUM 1: NOVEMBER

2008 | ADDENDUM 2: NOVEMBER 2009 | EFFECTIVE DATE: MAY 1, 2010 haseebahm@gmail.com DEVELOPED AND DISTRIBUTED BY: HASEEB AHMED | ISSUE DATE: 16 June, 2012 | FOR COMMENTS / SUGGESTIONS PLEASE CONTACT AT

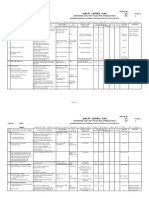

APPROXIMATE RT SPOT CALCULATOR FOR API 650 TANKS

PLEASE FILL IN THE REQUIRED DATA IN GREEN COLORED CELLS

TANK DATA Dia Height DATA FOR VERTICAL JOINTS 9 Vertical joints in 9th Shell 8 Vertical joints in 8th Shell 7 Vertical joints in 7th Shell 6 Vertical joints in 6th Shell 5 Vertical joints in 5th Shell 4 Vertical joints in 4th Shell 3 Vertical joints in 3rd Shell 2 Vertical joints in 2nd Shell 1 Vertical joints in Bottom shell Total Length of Vertical Welding SPOTS TO BE CONSIDERED DATA FOR HORIZONTAL JOINTS Number of Horizontal joints Circumference of each shell Total Length of Horizontal Welding SPOTS TO BE CONSIDERED DATA FOR ANNULAR PLATE JOINTS Number of joints in annular plates: Type of Butt Joint in Annular Plate (1 or 2) SPOTS TO BE CONSIDERED DATA FOR MISC RT REQUIREMENTS Length of welding requiring RT SPOTS TO BE CONSIDERED DATA FOR WELDERS

New welders introduced after above Shell course No. New welders introduced other than those for vertical joints 3

THE RESULTS WILL BE AUTOMATICALLY UPDATED IN THE PURPLE CELLS

SCHEMATIC DIAGRAM FULL

48.5 m 11.5 m

Plates in Length of Total Height of Shell Thickness Shell Vertical RT Course (m) (mm) Course Joints (m) Spots

3 0 0 0 0 13 13 13 13

2 0 0 0 0 2.46 3.01 3.01 3.01

6 0 0 0 0 31.98 39.13 39.13 39.13

0 0 0 0 0 8 8 12 16

1 0 0 0 0 2 2 13 39

2A 0 0 0 0 2.46 A 3.01 A 3.01 1 3.01 3 HEIGHT 1

0 0 0 0 0

9th Shell 8th Shell 7th Shell 6th Shell 5th Shell 4th Shell 3rd Shell

A A 1 3 2

A A 1 3 3

A A 1 3 4

A A 1 3 5

A A 1 3 6

A A 1 3 7

A A 1 3 8

A A 1 3 9

A A 1 3

A A 1 3

A A 1 3

A A 1 3

8 8

12 2nd Shell

16 Bottom Shell 10 11 12 13 14 15 16 17 18 19 20 21 22 THICKNESS

155.37 m 57 Spots and

Plates in Shell Course 0 Full Joints LEGEND A One random spot per 30m of vertical joint welding. 1 One T joint to be taken on the higher thickness side. 2 Two T joints to be taken. 3 Total three spots to be taken as follows: a. One T joint to be taken on the lowest course and b. Two random spots shall be taken, one of which is as close to the bottom as possible.

3 152.387 457.161 9

Nos. m m Nos.

12 Nos. 1 (1. With backing | 2. Without backing) 6 Nos. 1m 5 Nos.

(Length of film: 9")

SPOTS TO BE CONSIDERED TOTAL SPOTS TO BE CONSIDERED Precentage Contigency for Repairs/Reshoots TOTAL SPOTS TO BE CONSIDERED APPROXIMATE NUMBER OF RT CREW VISITS

0 Nos. 0 0 Nos. 77 and 10 % 85 and 0 Full Joints

Full Joints

9 Visits

(@ 9 Spots/Visit)

For Inputs/Correction/Suggestions please contact: Haseeb Ahmed haseebahm@gmail.com

Potrebbero piacerti anche

- Approximate RT Calculation For API 650 TankDocumento2 pagineApproximate RT Calculation For API 650 Tanksitehab100% (1)

- Approximate RT Calculation For API 650 Tank - D100BDocumento5 pagineApproximate RT Calculation For API 650 Tank - D100Baliraza20015Nessuna valutazione finora

- Storage Tank Inspection API 650Documento27 pagineStorage Tank Inspection API 650Pandu Damay Putra92% (12)

- API 650 Peaking - BandingDocumento4 pagineAPI 650 Peaking - BandingZaheedManoo100% (11)

- Dimensional Tolerances - API 650-14: Sr. Item ToleranceDocumento2 pagineDimensional Tolerances - API 650-14: Sr. Item Tolerancehrk100100% (6)

- 10) Itp - Tank Fabrication PDFDocumento6 pagine10) Itp - Tank Fabrication PDFAndy Chong100% (5)

- API 650 PageDocumento2 pagineAPI 650 PageGerry Dan ChanliongcoNessuna valutazione finora

- API 650 12th Edition 2013 - NDT RequirementDocumento1 paginaAPI 650 12th Edition 2013 - NDT Requirementfarjadulhaq100% (2)

- Summary of NDT Requirements For Storage TankDocumento1 paginaSummary of NDT Requirements For Storage TankAbdul Hamid DjaelaniNessuna valutazione finora

- Plumbness Check ReportDocumento50 paginePlumbness Check ReportMuhammad Fitransyah Syamsuar Putra88% (8)

- Job Methodology For DRT Tank Procedure - 0618-R1Documento15 pagineJob Methodology For DRT Tank Procedure - 0618-R1purshottam GHNessuna valutazione finora

- Report of Storage TankDocumento44 pagineReport of Storage TankAMALENDU PAUL100% (1)

- Tank Field Inspection and Test ProcedureDocumento29 pagineTank Field Inspection and Test Proceduresbmmla91% (22)

- Storage Tank (API 650)Documento20 pagineStorage Tank (API 650)sbmmla83% (6)

- Roundness Check Accetance of Storage Tank - TierDocumento1 paginaRoundness Check Accetance of Storage Tank - Tierarkaprava ghoshNessuna valutazione finora

- Erection Procedure (Storage Tank)Documento8 pagineErection Procedure (Storage Tank)TURNO100% (1)

- Tank Inspection NotesDocumento5 pagineTank Inspection Notesaneeshjose013Nessuna valutazione finora

- Storage Tank Hydrostatic Test Quality Control and Inspection Report FormDocumento1 paginaStorage Tank Hydrostatic Test Quality Control and Inspection Report FormsugiantobarusNessuna valutazione finora

- Storage Tank Weld JointsDocumento16 pagineStorage Tank Weld JointsDilip Varadharajan100% (1)

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTDocumento5 pagineHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTVKT TiwariNessuna valutazione finora

- Tank Bottom Plate Weld Sequence To Avoid DistortionDocumento1 paginaTank Bottom Plate Weld Sequence To Avoid Distortionengsam77782% (11)

- Inspection of Storage Tank API - 650Documento4 pagineInspection of Storage Tank API - 650Michael Albuquerque0% (1)

- Shell Corrosion Allowance For Aboveground Storage Tanks: Debra Tetteh-Wayoe, P.EngDocumento8 pagineShell Corrosion Allowance For Aboveground Storage Tanks: Debra Tetteh-Wayoe, P.Engkhabiran100% (1)

- Procedure Fabrikasi TankiDocumento10 pagineProcedure Fabrikasi TankiMuhammad Yunus NurdinNessuna valutazione finora

- Shell Plate Dimension CheckDocumento7 pagineShell Plate Dimension Checksetak0% (1)

- API-653 Now Permits Lap-Welded Patch Plates For Shell Repairs - Carmagen EngineeringDocumento2 pagineAPI-653 Now Permits Lap-Welded Patch Plates For Shell Repairs - Carmagen Engineeringmohsen_267100% (1)

- API 650 PoıntsDocumento4 pagineAPI 650 PoıntsSamet BelliNessuna valutazione finora

- ITP For Storage TankDocumento6 pagineITP For Storage TankAhmed Ben HmidaNessuna valutazione finora

- WPS SampleDocumento6 pagineWPS SampleAshishNessuna valutazione finora

- Tank-API-650-docx V-V-I-P PDFDocumento20 pagineTank-API-650-docx V-V-I-P PDFtomj9104100% (1)

- QCP-0714-11, Rev. A, Field Welded API Std. 650 Tanks' Shop Pre-Fabrication QC Procedure.Documento6 pagineQCP-0714-11, Rev. A, Field Welded API Std. 650 Tanks' Shop Pre-Fabrication QC Procedure.abdul aziz100% (1)

- P Peaking BandingDocumento4 pagineP Peaking BandingSUBHOMOYNessuna valutazione finora

- Fabrication:: Fabrication & Erection Storage TankDocumento9 pagineFabrication:: Fabrication & Erection Storage TankRyanto Sirait100% (1)

- Asme Sec I PWHT RequirementDocumento6 pagineAsme Sec I PWHT RequirementSajin ChandranNessuna valutazione finora

- Prepration of ITP For Storage Tanks Fabrication & ErectionDocumento27 paginePrepration of ITP For Storage Tanks Fabrication & ErectionRamuAlagappan93% (15)

- MDR Report Tank PDFDocumento11 pagineMDR Report Tank PDFWahyudi MetrizaNessuna valutazione finora

- Welding Parameter Sheet - PQR - TemplateDocumento1 paginaWelding Parameter Sheet - PQR - TemplatevalararumugamsNessuna valutazione finora

- Contractor Quality Control Plan For Storage Tank ErectionDocumento2 pagineContractor Quality Control Plan For Storage Tank ErectionHamid Alilou100% (4)

- 6-12-0002 Rev 8 Supplementary Specification For Carbon Steel VesselsDocumento7 pagine6-12-0002 Rev 8 Supplementary Specification For Carbon Steel Vesselsravi2007Nessuna valutazione finora

- Method For Replacement The Bottom Plate With New OneDocumento9 pagineMethod For Replacement The Bottom Plate With New OneMian Aamir Saddiq100% (3)

- API Tank Estimate SheetDocumento3 pagineAPI Tank Estimate SheetKjunwolf100% (1)

- Section 3 API-650 Practice QuestionsDocumento49 pagineSection 3 API-650 Practice QuestionsJosephInbarajan100% (5)

- Inspection TankDocumento22 pagineInspection Tanksbmmla100% (1)

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocumento1 paginaStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFมินคุง เอโอซีNessuna valutazione finora

- Itp Storage TankDocumento10 pagineItp Storage Tankmuhammad afrizalNessuna valutazione finora

- Allowable Stress API-650Documento1 paginaAllowable Stress API-650jojo_323100% (2)

- Drill Exam ComboDocumento79 pagineDrill Exam ComboMakiber100% (2)

- TANK Design DetailingDocumento17 pagineTANK Design DetailingTiffany Vabiola100% (8)

- QM 34 - TanksDocumento10 pagineQM 34 - Tanksmohamed elmasryNessuna valutazione finora

- Drilling PPDocumento26 pagineDrilling PPAnonymous T32l1R100% (1)

- Ut ProcedureDocumento4 pagineUt Procedureأحمد صبحىNessuna valutazione finora

- API 653 Practice Exam Q A 2012 PDFDocumento32 pagineAPI 653 Practice Exam Q A 2012 PDFAntony Bruno GenewinNessuna valutazione finora

- Welding Pipeline HandbookDocumento64 pagineWelding Pipeline HandbookJose Luis Roca Cordova100% (1)

- Baseline Data AquisitionDocumento4 pagineBaseline Data AquisitionmaheshNessuna valutazione finora

- Tank Design and DetailingDocumento17 pagineTank Design and DetailingFuatNessuna valutazione finora

- Api 653 Preparatory Course: Final Exam - Open BookDocumento8 pagineApi 653 Preparatory Course: Final Exam - Open Bookraobabar21Nessuna valutazione finora

- Final Exam (Open) : Weld Reinf. 1/8" THKDocumento7 pagineFinal Exam (Open) : Weld Reinf. 1/8" THKNuwan RanaweeraNessuna valutazione finora

- Final Exam (Open) : InstructionsDocumento8 pagineFinal Exam (Open) : InstructionssujadevNessuna valutazione finora

- D1.1-2010 Practice Exam AWS 2008 Validated To 2010 by KJDocumento11 pagineD1.1-2010 Practice Exam AWS 2008 Validated To 2010 by KJArroyo H Woos100% (1)

- Aramco Interview Questions PRDocumento11 pagineAramco Interview Questions PRhemant1284100% (2)

- Mechanical FitterDocumento9 pagineMechanical Fitterjayaarnav0% (1)

- Hydrotest Procedure As Per ASME B 31.1 (Power Piping)Documento10 pagineHydrotest Procedure As Per ASME B 31.1 (Power Piping)jayaarnav100% (3)

- Mustapha FfsDocumento21 pagineMustapha FfsjayaarnavNessuna valutazione finora

- Titanium Welding Trips and TricksDocumento19 pagineTitanium Welding Trips and Tricksjayaarnav100% (2)

- Steamfitter Pipefitter Practice ExamDocumento9 pagineSteamfitter Pipefitter Practice ExamAbo Hasan Abade67% (3)

- En 473 Level 2 Preparatory Program Schedule For Oct 2013Documento1 paginaEn 473 Level 2 Preparatory Program Schedule For Oct 2013jayaarnavNessuna valutazione finora

- API 570 Question PDFDocumento181 pagineAPI 570 Question PDFRamziAhmedNessuna valutazione finora

- NORSOK Z-006 - PreservationDocumento20 pagineNORSOK Z-006 - Preservationjoaocavti100% (4)

- Work Instruction On Tube ExpansionDocumento40 pagineWork Instruction On Tube Expansionjayaarnav100% (1)

- Open Book For API 653Documento10 pagineOpen Book For API 653jayaarnavNessuna valutazione finora

- Calculation of PipeReinforcement ASMEB31.1Documento3 pagineCalculation of PipeReinforcement ASMEB31.1jayaarnav100% (1)

- CWI SCWI Renewal PKG v1Documento2 pagineCWI SCWI Renewal PKG v1jayaarnavNessuna valutazione finora

- Cswip 3.2 Notes 1Documento42 pagineCswip 3.2 Notes 1Sisira Chandrasoma100% (7)

- Api 575Documento37 pagineApi 575Sakthi Pk100% (3)

- 3 2Documento3 pagine3 2jayaarnav100% (1)

- Inspection HandbookDocumento126 pagineInspection Handbooksteffy18295% (21)

- Interesting PicturesDocumento2 pagineInteresting PicturesjayaarnavNessuna valutazione finora

- RTDocumento16 pagineRTjayaarnavNessuna valutazione finora

- RTDocumento8 pagineRTjayaarnav33% (3)

- CWI SCWI Renewal PKG v1Documento2 pagineCWI SCWI Renewal PKG v1jayaarnavNessuna valutazione finora

- Lord of The Flies SummaryDocumento1 paginaLord of The Flies Summarynija keenNessuna valutazione finora

- Ork Rules For Space HulkDocumento11 pagineOrk Rules For Space HulkSpace_Hulker100% (1)

- Concept and Asset Bible For PTDocumento450 pagineConcept and Asset Bible For PTLucas Caspar FischerNessuna valutazione finora

- Primeval Bastionland PlaytestDocumento40 paginePrimeval Bastionland PlaytestaoshiNessuna valutazione finora

- New Master DataDocumento66 pagineNew Master DataDipak MoundekarNessuna valutazione finora

- Call of Cthulhu 1920 Character SheetDocumento2 pagineCall of Cthulhu 1920 Character SheetSimon Brackenridge100% (3)

- War Story EssayDocumento3 pagineWar Story EssayDeathTNessuna valutazione finora

- The Lviv Pogrom of 1941: The Germans, Ukrainian Nationalists, and The Carnival CrowdDocumento35 pagineThe Lviv Pogrom of 1941: The Germans, Ukrainian Nationalists, and The Carnival CrowdmiguelsiglerNessuna valutazione finora

- Livinghistory SerbiaDocumento10 pagineLivinghistory SerbiabalkanmonitorNessuna valutazione finora

- Reiigen Bridgehead Offensive Hasty Assault River CR Leavenw - Orth Ks Comba M Oyloe Et Al 23 May 84Documento86 pagineReiigen Bridgehead Offensive Hasty Assault River CR Leavenw - Orth Ks Comba M Oyloe Et Al 23 May 84Luke WangNessuna valutazione finora

- Tam Ks X N V: T) Meo-Kns/ KWC - N®V Apjy-A ( N ) Nw-Dm-Bn°V S - LVDSB 'B-Am-Sw V XN-) WDocumento4 pagineTam Ks X N V: T) Meo-Kns/ KWC - N®V Apjy-A ( N ) Nw-Dm-Bn°V S - LVDSB 'B-Am-Sw V XN-) WMuhammed Sabith KannurNessuna valutazione finora

- US Army Catalogue of GoodiesDocumento258 pagineUS Army Catalogue of GoodiesIan Greenhalgh100% (2)

- A Loyal Spy (1st Chapter)Documento17 pagineA Loyal Spy (1st Chapter)Saad AliNessuna valutazione finora

- CS Exam ResultDocumento15 pagineCS Exam ResultSid Onidal100% (8)

- Japanese Occupation of The PhilippinesDocumento5 pagineJapanese Occupation of The PhilippinesAlvin LucernasNessuna valutazione finora

- Service RulesDocumento72 pagineService RulesPrashant AryaNessuna valutazione finora

- Zagora Zbornik PDFDocumento84 pagineZagora Zbornik PDFTino TomasNessuna valutazione finora

- Environmental Health and Safety ManagerDocumento7 pagineEnvironmental Health and Safety Managerapi-78983915Nessuna valutazione finora

- ParisDocumento29 pagineParisTimothyNessuna valutazione finora

- Philippine LitDocumento335 paginePhilippine LitKate50% (2)

- List of Collective NounsDocumento11 pagineList of Collective NounsMrTeddy Cfrd100% (1)

- Qioptiq Sights BookletDocumento20 pagineQioptiq Sights BookletColumbia GomezNessuna valutazione finora

- 2S19 MstaDocumento5 pagine2S19 Mstajason maiNessuna valutazione finora

- New Era of Civilian's GovernmentDocumento17 pagineNew Era of Civilian's GovernmentNousheen ArshadNessuna valutazione finora

- Wwi Who Is To Blame DocumentsDocumento8 pagineWwi Who Is To Blame Documentsapi-276956064Nessuna valutazione finora

- Combo PDFDocumento209 pagineCombo PDFBasem Al-HajNessuna valutazione finora

- US Aircraft Bombs PDFDocumento33 pagineUS Aircraft Bombs PDFAndreas Hesse100% (2)

- cASHELESS GARAGEDocumento364 paginecASHELESS GARAGEbharatNessuna valutazione finora

- Armageddon 2089 - Main RulebookDocumento305 pagineArmageddon 2089 - Main RulebookKyle Scanlan100% (5)

- Rockaway Times 91516Documento52 pagineRockaway Times 91516Peter J. MahonNessuna valutazione finora