Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Montaje Cables Alta Tension DC

Caricato da

mauriciojjDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Montaje Cables Alta Tension DC

Caricato da

mauriciojjCopyright:

Formati disponibili

EBD-1500 SERIES INSTALLATION INSTRUCTIONS

4.2"

7.25"

10.5"

14.0"

11.7"

EBD-1500 (NATCO part no.48126009)

The EBD-1500 Entrance Bushing is a 1 NPT bushing designed to transfer up to 30,000 volts into crude oil electrostatic dehydrator and desalter vessels. This bushing has undergone continuous improvements in design and materials to optimize its electrical and mechanical performance. To complete the entrance bushing installation, a special corona resistant Teflon insulated HV (high voltage) cable is needed to connect the bushing to the transformer. It is recommended that the cable be installed inside two PFA sleeves. The PFA sleeves will add additional electrical insulation and move the cable toward the center of the conduit. Centering is important to reduce electrical stress points along the cable.

11.7"

CAUTION!!!

Only qualified personnel should install or service high-voltage transformers or other electrical equipment on NATCO Electrostatic Dehydrators or Desalters. Incorrect installation of electrical equipment may result in personal injury, damage to parts or process failure. For additional information concerning electrical or mechanical component installation on NATCO equipment, contact NATCO Engineering Department, Houston, Texas or the nearest NATCO Branch Office. 1

EBD-1500S (NATCO part no.48126008)

The EBD-1500S Entrance Bushing includes a 1 NPT x 1 NPT x 10 long swage. The swage permits the EBD-1500 bushings to be used with older process vessels, ie, 1 NPT entrance bushing connections. The swage extends the entrance bushing into the liquid phase of the process. This is very important because corona (ionized gas) present in the gas phase of electrostatic coalescers will attack Teflon and other materials used in the construction of entrance bushings.

HV cable

INSTALLATION INSTINSTRUCTIONS

1. Remove the entrance bushing from shipping crate. Be careful not to damage the insulating surfaces of the entrance bushing. 2. Before screwing the entrance bushing into the mounting flange inspect all connecting threads including the pipe extension (and the swage if it is an EBD-1500S). Make sure they are clean and not damaged. Apply a non-conductive thread sealer to both sets of threads and a layer of Teflon tape to the bushing threads. 3. Tighten all threaded connections, including the bushing to swage. Because pipe wrenches tend to distort a pipe, experience has shown that after the initial tightening it is a good idea to set the assembly aside for 10-15 minutes and then retighten. This helps avoid any leaks around the threads. Any leak will contaminate the transformer oil and will result in a premature failure of the entrance bushing or transformer components. 4. Place a new flange gasket on the vessel entrance bushing nozzle flange and pull the 3/16 stainless steel cable through the nozzle and gasket. The lower end of the cable should be connected to the top end of the electrode contact rod on the appropriate electrode set inside the vessel. Connect the other end of the cable to the lower end of the entrance bushing. Place a 7/16 back-up wrench on the flat part of the connecting rod while tightening the bolt until firm. 5. Carefully insert the entrance bushing through the nozzle and bolt the flange into place. Insert the 5/8 ID x 3/4 OD PFA sleeve into the entrance bushing, allowing it to extend up and out of the flange as shown on the right. 6. Slip the conduit or flexible hose over the PFA sleeve. The PFA sleeve must pass completely through the conduit and be long enough to extend into the diode housing (or transformer housing if it is an AC coalescer). 7. Connect the conduit to the diode or transformer housing. Trim the PFA sleeve so it extends at 2- 4 inside the housing (see pages 3 and 4). 8. Slip the 5/16 ID x 7/16 OD PFA sleeve over the high voltage cable and slide it up against the banana plug. Insert the PFA/HV cable combination through the 3/4 PFA sleeve, pushing the banana plug into the entrance bushing receptacle. To be sure the banana plug is firmly seated, gently unplug it, pulling on the HV cable, and then reinsert it by pushing on the 7/16 PFA sleeve. You should feel some resistance in both directions. 9. Attach the high-voltage cable to the appropriate polarity on the diode pack (see page 3 and 4) or to the transformer HV winding if it is an AC coalescer. 10. Refill the diode or transformer housing to the proper level with clean, dry transformer oil. Be sure there is no air trapped in the conduit or tubing that could become ionized by the high voltage. It is also a good policy to allow a little time for any air trapped in the transformer winding to be displaced. Replace the cover and follow normal start-up procedures. 2

7/16" PFA sleeve 3/4" PFA sleeve 1" conduit or flexible SS hose

Note: Conduit and swage should be filled with transformer oil.

Mounting flange

1" extension nipple if required

Vessel shell Normal crude oil level Adapter swage

Entrance bushing

3/16" stainless steel cable

Electrode contact rod

Cable weight

EBD-1500S INSTALLATION

TYPICAL NATCO CANADA EBD-1500 ENTRANCE BUSHING INSTALLATION

Diode box relief valve 1" Connection

Oil level

AC

Diode pack

Light fixture

Pressure-tight stainless steel hose

DC

Diode housing

Low-voltage junction box

5/8" x 3/4" PFA sleeve 5/16" x 7/16" PFA sleeve

High-voltage cable

Transformer/ Reactor tank

Ground wire 2" Flange extension

Normal crude oil level

4" Mounting flange

Vessel shell

HIG H VO LTAG E

C AUTIO N

Caution sign

Electrode hanger

Grounding float assembly

Low crude oil level

Grounding float low level

Entrance bushing

7/16" PFA Sleeve

Volt meter

Contact rod

Cable weight

Conduit seal

3/16" stainless steel cable

Circuit breaker

Conduit seal

Positive (+) Electrode assembly Negative (-) Electrode assembly

NOTE: Be sure the white insulating portion of the entrance bushing is extended into the oil phase far enough to remain covered when the grounding float ball is in the low (shorted) position. Both the (+) and (-) DC electrodes are similarly connected to their respective polarities on the diode pack.

TYPICAL NATCO USA EBD-1500S ENTRANCE BUSHING INSTALLATION

Diode box relief valve 1" Connection

Oil level

AC

Light fixture

Pressure-tight stainless steel hose

Diode pack

DC

Low-voltage junction box

Diode housing High-voltage cable

5/8" x 3/4" PFA sleeve 5/16" x 7/16" PFA sleeve

Transformer/ Reactor tank

Ground wire

4" Mounting flange

Special swage extension 1" NPT x 1-1/2" NPT

Vessel shell

Normal crude oil level

HIG H VO LTAG E

C AUTIO N

Caution sign

Electrode hanger

Grounding float assembly

Low crude oil level

Grounding float low level

Entrance bushing

7/16" PFA Sleeve

Volt meter

Contact rod

Cable weight

Conduit seal

3/16" stainless steel cable

Circuit breaker

Conduit seal

Positive (+) Electrode assembly Negative (-) Electrode assembly

NOTE: Be sure the white insulating portion of the entrance bushing is extended into the oil phase far enough to remain covered when the grounding float ball is in the low (shorted) position. Both the (+) and (-) DC electrodes are similarly connected to their respective polarities on the diode pack.

EBD-1500S INSTALLATION WITH ISOLATION AT THE DIODE BOX

TI-23 with Rajah connector High-voltage connection Conduit fill cap 3"x 1" NPT adapter swage

Light fixture

Oil level

AC

5/16" x 7/16" PFA sleeve

5/8" x 3/4" PFA sleeve

EBD-1500S Entrance bushing

DC

Diode pack

Low-voltage junction box

High-voltage diode housing 5/8" x 3/4" PFA sleeve 5/16" x 7/16" PFA sleeve Pressure-tight stainless steel hose

Transformer/ Reactor tank

Ground wire

Mounting flange

1" extension nipple if required Adapter swage

Normal crude oil level

HIG H VO LTAG E

C AUTIO N

Caution sign

Grounding float assembly

Entrance bushing

Electrode grounding level

Volt meter

Electrode hanger

Grounding float low level

Conduit seal

Contact rod 3/16" stainless steel cable

Cable weight

Vessel shell

Circuit breaker

Conduit seal Positive (+) Electrode assembly

NOTE: Be sure the white insulating portion of the entrance bushing is extended into the oil phase far enough to remain covered when the grounding float ball is in the low (shorted) position. Both the (+) and (-) DC electrodes are similarly connected, through the TI-23, to their respective polarities on the diode pack.

Negative (-) Electrode assembly

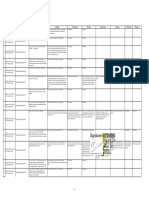

EBD-1500 AND EBD-1500S OPERATING SPECIFICATIONS

The EBD-1500 was extensively tested at the NATCO R&D Lab in Tulsa, Oklahoma. Tests included pressure/temperature tests as well as electrical tests. It was electrically tested to 60,000 volts AC and DC over an extended period of time without failure. The EBD-1500 Entrance Bushing is rated for continuous operation at 30,000 volts AC or DC. Extensive tests were conducted with the entrance bushing submerged in heavy crude (8 API) oil/water emulsions without tracking. Extensive temperature and pressure testing has determined a safe operating range for the bushing. The chart below gives the recommended pressure/temperature specifications for the EBD-1500 and EBD1500S entrance bushings.

Pressure/ Temperature Curve

1300 1200 1100 1000 900 800

EBD- 1500 Operating

Pressure (PSIG)

700 600 500 400 300 200 100 0 120 140 160 180 200 220 240 260 280 300 320 340

Temperature (deg.F)

Potrebbero piacerti anche

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileDa EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNessuna valutazione finora

- Marine Trans Owners Manual 1016313 RevH 0116 CDDocumento200 pagineMarine Trans Owners Manual 1016313 RevH 0116 CDMarco Aurelio BarbosaNessuna valutazione finora

- Electrical Machine Bearing DamageDocumento81 pagineElectrical Machine Bearing DamageAmit BiswasNessuna valutazione finora

- How To Import Medical Devices Into The USDocumento16 pagineHow To Import Medical Devices Into The USliviustitusNessuna valutazione finora

- Thyrotronic 07-02Documento8 pagineThyrotronic 07-02Hillary Mcgowan100% (1)

- Battery ChargerDocumento7 pagineBattery ChargerDeepakJainNessuna valutazione finora

- NATCO Presentation - Desalters PDFDocumento12 pagineNATCO Presentation - Desalters PDFshahmkamalNessuna valutazione finora

- Iso Tc251 Wg4 Macam May 2017 enDocumento4 pagineIso Tc251 Wg4 Macam May 2017 enpcesar777Nessuna valutazione finora

- TankGard Operation ManualDocumento18 pagineTankGard Operation ManualThaibinh NguyenNessuna valutazione finora

- Model"Dc": Dual Chamber Orifice FittingDocumento13 pagineModel"Dc": Dual Chamber Orifice FittingFrankNessuna valutazione finora

- Mog TrafoDocumento27 pagineMog TrafoPandrayar MaruthuNessuna valutazione finora

- Nta855 C400 D6 PDFDocumento110 pagineNta855 C400 D6 PDFIsmael Grünhäuser100% (4)

- TrolexDocumento56 pagineTrolexfazzlieNessuna valutazione finora

- Intro To Psychological AssessmentDocumento7 pagineIntro To Psychological AssessmentKian La100% (1)

- E217.11 Current Transformers IOSK PDFDocumento8 pagineE217.11 Current Transformers IOSK PDFERWIN ESCANILLANessuna valutazione finora

- Isometric Fire Figting SystemDocumento2 pagineIsometric Fire Figting SystemShailendra RamchurnNessuna valutazione finora

- Data Sheet UPSDocumento13 pagineData Sheet UPSAdi Toto HaryonoNessuna valutazione finora

- Dri InternshipDocumento38 pagineDri InternshipGuruprasad Sanga100% (3)

- EIL Document On Motor, PanelDocumento62 pagineEIL Document On Motor, PanelArindam Samanta100% (1)

- User Help Guide For SAP Asset Information Workbench by Utopia For S/4HANADocumento13 pagineUser Help Guide For SAP Asset Information Workbench by Utopia For S/4HANAmauriciojjNessuna valutazione finora

- ATEX Ex-EDocumento10 pagineATEX Ex-EBrajan's B.Nessuna valutazione finora

- Impact of Employee Motivation in The Banking SectorDocumento48 pagineImpact of Employee Motivation in The Banking Sectormohd talalNessuna valutazione finora

- How To Select A Variable Frequency DriveDocumento2 pagineHow To Select A Variable Frequency Drivehasbi fadli100% (1)

- General Technical Particulars Motors Project Name 10/01/2020 Sheet 1 of 2Documento2 pagineGeneral Technical Particulars Motors Project Name 10/01/2020 Sheet 1 of 2mishtinilNessuna valutazione finora

- Manual de Tuerca Hidraulica-Desbloqueado-editadoDocumento37 pagineManual de Tuerca Hidraulica-Desbloqueado-editadomauriciojjNessuna valutazione finora

- 2.0 Performance Testing - Sue06052010 - PTDocumento15 pagine2.0 Performance Testing - Sue06052010 - PTAbdul Hakam Mohamed YusofNessuna valutazione finora

- Operation and Installation Manual: Prds - Prs - DSH SystemsDocumento125 pagineOperation and Installation Manual: Prds - Prs - DSH Systemskikokiko Karim100% (2)

- Cable Erection PhilosophyDocumento26 pagineCable Erection PhilosophyRAJIV RANJANNessuna valutazione finora

- Chemical Engineering Projects List For Final YearDocumento2 pagineChemical Engineering Projects List For Final YearRajnikant Tiwari67% (6)

- Doctors ListDocumento212 pagineDoctors ListSaranya Chandrasekar33% (3)

- Pulsatron Parts Id PDFDocumento151 paginePulsatron Parts Id PDFmauriciojjNessuna valutazione finora

- Split Casing Pumps: Series Z22Documento19 pagineSplit Casing Pumps: Series Z22Marius GhitaNessuna valutazione finora

- WW-MFR2 (Multifunction Relay)Documento4 pagineWW-MFR2 (Multifunction Relay)KT MENONNessuna valutazione finora

- Sepam - I0 - (Io) Inputs For CSH30 and CSH120 - CSH200 - FAQs PDFDocumento2 pagineSepam - I0 - (Io) Inputs For CSH30 and CSH120 - CSH200 - FAQs PDFNADEEM KHANNessuna valutazione finora

- Chloride FP 40r Ds en GL 0616 Rev6Documento2 pagineChloride FP 40r Ds en GL 0616 Rev6Tanveer Ahmed100% (1)

- Flame Retardant and Fire Resistant Cable - NexansDocumento2 pagineFlame Retardant and Fire Resistant Cable - NexansprseNessuna valutazione finora

- Flame Retardant Vs Fire Rated CablesDocumento2 pagineFlame Retardant Vs Fire Rated CablesStephanie Stewart100% (1)

- Control Cables SpecDocumento15 pagineControl Cables SpecnatbalNessuna valutazione finora

- Electric Actuator InstructionDocumento40 pagineElectric Actuator Instructiongasm220% (1)

- TP-GT01 GeneratorDocumento10 pagineTP-GT01 Generatorوليد موسىNessuna valutazione finora

- High Voltage Cable Terminations & Joint Kits, LV, 3.3 33kV SPS CatalogueDocumento63 pagineHigh Voltage Cable Terminations & Joint Kits, LV, 3.3 33kV SPS CatalogueFire NowNessuna valutazione finora

- Mobile SS 132-33KV 63MVA - September 2020Documento140 pagineMobile SS 132-33KV 63MVA - September 2020mercedesbestsupplierNessuna valutazione finora

- Inspection and Test Plan: Project NameDocumento2 pagineInspection and Test Plan: Project NameehteshamNessuna valutazione finora

- Prisma P CatalogueDocumento344 paginePrisma P Cataloguelincolny2k100% (1)

- AC-32 Rev 2015Dec-CURRENTDocumento2 pagineAC-32 Rev 2015Dec-CURRENT李俊Nessuna valutazione finora

- 6.2. F-MPC60B - Manual - English PDFDocumento68 pagine6.2. F-MPC60B - Manual - English PDFThủy Tiên100% (1)

- 11KV Switchgear SA and SBDocumento19 pagine11KV Switchgear SA and SBVikrant DeshmukhNessuna valutazione finora

- TRF Protection Relay Manual Spad PDFDocumento16 pagineTRF Protection Relay Manual Spad PDFNesarkiran BagadeNessuna valutazione finora

- Siemens PTC RTD Thermocouples Section7 Rev1Documento16 pagineSiemens PTC RTD Thermocouples Section7 Rev1DelfinshNessuna valutazione finora

- Livening Up NotesDocumento1 paginaLivening Up NotesAceel FitchNessuna valutazione finora

- Gave RELAYDocumento49 pagineGave RELAYTayeb KaderNessuna valutazione finora

- Winding Temperature Simulation SystemDocumento3 pagineWinding Temperature Simulation SystemsenthilanviewNessuna valutazione finora

- SPAD330CDocumento17 pagineSPAD330CARA CESPEDES JORGENessuna valutazione finora

- Technical Bid T - 3560: (Note: Photo Copy of SSI / NSIC Certificate Is Not Acceptable)Documento12 pagineTechnical Bid T - 3560: (Note: Photo Copy of SSI / NSIC Certificate Is Not Acceptable)SeresdfrtNessuna valutazione finora

- Standards Specifications For Instrument CablesDocumento10 pagineStandards Specifications For Instrument CablesAmmar AltamimyNessuna valutazione finora

- Motor Starters: Explosionproof, Dust-Ignitionproof, WatertightDocumento37 pagineMotor Starters: Explosionproof, Dust-Ignitionproof, WatertightWaseem ArshadNessuna valutazione finora

- Braking Resistor FormulaDocumento72 pagineBraking Resistor FormulaAftandil QarmonNessuna valutazione finora

- Caterpillar XQ1000 Containerized Diesel Generator SetDocumento10 pagineCaterpillar XQ1000 Containerized Diesel Generator SetMacAllister MachineryNessuna valutazione finora

- 8-12-8 Fabrication of Piping PDFDocumento7 pagine8-12-8 Fabrication of Piping PDFasif rahimNessuna valutazione finora

- Product Specification Sheet: Outlet Entry Combined Pressure Reducing & Desuperheatering Valves (PRDS)Documento21 pagineProduct Specification Sheet: Outlet Entry Combined Pressure Reducing & Desuperheatering Valves (PRDS)Gỗ MộcNessuna valutazione finora

- Steam Separator and Steam Trap Are Almost Same in FunctionDocumento7 pagineSteam Separator and Steam Trap Are Almost Same in FunctionTHEOPHILUS ATO FLETCHERNessuna valutazione finora

- 7420p008 Uptimax Ni-CD BatteryDocumento16 pagine7420p008 Uptimax Ni-CD BatteryNazif HawariNessuna valutazione finora

- Siemens 3VT2 MCCB AccessoriesDocumento19 pagineSiemens 3VT2 MCCB AccessoriesSyarifudinNessuna valutazione finora

- P132 CortecDocumento2 pagineP132 CortecAshley OsbornNessuna valutazione finora

- Leak TestingDocumento5 pagineLeak Testingogie_0513Nessuna valutazione finora

- Pump Catalogue PDFDocumento48 paginePump Catalogue PDFShah Newaz KabirNessuna valutazione finora

- Heat ExchangerDocumento22 pagineHeat ExchangerYashwant SinghNessuna valutazione finora

- TERZ 94OMManualRev0107 PDFDocumento66 pagineTERZ 94OMManualRev0107 PDFRoberto Andres Vasquez Campusano75% (4)

- GII-S00135 DownloadInstructionsDocumento14 pagineGII-S00135 DownloadInstructionsJorge ContrerasNessuna valutazione finora

- Control Valve DatasheetDocumento13 pagineControl Valve DatasheetRakesh Karan SinghNessuna valutazione finora

- Flow-Switch-RapidropDocumento4 pagineFlow-Switch-RapidropNOMANNessuna valutazione finora

- UniGear ZS1Documento8 pagineUniGear ZS1SOUMENNessuna valutazione finora

- Digital Coriolis Mass Flowmeters Installation Guidelines and Quick Start - HARTDocumento12 pagineDigital Coriolis Mass Flowmeters Installation Guidelines and Quick Start - HARTPhaniNessuna valutazione finora

- Electrovalva E6-E11 SeriesDocumento3 pagineElectrovalva E6-E11 SeriesMonica GrecuNessuna valutazione finora

- Service Manual: LT-42EM91Documento32 pagineService Manual: LT-42EM91Robert FilipNessuna valutazione finora

- Purpose: Asset Management DesignationsDocumento9 paginePurpose: Asset Management DesignationsChristian SantillanNessuna valutazione finora

- TV Software Update Guide v3 PDFDocumento44 pagineTV Software Update Guide v3 PDFAnderson CapristanNessuna valutazione finora

- En16646-2014 Original PDFDocumento36 pagineEn16646-2014 Original PDFmauriciojjNessuna valutazione finora

- Satellite AIS For Dummies®, Special EditionDocumento67 pagineSatellite AIS For Dummies®, Special EditionALEXANDER DE JESUS PARRA UZCATEGUINessuna valutazione finora

- DataBook 3series 2P 50 PDFDocumento94 pagineDataBook 3series 2P 50 PDFmauriciojjNessuna valutazione finora

- CoolTUBE PresentationDocumento21 pagineCoolTUBE PresentationmauriciojjNessuna valutazione finora

- Touch 5 User & Installation ManualDocumento28 pagineTouch 5 User & Installation ManualmauriciojjNessuna valutazione finora

- Manual Deepsea Battery Charger Dse9461Documento46 pagineManual Deepsea Battery Charger Dse9461mauriciojjNessuna valutazione finora

- Foundation SystemsDocumento5 pagineFoundation SystemsmauriciojjNessuna valutazione finora

- Touch 5 User & Installation ManualDocumento28 pagineTouch 5 User & Installation ManualmauriciojjNessuna valutazione finora

- Use and Maintenance Instructions - Ql0208-Rev.2-2017 - enDocumento70 pagineUse and Maintenance Instructions - Ql0208-Rev.2-2017 - enmauriciojjNessuna valutazione finora

- Optimum Brochure UGOct2018Documento4 pagineOptimum Brochure UGOct2018mauriciojjNessuna valutazione finora

- Manual - Milton Roy Serie-GDocumento48 pagineManual - Milton Roy Serie-GmauriciojjNessuna valutazione finora

- DataBook 3series 2P 50 PDFDocumento94 pagineDataBook 3series 2P 50 PDFmauriciojjNessuna valutazione finora

- Grundfos Dosing PumpDocumento7 pagineGrundfos Dosing PumpRyan GohNessuna valutazione finora

- Grundfos Dosing LDocumento58 pagineGrundfos Dosing LmauriciojjNessuna valutazione finora

- Grundfos Dosing LDocumento58 pagineGrundfos Dosing LmauriciojjNessuna valutazione finora

- Guiacompra hdm2Documento1 paginaGuiacompra hdm2mauriciojjNessuna valutazione finora

- DataBook 3series 2P 50 PDFDocumento94 pagineDataBook 3series 2P 50 PDFmauriciojjNessuna valutazione finora

- CoolBLUE Inductive Absorbers PresentationDocumento49 pagineCoolBLUE Inductive Absorbers PresentationmauriciojjNessuna valutazione finora

- A Summary of AC Induction Motor Monitoring: PurposeDocumento4 pagineA Summary of AC Induction Motor Monitoring: Purposemauriciojj100% (1)

- Sap PM PDFDocumento82 pagineSap PM PDFmauriciojjNessuna valutazione finora

- Manual de Servicio Serie CSD PDFDocumento168 pagineManual de Servicio Serie CSD PDFmauriciojjNessuna valutazione finora

- DataBook 3series 2P 50 PDFDocumento94 pagineDataBook 3series 2P 50 PDFmauriciojjNessuna valutazione finora

- Castle 1-3K E ManualDocumento26 pagineCastle 1-3K E ManualShami MudunkotuwaNessuna valutazione finora

- 2133 Rla RlvaDocumento2 pagine2133 Rla RlvaAgung SubangunNessuna valutazione finora

- J130KDocumento6 pagineJ130KBelkisa ŠaćiriNessuna valutazione finora

- Aldehydes, Ketones, Carboxylic Acids, and EstersDocumento11 pagineAldehydes, Ketones, Carboxylic Acids, and EstersNATURE COMPUTERNessuna valutazione finora

- Benzil PDFDocumento5 pagineBenzil PDFAijaz NawazNessuna valutazione finora

- Dressmaking - Q1 TASK-SHEET v1 - Schalemar OmbionDocumento2 pagineDressmaking - Q1 TASK-SHEET v1 - Schalemar OmbionAlvaCatalinaNessuna valutazione finora

- GrowNote Faba South 3 Pre PlantingDocumento22 pagineGrowNote Faba South 3 Pre PlantingDawitNessuna valutazione finora

- Service Bulletins For Engine Model I0360kb.3Documento6 pagineService Bulletins For Engine Model I0360kb.3Randy Johel Cova FlórezNessuna valutazione finora

- Wisconsin Humane Society To Acquire Kenosha's Safe Harbor Humane Society - Press ReleaseDocumento3 pagineWisconsin Humane Society To Acquire Kenosha's Safe Harbor Humane Society - Press ReleaseTMJ4 NewsNessuna valutazione finora

- METHOD STATEMENT FOR INSTALLATION OF Light FixturesDocumento5 pagineMETHOD STATEMENT FOR INSTALLATION OF Light FixturesNaveenNessuna valutazione finora

- Funding HR2 Coalition LetterDocumento3 pagineFunding HR2 Coalition LetterFox NewsNessuna valutazione finora

- Sop For Enlistment of Engineering ConsultantsDocumento1 paginaSop For Enlistment of Engineering Consultantssatheb319429Nessuna valutazione finora

- Itrogen: by Deborah A. KramerDocumento18 pagineItrogen: by Deborah A. KramernycNessuna valutazione finora

- As ISO 9919-2004 Pulse Oximeters For Medical Use - RequirementsDocumento10 pagineAs ISO 9919-2004 Pulse Oximeters For Medical Use - RequirementsSAI Global - APACNessuna valutazione finora

- Task 5 Banksia-SD-SE-T1-Hazard-Report-Form-Template-V1.0-ID-200278Documento5 pagineTask 5 Banksia-SD-SE-T1-Hazard-Report-Form-Template-V1.0-ID-200278Samir Mosquera-PalominoNessuna valutazione finora

- Psychoanalysis AND History: Freud: Dreaming, Creativity and TherapyDocumento2 paginePsychoanalysis AND History: Freud: Dreaming, Creativity and TherapyJuan David Millán MendozaNessuna valutazione finora

- Epicor Software India Private Limited: Brief Details of Your Form-16 Are As UnderDocumento9 pagineEpicor Software India Private Limited: Brief Details of Your Form-16 Are As UndersudhadkNessuna valutazione finora

- Classification of Speech ActDocumento1 paginaClassification of Speech ActDarwin SawalNessuna valutazione finora

- GEC - ReviewerDocumento23 pagineGEC - ReviewerGlycel BagabagonNessuna valutazione finora

- Notes Marriage and Family in Canon LawDocumento5 pagineNotes Marriage and Family in Canon LawmacNessuna valutazione finora

- Lab Manual PDFDocumento68 pagineLab Manual PDFSantino AwetNessuna valutazione finora