Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Stereolithography - Wikipedia, The Free Encyclopedia

Caricato da

alexnadaDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Stereolithography - Wikipedia, The Free Encyclopedia

Caricato da

alexnadaCopyright:

Formati disponibili

Stereolithography - Wikipedia, the free encyclopedia

http://en.wikipedia.org/wiki/Stereolithography

Stereolithography

From Wikipedia, the free encyclopedia

Stereolithography (SLA), also known as optical fabrication, photo-solidification, solid free-form fabrication and solid imaging, is an additive manufacturing 3D printing technology used for producing models, prototypes, patterns, and production parts.

Contents

1 History 2 Technology 3 Advantages and disadvantages 4 See also 5 References 5.1 Notes 5.2 Bibliography 6 External links

An SLA produced part

History

The term stereolithography was coined in 1986 by Charles (Chuck) W. Hull,[1] who patented it as a method and apparatus for making solid objects by successively "printing" thin layers of the ultraviolet curable material one on top of the other. Hull's patent described a concentrated beam of ultraviolet light focused onto the surface of a vat filled with liquid photopolymer. The light beam draws the object onto the surface of the liquid layer by layer, and using polymerization or crosslinking to create a solid, a complex process which requires automation. In 1986, Hull founded the first company to generalize and commercialize this procedure, 3D Systems Inc,[2] [3] [4] which is currently based in Rock Hill, SC. More recently, attempts have been made to construct mathematical models of the stereolithography process and design algorithms to determine whether a proposed object may be constructed by the process.[5]

Technology

Stereolithography is an additive manufacturing process which employs a vat of liquid ultraviolet curable photopolymer "resin" and an ultraviolet laser to build parts' layers one at a time. For each layer, the laser beam traces a cross-section of the part pattern on the surface of the liquid resin. Exposure to the ultraviolet laser light cures and solidifies the pattern traced on the resin and joins it to the layer below. After the pattern has been traced, the SLA's elevator platform descends by a distance equal to the thickness of a single layer, typically 0.05 mm to 0.15 mm (0.002" to 0.006"). Then, a resin-filled blade sweeps across the cross section of the part, re-coating it with fresh material. On this new liquid surface, the subsequent layer pattern is traced, joining the previous layer. A complete 3-D part is

1 di 3

14/04/2012 15.52

Stereolithography - Wikipedia, the free encyclopedia

http://en.wikipedia.org/wiki/Stereolithography

formed by this process. After being built, parts are immersed in a chemical bath in order to be cleaned of excess resin and are subsequently cured in an ultraviolet oven. Stereolithography requires the use of supporting structures which serve to attach the part to the elevator platform, prevent deflection due to gravity and hold the cross sections in place so that they resist lateral pressure from the re-coater blade. Supports are generated automatically during the preparation of 3D Computer Aided Design models for use on the stereolithography machine, although they may be manipulated manually. Supports must be removed from the finished product manually, unlike in other, less costly, rapid prototyping technologies.

Stereolithography apparatus

Advantages and disadvantages

One of the advantages of stereolithography is its speed; functional parts can be manufactured as shortly as within a day. The length of time it takes to produce one particular part depends on the size and complexity of the project and can last from a few hours to more than a day. Most stereolithography machines can produce parts with a maximum size of approximately 505060 cm (20"20"24") and some, such as the Mammoth stereolithography machine (which has a build platform of 2107080 cm),[6] are capable of producing single parts of more than 2 m in length. Prototypes made by stereolithography are strong enough to be machined and can be used as master patterns for injection molding, thermoforming, blow molding, and various metal casting processes. Although stereolithography can produce a wide variety of shapes, it is often expensive; the cost of photo-curable resin ranges from $80 to $210 per liter, and the cost of stereolithography machines ranges from $100,000 to more than $500,000.

See also

Stereolithography (medicine)

References

Notes

1. ^ U.S. Patent 4,575,330 (Apparatus for Production of Three-Dimensional Objects by Stereolithography) 2. ^ (http://www.3dsystems.com/company/index.asp) 3D Systems Inc Company Info 3. ^ Stereolithography (http://www.photopolymer.com/stereolithography.htm) 4. ^ What is Stereolithography? (http://production3dprinters.com/sla/stereolithography) 5. ^ B. Asberg, G. Blanco, P. Bose, J. Garcia-Lopez, M. Overmars, G. Toussaint, G. Wilfong and B. Zhu, "Feasibility of design in stereolithography," Algorithmica, Special Issue on Computational Geometry in Manufacturing, Vol. 19, No. 1/2, Sept/Oct, 1997, pp. 6183. 6. ^ Mammoth stereolithography: Technical specifications (http://www.materialise.com/mammothspecifications) . materialise.com

Bibliography

2 di 3

14/04/2012 15.52

Stereolithography - Wikipedia, the free encyclopedia

http://en.wikipedia.org/wiki/Stereolithography

Kalpakjian, Serope and Steven R. Schmid. Manufacturing Engineering and Technology 5th edition. Ch. 20 (pp. 586587 Pearson Prentice Hall. Upper Saddle River NJ, 2006.

External links

Graphical Display of the Stereolithography Process (http://www.laserproto.com /ServicesProcess.aspx?PageID=5) : A resource page maintained by Laser Prototypes (Europe) Ltd Castle Island's Worldwide Guide to Rapid Prototyping (http://home.att.net/~castleisland/) , with comprehensive information on rapid prototyping, rapid tooling, stereolithography and solid freeform fabrication technology products and services. Complete rapid prototyping service bureau listings How Stereolithography (3-D Layering) Works (http://computer.howstuffworks.com /stereolith.htm/printable) from HowStuffWorks.com Manufacturing Engineering Centre (MEC), Cardiff University, UK (http://www.mec.cf.ac.uk /services/?view=sla&style=default) Rapid Prototyping and Stereolithography animation (http://www.protocam.com /html/video.html) Animation demonstrates stereolithography and the actions of an SL machine About 3D Systems, Company History (http://www.3dsystems.com/company/index.asp) Retrieved from "http://en.wikipedia.org/w/index.php?title=Stereolithography&oldid=486285639" Categories: American inventions Laser applications Solid freeform fabrication This page was last modified on 8 April 2012 at 17:28. Text is available under the Creative Commons Attribution-ShareAlike License; additional terms may apply. See Terms of use for details. Wikipedia is a registered trademark of the Wikimedia Foundation, Inc., a non-profit organization.

3 di 3

14/04/2012 15.52

Potrebbero piacerti anche

- 3d PrintingDocumento8 pagine3d PrintingMuhammed BasheerNessuna valutazione finora

- Direct Metal Laser-Sintering (DMLS) - HistoryDocumento12 pagineDirect Metal Laser-Sintering (DMLS) - HistoryalexnadaNessuna valutazione finora

- 3D Printing: A Seminar Report OnDocumento17 pagine3D Printing: A Seminar Report OnSourabh Raorane100% (1)

- Stereolithography ExplainedDocumento6 pagineStereolithography ExplainedsivaeinfoNessuna valutazione finora

- Sub-Wavelength Holographic Lithography (SWHL)Documento15 pagineSub-Wavelength Holographic Lithography (SWHL)МРязанскийNessuna valutazione finora

- New Sensors and Processing ChainDa EverandNew Sensors and Processing ChainJean-Hugh ThomasNessuna valutazione finora

- Stereolithography: 3D Printing Layer by LayerDocumento3 pagineStereolithography: 3D Printing Layer by LayerIonuț StănculeaNessuna valutazione finora

- Stereo LithographyDocumento6 pagineStereo LithographySowjanya Venigalla0% (1)

- A Review of Stereolithography - Processes and SystemsDocumento17 pagineA Review of Stereolithography - Processes and SystemsJeremiah PuaNessuna valutazione finora

- LaserMaterialProcessing AssignmentDocumento26 pagineLaserMaterialProcessing AssignmentTejas LadheNessuna valutazione finora

- A Review On Stereo-LithographyDocumento4 pagineA Review On Stereo-LithographyGRD JournalsNessuna valutazione finora

- Seminar Report StereolithographyDocumento8 pagineSeminar Report StereolithographyMahesh PrajapatiNessuna valutazione finora

- Report RPDDocumento15 pagineReport RPDShrikrishna BirajdarNessuna valutazione finora

- Me 5600 Term ProjectDocumento14 pagineMe 5600 Term Projectapi-324383351Nessuna valutazione finora

- Research Paper On StereolithographyDocumento7 pagineResearch Paper On Stereolithographyc9q0c0q7100% (1)

- A Review On Fabricating Procedures in Ra-59942624Documento18 pagineA Review On Fabricating Procedures in Ra-59942624manoj smNessuna valutazione finora

- Fused Deposition Modelling of Synthetic FibersDocumento15 pagineFused Deposition Modelling of Synthetic Fibersaariyaraj.pNessuna valutazione finora

- 7.3D PrintingDocumento18 pagine7.3D PrintingNasir SadiqNessuna valutazione finora

- Advanced Manufacturing Processes, Pune University, BEDocumento21 pagineAdvanced Manufacturing Processes, Pune University, BESachin KumbharNessuna valutazione finora

- Unit 3 PDFDocumento38 pagineUnit 3 PDFnarasimhanaiduNessuna valutazione finora

- StereolithographyDocumento13 pagineStereolithographyElstonD'cruzNessuna valutazione finora

- A Decomposition-Based Approach To Layered ManufacturingDocumento35 pagineA Decomposition-Based Approach To Layered Manufacturingdangquang_k46Nessuna valutazione finora

- 13 InTech-Capabilities and Performances of The Selective Laser Melting ProcessDocumento21 pagine13 InTech-Capabilities and Performances of The Selective Laser Melting ProcessPhilipe Saraiva CruzNessuna valutazione finora

- Research PaperDocumento10 pagineResearch PaperMalik ahxanNessuna valutazione finora

- Rapid Prototyping Technique of Stereolithography (SLADocumento23 pagineRapid Prototyping Technique of Stereolithography (SLAR RAJESWARINessuna valutazione finora

- Image Processing For Radiographic Films of Weld InspectionDocumento7 pagineImage Processing For Radiographic Films of Weld InspectionMahmoud AbdullahNessuna valutazione finora

- Comparison of RP Techniques PDFDocumento31 pagineComparison of RP Techniques PDFSantoshNessuna valutazione finora

- 3D Printed Chalk Holder with Laser PointerDocumento12 pagine3D Printed Chalk Holder with Laser PointerNAGARJUN RNessuna valutazione finora

- Prototyping, Are Being Developed As An Alternative To Subtractive Processes. TheseDocumento19 paginePrototyping, Are Being Developed As An Alternative To Subtractive Processes. TheseBalasivarama ReddyNessuna valutazione finora

- Task 03 PDFDocumento4 pagineTask 03 PDFSaad ShakilNessuna valutazione finora

- Rapid prototyping techniquesDocumento23 pagineRapid prototyping techniquesGirish JawalageriNessuna valutazione finora

- Solid Groung CuringDocumento16 pagineSolid Groung Curingselva_raj215414100% (2)

- Rapid PrototypingDocumento55 pagineRapid PrototypingPrashanth SaiNessuna valutazione finora

- Numerical Simulations of Wear: MonaöqvistDocumento59 pagineNumerical Simulations of Wear: MonaöqvistАлишер БердиевNessuna valutazione finora

- RP Processes Classification and ComparisonDocumento24 pagineRP Processes Classification and ComparisonB. selvababuNessuna valutazione finora

- 1 Overview of Rapid Prototyping: o o o o o oDocumento15 pagine1 Overview of Rapid Prototyping: o o o o o oVaisakh SomakumarNessuna valutazione finora

- Stereolithography ThesisDocumento5 pagineStereolithography ThesisPaperWritingServiceCollegeBuffalo100% (2)

- 3D Printing: Additive Manufacturing GuideDocumento10 pagine3D Printing: Additive Manufacturing GuideKelvin Dale YubidiNessuna valutazione finora

- Fabrication ProcessDocumento5 pagineFabrication ProcessSeafuri Khairunnisa UntadiNessuna valutazione finora

- Water Jet Procedd PDFDocumento788 pagineWater Jet Procedd PDFVijendraAgar100% (1)

- Additive ManufacturingDocumento4 pagineAdditive ManufacturingUttam AnimireddyNessuna valutazione finora

- Additiv Emanufacturing Solved QuestionsDocumento5 pagineAdditiv Emanufacturing Solved QuestionsSameer SonuNessuna valutazione finora

- Holographic and Shearographic NDT Application in Aerospace ManufacturingDocumento5 pagineHolographic and Shearographic NDT Application in Aerospace ManufacturingPDDELUCANessuna valutazione finora

- Applicability and Limitations of 3D Printing For Civil StructuresDocumento11 pagineApplicability and Limitations of 3D Printing For Civil StructuresaaaNessuna valutazione finora

- Rapid Prototyping: Ashish Menon-13Bme0317 Sumit Sankhyan - 13bme0051 Siddhartha SARKAR - 13BME0281Documento19 pagineRapid Prototyping: Ashish Menon-13Bme0317 Sumit Sankhyan - 13bme0051 Siddhartha SARKAR - 13BME0281AshishMenonNessuna valutazione finora

- Mm4 RPD Rapid Product Development: Group 2: Selective Laser SinteringDocumento16 pagineMm4 RPD Rapid Product Development: Group 2: Selective Laser SinteringDanial IrfanNessuna valutazione finora

- Fabrication of Stainless Steel Stamps for Microfluidic DevicesDocumento6 pagineFabrication of Stainless Steel Stamps for Microfluidic DevicesJarek PlaszczycaNessuna valutazione finora

- Kaushalendra PDFDocumento24 pagineKaushalendra PDFharshNessuna valutazione finora

- 3dprintingpracticelab 230710091102 b46f4fddDocumento36 pagine3dprintingpracticelab 230710091102 b46f4fddchantiNessuna valutazione finora

- Seminar Report Streolithography NNDocumento23 pagineSeminar Report Streolithography NNShubham DesaiNessuna valutazione finora

- Nanoscale Lithography, Techniques and TechnologyDocumento29 pagineNanoscale Lithography, Techniques and TechnologyAhmad AliNessuna valutazione finora

- Final Sla ReportDocumento19 pagineFinal Sla Reportapi-251662461Nessuna valutazione finora

- Stereolithography Apparatus (SLA)Documento19 pagineStereolithography Apparatus (SLA)Hamza ShafiqNessuna valutazione finora

- 4 Seminar Report After Index PDFDocumento24 pagine4 Seminar Report After Index PDFM. Sadiq. A. PachapuriNessuna valutazione finora

- 3D Printing Unit 3Documento62 pagine3D Printing Unit 3Aman SinghNessuna valutazione finora

- AMT Notes Unit-2Documento27 pagineAMT Notes Unit-2Suddapally VIVEK ReddyNessuna valutazione finora

- Influence of Ultrasonic Vibration On Micro-ExtrusionDocumento2 pagineInfluence of Ultrasonic Vibration On Micro-ExtrusionDeepak AgrawalNessuna valutazione finora

- Frontiers e ManufacturingDocumento9 pagineFrontiers e ManufacturingmartinsandovalandresNessuna valutazione finora

- In Situ Control of Roughness of Processed Surfaces by Re Ectometric MethodDocumento11 pagineIn Situ Control of Roughness of Processed Surfaces by Re Ectometric Methodalecandro_90Nessuna valutazione finora

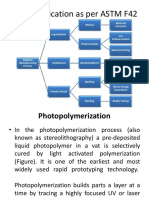

- AM Classification As Per ASTM F42Documento19 pagineAM Classification As Per ASTM F42RajijackNessuna valutazione finora

- The Onion and Personal Kanban - Not Out of ReachDocumento11 pagineThe Onion and Personal Kanban - Not Out of ReachalexnadaNessuna valutazione finora

- Explore Hidden Functions in MD04 - SCNDocumento7 pagineExplore Hidden Functions in MD04 - SCNalexnadaNessuna valutazione finora

- Color Palette and The 56 Excel ColorIndex ColorsDocumento23 pagineColor Palette and The 56 Excel ColorIndex ColorsalexnadaNessuna valutazione finora

- 50 Life Hacks To Simplify Your World TwistedSifterDocumento34 pagine50 Life Hacks To Simplify Your World TwistedSifteralexnadaNessuna valutazione finora

- Uechi RyuDocumento13 pagineUechi RyualexnadaNessuna valutazione finora

- Small Surface StrikesDocumento13 pagineSmall Surface StrikesalexnadaNessuna valutazione finora

- Stereolithography - Wikipedia, The Free EncyclopediaDocumento3 pagineStereolithography - Wikipedia, The Free EncyclopediaalexnadaNessuna valutazione finora

- Stereolithography - Wikipedia, The Free EncyclopediaDocumento3 pagineStereolithography - Wikipedia, The Free EncyclopediaalexnadaNessuna valutazione finora

- Trepanning On Unidirectional Composites Delamination Studies 5567-1Documento9 pagineTrepanning On Unidirectional Composites Delamination Studies 5567-1alexnadaNessuna valutazione finora

- Stereolithography - Wikipedia, The Free EncyclopediaDocumento3 pagineStereolithography - Wikipedia, The Free EncyclopediaalexnadaNessuna valutazione finora

- Stereolithography - Wikipedia, The Free EncyclopediaDocumento3 pagineStereolithography - Wikipedia, The Free EncyclopediaalexnadaNessuna valutazione finora

- Aikido Pioneers Prewar SampleDocumento90 pagineAikido Pioneers Prewar SampleAttila CzoborNessuna valutazione finora

- R980-500-380 Architecture Brochure 0809Documento8 pagineR980-500-380 Architecture Brochure 0809alexnadaNessuna valutazione finora