Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Lab Awet 5

Caricato da

Sikin SikinCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Lab Awet 5

Caricato da

Sikin SikinCopyright:

Formati disponibili

APPLICATIONS There are many applications of spray dryer in the industry.

They have been adopted for a wide variety of products such as milk, eggs, yeasts, sugar solutions, coffee extracts and also vegetables extracts, fruit juices and blood plasma; high throughputs can easily be accommodated. One of the common applications is in pharmaceutical field. Although only focusing only in this field, but there are many applications involved. Spray dryer have the effect on powder properties. Rotary atomizers produce more uniform particle sizes compared to pressure atomizers. Co-current dryers produce powders with lower bulk densities than counter current dryers. In granulation, spray dried granulation has improved flow, better distribution of drug colours and also requires less lubricant than wet massed products. It really important in resulting of shell of concentrated binder at the surface of the granular material, providing strong tablets and maximum use of binder. The bioavailability is one of the applications of spray dryer. Besides that, encapsulation is another application. With concurrent drier, heat exposure is minimized. The product is usually recovered about 15 oC below the outlet temperature. Microencapsulation of products such as antibiotics, vaccines, peptides and proteins is one of the applications. Spray dryer also applied in inhalation where highly specialized spray drying nozzles that give increased particle engineering capabilities even on large scale making it possible to accurately manipulate aerodynamic particle size and properties.

Lastly, spray dryer is applied in controlling the released products. it creates a shell-like structure around the granular allows spray drying to be used for the manufacture of controlled-release products. ADVANTAGES Spray dryer has a lot of advantages and that is why this equipment is widely used in the industry. There are several reasons why spray dryer is used. Firstly, is because of its particle size control. Dry particle size can be easily controlled by atomization of the liquid feed and the design of the hot gas inlet. It can increase yields for products that require classification. Spray dryers can typically produce 20 to 500 micron average particles size in a bell shaped distribution. Apart from that, the shape of most spray dryer particles is spherical; provides for fluid-like flow properties. This makes many downstream operations such as packaging, pressing, filtering and handling easier and less costly. Another advantage of spray dryers is the homogenous solid mixture produced. it produced the most homogenous product for multi-component solutions and slurries. The chemical composition of every particle is the same. The evaporative cooling of the product is another advantage. In the air, heat and mass transfer occur. Hence, vapour films the surrounding the droplet. It keeps the particles at the saturation temperature. Furthermore, spray dryer only need a short residence time. Atomization of the liquid feed causes the surface area are produced, enables short gas residence time that ranging from 3.40 seconds depending upon the application which permits spray drying without thermal degradation. There are fast turn-around times and product changes as there is no product hold up in the spray drying equipment.

Lastly is its advantage of reduction in corrosion potential. Spray dryer is a gas suspended process, so the dry chamber remains dry by design. Therefore, there are many corrosive materials can be processed with carbon steel as the primary material of construction of the spray dryer chamber that reduces capital costs. DISADVANTAGES Spray dryer is often used in large scale production of food. The problem is fruit and flavouring powders are often sticking to the walls of the dryers during the spray drying process. This can cost pharmaceutical money in cleaning costs and lost produce. Besides that, small scale spray dryer used in the laboratory is not performing as well as big scale spray dryer. PRECAUTION For a given degree of atomization the diameter must be sufficiently large to ensure that the droplets do not hit the wall before they are dry. At the other extreme, it should not be so large that the atomization and matching flow of hot gas are not under control; this would result in a non-uniform interaction between the air and the particles. During the process of spray drying, do not touch the drying chamber as it is very hot.

REFERENCE Ranken M.D, Kill R.C, Baker C.G.J, 1997. Food Industries Manual 24th Edition. London: Blackie Academic and Professional.

Potrebbero piacerti anche

- SpectroscopDocumento104 pagineSpectroscopSikin SikinNessuna valutazione finora

- TT 0309Documento2 pagineTT 0309Sikin SikinNessuna valutazione finora

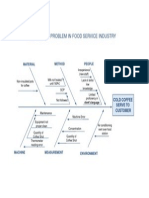

- Ishikawa DiagramDocumento1 paginaIshikawa DiagramSikin SikinNessuna valutazione finora

- Universiti Malaysia Sabah: Senarai Semak Latihan IndustriDocumento3 pagineUniversiti Malaysia Sabah: Senarai Semak Latihan IndustriSikin SikinNessuna valutazione finora

- (Your Name & Full Address) (Date) : Li Placement Application Cover Letter SampleDocumento2 pagine(Your Name & Full Address) (Date) : Li Placement Application Cover Letter SampleSikin SikinNessuna valutazione finora

- (Company's Name & Full Address) : UMS/SSMP6.8/600-3/15/1 (Date)Documento1 pagina(Company's Name & Full Address) : UMS/SSMP6.8/600-3/15/1 (Date)Sikin SikinNessuna valutazione finora

- RUJUKANDocumento2 pagineRUJUKANSikin SikinNessuna valutazione finora

- Serial Dilution MethodDocumento3 pagineSerial Dilution Methoddraneesh75% (4)

- Lab YogurtDocumento6 pagineLab YogurtSikin Sikin0% (1)

- EnumerationDocumento7 pagineEnumerationSikin Sikin100% (1)

- Microbiology Lab 3Documento6 pagineMicrobiology Lab 3Sikin SikinNessuna valutazione finora

- Lab SauerkrautDocumento6 pagineLab SauerkrautSikin Sikin100% (2)

- Eastern and Western Cookery SinopsisDocumento9 pagineEastern and Western Cookery SinopsisSikin SikinNessuna valutazione finora

- Lab Preservation 2Documento6 pagineLab Preservation 2Sikin SikinNessuna valutazione finora

- Lab Preservation 1Documento7 pagineLab Preservation 1Sikin SikinNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- AUC SheetDocumento26 pagineAUC SheetTanmay SagarNessuna valutazione finora

- Photo-Realistic 3D Model Extraction From Camera Array CaptureDocumento11 paginePhoto-Realistic 3D Model Extraction From Camera Array CaptureJohn NaylorNessuna valutazione finora

- Home Power Dec-Jan 07Documento132 pagineHome Power Dec-Jan 07Rosario Llanos GomezNessuna valutazione finora

- Sri Chaitanya Physics Integer Type Question BANKkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkDocumento74 pagineSri Chaitanya Physics Integer Type Question BANKkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkkSai GokulNessuna valutazione finora

- Week 5 - Random Variables, CDF, PDFDocumento16 pagineWeek 5 - Random Variables, CDF, PDFHaris GhafoorNessuna valutazione finora

- Natural ColorDocumento14 pagineNatural ColorleeNessuna valutazione finora

- Physics - 11Documento11 paginePhysics - 11Ishika GuptaNessuna valutazione finora

- 11th - STD - Physics - Volume II - EM - WWW - Tntextbooks.in PDFDocumento328 pagine11th - STD - Physics - Volume II - EM - WWW - Tntextbooks.in PDFTheresaNessuna valutazione finora

- Pharmaceutical ChemistryDocumento19 paginePharmaceutical ChemistryRaj Nemala Raj NemalaNessuna valutazione finora

- Zeljkovic CedomirDocumento6 pagineZeljkovic CedomirPatriceEmNessuna valutazione finora

- Kodaikanal Weir GateDocumento32 pagineKodaikanal Weir GateHarish Kumar MahavarNessuna valutazione finora

- ChromatographyDocumento31 pagineChromatographySelim Akhter100% (4)

- 4c Lab3 Heat EnginesDocumento4 pagine4c Lab3 Heat EnginesAiza AliNessuna valutazione finora

- Ch.2 Deflection 1Documento19 pagineCh.2 Deflection 1Long TingNessuna valutazione finora

- MIT15 450F10 Rec03 PDFDocumento9 pagineMIT15 450F10 Rec03 PDFaluiscgNessuna valutazione finora

- Energy Guide Midea - Mrc07m6aww Mrc07m6ewwDocumento1 paginaEnergy Guide Midea - Mrc07m6aww Mrc07m6ewwharry HendersonNessuna valutazione finora

- Cromax 4140 PDFDocumento2 pagineCromax 4140 PDFDidik PrihantoroNessuna valutazione finora

- HW1 Phys3041Documento3 pagineHW1 Phys3041Sam TseNessuna valutazione finora

- 7 Anthropometry and Workplace DesignDocumento22 pagine7 Anthropometry and Workplace DesignDeshanBenhurNessuna valutazione finora

- Construction and Building Materials: S. Jeeva Chithambaram, Sanjay KumarDocumento8 pagineConstruction and Building Materials: S. Jeeva Chithambaram, Sanjay KumarKartickPaiNessuna valutazione finora

- Specification of Ground AnchorDocumento15 pagineSpecification of Ground AnchordonnyNessuna valutazione finora

- Matlab For SHRT Circuit AnalysisDocumento6 pagineMatlab For SHRT Circuit AnalysisM B Hemanth KumarNessuna valutazione finora

- 110 MBRSDocumento4 pagine110 MBRSknsvel20005966Nessuna valutazione finora

- Ch. 9 (B) LecDocumento38 pagineCh. 9 (B) LecTom UlesNessuna valutazione finora

- Bmsee Ii Math Challenge!Documento32 pagineBmsee Ii Math Challenge!Venus Cadenas AscarezNessuna valutazione finora

- Cross Taping - A Practical Guide 12Documento2 pagineCross Taping - A Practical Guide 12jfjjfjfjjfjfNessuna valutazione finora

- High Voltage Testing LaboratoryDocumento6 pagineHigh Voltage Testing LaboratoryMohd Izham IdrisNessuna valutazione finora

- Luisa 1Documento20 pagineLuisa 1Walenty JanowiczNessuna valutazione finora

- Sci NotesDocumento4 pagineSci NotesnidhiyourmomNessuna valutazione finora

- System of Linear InequalitiesDocumento7 pagineSystem of Linear InequalitiesDominic SavioNessuna valutazione finora