Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Safety Manual

Caricato da

BranislavVorgicTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Safety Manual

Caricato da

BranislavVorgicCopyright:

Formati disponibili

www.adm.gov.ae/hse - hse@adm.abudhabi.

ae

www.adm.gov.ae/hse - hse@adm.abudhabi.ae

The Municipality of abu Dhabi City invites all Consultant

Offces operating in the Building & Construction Sector

to observe the following:

All contractors are obliged to prepare and submit

Health, Safety & Environment (HSE) plans or their

projects.

HSE plans to be approved by the consultant.

HSE plans have to be added to the requisites of

obtaining permits for starting construction and

infrastructure works.

This requirement has been put into effect as of

26/12/2010.

The guidlines for Developing HSE Plans can be

downloaded from the website

(www.adm.gov.ae/hse).

For inquiries please contact us on: hse@adm.abudhabi

or call the Municipalitys toll-free number.

To all Building and Construction

Consultancy Offces

Announcement

80022220 www.adm.gov.ae/hse

Introduction

1. Project Details

2. Project Brief Description and Project Layout

3. EHS Management Requirements

4. Planning

5. Implementation and Operations

6. Audit and Review

7. Appendices

8. Forms

9. Checklists

10. Screen Windows

..................................................................................... 3

................................................................................ 5

...................................... 7

............................................... 8

...................................................................................... 11

.................................................. 13

........................................................................ 17

................................................................................... 19

........................................................................................ 20

.................................................................................... 34

......................................................................... 54

2

With reference to The Municipality of Abu Dhabi City policy and the vision

of Department of Municipal Affairs, The Municipality of Abu Dhabi City and

based on Abu Dhabi - EHSMS framework is keen to support and assist

consultants, contractors and developers in building and construction sector

to establish and develop their EHS plans. This would improve the efforts

and measures to maintain high standards of EHS at construction projects in

order to protect people, assets and environment.

This booklet contains the basic elements for developing Environment,

Health and Safety (EHS) plan. The implementation of the EHS plan will

enhance the EHS standards to achieve best levels of environment, health

and safety compliance in construction sites in Abu Dhabi Emirate.

4

6

Leadership & Commitment

Defne how senior management lead by example and demonstrate

commitment through participation & communication with employees

on EHS issues.

EHS Policy:

Includes commitment towards continual improvement.

Contains commitment to comply with applicable

current legislations & other requirements.

It should be signed by the top management.

Organization, Roles & Responsibilities:

Project & EHS organizational chart.

EHS personnel roles & responsibilities.

Management of subcontractors and suppliers.

Project key personnel & their contacts.

Communication:

Regular and periodic meetings.

EHS alerts and notice boards.

Rewards, incentives, recognition & discipline.

Training:

EHS induction.

Toolbox talks.

Special EHS training and awareness.

Site Inspection and Monitoring

Incidents Reporting and Investigation

Site EHS Rules & Instructions

Personal Protective Equipment (PPE)

EHS Document Control and Recording System

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

3.10

3.0 EHS Management

Requirements

9

10

Risk Management:

Identifcation of hazards, assessing the risks and specifying control

measures.

Legal and Other Requirements:

EHS laws, regulations, codes of practice, etc.

Emergency Management and Evacuation Plan

Site Security Plan and Access Control.

Permit To Work (PTW)

Traffc Management Plan

How to manage detours, diversions, road closure and vehicles

movement (refer to Traffc Engineering and Roads Safety Department

procedures and guidelines).

4.1

4.2

4.3

4.4

4.5

4.6

4.0 Planning

12

Environmental Arrangements

How to manage the environmental aspects and impacts by developing &

implementing control measures for the following:

Waste Management:

Include appropriate control measures for collection,

segregation and disposal for the waste with conformance

of Abu Dhabi Waste Management Center procedures and

guidelines.

Hazardous waste

Non-Hazardous waste

Soil, Water-Courses and Groundwater Pollution Protection:

Containment areas (bunding) for oil, fuel or chemicals

storage tanks

Washing area for concrete mixing trucks and pumps

Dripping trays for machinery, equipment and trucks

Oil spill combating kits or materials

(Refer to Abu Dhabi Environment Agency - EAD

guidelines, standards and codes of practice).

Air Pollution Protection:

Dust suppression program

Air emission (periodic maintenance programs for the

engines of vehicles, trucks, equipment, plants,

machinery, etc.)

5.3

16

6.0 Audit and Review

Contractor shall defne the basis under which internal & external EHS

auditing and management reviews will be conducted.

18

Checklists

(not required submission to the municipality, just for guidance).

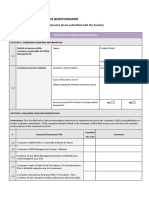

Risk Assessment

(required to be submitted to the municipality attached with the EHS

plan).

EHS Performance quarterly Report

(required to be submitted to the municipality on quarterly basis).

Incidents Report

(required to be submitted to the municipality whenever there is a

reportable incident).

EHS Induction Training

(not required submission to the municipality, just for guidance).

Toolbox Talks

(not required submission to the municipality, just for guidance).

NB: All EHS records should be kept on site and shown when requested.

7.1

7.2

7.3

7.4

7.5

7.6

21

Version 2.0 Page 1 of 3

F0RH E

ENT|TY 0UARTERLY Eh8H8 PERF0RHAN6E REP0RT|NC

GeneraI Information

Registration Number: Classification Code:

Name of Entity:

Address of Entity: Telephone Number:

Number of Employees:

Working Hours Performed

this Quarter:

Reporting Period:

Year:

Q1 (Jan-Mar) Q2 (Apr-Jun) Q3 (Jul-Sep) Q4 (Oct-Dec)

Reporting Timeframe:

End of the second

week in April

End of the second

week in July

End of the second

week in October

End of the second

week in January

HeaIth and Safety Incident Consequence and Severity Summary

(A single incident may be reported in more than one category)

Health and Safety

ncident Summary:

(Total number of each

type of incident

Reported and

Recorded in the

Reporting Period)

Near Miss:

Medical

Treatment Case:

Reportable

Dangerous

Occurrence:

Reportable

Occupational

llness /

Disease:

First Aid njury:

Restricted

Workday Case:

Reportable

Serious njury:

Equipment /

Property

Damage:

Lost Time njury:

Journey

ncident:

Fatality:

Environment, HeaIth and Safety Performance - CompuIsory Reporting to ReIevant Authority

Note: Refer to the AD EHSMS Glossary of Terms for definitions of EHS terms.

KPI 2-01

EHS Department

Resources

Number of

Employees in EHS

Department

Number of UAE Nationals in

EHS Department

No. of Nationals x 100

No. of Employees in EHS Dept.

!Zero Divide

KPI 2-02

Number of EHSMS

Workshops / Seminars

or Similar Training

Organized / Performed

/ Attended

No. of Participants Title / Subject

Training Level

(Management, Supervisory,

Operational)

Duration (Hrs)

KPI 2-03

Number of written warning notices received

from the SRA as a result of non-compliance to

EHSMS requirements

Number of warning notices received:

Number of improvement notices received:

Number of prohibition notices received:

KPI 2-04

Number of fines / penalties / prosecutions

received from the SRA as a result of non-

compliance to EHSMS requirements

Number of penalties / fines received:

Number of enforceable undertakings

performed:

Total value of all fines / penalties/

enforceable undertakings enforced (AED):

KPI 2-05

Lost Time njury Frequency Rate (LTFR)

Number of Lost

Time njuries in the

Reporting Period

Number of Working

Hours in Reporting

Period

No. of LT's x 1,000,000

Working Hours

!Zero Divide

22

23

Version 2.0 Page 2 of 3

F0RH E

ENT|TY 0UARTERLY Eh8H8 PERF0RHAN6E REP0RT|NC

KPI 2-06

Lost Time njury Severity Rate (LTSR)

Number of Work Days

lost due to njuries in

the Reporting Period

Number of Working

Hours in Reporting

Period

No. of Days Lost x 1,000,000

Working Hours

!Zero Divide

KPI 2-07

Total Reportable Case Frequency (TRCF)

Number of Total

Reportable Cases in

the Reporting Period

Number of Working

Hours in Reporting

Period

TRC x 1,000,000

Working Hours

!Zero Divide

KPI 2-08 - 2.09 - 2.10

Environmental ncidents - Severity

(Number of Pollution ncidents in Reporting

Period)

Number of Pollution

ncidents - Minor

Number of Pollution

ncidents - Moderate

Number of Pollution

ncidents - Major

KPI 2-11

Environmental ncident - Type

(Number of Pollution ncidents in Reporting

Period)

(ncluding fuel, oil, waste material or other

polluting substance)

Spill / Release / Discharge to Land

Spill / Release / Discharge to Water, including Groundwater

Release / Discharge to Atmosphere

Unauthorized / Accidental Vegetation Removal or Harm

Accidental Harm to Animal Species

Unauthorized / Accidental Damage to Heritage Site / tem

Other (Provide Details): _ _

KPI 2-12

Power Consumption

(Total Kilowatts Hours (kW h) and

kW h per Employee)

This Reporting Quarter Previous Reporting Quarter

Percentage Reduction

or ncrease

(ndicate reduction as a

negative figure eg 3.5 %)

Total kW h

kW h Per

Employee

Total kW h

kW h Per

Employee

kW h Per Employee

KPI 2-13

Water Consumption

Water use (in production

processes, office activities or as

drinking water)

(Total cubic meters (m

3

) and m

3

per Employee)

This Reporting Quarter Previous Reporting Quarter

Percentage Reduction

or ncrease

(ndicate reduction as a

negative figure eg 3.5 %)

Total m

3

m

3

Per Employee Total m

3

m

3

Per Employee m

3

Per Employee

KPI 2-14

Paper Consumption

Average number of paper pages

used per employee per month

This Reporting Quarter Previous Reporting Quarter

Percentage Reduction

or ncrease

(ndicate reduction as a

negative figure eg 3.5 %)

Average No. of Pages used per

Employee

Average No. of Pages used per

Employee

% Per Employee ncrease

or Decrease

KPI 2-15

Fuel Consumption

Average fuel consumption of entity

owned and /or operated vehicles.

(Liters per 100 kilometers)

This Reporting Quarter Previous Reporting Quarter

Percentage Reduction

or ncrease

(ndicate reduction as a

negative figure eg 3.5 %)

Number of vehicles

owned and/or

operated by entity

Average fuel

consumption of

vehicles

(Combined Cycle

L/100 klms)

Number of

vehicles owned

and/or

operated by entity

Average fuel

consumption of

vehicles

(Combined Cycle

L/100 klms)

% Fleet Fuel Consumption

ncrease or Decrease

KPI 2-16

Non-Hazardous Waste Disposal

Amount of non-hazardous (solid

and liquid) waste collected by

Service Providers for disposal.

This Reporting Quarter Previous Reporting Quarter

Percentage Reduction

or ncrease

(ndicate reduction as a

negative figure eg 3.5 %)

Solid (kg) Liquid (L) Solid (kg) Liquid (L) Solid (kg) Liquid (L)

24

Version 2.0 Page 3 of 3

F0RH E

ENT|TY 0UARTERLY Eh8H8 PERF0RHAN6E REP0RT|NC

KPI 2-17

Non-Hazardous Waste Recycling

Amount of segregated non-

hazardous (solid and liquid) waste

collected by Service Providers for

recycling / reuse / further

processing.

This Reporting Quarter Previous Reporting Quarter

Percentage Reduction

or ncrease

(ndicate reduction as a

negative figure eg 3.5 %)

Solid (kg) Liquid (L) Solid (kg) Liquid (L) Solid (kg) Liquid (L)

KPI 2-18

Hazardous Waste Disposal

Amount of hazardous (solid and

liquid) waste collected by Service

Providers for disposal.

This Reporting Quarter Previous Reporting Quarter

Percentage Reduction

or ncrease

(ndicate reduction as a

negative figure eg 3.5 %)

Solid (kg) Liquid (L) Solid (kg) Liquid (L) Solid (kg) Liquid (L)

KPI 2-19

Hazardous Waste Recycling

Amount of hazardous (solid and

liquid) waste collected by Service

Providers for recycling / reuse /

further processing.

This Reporting Quarter Previous Reporting Quarter

Percentage Reduction

or ncrease

(ndicate reduction as a

negative figure eg 3.5 %)

Solid (kg) Liquid (L) Solid (kg) Liquid (L) Solid (kg) Liquid (L)

DecIaration

declare that all information provided in this document is true, correct and complete.

Signature of the

Authorised

Contact Person :

Official

Stamp:

Date : _____ / _____ / _____

OfficiaI Use

Remarks :

ReIevant Authority Stamp Entered into Database by:

Name:

Signature:

Date: _____ / _____ / _____

Reviewed by:

Name:

Signature:

Date: _____ / _____ / _____

25

Version 2.0 Page 1 of 7

F0RH C

ENT|TY Eh8 |N6|0ENT REP0RT|NC

Part A - Incident Notification

To be submitted to the concerned Sector Regulatory Authority within 24 hours for all Reportable ncidents

1. GeneraI Information

Name of Entity:

Registration Number: Classification Code:

Address of Entity:

Authorized Contact Person: Email Address:

Telephone Number: Mobile Number:

Report on Behalf of

Non-Nominated Contractor

Entity:

Yes

No

Entity Name:

Contact Person: Contact Number:

2. ReportabIe Incident Information - ImmediateIy ReportabIe to SRA - within 24 Hours

Health and Safety ncident:

(May select more than one)

Serious FataI

Reportable Dangerous Occurrence

Reportable Occupational

llness / Disease

Fatality

Reportable Serious njury

Environmental ncident:

(May select more than one)

Environment - Moderate Environment - Major

Spills / Releases /

Discharges to

Land

Spills / Releases / Discharges to

Water, including Groundwater

Releases / Discharges

to Atmosphere

Vegetation

Removal / Harm

Harm to Animal Species

Damage to Heritage

Site

Other:___________________________________________________________________

3. RecordabIe Incident Information - Not Required to be ImmediateIy Reported To SRA

For Entity Use OnIy - data to be submitted as part of EHS Performance QuarterIy Report - Form E or E2

Health and Safety ncident:

(May select more than one)

Minor / No Injury / SIight Moderate

Near Miss Lost Time njury

First Aid njury Medical Treatment Case

Equipment / Property Damage Restricted Workday Case

Environmental ncident:

(May select more than one)

Environment - Minor

Spills / Releases /

Discharges to

Land

Spills / Releases / Discharges to

Water, including Groundwater

Releases / Discharges

to Atmosphere

Vegetation

Removal / Harm

Harm to Animal Species

Damage to Heritage

Site

Other:___________________________________________________________________

Version 2.0 Page 2 of 7

F0RH C

ENT|TY Eh8 |N6|0ENT REP0RT|NC

4. Incident DetaiIs:

Description of Circumstances

leading to the ncident:

Date of ncident: _ / _ / _ Time (24 hr): :

ncident Workplace Address:

ncident Location on Site:

Police Report Number:

(f applicable)

5. Injured Person's PersonaI DetaiIs (If appIicabIe)

Name: Occupation:

Nationality: Date of Birth: / /

Passport Number: Residency Visa Number:

Contact Address:

Contact Phone Number: Gender: Male Female

Part A - DecIaration by Entity:

declare that all information provided in this document is true, correct and complete.

Signature of the

Authorized

Contact Person :

Official

Stamp:

Date : _____ / _____ / _____

OfficiaI Use - Part A

Remarks :

Inspection / Incident Investigation Required by Sector ReguIatory Authority

Yes No

Remarks:

ReIevant Authority Stamp

Entered into Database by:

ncident Record Number:

Name:

Signature:

Date: _____ / _____ / _____

Reviewed by:

Name:

Signature:

Date: _____ / _____ / _____

26

Version 2.0 Page 3 of 7

F0RH C

ENT|TY Eh8 |N6|0ENT REP0RT|NC

Part B - Incident Investigation

To be completed and submitted to SRA as soon as practicable

Maximum One Month from Date of ncident - For all Reportable ncidents

1. Injury DetaiIs

Nature of njury / llness /

Damage:

Abrasions / Bruising Traumatic Amputation Bite / Sting

Burn Concussion Crush / nternal njury

Cuts/ Laceration / Open

Wound

Hearing Loss / Deafness Dislocation

Electric Shock

Equipment / Property

Damage

Fracture

Foreign Body in Eye Foreign Body under Skin Hernia

Heat Related llness nfectious Disease

Musculoskeletal Disorder

- Chronic / RS

Nerve / Spinal Cord

njury

Occupational llness /

Disease

Poisoning / Toxic Effect -

ngestion

Poisoning / Toxic Effect -

nhalation

Psychological (Stress) Respiratory Disease

Skin rritation / Disease Strain / Sprain Other _______________

Mechanism of njury / llness:

Animal Bit / Sting Biological Factors Cave-n or Collapse

Chemicals / Substances

/ Radiation

Drowning / Submersion Dust / Fumes / Gases

Extreme Temperature /

Fire

Electricity Fall from Height

Hit by Moving Object /

Crush / Vehicle

Manual Handling Mental Stress

Occupational Violence Penetrating njury (needle stick, puncture wound)

Repetitive Motion Slip, Trip and Fall Sound and Pressure

Struck by Falling Object Other Unspecified Mechanism:_____________________

Journey ncident -

ncident occurred during work-related travel, including traveling to

or from work. Refer AD EHSMS Glossary of Terms.

Agency / Source of

njury / llness:

Animal / Human Confined Space Environmental Conditions

Fixed Machinery / Plant nfectious Agent

Materials or Chemical

Substances

Mobile Plant / Equipment Non-Powered Equipment / Tools / Appliances

Powered Equipment /

Tools / Appliances

Road Transport /

Vehicles

Scaffolding or Ladders

Sharps / Scalpels /

Needles / Etc

Trench or Excavations Other ______________

27

Version 2.0 Page 4 of 7

F0RH C

ENT|TY Eh8 |N6|0ENT REP0RT|NC

Bodily

Location:

Head /

Neck

Cervical Spine Ear Eye

Face (excluding eye) Forehead Mouth

Neck Nose Scalp

Trunk

Abdomen Back Genitals

Pelvis Spine Thorax

Upper

Extremity

Clavicle (Collar Bone) Elbow

Fingers (other than

Thumbs)

Forearm Hand Shoulder

Thumb Upper Arm Wrist

Lower

Extremity

Ankle Buttocks Foot

Hip / Groin Knee Lower Leg

Thigh Toes

nternal

Organs

Arteries Brain Heart

ntestines Kidney Liver

Lungs Spleen Stomach

General Heat Related Occupational llness Other: ______________

Other ReIevant Incident Information:

Remarks:

2. Risk Assessment:

Likelihood of Recurrence:

Severity of Outcome:

Level of Risk:

3. Corrective Actions to Prevent Recurrence

Actions: By Whom: By When: Date Completed:

4. Actions CompIete:

Name:___ __________________________________________________

Signed (EHS Manager / Equivalent) :____________________________________

Feedback to person(s) involved.

Title:_

Date:_

28

Version 2.0 Page 5 of 7

F0RH C

ENT|TY Eh8 |N6|0ENT REP0RT|NC

DecIaration by Injured Person (If PossibIe)

declare that all information provided in this document is true, correct and complete.

Name of njured

Person or

Representative:

Signature of njured

Person or

Representative:

Date : _____ / _____ / _____

Part B - DecIaration by Entity:

declare that all information provided in this document is true, correct and complete.

Signature of the

Authorized

Contact Person :

Official

Stamp:

Date : _____ / _____ / _____

Incident Reporting Progress

Open Closed

Further evidence attached to report (eg. Photos, Drawings, SDS, Copy of Police Report, Detail nvestigation Report, etc)

OfficiaI Use - Part B

Remarks :

Incident Investigation / FoIIow-up Required by Sector ReguIatory Authority

Yes No

Remarks:

ReIevant Authority Stamp Entered into Database by:

Name:

Signature:

Date: _____ / _____ / _____

Reviewed by:

Name:

Signature:

Date: _____ / _____ / _____

Personal inIormation will not be disclosed to other parties without your consent unless required to do so by law.

29

F0RH C

ENT|TY Eh8 |N6|0ENT REP0RT|NC

Entity EHS Incident Report Form (AD EHSMS Form G) - Guidance Notes

What is this Form used for?

This form has been designed to be used by entities nominated under the Abu Dhabi EHSMS as an

EHS ncident Report Form.

This form has primarily been designed to report certain EHS incidents to the concerned Sector

Regulatory Authority (AD EHSMS Form G Part A Section 2).

The form can also be used to report and record all EHS incidents within the entity (AD EHSMS Form

G Part A Section 3) - not all EHS incidents are reportable to concerned Sector Regulatory

Authorities.

Specific EHS incidents may require reporting to other relevant authorities (eg. Police, Ministry of

Labour, EAD, etc).

What Incidents need to be reported to the concerned Sector ReguIatory Authority?

AD EHSMS Reportable ncidents include:

Fatality;

Reportable Serious njury;

Reportable Dangerous Occurrence;

Reportable Occupational llness / Disease; and

Major or Moderate Pollution ncident (EAD reporting may be required).

Reporting Timeframes (ReportabIe Incidents)

The concerned Sector Regulatory Authority must be officially notified within 24 hours of an incident

occurring at a workplace which results in a reportable incident using Part A of this Form.

ncident investigation and report must be complete and submitted to the concerned Sector Regulatory

Authority within one month of the incident date using Part B of this Form.

Definitions - Full definitions of terms used in this document refer to the AD EHSMS RF - Glossary of Terms.

OccupationaI IIIness or Injury:

Any of the work-related diseases listed in (Schedule No. 1 of Federal Law No. 8 of 1980 and EHS RI Mechanism

03 EHS Performance and Incident Reporting Schedule C) or any other injury sustained by a worker during and

by reason of carrying out his duties. An injury may be considered as an occupational injury if it occurs at work or

arises from a work practice or the conditions in a workplace.

Occupational njuries include the recurrence, aggravation or exacerbation of previous work-related injuries. For

example, if an employee has previously had a work-related knee injury and the injury happens again because of

work, the new injury may have to be reported.

FataIity:

Fatality is a death resulting from an injury or illness, regardless of the time intervening between injury and death.

ReportabIe Dangerous Occurrences - Schedule A of AD EHS RI - Mechanism 3.0

For detail definitions of the following incidents refer to Schedule A of AD EHS RI Mechanism 3.0

Explosion or Fire;

Collapse of Equipment;

Machinery Damage;

Collapse of Building / Structure or Excavation;

Overhead Electric Lines;

Malfunction of Radiation Generating Equipment;

Escape of Flammable Substances / Hazardous Substances; and

Fall from Heights

30

F0RH C

ENT|TY Eh8 |N6|0ENT REP0RT|NC

Serious Injuries that require Immediate Notification - ScheduIe B of AD EHS RI - Mechanism 3.0

An incident requiring reporting is classified as:

the employee requiring medical treatment within 48 hours of exposure to a substance;

an employee requiring immediate treatment as an in-patient in a hospital; and

an employee requiring immediate medical treatment for:

the loss of a distinct part or organ of the injured person's body, including the amputation of any part of

an employee's body;

loss of consciousness and/or requiring resuscitation;

a serious head injury;

a serious eye injury, including loss of sight (temporary or permanent);

the separation of skin from any underlying tissue (such as scalping or de-gloving);

electric shock;

a spinal injury;

dislocation of the shoulder, hip, knee or spine;

the loss of bodily function; and

serious laceration.

Lost Time Injury

Lost Time njury (LT) is a work-related injury or illness that results an individual is unable to work on a

subsequent scheduled work day or shift.

Example: An employee is injured on the job on Tuesday. He was scheduled to work on Wednesday and

Thursday on regular time and Saturday on overtime. He was instructed to stay off work until Sunday, and did so.

This is a lost time injury. The employee missed three scheduled days of work (Wednesday Thursday, and

Saturday) and all three days are counted as lost workdays for this case.

OccupationaI IIIness

Any work-related abnormal condition or disorder, other than an injury, which is mainly caused by exposure to

environmental factors associated with the employment.

t includes acute and chronic illness or diseases that may be caused by repetitive motion, inhalation, absorption,

ingestion or direct contact.

Whether a case involves a work-related injury or an Occupational llness is determined by the nature of the

original event or exposure that caused the case, not by the resulting condition of the affected employee.

An injury results from a single event and cases resulting from anything other than a single event are considered

Occupational llness.

PoIIution Incident

An incident or set of circumstances during or as a consequence of which there is likely to be a leak spill or other

escape or deposit of a substance, as a result of which pollution has occurred, is occurring or is likely to occur. t

includes an incident or set of circumstances in which a substance has been placed or disposed of on premises.

Major PoIIution Incident

Substances or materials have escaped the site causing significant pollution of adjoining areas which will require

containment, clean up and/or remediation involving other agencies and/or additional resources not available to

local site management. rreversible or long term environmental impacts have occurred or are likely to occur to

the environment and/or there is a significant health risk to workers and/or the community. Significant, long-term

remediation and regulatory intervention will be required.

Moderate PoIIution Incident

Substances or materials have escaped the site causing pollution of adjoining areas which may require

containment, clean up and/or remediation involving other agencies and/or additional resources not available to

local site management. Moderate reversible environmental impact has occurred or is likely to occur to the

environment and/or there is a moderate health risk to workers and/or the community. Moderate, medium-term

remediation and regulatory intervention may be required.

31

Ref.No.:ADM/HSED/FM//

IssuanceDate:July

IssueNo.:

EHSInductionTraining

GeneralInformation

CompanyName: ProjectName:

InducteesName: InductionDate:

Topicstodiscuss

S/N Description YES NO Remarks

ProjectDescription

CompanyHSEPolicy

IntroductionofKeyPersonnel

SiteLayoutandwelfareFacilities(restarea,toilet,etc.)

SiteRules(e.g.drug&alcohol&smokingpolicy,differentsignage,nohorseplaying,

wearingPPEs,avoidwearingJewelries,etc.)

Environment&WasteDisposal

Workpermits

RiskAssessment/RiskRegister

AccidentReporting

OtherRelevantTopicsforDiscussion(ifapplicable)

ManagementofChange(newprocess,equipment&machinery,procedures,etc.)

Relevant&applicablelaws,regulations

Signature&Remarks

EmployeesSignature: Remarks:

Conductedby:________________________________

JobTitle:________________________________

Signature:________________________________

Remarks:

Note:Forguidanceanditisnotlimitedtoitscontent

32

EHS

Ref. No. : ADM/HSED/FM/003/10

Issuance Date: July 2010

Issue No.: 01

Tool Box Talk

General Information

Company Name: Project Name:

Date:____________________________________________________________ Location:__________________________________________________

A. Specifc job to be carried out:

B. Topics Discussed:

1. 4.

2. 5.

3. 6.

C. Name and Signature of workers attended

Conducted By:

Name :

Job Title :

Signature :

Note: For guidance and it is not limited to its content

Name Signature Name Signature

33

The inspection checklists include the

followings:

Confned Spaces

Traffc Management

Electrical Installation

Environment

Excavations

Fire & Emergency

Hazardous Substances

Housekeeping

Ladders

Lifting Equipment & Gears

Machinery

Portable Tools

Personal Protective Equipment (PPE)

Scaffolds

Site General

Vehicles & Mobile Equipment

Welding & Gas Cutting

Welfare Facilities

Working Platforms & Cantilevers

Inspection Checklists

34

35

Ref. No. : ADM/HSED/FM/004/10

Issuance Date: July 2010

Issue No.: 01

Checklist

Conf ined Spaces

General Information

Company Name: Project Name:

Conducted By: Date:

Poor: Absence of major control measures (high risk), work to be stopped and risk assessment to be reviewed immediately.

Fair: Some minor controls are missing (medium risk), additional control measures to be implemented.

Good: All required controls are in place (low risk), only monitoring is required.

Description

Item

Evaluation

Remarks

(insert your observation, and proposed

corrective action plan)

Good Fair Poor N/A

Hazards identifed, risk evaluated, assessed &

communicated before commencement of work.

Permit To Work implemented & posted in place.

Mechanical and / or electrical isolation of the confned

space done.

Adequate ventilation to ensure a suffcient supply of air

conducted.

Cleaning & purging to remove all hazardous (fammable

& or toxic) gases & fumes performed.

Testing of oxygen concentration conducted to

acceptable standard level.

Detecting of fammable & or toxic gases conducted to

ensure their absence or below minimum levels.

Provision of emergency retrieval system (full body

harness, tripod and hoist)

Availability of the backup personnel or rescue

attendants.

Use of non spark tools / devices (intrinsically safe tools

or devices).

Suffcient lighting is available.

Proper PPE & SCBA (Self Contained Breathing

Apparatus) is used.

Suitable access / egress provided.

Area or surrounding isolated with barriers & or cones

and suitable signage in place (where applicable).

Approved By:

Position Name Date Signature

HSE Engineer / Manager

Distribution and Acknowledgment:

Project Manager

Project Engineer

Note: For guidance and it is not limited to its content

EHS Engineer/Manager

Ref. No. : ADM/HSED/FM/003/10

Issuance Date: July 2010

Issue No.: 01

General Information

Company Name: Project Name:

Conducted By: Date:

Poor: Absence of major control measures (high risk), work to be stopped and risk assessment to be reviewed immediately.

Fair: Some minor controls are missing (medium risk), additional control measures to be implemented.

Good: All required controls are in place (low risk), only monitoring is required.

Description

Item

Evaluation

Remarks

(insert your observation, and

proposed corrective action plan)

Good Fair Poor N/A

Advance warning signs boards.

Roadwork signs boards.

Guide signs boards.

Digital or LED* signs boards.

Arrows signs boards.

Delineators.

Cones.

Tubular fexible posts (bollards).

Painted pavement markings.

Raised pavement markings.

Water flled plastic barriers.

Concrete barriers.

Longitudinal crashworthy barriers

Warning lights (fashing lights & beacons).

Street lighting.

Temporary traffc lights.

Rumble strips

Crash cushion (shock absorber)

Buffer zones

Tapers

Flaggers

Pedestrian walkways.

Construction lane access / egress

Fences

Glare screens

Turning radius and lane width.

Approved By:

Position Name Date Signature

HSE Engineer / Manager

Distribution and Acknowledgment:

Project Manager

Project Engineer

Note: For guidance and it is not limited to its content

Checklist

Traff ic Management

Evaluation Remarks

(insert your observation,and proposed

corrective action plan)

36

EHS Engineer/Manager

Ref. No. : ADM/HSED/FM/004/10

Issuance Date: July 2010

Issue No.: 01

Checklist

Electrical Installation

General Information

Company Name: Project Name:

Conducted By: Date:

Poor: Absence of major control measures (high risk), work to be stopped and risk assessment to be reviewed immediately.

Fair: Some minor controls are missing (medium risk), additional control measures to be implemented.

Good: All required controls are in place (low risk), only monitoring is required.

Description

Item

Evaluation

Remarks

(insert your observation, and

proposed corrective action plan)

Good Fair Poor N/A

Electrical hazards identifed and all associated risks have

been assessed.

Permit To Work (PTW) is used & available on site for

electrical work.

All electrical installations commissioning and repairing

carried out by competent electricians.

All electrical installation and appliances comply with the

relevant international standards.

All external electrical installations are weather proof .

All electrical installations provided with Earth Leakage

Circuit Breakers (ELCB).

All distribution boards are locked and signed.

Cables/wires running across the site are in good

condition, properly protected & checked regularly.

Cables are free of joints, & only industrial sockets used

for extending cables.

No naked wires inserted into electrical sockets, & only

earthed & fused plugs to be used.

Sockets are not overloaded.

Level of lighting suitable for the task.

Tag out / lock out system implemented .

Approved By:

Position Name Date Signature

HSE Engineer / Manager

Distribution and Acknowledgment:

Project Manager

Project Engineer

Note: For guidance and it is not limited to its content

Evaluation

Remarks

(insert your observation,and proposed

corrective action plan)

37

EHS Engineer/Manager

Ref.No.:ADM/HSED/FM//

IssuanceDate:July

IssueNo.:

Checklist

Environment

GeneralInformation

CompanyName: ProjectName:

ConductedBy: Date:

Poor:Absenceofmajorcontrolmeasures(highrisk),worktobestoppedandriskassessmenttobereviewedimmediately.

Fair:Someminorcontrolsaremissing(mediumrisk),additionalcontrolmeasurestobeimplemented.

Good:Allrequiredcontrolsareinplace(lowrisk),onlymonitoringisrequired.

Description

Item

Evaluation

Remarks

(insertyourobservation,and

proposedcorrectiveactionplan)

Good Fair Poor N/A

Wasteissegregated&collectedatdesignated

appropriateareas(hazardousfromnon-hazardous)&

adequatewastecontainers/skipsprovided.

Wasteisremoved/disposedregularly&accordingtothe

AbuDhabiWasteCenterguidelines.

Properoil/chemicalsleakage&spillcontrolinplaces

(tanksbunding,drippingtrays,oilspillresponse

materials).

Allocationofdesignatedareaforwashingconcrete

mixers&pumps.

Propercollection&disposalofwastewater&sewage

water.

Propermanagementofnoisegeneratedfromtheproject,

byinstallingnoiseenclosuremeasures(e.g.silencers,&

workscheduling).

Dustand/orfumescontrolmeasureshavebeen

implemented.

Regularmaintenanceformobileequipment,vehicles&

machines.

ApprovedBy:

Position Name Date Signature

HSEEngineer/Manager

DistributionandAcknowledgment:

ProjectManager

ProjectEngineer

Note:Forguidanceanditisnotlimitedtoitscontent

Remarks

(insert your observation,and proposed

corrective action plan)

38

EHS Engineer/Manager

Ref.No.:ADM/HSED/FM//

IssuanceDate:July

IssueNo.:

Checklist

Excavation

GeneralInformation

CompanyName: ProjectName:

ConductedBy: Date:

Poor:Absenceofmajorcontrolmeasures(highrisk),worktobestoppedandriskassessmenttobereviewedimmediately.

Fair:Someminorcontrolsaremissing(mediumrisk),additionalcontrolmeasurestobeimplemented.

Good:Allrequiredcontrolsareinplace(lowrisk),onlymonitoringisrequired.

Description

Item

Evaluation Remarks

(insertyourobservation,and

proposedcorrectiveactionplan)

Good Fair Poor N/A

assessed.

Suitableaccess/egressprovided.

Fallingprotectionsysteminstalledproperly(i.e.barriers,

stopblocker,toeboards,conesandwarningtapes

etc).

Appropriatesupportingsystem/method(shoring,

buttering,orstepping)

Spoilheapsstableandkeptinsafedistancefromthe

edgeoftrenches

Oxygentestedandgaseslevelswithinacceptablelevel

(forexcavationwithdepthmorethanmeter).

Emergencypreparednessplandeveloped,

communicatedandimplemented

Propersignage&warninglights(warningsigns,tapes,

etc)andinstructions(i.e.PTW,emergencynotice..etc)

displayed.

permissionsobtained&displayedvisibly.

Excavatorsareingoodworkingcondition

Propertrainingandawarenessdeliveredtoallinvolved

employees(i.e.toolboxtalk&specializedtraining).

ApprovedBy:

Position Name Date Signature

HSEEngineer/Manager

DistributionandAcknowledgment:

ProjectManager

ProjectEngineer

Note:Forguidanceanditisnotlimitedtoitscontent

Remarks

(insert your observation,and proposed

corrective action plan)

Checklist

Excavations

39

EHS Engineer/Manager

Ref.No.:ADM/HSED/FM//

IssuanceDate:July

IssueNo.:

Checklist

Fire&Emergency

GeneralInformation

CompanyName: ProjectName:

ConductedBy: Date:

Poor:Absenceofmajorcontrolmeasures(highrisk),worktobestoppedandriskassessmenttobereviewedimmediately.

Fair:Someminorcontrolsaremissing(mediumrisk),additionalcontrolmeasurestobeimplemented.

Good:Allrequiredcontrolsareinplace(lowrisk),onlymonitoringisrequired.

Description

Item

Evaluation

Remarks

(insertyourobservation,and

proposedcorrectiveactionplan)

Good Fair Poor N/A

Fireriskassessmentoftheprojectiscarriedout&the

controlmeasuresimplemented.

Goodhousekeepingpractices&dailyremovalofwaste.

designatedareaallocated.

PermitToWork(PTW)procedureforhotworks.

Evacuationplandeveloped&distributed.Emergency

communicated.

Adequatemeansofescapeallocated&unobstructed.

sitemaintained&inspectedregularly.

testedregularly.

Emergencysignage&assemblypointsareinplaces&

communicatedtoallparties.

ApprovedBy:

Position Name Date Signature

HSEEngineer/Manager

DistributionandAcknowledgment:

ProjectManager

ProjectEngineer

Note:Forguidanceanditisnotlimitedtoitscontent

Remarks

(insert your observation,and proposed

corrective action plan)

40

EHS Engineer/Manager

Ref.No.:ADM/HSED/FM//

IssuanceDate:July

IssueNo.:

Checklist

HazardousSubstances

GeneralInformation

CompanyName: ProjectName:

ConductedBy: Date:

Poor:Absenceofmajorcontrolmeasures(highrisk),worktobestoppedandriskassessmenttobereviewedimmediately.

Fair:Someminorcontrolsaremissing(mediumrisk),additionalcontrolmeasurestobeimplemented.

Good:Allrequiredcontrolsareinplace(lowrisk),onlymonitoringisrequired.

Description

Item

Evaluation

Remarks

(insertyourobservation,andproposed

correctiveactionplan)

Good Fair Poor N/A

Properlystored,ventilated,isolated,&suitablesigns

displayed.

MaterialSafetyDataSheet(MSDS)available,and

communicatedtoconcernedpersonnel.

Emergencyescape&breathingapparatusavailable,

testedandingoodcondition

AppropriatePPEisprovidedtotheworkeranditisworn

duringthework.

Hazardoussubstancescontainers/drumshaveeligible

labeling&protectedfromleakageorspillage.

Emptyhazardoussubstancescontainers,drums&

receptaclesshouldbeproperlymaintained&controlled.

ApprovedBy:

Position Name Date Signature

HSEEngineer/Manager

DistributionandAcknowledgment:

ProjectManager

ProjectEngineer

Note:Forguidanceanditisnotlimitedtoitscontent

Remarks

(insert your observation,and proposed

corrective action plan)

41

EHS Engineer/Manager

42

Ref.No.:ADM/HSED/FM//

IssuanceDate:July

IssueNo.:

Checklist

Housekeeping

GeneralInformation

CompanyName: ProjectName:

ConductedBy: Date:

Poor:Absenceofmajorcontrolmeasures(highrisk),worktobestoppedandriskassessmenttobereviewedimmediately.

Fair:Someminorcontrolsaremissing(mediumrisk),additionalcontrolmeasurestobeimplemented.

Good:Allrequiredcontrolsareinplace(lowrisk),onlymonitoringisrequired.

Description

Item

Evaluation

Remarks

(insertyourobservation,and

proposedcorrectiveactionplan)

Good Fair Poor N/A

Clearandsafeaccesstoworkarea.

Propermaterialsstackingandanyloosematerialshave

beenproperlysecured.

orderliness

Constructionwasteanddebriscollectedindesignated

areas.

Adequaterubbishcontainersandrubbishremoveddaily.

Oldtimberde-nailed&allsteelbarscapped.

ApprovedBy:

Position Name Date Signature

HSEEngineer/Manager

DistributionandAcknowledgment:

ProjectManager

ProjectEngineer

Note:Forguidanceanditisnotlimitedtoitscontent

Remarks

(insert your observation,and proposed

corrective action plan)

EHS Engineer/Manager

Ref.No.:ADM/HSED/FM//

IssuanceDate:July

IssueNo.:

Checklist

Ladders

GeneralInformation

CompanyName: ProjectName:

ConductedBy: Date:

Poor:Absenceofmajorcontrolmeasures(highrisk),worktobestoppedandriskassessmenttobereviewedimmediately.

Fair:Someminorcontrolsaremissing(mediumrisk),additionalcontrolmeasurestobeimplemented.

Good:Allrequiredcontrolsareinplace(lowrisk),onlymonitoringisrequired.

Description

Item

Evaluation

Remarks

(insertyourobservation,and

proposedcorrectiveactionplan)

Good Fair Poor N/A

Properlymanufactured(nohandmadewoodenladders).

Allladdersareingoodcondition&suitableforthetask.

Positionedatsuitableworkingangleat

o

tohorizontal.

Securedtop&bottom,andextendedmeterabovethe

platformlevel.

Intermediatelandingplaceprovidedforladdersrise

morethanmeters.

stiles.

Extendableladdersareproperlysecured(i.e.extension

Rungsclearofgrease,oilorotherslipperysubstances.

glassladderscanbeusedinstead).

protectioncage

Laddersshouldbecheckedbeforeuse®ularly

maintained.

ApprovedBy:

Position Name Date Signature

HSEEngineer/Manager

DistributionandAcknowledgment:

ProjectManager

ProjectEngineer

Note:Forguidanceanditisnotlimitedtoitscontent

Remarks

(insert your observation,and proposed

corrective action plan)

43

EHS Engineer/Manager

Ref. No. : ADM/HSED/FM/004/10

Issuance Date: July 2010

Issue No.: 01

Checklist

Lifting Equipments and Gears

General Information

Company Name: Project Name:

Conducted By: Date:

Poor: Absence of major control measures (high risk), work to be stopped and risk assessment to be reviewed immediately.

Fair: Some minor controls are missing (medium risk), additional control measures to be implemented.

Good: All required controls are in place (low risk), only monitoring is required.

Description

Item

Evaluation

Remarks

(insert your observation, and

proposed corrective action plan)

Good Fair Poor N/A

Cranes & slings certifed by 3

rd

party, inspected &

maintained regularly & records maintained.

Lifting plan / procedure prepared & communicated.

All lifting equipments & gears are inspected & certifed by

3

rd

party.

Operator & rigger are competent (third party trained). The

driver & operator are licensed.

Slings, wires, ropes, chains, belts, hooks, shackles are in

good condition, appropriate for job & inspected regularly &

records maintained.

Load charts known & considered before any lifting begins.

Load indicators, alarms & other safety devises are

operational.

Ground condition checked & required corrective actions

implemented.

Outriggers are operational & sole plate provided.

Lifting operation area barricaded & suitable sign boards are

in place.

Approved By:

Position Name Date Signature

HSE Engineer / Manager

Distribution and Acknowledgment:

Project Manager

Project Engineer

Note: For guidance and it is not limited to its content

Remarks

(insert your observation,and proposed

corrective action plan)

Checklist

Lifting Equipment and Gears

Load indicators, alarm & other safety

devices are operational.

44

EHS Engineer/Manager

Ref. No. : ADM/HSED/FM/004/10

Issuance Date: July 2010

Issue No.: 01

Checklist

Machinery

General Information

Company Name: Project Name:

Conducted By: Date:

Poor: Absence of major control measures (high risk), work to be stopped and risk assessment to be reviewed immediately.

Fair: Some minor controls are missing (medium risk), additional control measures to be implemented.

Good: All required controls are in place (low risk), only monitoring is required.

Description

Item

Evaluation

Remarks

(insert your observation, and

proposed corrective action plan)

Good Fair Poor N/A

Machine maintained in good working order regularly and

records kept on site.

Machine operated according to the manufacturer

instructions.

Competent operators trained and certifed.

Good overall condition and regular maintenance.

All suitable guard provided

All electrical installations are protected and free of

damages (circuit breakers, plugs, wires).

Protection against weather condition.

Emergency stop button and other safety devices are

operational and clearly marked.

Safety signs and manufacturer instructions clearly

displayed and properly followed.

Suitable PPE provided and properly used

Approved By:

Position Name Date Signature

HSE Engineer / Manager

Distribution and Acknowledgment:

Project Manager

Project Engineer

Note: For guidance and it is not limited to its content

45

EHS Engineer/Manager

Ref. No. : ADM/HSED/FM/003/10

Issuance Date: July 2010

Issue No.: 01

Checklist

Portable Tools

General Information

Company Name: Project Name:

Conducted By: Date:

Poor: Absence of major control measures (high risk), work to be stopped and risk assessment to be reviewed immediately.

Fair: Some minor controls are missing (medium risk), additional control measures to be implemented.

Good: All required controls are in place (low risk), only monitoring is required.

Description

Item

Evaluation

Remarks

(insert your observation, and

proposed corrective action plan)

Good Fair Poor N/A

Electrical Tools:

Power cables present no hazard or obstruction &

connections are appropriate, earthed & fused.

User competent & authorized.

Guard is ftted, adjusted & tool in good condition.

Emergency stop is available & operational.

Manufacturer instruction is available & followed.

All hoses, couplings & fttings of correct rating.

Pneumatic Tools:

Hoses, couplings & fttings inspected & maintained

regularly.

Tools secured to the hose by positive means to prevent

disconnection.

Air supply lines protected from damage, maintained &

inspected regularly.

Safety device is provided for air hose with large diameter.

Manufacturer instruction is available & followed.

Manual (unpowered) Tools:

Tool checked & inspected before use.

Home-made tool is not used & tool fts the job.

Suitable PPE provided for all above types of tools.

Approved By:

Position Name Date Signature

HSE Engineer / Manager

Distribution and Acknowledgment:

Project Manager

Project Engineer

Note: For guidance and it is not limited to its content

46

EHS Engineer/Manager

Ref. No. : ADM/HSED/FM/003/10

Issuance Date: July 2010

Issue No.: 01

General Information

Company Name: Project Name:

Conducted By: Date:

Poor: Absence of major control measures (high risk), work to be stopped and risk assessment to be reviewed immediately.

Fair: Some minor controls are missing (medium risk), additional control measures to be implemented.

Good: All required controls are in place (low risk), only monitoring is required.

Description

Item

Evaluation

Remarks

(insert your observation, and

proposed corrective action plan)

Good Fair Poor N/A

PPE policy and signage displayed.

Minimum PPE (i.e. helmet, safety boots, hi-visibility vest,

& safety glasses) provided to all employees & records

maintained.

PPE checkpoint on the entrance.

PPE comply with the relevant international standards &

clearly marked (i.e. CE or EN mark).

Users trained on using, maintenance, and storage of PPE.

Additional PPE have been provided as appropriate for

those who are executing critical activities (e.g. full body

harness for working at height, full face mask, & respiratory

apparatus, etc).

PPE correctly selected based on the task risk assessment.

Regularly inspected, cleaned and maintained and/or re-

placed as deemed necessary.

Approved By:

Position Name Date Signature

HSE Engineer / Manager

Distribution and Acknowledgment:

Project Manager

Project Engineer

Note: For guidance and it is not limited to its content

Checklist

Personal Protective Equipment (PPE)

47

EHS Engineer/Manager

Ref. No. : ADM/HSED/FM/003/10

Issuance Date: July 2010

Issue No.: 01

General Information

Company Name: Project Name:

Conducted By: Date:

Poor: Absence of major control measures (high risk), work to be stopped and risk assessment to be reviewed immediately.

Fair: Some minor controls are missing (medium risk), additional control measures to be implemented.

Good: All required controls are in place (low risk), only monitoring is required.

Description

Item

Evaluation

Remarks

(insert your observation, and

proposed corrective action plan)

Good Fair Poor N/A

All scaffolds erected, inspected, altered & dismantled by

competent team.

Clear and visible signage and scaff-tag

Access ladder provided and properly secured

Sound scaffolding materials free of damage

Platforms are properly made of planks, free of damage,

tied & no gaps between planks/timbers.

All platform blanks tied down properly

Proper falling protection provided (guard rail/hand rail, mid

rail, toe board, mesh/bricks guard & safety net).

Scaffolding properly secured ties, and all braces properly

installed.

Sole/base plate or timber provided.

Overhead protection provided.

Mobile scaffold provides with guard rails, toe board, full &

proper platform, access ladder & wheels locked.

Personal protective equipments provided and properly

used (full body harness connected to fxed anchor or

life line)

Approved By:

Position Name Date Signature

HSE Engineer / Manager

Distribution and Acknowledgment:

Project Manager

Project Engineer

Note: For guidance and it is not limited to its content

Checklist

Scaffolds

48

EHS Engineer/Manager

Ref. No. : ADM/HSED/FM/003/10

Issuance Date: July 2010

Issue No.: 01

General Information

Company Name: Project Name:

Conducted By: Date:

Poor: Absence of major control measures (high risk), work to be stopped and risk assessment to be reviewed immediately.

Fair: Some minor controls are missing (medium risk), additional control measures to be implemented.

Good: All required controls are in place (low risk), only monitoring is required.

Description

Item

Evaluation

Remarks

(insert your observation, and

proposed corrective action plan)

Good Fair Poor N/A

Availability of the site safety sign board.

Proper site security and appropriate fencing (e.g. closed

metallic boards, hoarding).

Site visitors induction training procedure.

Suffcient site offces and car parking.

Adequate safety signage / notice boards.

Availability of the HSE documents & records(e.g. HSE

manual, HSE plan, risk assessment, work permit, inci-

dents reports, induction & toolbox talk records, inspection

records, & training records, etc)

Approved By:

Position Name Date Signature

HSE Engineer / Manager

Distribution and Acknowledgment:

Project Manager

Project Engineer

Note: For guidance and it is not limited to its content

Checklist

Site General

49

EHS Engineer/Manager

EHS EHS

EHS

Ref. No. : ADM/HSED/FM/003/10

Issuance Date: July 2010

Issue No.: 01

General Information

Company Name: Project Name:

Conducted By: Date:

Poor: Absence of major control measures (high risk), work to be stopped and risk assessment to be reviewed immediately.

Fair: Some minor controls are missing (medium risk), additional control measures to be implemented.

Good: All required controls are in place (low risk), only monitoring is required.

Description

Item

Evaluation

Remarks

(insert your observation, and

proposed corrective action plan)

Good Fair Poor N/A

Vehicles & mobile equipment are licensed by concerned

authority .

Driver/operator is licensed and competent.

Engine in good operational condition.

No visible leaks

Windows & mirrors are clean & obstruction free.

Seat is in good condition and seat belt functioning

properly.

Lights / indicators / wipers / horns properly operational

Tyres free of damage and fully infated

Reversing alarm & beacons working properly

Periodical inspection & maintenance & record kept

Provided with fre extinguisher and frst aid box, and in

good condition

Provided with the noise silencer/enclosure.

Approved By:

Position Name Date Signature

HSE Engineer / Manager

Distribution and Acknowledgment:

Project Manager

Project Engineer

Note: For guidance and it is not limited to its content

Checklist

Vehicles and Mobile Equipment

50

EHS Engineer/Manager

Ref. No. : ADM/HSED/FM/003/10

Issuance Date: July 2010

Issue No.: 01

General Information

Company Name: Project Name:

Conducted By: Date:

Poor: Absence of major control measures (high risk), work to be stopped and risk assessment to be reviewed immediately.

Fair: Some minor controls are missing (medium risk), additional control measures to be implemented.

Good: All required controls are in place (low risk), only monitoring is required.

Description

Item

Evaluation

Remarks

(insert your observation, and

proposed corrective action plan)

Good Fair Poor N/A

Hazard identifcation & risk assessment conducted, & required control

measures have been implemented.

Valid & approved permit to work available all time & displayed in visible

location.

Working area properly contained & warning signs displayed.

All fammable / combustible materials have been removed from the

working area or properly protected from spark.

All possible health effects (acute and chronic) have been identifed and

proper control measures implemented.

Suffcient ventilation has been provided.

Task is carried out by competent person (s).

Adequate / suffcient fre fghting equipment are available in the

working area during & after the work.

Suitable PPE provided and used all the time.

Electrical Arc Welding:

Welding leads and returns cables have the same length, properly

installed & protected, & free of damage.

Electrical cables are in good condition, free of damage, & properly

protected.

Industrial plugs & sockets provided.

Electrode holders are fully insulated & free of damage.

Earth connection bolted or clamped to ensure a good electrical

contact.

Welding machine frame effectively grounded.

Gas Welding and Cutting:

Different gas cylinders are clearly identifed and marked.

Different types of Gas cylinders have been separated, properly stored,

and not exposed to direct sun.

Proper training on handling gas cylinders for all users (this will include

clothing, moving cylinders, hazards and precaution measures.etc).

Cylinder attachments (regulators, hoses, non-return valves, fashback arres-

tors, blowpipes) are maintained in good working order and free of damage.

Approved By:

Position Name Date Signature

HSE Engineer / Manager

Distribution and Acknowledgment:

Project Manager

Project Engineer

Note: For guidance and it is not limited to its content

Checklist

Welding and Gas Cutting

Evaluation

Remarks

(insert your observation,and proposed

corrective action plan)

51

EHS Engineer/Manager

Ref. No. : ADM/HSED/FM/003/10

Issuance Date: July 2010

Issue No.: 01

General Information

Company Name: Project Name:

Conducted By: Date:

Poor: Absence of major control measures (high risk), work to be stopped and risk assessment to be reviewed immediately.

Fair: Some minor controls are missing (medium risk), additional control measures to be implemented.

Good: All required controls are in place (low risk), only monitoring is required.

Description

Item

Evaluation

Remarks

(insert your observation, and

proposed corrective action plan)

Good Fair Poor N/A

Adequate ablutions / toilets / washing facilities.

Appropriate clean & cool rest area with clean & cold

drinking water.

Food storage facility.

Changing rooms with facility for keeping protective

clothing used at work (locker).

Prayer area clearly identifed & kept clean all the time

Safe access & egress to and from the facility

Welfare facilities are in clean good hygienic condition.

Designated smoking area with proper fre fghting

equipments

Approved By:

Position Name Date Signature

HSE Engineer / Manager

Distribution and Acknowledgment:

Project Manager

Project Engineer

Note: For guidance and it is not limited to its content

Checklist

Welfare Facilities

Evaluation Remarks

(insert your observation,and proposed

corrective action plan)

52

EHS Engineer/Manager

Ref. No. : ADM/HSED/FM/003/10

Issuance Date: July 2010

Issue No.: 01

General Information

Company Name: Project Name:

Conducted By: Date:

Poor: Absence of major control measures (high risk), work to be stopped and risk assessment to be reviewed immediately.

Fair: Some minor controls are missing (medium risk), additional control measures to be implemented.

Good: All required controls are in place (low risk), only monitoring is required.

Description

Item

Evaluation

Remarks

(insert your observation, and

proposed corrective action plan)

Good Fair Poor N/A

Platform is properly designed (the minimum dimension

are in accordance with the safety standards) and

suitable for the purpose.

Platform free of damage and in good condition.

All platform planks tied down properly with no gaps

between planks.

Proper falling protection provided (handrail, mid-rail, toe

board, boy harness, lifeline & safety net).

Load capacity identifed and clearly marked.

Platforms are not used to carry another platform.

Adequate bracing / outriggers installed (Mobile Elevated

Working Platforms MEWP).

3

rd

party inspection. Regular maintenance & adherence

to the manufacturers manual (MEWP & cradles).

Cantilever provided with guard rail, mid rail, toe board, &

mesh / bricks guard.

Cantilever should not be overloaded

(apply only tested load).

Cantilever must be inspected whenever installed,

altered, or shifted by competent person.

Proper PPE should be provided.

Approved By:

Position Name Date Signature

HSE Engineer / Manager

Distribution and Acknowledgment:

Project Manager

Project Engineer

Note: For guidance and it is not limited to its content

Checklist

Working Platforms and Cantilevers

Evaluation Remarks

(insert your observation,and proposed

corrective action plan)

53

EHS Engineer/Manager

The following screen windows illustrate the steps on how to

upload the EHS plan into the Building Permits Electronic System

(CDP).

54

55

56

Potrebbero piacerti anche

- PPEA-WI-012 - B Consultation and Communication at SiteDocumento6 paginePPEA-WI-012 - B Consultation and Communication at SiteDeepakNessuna valutazione finora

- Safety Legislation, Regulation and PolicyDocumento110 pagineSafety Legislation, Regulation and PolicyNichoNessuna valutazione finora

- Safety Climate Tool For WebDocumento4 pagineSafety Climate Tool For WebMr-SmithNessuna valutazione finora

- 2F1.PMSR.3 27 Oct 2022 HSE Workers ConsultationDocumento7 pagine2F1.PMSR.3 27 Oct 2022 HSE Workers ConsultationMusadiq HussainNessuna valutazione finora

- En Allround Delekatalog 2017Documento68 pagineEn Allround Delekatalog 2017Hanafiah RozaliNessuna valutazione finora

- HAZARDS AND RISKS IDENTIFICATIONDocumento28 pagineHAZARDS AND RISKS IDENTIFICATIONPhillip LNessuna valutazione finora

- Checklist - Planning The Safe Use, Erection and Dismantling of Prefabricated or Modular ScaffoldingDocumento13 pagineChecklist - Planning The Safe Use, Erection and Dismantling of Prefabricated or Modular ScaffoldingNoor Aimi Ayunie Mohd AzmiNessuna valutazione finora

- RRC Brochure PDFDocumento57 pagineRRC Brochure PDFbutahraNessuna valutazione finora

- JHA For Radiography TestDocumento8 pagineJHA For Radiography TestM8Rskn6wcNessuna valutazione finora

- NGC1 Flash Cards 3Documento38 pagineNGC1 Flash Cards 3aitzaz561Nessuna valutazione finora

- 4-1/2in. Angle Grinder: Owner'S ManualDocumento14 pagine4-1/2in. Angle Grinder: Owner'S ManualboomissyNessuna valutazione finora

- Emergency Response PlanDocumento1 paginaEmergency Response PlanArslanSaeedNessuna valutazione finora

- Mashooq CV (Updated)Documento3 pagineMashooq CV (Updated)Manda Khel Apna DesNessuna valutazione finora

- Health Safety Environmental Manager in Houston TX Resume Fabian Gregory WomacDocumento2 pagineHealth Safety Environmental Manager in Houston TX Resume Fabian Gregory WomacFabianGregoryWomacNessuna valutazione finora

- Unit Ig1: Management of Health and SafetyDocumento15 pagineUnit Ig1: Management of Health and SafetyVikash Kumar RayNessuna valutazione finora

- Workers' Participation in ManagementDocumento37 pagineWorkers' Participation in ManagementPiyush ParmarNessuna valutazione finora

- Unit Diploma Nebosh DniDocumento32 pagineUnit Diploma Nebosh DniScribdTranslationsNessuna valutazione finora

- Part 1 - Personal Details and Declaration IGC3 NEBOSHDocumento9 paginePart 1 - Personal Details and Declaration IGC3 NEBOSHEngi SaifNessuna valutazione finora

- IG 1 Element 3 New Slides Part 2 ModifiedDocumento75 pagineIG 1 Element 3 New Slides Part 2 ModifiedPradeepNessuna valutazione finora

- Accident Investigation and ReportingDocumento19 pagineAccident Investigation and Reportingvebsdgr8Nessuna valutazione finora

- HSW Book ExtractDocumento10 pagineHSW Book ExtractSammie WilliamsNessuna valutazione finora

- Quarterly Safety ChecklistDocumento2 pagineQuarterly Safety ChecklistAJ CompilationNessuna valutazione finora

- HSE TrainingDocumento12 pagineHSE Trainingpaeg6512100% (1)

- May Nebosh Paper SoutionDocumento10 pagineMay Nebosh Paper SoutionRebel KhanNessuna valutazione finora

- Improving Safety in IraqDocumento6 pagineImproving Safety in IraqMisty LaurenNessuna valutazione finora

- Reviewer of NeboshDocumento22 pagineReviewer of NeboshJie DVNessuna valutazione finora

- Muhammad Jawad HSE EngineerDocumento3 pagineMuhammad Jawad HSE EngineerJawad abbasiNessuna valutazione finora

- Health and Safety & TOPdesk: A Safe CombinationDocumento2 pagineHealth and Safety & TOPdesk: A Safe CombinationTOPdeskNessuna valutazione finora

- Unit A Rev NotesDocumento138 pagineUnit A Rev Noteskhaled osmanNessuna valutazione finora

- HSEQ Questionaire For Contractor EvaluationDocumento6 pagineHSEQ Questionaire For Contractor EvaluationNasih Tr100% (1)

- OSHA Emergency Response Plan: 29 CFR 1910.120 (Q)Documento16 pagineOSHA Emergency Response Plan: 29 CFR 1910.120 (Q)Prajwal ShahiNessuna valutazione finora

- Health and Safety Standard Assignment BriefDocumento13 pagineHealth and Safety Standard Assignment BriefMuhammad SadatNessuna valutazione finora

- Element 4Documento5 pagineElement 4ridgellNessuna valutazione finora

- NEBOSH International Diploma For Occupational Health & Safety For Occupational Health & Safety Management Professionals Management ProfessionalsDocumento3 pagineNEBOSH International Diploma For Occupational Health & Safety For Occupational Health & Safety Management Professionals Management ProfessionalsOsman KantheNessuna valutazione finora

- Procedureriskassessment PDFDocumento20 pagineProcedureriskassessment PDFMinhDũngNessuna valutazione finora

- IB2 Hazardous Substances and Other ChemicalsDocumento84 pagineIB2 Hazardous Substances and Other ChemicalsAkhilesh Kumar Singh100% (1)

- Risk - Assessment - Form 14th Oct 2017Documento2 pagineRisk - Assessment - Form 14th Oct 2017hunstreteNessuna valutazione finora

- Membership Categories 2012 IOSHDocumento2 pagineMembership Categories 2012 IOSHHarthwell Capistrano100% (1)

- NEBOSH International General Certificate - IGC3Documento24 pagineNEBOSH International General Certificate - IGC3Ehsan MirzaNessuna valutazione finora

- Nebosh HSWDocumento6 pagineNebosh HSWMohammad AshrafNessuna valutazione finora

- Updated - COSHH Risk Assessment 1 - Sherwin Willams PrimerDocumento2 pagineUpdated - COSHH Risk Assessment 1 - Sherwin Willams PrimerPaul McGahanNessuna valutazione finora

- The American University in Cairo Environmental Health & Safety DepartmentDocumento91 pagineThe American University in Cairo Environmental Health & Safety DepartmentBabbooNessuna valutazione finora

- Nebosh: Element 4: Health and Safety Management Systems - CheckDocumento29 pagineNebosh: Element 4: Health and Safety Management Systems - CheckmohammadNessuna valutazione finora

- Occupational Health and Safety Program: How To Implement A FormalDocumento52 pagineOccupational Health and Safety Program: How To Implement A Formaldnzk dnzkNessuna valutazione finora

- Kick - Off Meeting - Revanta Vendor Name - Prism Johnson Limited - RMC India Division Scope of Work - Supply of Ready Mix ConcreteDocumento28 pagineKick - Off Meeting - Revanta Vendor Name - Prism Johnson Limited - RMC India Division Scope of Work - Supply of Ready Mix ConcreteSahim Dandoti100% (1)

- Safety Induction-JGCDocumento28 pagineSafety Induction-JGCDwi Yusuf Pambudi Harto100% (1)

- Group 1 Safety EngineeringDocumento103 pagineGroup 1 Safety EngineeringErnielle Rae Dela CruzNessuna valutazione finora

- Worksafe Rights Responsibilities ChartDocumento1 paginaWorksafe Rights Responsibilities Chartapi-405286554Nessuna valutazione finora

- Construction Project Public Protection ANSI StandardDocumento49 pagineConstruction Project Public Protection ANSI StandardJeerawatNessuna valutazione finora

- MUDASSIRDocumento1 paginaMUDASSIRSn AhsanNessuna valutazione finora

- Confined Space - Introduction: Canadian Government Departments Responsible For OH&S Confined Space - ProgramDocumento7 pagineConfined Space - Introduction: Canadian Government Departments Responsible For OH&S Confined Space - ProgramAnge JuanNessuna valutazione finora

- Overhead Lines Case StudiesDocumento3 pagineOverhead Lines Case StudiesBinoy GopinathanNessuna valutazione finora

- ILO RecommedationsDocumento10 pagineILO RecommedationsAmin UllahNessuna valutazione finora

- JHA - (Power Brush & Touch-Up Painting Activities 1)Documento1 paginaJHA - (Power Brush & Touch-Up Painting Activities 1)shaiful annuarNessuna valutazione finora

- Safe Work Procedure A Complete Guide - 2020 EditionDa EverandSafe Work Procedure A Complete Guide - 2020 EditionNessuna valutazione finora

- Personal protective equipment Complete Self-Assessment GuideDa EverandPersonal protective equipment Complete Self-Assessment GuideValutazione: 5 su 5 stelle5/5 (1)