Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Case Write Up Harley Davidson

Caricato da

ksasi27Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Case Write Up Harley Davidson

Caricato da

ksasi27Copyright:

Formati disponibili

Case Write up Harley Davidson Motor Company: Enterprise Software Selection. Submitted by: K.

. Sasi Kumar, Id: 20120054 Brief summary: This case gives an insight about how Harley Davidson Motor Company chooses its software requirements and suppliers in implementing Enterprise wide procurement and supplier Management System. The Organisational Structure consisted of three interlocking circles: Create Demand Circle (CDC), Produce Product Groups (PPG), and Provide Support (PSC) and each circle have an Information Technology Circle (ITC). Garry Berryman, joined Purchase Organization which is the part of PPG group. He emphasised improvement in the supplier relationships because about 55-60 % of motor cycles value are from purchased parts. Under his leadership, a corporate wide Supply Management Strategy (SMS) was developed, aimed to ensure that right product, at the right time, with the best quality for the lowest possible costs is delivered. The idea for implementing SMS was shifting organization focus from a Short-term to longterm on supplier relationships. They developed a project called Supplier Information Link (SiLK) through which they estimated that purchasing cost can be reduced by $34 million over five years and other benefits like reduced complexity through uniform procuremement process across all sites, data consolidation for decision making, elimination of duplicate entry etc. The initial step was forming a Project team with part time members from each procurement organizations. Soon the team conducted Mapping as is process to map the existing system of processes. The team was able to identify many commonalities across sites through this exercise. The team conducted a stakeholder Survey and found that about 85% of time is spent on non-strategic activities such as reviewing inventory, expediting, and data entry as against a goal of SMS having personnel spend at least 70% of their time on supplier management activities. After mapping as-is and stake holder survey, the team defined to be process in to requirements for new purchasing information systems. They developed functional specifications or request for Quote (RFQ) and then the team began supplier selection process. RFQ for new systems to support SMS was given to the potential suppliers and called for proposals and presentations. They narrow down the supplier by limiting able to meet the requirement by not less than 90% and final three suppliers were shortlisted. Each supplier was compared both quantitatively and qualitatively. Conclusion: They were right in linking software selection process to the overall supplier management strategy. It helped them in finding a system that suits functionally and able to address change management issues with future in consideration. Definitely, the steps adopted in selecting the suppliers paid them with consolidated information for decision making. Quantitative parameters and qualitative parameters were assessed and compared for each supplier to come to a decision. If, I were a team member I would choose supplier 1 as he is functionally acceptable and for their system flexibility.

Potrebbero piacerti anche

- Gamification in Consumer Research A Clear and Concise ReferenceDa EverandGamification in Consumer Research A Clear and Concise ReferenceNessuna valutazione finora

- AOL.com (Review and Analysis of Swisher's Book)Da EverandAOL.com (Review and Analysis of Swisher's Book)Nessuna valutazione finora

- Raymond James QuestionsDocumento1 paginaRaymond James QuestionsNikhil ChawlaNessuna valutazione finora

- Harley-Davidson Enterprise Software Selection 2016Documento3 pagineHarley-Davidson Enterprise Software Selection 2016tt_kobraNessuna valutazione finora

- IBM CounterclaimDocumento47 pagineIBM CounterclaimChristopher Barnett100% (1)

- Haier Group: OEC ManagementDocumento10 pagineHaier Group: OEC ManagementNitinchandan KumarNessuna valutazione finora

- EFI Case - Mukund - Kabra - Sales ManagementDocumento2 pagineEFI Case - Mukund - Kabra - Sales ManagementMukund KabraNessuna valutazione finora

- Managing A Global TeamDocumento17 pagineManaging A Global TeamAdil Huseyin HeymunNessuna valutazione finora

- Visi ON: Presented By: Aleena Elizabeth Joseph Jijo Mathew Kuruvilla Mansi Agrawal Meghna PeethambaranDocumento25 pagineVisi ON: Presented By: Aleena Elizabeth Joseph Jijo Mathew Kuruvilla Mansi Agrawal Meghna PeethambaranKavitha PeethambaranNessuna valutazione finora

- Sonoco Case StudyDocumento2 pagineSonoco Case StudyMohanrasu GovindanNessuna valutazione finora

- When Workers Rate The BossDocumento3 pagineWhen Workers Rate The BossSHIVANGI MAHAJAN PGP 2021-23 BatchNessuna valutazione finora

- Jindi EnterprisesDocumento2 pagineJindi EnterprisesVvb SatyanarayanaNessuna valutazione finora

- OB Group AssignmentDocumento3 pagineOB Group AssignmentAshish SandapuNessuna valutazione finora

- 15 1995 Microsoft Corporation-CaseDocumento19 pagine15 1995 Microsoft Corporation-CaseNeelesh Kamath100% (1)

- Harley Davidson Motor Company Enterprise PDFDocumento2 pagineHarley Davidson Motor Company Enterprise PDFPetter PNessuna valutazione finora

- Business Analytics-Bharti Airtel: Group 7 Members: Rajani Nair Akansha Dwivedi Moumita Basak Jayasekharan UnnikrishnanDocumento7 pagineBusiness Analytics-Bharti Airtel: Group 7 Members: Rajani Nair Akansha Dwivedi Moumita Basak Jayasekharan UnnikrishnanRajani Nair (PGPMX-2019 Batch 1)Nessuna valutazione finora

- Case Study 1Documento3 pagineCase Study 1Kate Thurgood0% (1)

- GSCM-Global Sourcing-Li and Fung - ZaraDocumento51 pagineGSCM-Global Sourcing-Li and Fung - ZaraakhilNessuna valutazione finora

- A&D High Tech - Team 2Documento9 pagineA&D High Tech - Team 2Pradnya SalveNessuna valutazione finora

- FordDocumento11 pagineFordAbhimanyu BhardwajNessuna valutazione finora

- Quality Talk May 2019Documento13 pagineQuality Talk May 2019AnkurNessuna valutazione finora

- SHRM Case Analysis 2Documento4 pagineSHRM Case Analysis 2SAntosh TamhaneNessuna valutazione finora

- Tektronix ByWeNotIDocumento5 pagineTektronix ByWeNotIDevesha TrivediNessuna valutazione finora

- NCM Sworkit & BetterbackDocumento10 pagineNCM Sworkit & BetterbackNarula PrashantNessuna valutazione finora

- ERGONOMICA CONSULTING AND SOLLTRAM HOTELS-SummaryDocumento5 pagineERGONOMICA CONSULTING AND SOLLTRAM HOTELS-SummaryHitesh Singh RajpurohitNessuna valutazione finora

- Facility Location of DHL FinalDocumento15 pagineFacility Location of DHL FinalbrijeshNessuna valutazione finora

- MIS Group 1 Sec F Assignment 2Documento2 pagineMIS Group 1 Sec F Assignment 2Debasmita KumarNessuna valutazione finora

- Assignment II - Case Study EvaluationDocumento11 pagineAssignment II - Case Study Evaluationdevics1997Nessuna valutazione finora

- Ques 1. How Hard Do You Think Installing Otisline Was in 1990?Documento1 paginaQues 1. How Hard Do You Think Installing Otisline Was in 1990?Rashmi RanjanNessuna valutazione finora

- MIS PackagesDocumento21 pagineMIS PackagesRajMalhotra100% (1)

- 03.McAfee. Mastering The Three Worlds of Information TechnologyDocumento10 pagine03.McAfee. Mastering The Three Worlds of Information Technology5oscilantesNessuna valutazione finora

- Review PaperDocumento6 pagineReview PaperCarmelita EsclandaNessuna valutazione finora

- How Would You Explain The Business Model of Jamcracker in The Saas Space?Documento2 pagineHow Would You Explain The Business Model of Jamcracker in The Saas Space?Mukul MathurNessuna valutazione finora

- CiscoDocumento80 pagineCiscoAnonymous fEViTz3v6Nessuna valutazione finora

- The Best of IntentionsDocumento13 pagineThe Best of IntentionsMuzna FaisalNessuna valutazione finora

- Destin Brass ProductDocumento5 pagineDestin Brass ProductRamalu Dinesh ReddyNessuna valutazione finora

- PPG-Self Directed Workforce Company OverviewDocumento3 paginePPG-Self Directed Workforce Company OverviewKrishNessuna valutazione finora

- Stamypor CaseDocumento15 pagineStamypor CaserockysanjitNessuna valutazione finora

- IB SummaryDocumento7 pagineIB SummaryrronakrjainNessuna valutazione finora

- MashaweerDocumento5 pagineMashaweerebruklcnNessuna valutazione finora

- Business Intelligence Software at Sysco 1Documento5 pagineBusiness Intelligence Software at Sysco 1Dellendo FarquharsonNessuna valutazione finora

- TVAHelp ComDocumento51 pagineTVAHelp ComSunil KesarwaniNessuna valutazione finora

- C2 JamcrackerDocumento1 paginaC2 JamcrackerSanglap BanerjeeNessuna valutazione finora

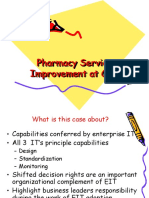

- Pharmacy Service Improvement at CVSDocumento18 paginePharmacy Service Improvement at CVSnatya lakshitaNessuna valutazione finora

- Business Strategy Case Study - DoCoMoDocumento18 pagineBusiness Strategy Case Study - DoCoMoRobinHood TiwariNessuna valutazione finora

- ME15 - Unit 3Documento59 pagineME15 - Unit 3Bharathi RajuNessuna valutazione finora

- Mis Case Submission: CISCO SYSTEMS, Inc.: Implementing ERPDocumento3 pagineMis Case Submission: CISCO SYSTEMS, Inc.: Implementing ERPMalini RajashekaranNessuna valutazione finora

- ACC IntroductiontoCostAccountingDocumento3 pagineACC IntroductiontoCostAccountingChristopher Lewis0% (1)

- Arcor GroupDocumento3 pagineArcor GroupSonu Avinash Singh0% (1)

- Case: The Dabbawala System: Presented byDocumento5 pagineCase: The Dabbawala System: Presented byAyush BhatnagarNessuna valutazione finora

- Harrah's EntertainmentDocumento2 pagineHarrah's EntertainmentKrishNessuna valutazione finora

- Group 7 - Oscar MayerDocumento17 pagineGroup 7 - Oscar Mayershagun100% (1)

- Perk Priority AnalysisDocumento1 paginaPerk Priority Analysisshashank_swNessuna valutazione finora

- Company Customers Competitors Collaborators ContextDocumento3 pagineCompany Customers Competitors Collaborators ContextSanjay SankhalaNessuna valutazione finora

- Marketing Plan Project - GreatsDocumento9 pagineMarketing Plan Project - Greatsapi-429501712Nessuna valutazione finora

- Enterprise Resource Planning Case Studies 123Documento9 pagineEnterprise Resource Planning Case Studies 123Shah ParthivNessuna valutazione finora

- Knowledge ManagementDocumento3 pagineKnowledge ManagementNidhiNessuna valutazione finora

- MDCMDocumento13 pagineMDCMdhruv_agarwalNessuna valutazione finora

- Himanshu Rao (Marketing) Entrepreneurship Assignment PDFDocumento9 pagineHimanshu Rao (Marketing) Entrepreneurship Assignment PDFHimanshu RaoNessuna valutazione finora

- Z Score For 3 Indian Companies in Power Sector: Safe ZoneDocumento5 pagineZ Score For 3 Indian Companies in Power Sector: Safe Zoneksasi27Nessuna valutazione finora

- HRM Sample Interview ReportDocumento3 pagineHRM Sample Interview Reportksasi27Nessuna valutazione finora

- Jaguar Case SummaryDocumento2 pagineJaguar Case Summaryksasi27100% (2)

- Is Mix Design Final PlainDocumento6 pagineIs Mix Design Final Plainksasi27Nessuna valutazione finora

- CSE 473 Pattern Recognition: Instructor: Dr. Md. Monirul IslamDocumento57 pagineCSE 473 Pattern Recognition: Instructor: Dr. Md. Monirul IslamNadia Anjum100% (1)

- Prose 2 - Lost Spring - Important QADocumento5 pagineProse 2 - Lost Spring - Important QADangerous GamingNessuna valutazione finora

- Technical Data Sheet: BS-510 All Pressure Solvent CementDocumento1 paginaTechnical Data Sheet: BS-510 All Pressure Solvent CementBuwanah SelvaarajNessuna valutazione finora

- Science - Sound DiffractionDocumento12 pagineScience - Sound DiffractionElissah S PabilonaNessuna valutazione finora

- An Introduction To Formal Language and Automata Solution Manual PDFDocumento4 pagineAn Introduction To Formal Language and Automata Solution Manual PDFAsad IkramNessuna valutazione finora

- Cellular Respiration MDL361Documento46 pagineCellular Respiration MDL361Krystal CraigNessuna valutazione finora

- EagleBurgmann H7N ENDocumento5 pagineEagleBurgmann H7N ENlamtony2013Nessuna valutazione finora

- Super 6 Comprehension StrategiesDocumento1 paginaSuper 6 Comprehension StrategiesrosypatelNessuna valutazione finora

- A Guide To Become A Succesful Marine EngineerDocumento99 pagineA Guide To Become A Succesful Marine EngineerTammam Hassan100% (1)

- Surface TensisonDocumento28 pagineSurface TensisonJAWAD AHMAD BURTNessuna valutazione finora

- IG Client Sentiment Report 2020-12-03 12 - 00 PDFDocumento36 pagineIG Client Sentiment Report 2020-12-03 12 - 00 PDFEno Ronaldfrank OguriNessuna valutazione finora

- Internship Report PDFDocumento11 pagineInternship Report PDFASWIN KUMARNessuna valutazione finora

- SuperboltDocumento32 pagineSuperboltRajeev Chandel100% (1)

- CC Course IntroDocumento11 pagineCC Course IntroSaid TahatNessuna valutazione finora

- Links of XII Physics Investigatory Project Allowtment 2Documento3 pagineLinks of XII Physics Investigatory Project Allowtment 2yashtomarsoop07Nessuna valutazione finora

- MOEMS 2020 Questions Paper Division EDocumento20 pagineMOEMS 2020 Questions Paper Division EHarleenaDivs50% (4)

- SRMDocumento4 pagineSRMinocente333Nessuna valutazione finora

- Purposive Communication NotesDocumento33 paginePurposive Communication NotesAlexis DapitoNessuna valutazione finora

- 3393 - Supervision of Concrete Construction Volume 2Documento271 pagine3393 - Supervision of Concrete Construction Volume 2Oum ChhayNoy100% (11)

- Panasonic Sa Akx10ph PNDocumento114 paginePanasonic Sa Akx10ph PNimmortalwombatNessuna valutazione finora

- Assignment-2: 1) Explain Classification With Logistic Regression and Sigmoid FunctionDocumento6 pagineAssignment-2: 1) Explain Classification With Logistic Regression and Sigmoid FunctionpraneshNessuna valutazione finora

- Post Covid StrategyDocumento12 paginePost Covid Strategyadei667062Nessuna valutazione finora

- The Effect of The Gastrocnemius On The Plantar Fascia: Javier Pascual HuertaDocumento18 pagineThe Effect of The Gastrocnemius On The Plantar Fascia: Javier Pascual HuertamarcelonorisNessuna valutazione finora

- Microsoft PowerPoint - Sesi 2-Communication Skills - PPT (Comp PDFDocumento21 pagineMicrosoft PowerPoint - Sesi 2-Communication Skills - PPT (Comp PDFSarah Eddiah0% (1)

- Experimental Psychology & The Scientific MethodDocumento73 pagineExperimental Psychology & The Scientific MethodRuru LavariasNessuna valutazione finora

- Understanding Terrorism and Political Violence PDFDocumento304 pagineUnderstanding Terrorism and Political Violence PDFmihaela buzatuNessuna valutazione finora

- Artuz Albert PDFDocumento4 pagineArtuz Albert PDFJasmin Kate DatuinNessuna valutazione finora

- SeptalkanDocumento5 pagineSeptalkanReniNessuna valutazione finora

- Spring 2010 MidTerm OPKST CS101 Bc100200572Documento6 pagineSpring 2010 MidTerm OPKST CS101 Bc100200572cs619finalproject.comNessuna valutazione finora

- Senior Curriculum Vol 1 2012 FinalDocumento361 pagineSenior Curriculum Vol 1 2012 Finald-fbuser-27550451Nessuna valutazione finora