Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Low Hydrogen

Caricato da

seeralan balakrishnanDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Low Hydrogen

Caricato da

seeralan balakrishnanCopyright:

Formati disponibili

LOW HYDROGEN COVERED ELECTRODES

Stub Loss Correction Table

for Coated Electrodes

2" 3" 4" 5" Deposition (50 mm) (75 mm) (100 mm)(125 mm) Efficiency STUB STUB STUB STUB 12" (300 mm) Electrode 60% 65% 70% 75% 80% 14" (350 mm) Electrode 60% 65% 70% 75% 80% 18" (450 mm) Electrode 60% 65% 70% 75% 80% 50.0% 54.2% 58.3% 62.5% 66.6% 51.4% 55.7% 60.0% 64.3% 68.5% 53.3% 57.7% 62.2% 66.6% 71.1% 45.0% 48.7% 52.5% 56.2% 60.0% 47.1% 51.1% 55.0% 58.9% 62.8% 50.0% 54.2% 58.3% 62.5% 66.6% 40.0% 43.3% 46.6% 50.0% 53.3% 42.8% 46.4% 50.0% 53.6% 57.1% 46.6% 50.5% 54.4% 58.3% 62.2% 35.0% 37.9% 40.8% 43.7% 46.6% 38.5% 41.8% 45.0% 48.2% 51.4% 43.3% 46.9% 50.5% 54.2% 57.7%

Atom Arc The Original Iron Powder Low Hydrogen Electrode

Atom Arc low hydrogen electrodes are available in a variety of strengths and chemical analyses for welding almost every type of mild and low alloy steel. With the introduction of these iron powder electrodes, fabricators can increase productivity while reducing overall welding cost. Moisture resistant coatings are incorporated in all Atom Arc electrodes. The flux coatings are manufactured to effectively resist moisture pick-up in opened containers. The improved coating provides an extra degree of reliability, especially for electrodes exposed to high humidity environments. Moisture testing results are conducted in accordance with AWS A5.1 and A5.5 specifications. AWS structural code allows a maximum of 0.4% moisture by weight for all E70XX electrodes. Military requirements vary depending on the specific electrode classification*. Although moisture resistant coatings prolong the exposure time, storage and reconditioning should not be eliminated. Electrode storage and reconditioning should be a common practice when using low hydrogen electrodes. For this reason, Atom Arc low hydrogen electrodes are manufactured with moisture levels below 0.15% when packaged in hermetically sealed containers. Unopened containers can be stored safely for an indefinite length of time under normal dry storage conditions. They should be protected from humid air after the container is opened by storing at 225F to 300F (107C to 149C), or if the need arises, can be reconditioned by baking for one hour at 700F (371C).

Atom Arc Coated Electrodes Deposition Data and Current Ranges*

Electrode Deposition Diameter Range Optimum Rate lbs./hr. Efficiency in. (mm) Amperage Amperage (kg/hr) %

Electrode Dimension Conversion Chart

Diameter Inches mm 5/64 3/32 1/8 5/32 3/16 7/32 1/4 5/16 2.0 2.4 3.2 4.0 4.8 5.6 6.4 8.0 Length Inches 12 12 14 14 14 18 18 18 mm 300 300 350 350 350 450 450 450

E7018, E8018, etc...

3/32 (2.4) 1/8 (3.2) 5/32 (4.0) 3/16 (4.8) 7/32 (5.6) 1/4 (6.4) 70-100 90-160 90-160 130-220 130-220 200-300 200-300 250-350 250-350 300-400 300-400 90 120 140 140 170 200 250 250 300 300 350 1.7 2.6 2.7 3.1 3.8 4.9 5.4 6.5 7.2 7.7 8.7 (0.8) (1.2) (1.2) (1.4) (1.7) (2.2) (2.4) (2.9) (3.3) (3.5) (3.9) 66.3 71.6 70.9 75.0 73.5 76.4 74.6 75.0 74.0 78.0 77.0

*Note: Efficiencies for coated electrodes do not include stub loss. The ESAB QA Program specifies that all Military orders are processed as Special Orders, and not OTS (off the shelf) items. Only wire marked and manufactured to the Military is responsive to and acceptable under Military Specification. All requests for information and placement of orders for materials requiring military approvals must be directed to Customer Service for Quote, minimum quantity, testing charges, and availability of all Military and ASME Code items. In addition, military approvals are dependant upon required specification (1D, 1E, etc.), amendment required, level of packaging, package form, restricted/non-restricted copper, if mechanical properties of weld metal as-deposited are other than specified, what holding time should be used for stress relief, etc. Therefore, not all wires in all categories can be provided with military certification.

LOW HYDROGEN COVERED ELECTRODES

Atom Arc 7018

AWS Class E7018 Conforms to E7018H4R AC-DCEP (Electrode Positive) Electrode Imprint Marking: 7018 Code and Specification Data: **

AWS A5.1, ASME SFA 5.1 Military - MIL-E-22200/1, MIL 7018 ABS - AWS A5.1, 2Y Det Norske Veritas - 3Y (H10) Lloyds - 3m, 3Ym (H10) CWB-CSA W48

Atom Arc 7018-1

AWS Class E7018-1 Conforms to E7018-1H4R AC-DCEP (Electrode Positive) Electrode Imprint Marking: 7018-1 Code and Specification Data: **

AWS A5.1, ASME SFA 5.1 ABS - AWS A5.1, 3Y (H10) Lloyds - 3m, 3Ym (H10) Det Norske Veritas - 3Y(H10) CWB-CSA W48.1

Description:

Atom Arc 7018-1 is an all-position low hydrogen iron powder electrode that displays exceptional impacts at low temperatures in both the as welded and stress relieved conditions. It adequately meets the AWS requirements for a minimum of 20 ft.-lbs. (27 J) at -50F (-10C). The smooth metal transfer keeps spatter to a minimum, and the complete slag coverage is designed for easy removal. Atom Arc 7018-1 is intended for the wide variety of carbon and low alloy steels in the 50 ksi (345 MPa) minimum yield. It is an ideal choice for applications that require impact toughness at low temperatures.

Description:

Atom Arc 7018 is an iron powder, low hydrogen moisture resistant electrode. The wider operating ranges and smooth weld metal transfer minimizes post weld clean up. This premium quality electrode meets a multitude of codes and welding specifications. Atom Arc 7018 was developed to weld carbon and low alloy steels, including a variety of hardenable steels.

Typical Mechanical Properties

As Welded Yield Strength, psi (MPa) Tensile Strength, psi (MPa) % Elongation in 2" (51 mm) % Reduction in Area 68,000 (470) 78,000 (540) 30 75.5 Stress Relieved 8 hrs. @1150F (621C) 57,000 (395) 71,000 (490) 33 77 Stress Relieved 8 hrs. @1150F (621C) ft.-lbs. (J) 193 (262)

Typical Mechanical Properties

As Welded Yield Strength, psi (MPa) Tensile Strength, psi (MPa) % Elongation in 2" (51 mm) % Reduction in Area 69,000 (475) 82,000 (565) 30 72 Stress Relieved 8 hrs. @1150F (621C) 58,000 (400) 73,000 (505) 33 72 Stress Relieved 8 hrs. @1150F (621C) ft-lbs. (J) 165 (224)

Typical Charpy V-Notch Impact Properties

As Welded ft.-lbs. (J) 168 (228)

Testing Temp. -20F (-29C)

Typical Charpy V-Notch Impact Properties

As Welded ft.-lbs. (J) 104 (141)

Typical Undiluted Weld Metal Analysis (%)

C 0.045 Mn 1.10 Si 0.40 P 0.015 S 0.014 Testing Temp. -50F (-46C)

Preheat:

Preheat is generally not required with Atom Arc 7018 to prevent underbead cracking. Preheat should be used with hardenable steels to prevent the formation of hard heat-affected zones and eliminate tendencies toward quench cracking on cooling. Preheat may also be required in welding heavy sections.

Typical Undiluted Weld Metal Analysis (%)

C 0.04 Mn 1.35 Si 0.32 P 0.014 S 0.015

Preheat:

Preheat is generally not required with Atom Arc 7018-1 to prevent underbead cracking. Preheat should be used with hardenable steels to prevent the formation of hard heat-affected zones and eliminate tendencies toward quench cracking on cooling. Preheat may also be required in welding heavy sections.

Standard Diameters and Packages

3/32" (2.4 mm), 1/8" (3.2 mm), 5/32" (4.0 mm), 3/16" (4.8 mm), 7/32" (5.6 mm), and 1/4" (6.4 mm) diameters availalble in 5# (2.3 kg) Value Pac, 11# (5 kg) Quad Pac, 50# (22.7 kg) carton, 10 & 50# (4.5 & 22.7 kg) HSC

Standard Diameters and Packages

3/32" (2.4 mm) x 11# (5 kg) Quad Pac, 10 & 50# (4.5 & 22.7 kg) HSC 1/8" (3.2 mm) x 11# (5 kg) Quad Pac, 10 & 50# (4.5 & 22.7 kg) HSC 5/32" (4.0 mm) x 11# (5 kg) Quad Pac, 10 & 50# (4.5 & 22.7 kg) HSC 3/16" (4.8 mm) x 11# (5 kg) Quad Pac, 10 & 50# (4.5 & 22.7 kg) HSC 7/32" (5.6 mm) x 10 & 50# (4.5 & 22.7 kg) HSC 1/4" (6.4 mm) x 10 & 50# (4.5 & 22.7 kg) HSC

HSC = Hermetically Sealed Containers Recommended Welding Parameters page 6-9. ** Any item requiring approval certification must be special or-

10

LOW HYDROGEN COVERED ELECTRODES

Atom Arc 7018-AC

AWS Class E7018 AC-DCEP (Electrode Positive) Electrode Imprint Marking: 7018AC Code and Specification Data: **

AWS A5.1, ASME SFA 5.1 CWB-CSA 48.1

Atom Arc 7018-SR

AWS Class E7018 Conforms to E7018H4R AC-DCEP (Electrode Positive) Electrode Imprint Marking: 7018-SR Code and Specification Data: **

AWS A5.1, ASME SFA 5.1

Description:

Atom Arc 7018AC is a product specifically designed to have optimum arc characteristics when used with AC power sources having 75 to 80 open circuit voltage. Compared to standard Atom Arc 7018 operating on AC, this electrode will have easier arc starting and restrike, a smoother arc, and lower spatter. It is useable on a wide range of steels.

Description:

Atom Arc 7018-SR is an all-position, iron powder low hydrogen electrode. The moisture resistance and welder appeal is similar to other Atom Arc electrodes. Atom Arc 7018-SR was developed to maintain 70 ksi (483 MPa) tensile strength after 16 hours stress relieving.

Typical Mechanical Properties

Stress Relieved 8 hrs. 16 hrs. @1150F @1150F (621C) (621C)

Typical Mechanical Properties

As Welded Yield Strength, psi (MPa) Tensile Strength, psi (MPa) % Elongation in 2" (51 mm) % Reduction in Area 78,000 (540) 86,000 (595) 29 72 As Welded Yield Strength, psi (MPa) Tensile Strength, psi (MPa) % Elongation in 2" (51 mm) % Reduction in Area

Typical Charpy V-Notch Impact Properties

Testing Temp. -20F (-29C) As Welded ft.-lbs. (J) 46 (62)

69,000 (475) 61,000 (420) 59,000 (410) 83,000 (570) 77,000 (530) 74,000 (510) 32 35 35 76 76 77

Typical Charpy V-Notch Impact Properties

Stress Relieved 8 hrs. 16 hrs. @1150F @1150F (621C) (621C) ft-lbs. (J) ft-lbs. (J) 133 (180) 185 (250)

Typical Undiluted Weld Metal Analysis (%)

C 0.047 Mn 0.95 Si 0.30 P 0.014 S 0.015 Testing Temp -20F (-29C) As Welded 114 (195)

Preheat:

Preheat is generally not required with Atom Arc 7018AC to prevent underbead cracking. Preheat should be used with hardenable steels to prevent the formation of hard heat-affected zones and eliminate tendencies toward quench cracking on cooling. Preheat may also be required in welding heavy sections.

Typical Undiluted Weld Metal Analysis (%)

C 0.06 Mn 1.35 Si 0.35 P 0.014 S 0.014 Mo 0.10

Standard Diameters and Packages

3/32" (2.4 mm) x 10 & 50# (4.5 & 22.7 kg) HSC 1/8" (3.2 mm) x 10 & 50# (4.5 & 22.7 kg) HSC 5/32" (4.0 mm) x 10 & 50# (4.5 & 22.7 kg) HSC 3/16" (4.8 mm) x 10 & 50# (4.5 & 22.7 kg) HSC

Standard Diameters and Packages

3/32" (2.4 mm) x 5# (2.3 kg) Value Pac, 11# (5 kg) Quad Pac, 10 & 50# (4.5 & 22.7 kg) HSC 1/8" (3.2 mm) x 5# (2.3 kg) Value Pac, 11# (5 kg) Quad Pac, 10 & 50# (4.5 & 22.7 kg) HSC 5/32" (4.0 mm) x 5# (2.3 kg) Value Pac, 11# (5 kg) Quad Pac, 10 & 50# (4.5 & 22.7 kg) HSC 3/16" (4.8 mm) x 11# (5 kg) Quad Pac

HSC = Hermetically Sealed Containers ** Any item requiring approval certification must be special ordered - Contact ESAB Customer Service

Recommended Welding Parameters page 9.

11

Potrebbero piacerti anche

- Low Hydrogen Mild Steel ElectrodesDocumento6 pagineLow Hydrogen Mild Steel ElectrodesAdura OgunnuNessuna valutazione finora

- Product Data Sheet: Afrox 7018-1Documento2 pagineProduct Data Sheet: Afrox 7018-1Gervasio AndradeNessuna valutazione finora

- FabCO 811N1Documento2 pagineFabCO 811N1Sleyda MunozNessuna valutazione finora

- NAM Cat CombinedCh1Documento16 pagineNAM Cat CombinedCh1Thanh Do VanNessuna valutazione finora

- ENG DS OMI 2 Pole Series Relay Data Sheet E 0411Documento3 pagineENG DS OMI 2 Pole Series Relay Data Sheet E 0411letterniNessuna valutazione finora

- Wiring AccessoriesDocumento56 pagineWiring AccessoriesKrizia De PeraltaNessuna valutazione finora

- AccuRibbon LXE 126 WebDocumento4 pagineAccuRibbon LXE 126 Webbharatsehgal00Nessuna valutazione finora

- Fabcor 86 RDocumento2 pagineFabcor 86 RAnonymous fj4iRr1Nessuna valutazione finora

- Monolithic Insulated Joint BrochureDocumento8 pagineMonolithic Insulated Joint Brochuremarita_msNessuna valutazione finora

- Pipe Welding Electrodes 1Documento5 paginePipe Welding Electrodes 1Adura OgunnuNessuna valutazione finora

- Metco 470AW 10-632Documento8 pagineMetco 470AW 10-632JSH100Nessuna valutazione finora

- SR 4Documento12 pagineSR 4Parker333Nessuna valutazione finora

- Datasheets - High TG Material: General InformationDocumento3 pagineDatasheets - High TG Material: General InformationAnonymous T9zQADFxZRNessuna valutazione finora

- LG Bus Duct System Guide - Leader in Electrics & AutomationDocumento51 pagineLG Bus Duct System Guide - Leader in Electrics & AutomationRajneesh KatochNessuna valutazione finora

- Selectrode: High Deposition 316L Stainless Steel International ClassificationsDocumento2 pagineSelectrode: High Deposition 316L Stainless Steel International ClassificationsMohamed AdelNessuna valutazione finora

- ATOM ARC LOW HYDROGEN ELECTRODESDocumento2 pagineATOM ARC LOW HYDROGEN ELECTRODESanupmenon menonNessuna valutazione finora

- Low Hydrogen Low Alloy Electrodes for High Strength Steel WeldsDocumento2 pagineLow Hydrogen Low Alloy Electrodes for High Strength Steel WeldsFranklin Aranda ChacónNessuna valutazione finora

- ESAB Consumable PDFDocumento165 pagineESAB Consumable PDFbond8031Nessuna valutazione finora

- RT Duroid 6006 6010 Laminate Data SheetDocumento2 pagineRT Duroid 6006 6010 Laminate Data SheetdrhammoudaNessuna valutazione finora

- PVC Insulated Cables GuideDocumento71 paginePVC Insulated Cables GuidemealysrNessuna valutazione finora

- Cigweld-Deposited Rates PDFDocumento7 pagineCigweld-Deposited Rates PDFNam_HitechNessuna valutazione finora

- B-62 2507 Rev 06Documento5 pagineB-62 2507 Rev 06Shaik ShahNessuna valutazione finora

- Hoballoy 8018B2: AWS E8018-B2 H4R Elding OsitionsDocumento2 pagineHoballoy 8018B2: AWS E8018-B2 H4R Elding OsitionsJuanNessuna valutazione finora

- Welding Technology Steelconstr - EngDocumento32 pagineWelding Technology Steelconstr - EngLukman Tarigan SumatraNessuna valutazione finora

- A 795 - 00 QTC5NS9BNZK1TQDocumento6 pagineA 795 - 00 QTC5NS9BNZK1TQsachinguptachdNessuna valutazione finora

- LSIS Bus Duct System CatalogDocumento52 pagineLSIS Bus Duct System CatalogedcooNessuna valutazione finora

- 2010 BurndyDocumento99 pagine2010 BurndycarloscaduNessuna valutazione finora

- Innershield NR - 440ni2: Typical Applications Key FeaturesDocumento1 paginaInnershield NR - 440ni2: Typical Applications Key FeaturesH_DEBIANENessuna valutazione finora

- Pipeline electrode and welding guideDocumento66 paginePipeline electrode and welding guideDenny SyamsuddinNessuna valutazione finora

- Eti Ohe 11 5 89Documento12 pagineEti Ohe 11 5 89Abhishek PandeyNessuna valutazione finora

- How To Use This Catalog: Have A Soundcard? - Click On MeDocumento234 pagineHow To Use This Catalog: Have A Soundcard? - Click On MeitalangeloNessuna valutazione finora

- Selectrode: 317L Flux Coated TigDocumento3 pagineSelectrode: 317L Flux Coated TigUta GilangNessuna valutazione finora

- h2066-HASTELLOY C-22 Welding DataDocumento4 pagineh2066-HASTELLOY C-22 Welding DataGovindarajalu PadmanabhanNessuna valutazione finora

- SAW Wire / Flux: Typical Chemical Composition of Rod (WT%) Product FeaturesDocumento4 pagineSAW Wire / Flux: Typical Chemical Composition of Rod (WT%) Product Featuresehsan.mNessuna valutazione finora

- ST Series Soft Termination MLCCsDocumento10 pagineST Series Soft Termination MLCCsppanagos5664Nessuna valutazione finora

- SPEC..600 Volt USE-2Documento4 pagineSPEC..600 Volt USE-2quatudogonNessuna valutazione finora

- AWS E8018-B2 welding rodDocumento2 pagineAWS E8018-B2 welding rodRodrigoNessuna valutazione finora

- Antamount: Vishay SpragueDocumento22 pagineAntamount: Vishay SpraguemohamedNessuna valutazione finora

- Psi SpecDocumento645 paginePsi SpecManickavasagam Sadasivam100% (3)

- HS25 Incremental EncoderDocumento4 pagineHS25 Incremental Encoderoswaldo58Nessuna valutazione finora

- KV-32HQ100 KV-36HQ100 Ae-7aDocumento112 pagineKV-32HQ100 KV-36HQ100 Ae-7aAgostinho GomesNessuna valutazione finora

- ESAB OK Autrod 12.51Documento2 pagineESAB OK Autrod 12.51hooky1Nessuna valutazione finora

- RT Duroid 6006 6010 Laminate Data SheetDocumento2 pagineRT Duroid 6006 6010 Laminate Data SheetSaravanakumar SermarajaNessuna valutazione finora

- 22%Cr DUPLEX STAINLESS STEEL WELDING CONSUMABLESDocumento7 pagine22%Cr DUPLEX STAINLESS STEEL WELDING CONSUMABLESNguyen Anh TuanNessuna valutazione finora

- W - Section 1 - Mma Welding - Saf Fro General Catalogue68475045296859596 PDFDocumento8 pagineW - Section 1 - Mma Welding - Saf Fro General Catalogue68475045296859596 PDFputriNessuna valutazione finora

- Esab DublexDocumento8 pagineEsab DublexSuphi YükselNessuna valutazione finora

- 4418 DatasheetDocumento5 pagine4418 DatasheetwholenumberNessuna valutazione finora

- Product CAT CST - DatasheetDocumento15 pagineProduct CAT CST - Datasheetfaisalardy20Nessuna valutazione finora

- AASHTO-M203-1235767gDocumento8 pagineAASHTO-M203-1235767gGanesh PersaudNessuna valutazione finora

- 1-12 To 4 Guardsman G SeriesDocumento6 pagine1-12 To 4 Guardsman G SeriesAnonymous PkAjjOZBNessuna valutazione finora

- Manual de Alambres Solidos LincolnDocumento32 pagineManual de Alambres Solidos LincolnBartolome VasquezNessuna valutazione finora

- Fusibles NHDocumento4 pagineFusibles NHPaul SchaefferNessuna valutazione finora

- Materials Data for Cyclic Loading: Low-Alloy SteelsDa EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsValutazione: 5 su 5 stelle5/5 (2)

- Solution Manual for 100 Genesys Design Examples: Second EditionDa EverandSolution Manual for 100 Genesys Design Examples: Second EditionNessuna valutazione finora

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsDa EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNessuna valutazione finora

- CCW - PVC Steel Wire Hose CatalogueDocumento1 paginaCCW - PVC Steel Wire Hose Catalogueseeralan balakrishnanNessuna valutazione finora

- Refrigeration & Air Conditioning: Emerson Flow Controls Expansion ValvesDocumento1 paginaRefrigeration & Air Conditioning: Emerson Flow Controls Expansion Valvesseeralan balakrishnanNessuna valutazione finora

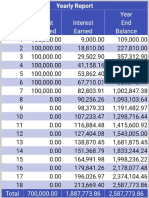

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Materials System Specification: 34-SAMSS-010 03 October 2019 Quality Requirements For Pressure Retaining InstrumentsDocumento10 pagineMaterials System Specification: 34-SAMSS-010 03 October 2019 Quality Requirements For Pressure Retaining Instrumentsseeralan balakrishnanNessuna valutazione finora

- Itrade Networks Company ProfileDocumento8 pagineItrade Networks Company Profileseeralan balakrishnanNessuna valutazione finora

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Pyrometer Tp7: The Universal Infrared Thermometer For Many Fields of ApplicationDocumento6 paginePyrometer Tp7: The Universal Infrared Thermometer For Many Fields of Applicationseeralan balakrishnanNessuna valutazione finora

- Shunt Open - Release 24V DC E1/6-T8Documento2 pagineShunt Open - Release 24V DC E1/6-T8seeralan balakrishnanNessuna valutazione finora

- P5 product data sheet specsDocumento4 pagineP5 product data sheet specsseeralan balakrishnanNessuna valutazione finora

- Smart Scholar CalculationDocumento5 pagineSmart Scholar Calculationseeralan balakrishnanNessuna valutazione finora

- SPECIFICATIONS AND ACCESSORIES FOR THE IH8R HEADLAMPDocumento4 pagineSPECIFICATIONS AND ACCESSORIES FOR THE IH8R HEADLAMPseeralan balakrishnanNessuna valutazione finora

- Singlevoteprice21 1576480252Documento1 paginaSinglevoteprice21 1576480252seeralan balakrishnanNessuna valutazione finora

- Rail BeamsDocumento1 paginaRail Beamsseeralan balakrishnanNessuna valutazione finora

- Model Number DetailsDocumento1 paginaModel Number Detailsseeralan balakrishnanNessuna valutazione finora

- General Combined Brochure RevisedDocumento406 pagineGeneral Combined Brochure Revisedseeralan balakrishnanNessuna valutazione finora

- RF Planning BibleDocumento128 pagineRF Planning BibleDipanka Borah100% (1)

- Tuv Application Form Saudi Arabia Saso ProgramDocumento3 pagineTuv Application Form Saudi Arabia Saso Programseeralan balakrishnanNessuna valutazione finora

- Sewage TreatmentDocumento1 paginaSewage Treatmentseeralan balakrishnanNessuna valutazione finora

- Nikola Tesla - Wikipedia, The Free EncyclopediaDocumento15 pagineNikola Tesla - Wikipedia, The Free Encyclopediaseeralan balakrishnanNessuna valutazione finora

- Professional infrared thermometer for -50°C to 1000°CDocumento6 pagineProfessional infrared thermometer for -50°C to 1000°Cseeralan balakrishnanNessuna valutazione finora

- Compressor Specifications - © Bristol Compressors International, IncDocumento1 paginaCompressor Specifications - © Bristol Compressors International, Incseeralan balakrishnanNessuna valutazione finora

- Onion AgmarkDocumento33 pagineOnion Agmarkseeralan balakrishnanNessuna valutazione finora

- Las Tek FillerDocumento2 pagineLas Tek Fillerseeralan balakrishnanNessuna valutazione finora

- Nokia E71 Vs Samsung B7330 OmDocumento2 pagineNokia E71 Vs Samsung B7330 Omseeralan balakrishnanNessuna valutazione finora

- B 815791 FCDocumento3 pagineB 815791 FCseeralan balakrishnanNessuna valutazione finora

- 18 Questions and Answers in Planning & SchedulingDocumento8 pagine18 Questions and Answers in Planning & SchedulingBeni Best100% (3)

- Lectra Clean® Heavy Duty Energized Electrical Parts Degreaser, 5 GalDocumento2 pagineLectra Clean® Heavy Duty Energized Electrical Parts Degreaser, 5 Galseeralan balakrishnanNessuna valutazione finora

- Pharmaceutical Calculation - PDF 2Documento31 paginePharmaceutical Calculation - PDF 2Cheeyongg Lookonthebrightside100% (4)

- Hikvision Port Forwarding For CCTVDocumento35 pagineHikvision Port Forwarding For CCTVbuzzkillaNessuna valutazione finora

- SambarDocumento1 paginaSambarseeralan balakrishnanNessuna valutazione finora

- 6 Ways To Make Candle Making EasyDocumento17 pagine6 Ways To Make Candle Making Easyelcuco2011100% (1)

- Regular chimney inspections extend plant operationsDocumento6 pagineRegular chimney inspections extend plant operationstecvidyaNessuna valutazione finora

- D 5117 - 96 - Rduxmtctukve PDFDocumento4 pagineD 5117 - 96 - Rduxmtctukve PDFchabibNessuna valutazione finora

- Karbohidrat: Dyke Gita Wirasisya, S.Farm., M.SC., Apt Program Studi Farmasi, Fakultas Kedokteran, Universitas MataramDocumento37 pagineKarbohidrat: Dyke Gita Wirasisya, S.Farm., M.SC., Apt Program Studi Farmasi, Fakultas Kedokteran, Universitas Matarambrahmani ptrNessuna valutazione finora

- Pop-up and Starter Fertilizers for Corn: Rates, Placement and Nutrient RemovalDocumento5 paginePop-up and Starter Fertilizers for Corn: Rates, Placement and Nutrient RemovaluserNessuna valutazione finora

- Carbon Black ProcessDocumento4 pagineCarbon Black ProcessAnonymous azD9vQD100% (1)

- The Efficacy of Using Dalandan Peel As A ChalkDocumento12 pagineThe Efficacy of Using Dalandan Peel As A ChalkWillem James Faustino Lumbang100% (1)

- Group II Cation AnalysisDocumento4 pagineGroup II Cation AnalysisClare CaspeNessuna valutazione finora

- ASTM D 5861-Ensayo de Adhesión FRP A Sustrato MetálicoDocumento2 pagineASTM D 5861-Ensayo de Adhesión FRP A Sustrato MetálicoFernando Alfredo Sepúlveda JiménezNessuna valutazione finora

- Magnesia Carbon Refractories Product GuideDocumento35 pagineMagnesia Carbon Refractories Product GuideSiddhartha BogawatNessuna valutazione finora

- Construction Materials For Marine Diesel EnginesDocumento5 pagineConstruction Materials For Marine Diesel EnginesVijay ANessuna valutazione finora

- Heavy Duty Slurry Pumps Specs & Performance DataDocumento12 pagineHeavy Duty Slurry Pumps Specs & Performance DataMaximiliano BettarelNessuna valutazione finora

- Case Study of Bakey's Food Private Limited (Edited)Documento7 pagineCase Study of Bakey's Food Private Limited (Edited)Omkar Gholap100% (1)

- Dow Corning - Fabricating With XIAMETER® High Consistency Silicone Rubber PDFDocumento50 pagineDow Corning - Fabricating With XIAMETER® High Consistency Silicone Rubber PDFLin NiuNessuna valutazione finora

- Dungs ATEX en 161 Solenoid ValvesDocumento12 pagineDungs ATEX en 161 Solenoid Valvesstefan-romocki-4927Nessuna valutazione finora

- Turbocharger Service InstructionsDocumento4 pagineTurbocharger Service Instructionskarol1177Nessuna valutazione finora

- Origins and Transformations of Dissolved Organic Matter in Large Arctic RiversScientific ReportsDocumento11 pagineOrigins and Transformations of Dissolved Organic Matter in Large Arctic RiversScientific ReportsEstefania GrisalesNessuna valutazione finora

- Spent Coffee Grounds Heat Coffee RoastingDocumento15 pagineSpent Coffee Grounds Heat Coffee RoastingMJundiNessuna valutazione finora

- Bond Length: Measuring the Average Distance Between Atoms in a Covalent BondDocumento9 pagineBond Length: Measuring the Average Distance Between Atoms in a Covalent BondMiteigiNessuna valutazione finora

- Hardtop Ultra Comp ADocumento13 pagineHardtop Ultra Comp Anuryati jahariNessuna valutazione finora

- Brosur Mixer Pump MP 25 MIXIT PUTZMEISTER Mortar Machine Shotcrete Plastering Painting Floor Screed Concrete Repairing Grouting IndonesiaDocumento2 pagineBrosur Mixer Pump MP 25 MIXIT PUTZMEISTER Mortar Machine Shotcrete Plastering Painting Floor Screed Concrete Repairing Grouting IndonesiaPierre RoringNessuna valutazione finora

- Presentation On Forged Mill Balls Production in South AfricaDocumento23 paginePresentation On Forged Mill Balls Production in South AfricaRamoutar (Ken) SeecharranNessuna valutazione finora

- CODEX STANDARD FOR FERMENTED MILKSDocumento11 pagineCODEX STANDARD FOR FERMENTED MILKSvabimhah100% (2)

- Progress in Polyethylene Terephthalate RecyclingDocumento24 pagineProgress in Polyethylene Terephthalate RecyclingyuppeNessuna valutazione finora

- Saudi Aramco Test Report: Internal Tank Bottom Testing 30-Oct-17 CP-SATR-X-3205Documento8 pagineSaudi Aramco Test Report: Internal Tank Bottom Testing 30-Oct-17 CP-SATR-X-3205Tayyab AchakzaiNessuna valutazione finora

- MSS SP-44-2016 Steel Pipeline FlangesDocumento52 pagineMSS SP-44-2016 Steel Pipeline Flangesarnoldbatista55100% (2)

- Final Product 7 Learning Cycles - 6th Grade MatterDocumento46 pagineFinal Product 7 Learning Cycles - 6th Grade Matterapi-310725472Nessuna valutazione finora

- Angelo BanaresDocumento11 pagineAngelo BanaresNathan Russel PangilinanNessuna valutazione finora

- 2012 A Level Answers P1 and P2 Compiled FinalDocumento12 pagine2012 A Level Answers P1 and P2 Compiled FinalWesley TanNessuna valutazione finora

- High Temp Grease Technical Data SheetDocumento2 pagineHigh Temp Grease Technical Data SheetErickNessuna valutazione finora