Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sect.4 - Design Loads

Caricato da

MardiSantosoDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sect.4 - Design Loads

Caricato da

MardiSantosoCopyright:

Formati disponibili

Section 4 - Design Loads

4-1

Section 4 Design Loads

A. 1.

General, Definitions General. c0 = 10,75 S = 10,75 cL cL

This Section provides data regarding design loads for determining the scantlings of the hull structural elements by means of the design formula given in the following Section or by means of direct calculations. The dynamic portions of the design loads are design values which can only be applied within the design concept of this Volume. 2. 2.1 Definitions Load centre Vertical stiffening system: 0,5 @ stiffener spacing above the lower support of plate field, or lower edge of plate when the thickness changes within the plate field. Horizontal stiffening system: Midpoint of plate field.

300 S L 100

1 ,5

for 90 < L < 300 m for L > 300 m

= length coefficient = L 90 for L < 90 m for L > 90 m

= 1,0 cRW

2.1.1 For plates:

= service range coefficient = 1,00 for unlimited service range = 0,90 for service range P = 0,75 for service range L = 0,60 for service range T

= probability factor = 1,0 for plate panels of the outer hull (shell plating, weather decks) = 0,75 for secondary stiffening members of the outer hull (frames, deck beams), but not less than fQ according to Section 5, D.1. = 0,60 for girders and girder systems of the outer hull (web frames, stringers, grillage systems), but not less than fQ/1,25

2.1.2 For stiffeners and girders: Centre of span R. 2.2 v0 c z x p0 Definition of symbols = ship's speed according to Section 1, H.5. = density of cargo as stowed in [t/m3] = density of liquids in [t/m3] = 1,0 t/m3 for fresh water and sea water = vertical distance of the structure's load centre above base line in [m] = distance from aft end of length L in [m] = basic external dynamic load = 2,1 @ (CB + 0,7) @ c0 @ cL @ f @ cRW [kN/m2] for wave directions with or against the ships heading =

2,6. ( C B + 0,7). c 0 . c L [kN/m2]

cD, cF = distribution factors according to Table 4.1.

B. 1.

External Sea Loads Load on weather decks

1.1 The load on weather deck is to determined according to the following formula: pD = p0 20 @ T c [kN/m2] (10 % z - T) H D

p01

for wave directions transverse the ships heading CB c0 = moulded block coefficient according to Section 1, H.4., where CB is not to be taken less than 0,60. = wave coefficient L = for L < 90 m % 4,1 25

1.2 For strength decks which are to be treated as weather decks as well as for forecastle decks the load is not to be less than the greater of the following two values: pDmin = 16 @ f [kN/m2] or pDmin = 0,7 @ p0 [kN/m2]

4-2

Section 4 - Design Loads

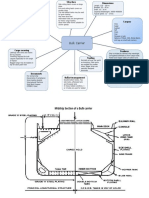

Table 4.1 Distribution factors for sea loads on ship's sides and weather decks Range A 0< 0,2 < x < 0,2 L x < 0,7 L 1,0 + Factor cD 1,2 x L 1,0 + Factor cF1) 5 CB 0,2 x L

1,0 c x - 0,7 3 L c = 0,15 L - 10 where: Lmin = 100 m Lmax = 250 m

1,0

0,7 <

x < 1,0 L

1,0 +

20 CB

x - 0,7 L

1)

Within the range A the ratio x/L need not be taken less than 0,1, within the range F the ratio x/L need not be taken greater than 0,93

= horizontal distance between load centre and centreline [m]

2.1.2 For elements the load centre of which is located above the load water line: ps Fig. 4.1 Longitudinal sections A, M, and F according to Table 4.1 = p0 @ cF 20 10 % z - T [kN/m2]

1.3 Where deck cargo is intended to be carried on the weather deck resulting in load greater than the value determined according to 1.1, the scantlings are governed by the greater load (see also C). Where the stowage height of deck cargo is less than 1,0 m, the deck cargo load may be required to be increased by the following value: pz hc 2. 2.1 = 10 (1 S hc) [kN/m2] = stowage height of the cargo in [m] Load on ship's sides and bow structures Load on ship's sides

for wave directions with or against the ship's heading. 20 |y| ps2 @ = p01 [kN/m2] 5 % z - T B for wave directions transverse to the ship's heading including quasi-static pressure increase due to heel 2.2 Load on bow structures

The design load for bow structures from forward to 0,1 L behind F.P. and above the ballast waterline in accordance with the draft Tb in 4.1 is to be determined according to the following formula : pe = c 0,20 @ v0 % 0,6 L with Lmax = 300 m. c = 0,8 in general = 0,4 (1,2 & 1,09 @ sin ) for extremely flared sides where the flare angle is larger than 40 The flare angle at the load centre is to be measured in the plane of frame between a vertical line and the tangent to the side shell plating. For unusual bow shapes pe can be specially considered. pe must not be smaller than ps according to 2.1.1 or 2.1.2 respectively.

2

[kN'm2]

The external load ps on the ship's sides is to be determined according to 2.1.1 and 2.1.2. 2.1.1 For elements the load centre of which is located below load waterline: ps = 10 (T - z) % p0 @ cF 1 % z T z T [kN/m2]

for wave directions with or against the ship's heading. ps1 = 10 (T - z)% p01 1% z T 1% @2 |y| [kN/m2] B

for wave directions transverse to the ship's heading including quasi-static pressure increase due to heel

Section 4 - Design Loads

4-3

Aft of 0,1 L from F.P. up to 0,15 L from F.P. the pressure between pe and ps is to be graded steadily. The design load for bow doors is given in Section 6, H.3. 2.3 Load on stern structures

cSL

= distribution factor, see also Fig. 4.2

The design load for stern structures from the aft end to 0,1 L forward of the aft end of L and above the smallest design ballast draught at the centre of the rudder stock up to T + c0/2 is to be determined according to the following formula: pe = cA @ L [kN/m2] with Lmax = 300 m. cA c pe 3. = 0,3 @ c $ 0,36 = see 2.2 = must not be smaller than ps according to 2.1.1 or 2.1.2 respectively Load on the ship's bottom cSL Fig. 4.2 Distribution factor cSL = 0 x - 0,5 L c2 for x < 0,5 L x < 0,5 + c2 L x < 0,65 + c2 L x > 0,65 + c2 L

for 0,5 <

= 1,0

The external load pB of the ship's bottom is to be determined according to the following formula: pB 4. = 10 @ T + p0 @ cF [kN/m ].

2

for 0,5 + c2 < 1 -

Design bottom slamming pressure c2

x L = 0,5 1 % 0,35 - c2 = 0,33 @ CB + L 2500

for

4.1 The design bottom slamming pressure may be determined by the following formula: pSL = 162 L @ c1 @ cSL @ cA @ cs for L < 150 m = 1984 (1,3 - 0,002 L) c1 @ cSL @ cA @ cs [kN/m2] for L > 150 m c1 = 3,6 - 6,5 Tb L

0 ,2

[kN/m2]

c2max = 0,35 cA A = 10/A = loaded area between the supports of the structure considered in [m2] 0,3 < cA < 1,0 cA cs 5. = 1,0 for plate panels and stiffeners. = 1 % cRW 2

c1max = 1,0 Tb = smallest design ballast draught at F.P for normal ballast conditions in [m],according to which the strengthening of bottom forward, see Section.6, E. has to be done. This value has to be recorded in the Class Certificate and in the loading manual. Where the sequential method for ballast water exchange is intended to be applied, Tb is to be considered for the sequence of exchange. Note With respect to the observation of the smallest design ballast draught Tb, an exception is possible, if during the exchange of ballast water weather conditions are observed the parameters of which are put down in the annex to the Certificate of Class.

Load on decks of superstructures and deckhouses

5.1 The load on exposed decks and parts of superstructure and deckhouse decks, which are not to be treated as strength deck, is to be determined as follows: pDA pD n = pD @ n [kN/m2] = load according 1.1 = 1 S z S H 10

= 1,0 for the forecastle deck nmin = 0,5 For deckhouses the value so determined may be multiplied by the factor 0,7 b % 0,3 B

4-4

Section 4 - Design Loads

b B

= breadth of deckhouse = largest breadth of ship at the position considered. pc h

pbc = pc (1 + av)

[kN/m2] [kN/m2]

= static bulk cargo load = 9,81 c h n

Except for the forecastle deck the minimum load is: pDAmin = 4 [kN/m2] 5.2 For exposed wheel house tops the load is not to be taken less than p = 2,5 [kN/m2]

= distance between upper edge of cargo and the load centre [m] = tan2 45o 2 sin2 % cos2

n 2.

= angle in degrees between the structural element considered and a horizontal plane = angle of repose of the cargo in degrees Load on inner bottom

C. 1.

Cargo Loads, Load on Accommodation Decks Load on cargo decks

1.1 The load on cargo decks is to be determined according to the following formula: = pc (1 + av) [kN/m2] pL pc = static cargo load in [kN/m2] if no cargo load is given: pc = 7 @ h for 'tween decks but not less than 15 kN/m2. h = mean 'tween deck height in [m]. In way of hatch casings the increased height of cargo is to be taken into account av = acceleration factor as follows: = F@m F m = 0,11 v0 L = mo - 5 (mo - 1) = 1,0 = 1 % mo v0 m0 % 1 0,3 x L for 0 < for 0,2 < x < 0,2 L x < 0,7 L

2.1 The inner bottom cargo load is to be determined as follows: pi G V h = 9,81 @ G @ h (1 + av) V [kN/m2]

= mass of cargo in the hold in [t] = volume of the hold in [m3] (hatchways excluded) = height of the highest point of the cargo above the inner bottom in [m], assuming hold to be completely filled. see 1.1 For calculating av the distance between the centre of gravity of the hold and the aft end of the length L is to be taken.

av

2.2 For inner bottom load in case of ore stowed in conical shape, see Section 23, B.3. 3. 3.1 is: p 3.2 p Loads on accommodation and machinery decks The deck load in accommodation and service spaces = 3,5 ( 1 + av ) [kN/m2]

x x - 0,7 for 0,7 < < 1,0 L L

= (1,5 + F) = see A.2.2. v0 is not to be taken less than L [kN]

The deck load of machinery decks is: = 8 ( 1 + av ) [kN/m2]

1.2 For timber and coke deck cargo the load on deck is to be determined by the following formula: pL hs = 5 @ hs (1 + av) [kN/m2] = stowing height of cargo in [m].

3.3 Significant single forces are also to be considered, if necessary.

D. 1.

Load on Tank Structures Design pressure for filled tanks

1.3 The loads due to single forces PE (e.g. in case of containers) are to be determined as follows: P = PE (1 + av) [kN].

1.1 The design pressure for service conditions is the greater of the following values: p1 or = 9,81@ h1 @ (1 + av) + 100 @ pv [kN/m2]

1.4 The cargo pressure of bulk cargoes is to be determined by the following formula:

Section 4 - Design Loads

4-5

p1 h1 av n

= 9,81@ [h1@ cosn%(0,3 @ b %y) sinn]%100 @ pv [kN/m2] = distance of load centre from tank top in [m] see C.1.1 = design angle of heel in degrees for tanks = arctan fbk@ H in general B

Regarding the design pressure of fuel tanks and ballast tanks which are connected to an overflow system, the dynamic pressure increase due to the overflowing is to be taken into account in addition to the static pressure height up to the highest point of the overflow system, see also Regulation for Construction, Equipment and Testing of Closed Fuel Overflow Systems. 2. Design pressure for partially filled tanks

fbk n b y pv

= 0,5 for ships with bilge keel = 0,6 for ships without bilge keel $ 20o for hatch covers of holds carrying liquids = upper breadth of tank in [m] = distance of load centre from the vertical longitudinal central plane of tank in [m] = set pressure of pressure relief valve in [bar], if a pressure relief valve is fitted = working pressure during ballast water exchange [bar] = z 2,5 % pv 10

2.1 For tanks which may be partially filled between 20% and 90% of their height, the design pressure is not to be taken less than given by the following formulae: 2.1.1 For structures located within 0,25 Rt from the bulkheads limiting the free liquid surface in the ship's longitudinal direction: pd Rt = 4 & L 150 Rt @ @ nx % 100 pv [kN/m2]

= distance in [m] between transverse bulkheads or effective transverse wash bulkheads at the height where the structure is located.

z pv

= distance from top of overflow to tank top [m] = pressure losses in the overflow line [bar]

2.1.2 For structures located within 0,25 bt from the bulkheads limiting the free liquid surface in the ship's transverse section: pd bt = 5,5 B b @ @ ny % 100 @ pv [kN/m2] 20 t

pvmin = 0,1 [bar] pvmin = 0,1 [bar] during ballast water exchange for both, the sequential method as well as the flowthrough method = 0,2 bar (2,0 mWS) for cargo tanks of tankers (see also Rules for Machinery Installations, Volume III, Section 15). Smaller set pressures than 0,2 bar may be accepted in special cases. The actual set pressure will be entered into the class certificate. 1.2 p2 h2 The maximum static design pressure is: = 9,81 @ h2 [kN/m2] = distance of load centre from top of overflow or from a point 2,5 m above tank top, whichever is the greater. Tank venting pipes of cargo tanks of tankers are not to be regarded as overflow pipes.

nx ny x1 y1

= distance in [m] between tank sides or effective longitudinal wash bulkhead at the height where the structure is located. 4 = 1 & x Rt 1 = 1 & 4 y bt 1

= distance of structural element from the tanks end in the ships longitudinal direction in [m] = distance of structural element from the tanks sides in the ships transverse direction in [m]

2.2 For tanks with ratios Rt/L > 0,1 or bt/B > 0,6 a direct calculation of the pressure pd may be required.

For tanks equipped with pressure relief valves and/or for tanks intended to carry liquids of a density greater than 1 t/m3, the head h2 is at least to be measured to a level at the following distance hp above tank top: hp = 2,5 @ [mWS], head of water in [m], or = 10 @ pv [mWS], where pv > 0,25 @ .

E. 1.

Design Values of Acceleration Components Acceleration components

The following formulae may be taken for guidance when calculating the acceleration components owing to ship's motions.

4-6

Section 4 - Design Loads

Vertical acceleration: az = a0 1 % 5,3 45 L

2

GM x - 0,45 L

2

= metacentric height in [m] = 1,0 = probability factor depending on probability level Q as outline in Table 4.2.

0,6 CB

1 ,5

kmin fQ

Transverse acceleration: ay = a0

2 x z-T 0,6 % 2,5 - 0,45 % k 1 % 0,6 @ k L B 2

Table 4.2 Probability factor fQ for a straightline spectrum of seaway-induced stress ranges Q 10-8 10-7 10-6 10-5 10-4 2. Combined acceleration fQ 1,000 0,875 0,750 0,625 0,500

Longitudinal acceleration: ax where A = 0,7 ! L z - T 0,6 % 5 1200 L CB = a0 0,06 % A 2 - 0,25 A

The acceleration components take account of the following components of motion: Vertical acceleration (vertical to the base line) due to heave, and pitch. Transverse acceleration (vertical to the ship's side) due to roll, yaw and sway including gravity component of roll. Longitudinal acceleration (in longitudinal direction) due to surge and pitch including gravity component of pitch. ax, ay and az are maximum dimensionless accelerations (i.e., relative to the acceleration gravity g) in the related direction x, y and z. For calculation purposes they are considered to act separately. a0 L0 k = 0,2 v0 L0 % 3 @ c0 @ cL @ cRW L0 fQ

The combined acceleration a may be determined by means of the "acceleration ellipse" according to Fig. 4.3 (e.g. y-zplane).

= length of ship L [m], but for determination of a0 the length L0 shall not be taken less than 100m = 13 @ GM B Fig. 4.3 Acceleration ellipse

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Manoeuvre The ShipDocumento37 pagineManoeuvre The ShipAldo Trinovachaesa100% (1)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- ScantlingDocumento39 pagineScantlingSky R100% (1)

- THEORIES AND FACTORS AFFECTING TRIM AND STABILITYDocumento8 pagineTHEORIES AND FACTORS AFFECTING TRIM AND STABILITYClint Oceas Ibaya100% (1)

- Volume 05 - Reed's Ship Construction For Marine Students (5th Edition 1996) PDFDocumento103 pagineVolume 05 - Reed's Ship Construction For Marine Students (5th Edition 1996) PDFLelosPinelos12392% (12)

- Application of Air Cavities On High-Speed Ships in RussiaDocumento10 pagineApplication of Air Cavities On High-Speed Ships in RussiaMahdiNessuna valutazione finora

- TDP 796-069 PreviewDocumento8 pagineTDP 796-069 PreviewMardiSantoso50% (2)

- TDP 796-043 PreviewDocumento8 pagineTDP 796-043 PreviewMardiSantoso100% (1)

- Stress Calculation For Aluminium PlateDocumento8 pagineStress Calculation For Aluminium PlateJacques Ontal100% (1)

- CFX12 A ScriptingDocumento50 pagineCFX12 A ScriptingMardiSantosoNessuna valutazione finora

- Pre Stressed Modal Analysis Using FiniteDocumento8 paginePre Stressed Modal Analysis Using Finitegreat2008Nessuna valutazione finora

- Mech-HT 120 Lect-06 TransientDocumento17 pagineMech-HT 120 Lect-06 TransientMardiSantosoNessuna valutazione finora

- Stress Calculation For Aluminium PlateDocumento8 pagineStress Calculation For Aluminium PlateJacques Ontal100% (1)

- Lrs Ship VibrationDocumento11 pagineLrs Ship VibrationTricia Coffey100% (1)

- Pre Stressed Modal Analysis Using FiniteDocumento8 paginePre Stressed Modal Analysis Using Finitegreat2008Nessuna valutazione finora

- CFX Intro 12.0 WS8 Brake RotorDocumento46 pagineCFX Intro 12.0 WS8 Brake RotorMardiSantosoNessuna valutazione finora

- CFX12 10 HeatTransferDocumento17 pagineCFX12 10 HeatTransferMardiSantosoNessuna valutazione finora

- Fire Sprinklers PDFDocumento28 pagineFire Sprinklers PDFChristopher BrownNessuna valutazione finora

- CFX12 06 ReviewDay1Documento7 pagineCFX12 06 ReviewDay1MardiSantosoNessuna valutazione finora

- Mech-HT 120 Lect-05 NonlinearDocumento18 pagineMech-HT 120 Lect-05 NonlinearTuan NgoNessuna valutazione finora

- MC Design Engineers Guide PDFDocumento19 pagineMC Design Engineers Guide PDFgovindsrNessuna valutazione finora

- Mech-HT 120 Lect-02 FundamentalsDocumento17 pagineMech-HT 120 Lect-02 FundamentalsMardiSantosoNessuna valutazione finora

- CFX Intro 12.0 WS3 Room StudyDocumento36 pagineCFX Intro 12.0 WS3 Room StudyMardiSantosoNessuna valutazione finora

- Mech-HT 120 Lect-04 SteadyStateDocumento24 pagineMech-HT 120 Lect-04 SteadyStateMardiSantosoNessuna valutazione finora

- WB-Mech 120 Ch07 BucklingDocumento18 pagineWB-Mech 120 Ch07 BucklingMardiSantosoNessuna valutazione finora

- Skew Angle PaperDocumento21 pagineSkew Angle Paperm_b_sNessuna valutazione finora

- Displacement Method For Determining Acceptable Piping VibrationDocumento12 pagineDisplacement Method For Determining Acceptable Piping VibrationMardiSantosoNessuna valutazione finora

- Engine GE-1, DisplacementDocumento3 pagineEngine GE-1, DisplacementMardiSantosoNessuna valutazione finora

- Tanks.140mm Gun - KruseDocumento16 pagineTanks.140mm Gun - KrusebearmanpigNessuna valutazione finora

- Guide To ColorsDocumento1 paginaGuide To ColorsMardiSantosoNessuna valutazione finora

- Ship Power PlantDocumento141 pagineShip Power Plantnguyentrunghieu51dltt100% (2)

- 04 - Modal and Harmonic Analysis With ANSYSDocumento58 pagine04 - Modal and Harmonic Analysis With ANSYScolumbo1986Nessuna valutazione finora

- Liquids Have No Shape of Their OwnDocumento58 pagineLiquids Have No Shape of Their OwnAshraf Kamal EllamsyNessuna valutazione finora

- 4 - Frequency Response AnalysisDocumento30 pagine4 - Frequency Response Analysisahmed4665Nessuna valutazione finora

- Ergonomic Work DesignDocumento39 pagineErgonomic Work DesignMardiSantosoNessuna valutazione finora

- MARKET REPORTDocumento5 pagineMARKET REPORTSandesh Tukaram GhandatNessuna valutazione finora

- The Cruise Industry PDFDocumento53 pagineThe Cruise Industry PDFBrian Castañeda100% (1)

- Aroiama 11 ReportDocumento5 pagineAroiama 11 ReportAnonymous ycFeyuLAtNessuna valutazione finora

- H246 Leonora Christina Low ResDocumento2 pagineH246 Leonora Christina Low Resgochi bestNessuna valutazione finora

- Thickness Measurement and Close-Up Survey GuidanceDocumento67 pagineThickness Measurement and Close-Up Survey GuidanceEswaranNessuna valutazione finora

- 10 key ship structural membersDocumento5 pagine10 key ship structural membersJOSHUA DURADONessuna valutazione finora

- Training Title...Documento21 pagineTraining Title...TeshaleNessuna valutazione finora

- General - Estonia EstoniaDocumento6 pagineGeneral - Estonia Estoniawaleed yehiaNessuna valutazione finora

- Marine Emergencies GuideDocumento27 pagineMarine Emergencies GuidevegihatNessuna valutazione finora

- 03 The Ship Design ProcessDocumento10 pagine03 The Ship Design Processw12n_sbyNessuna valutazione finora

- Underway Replenishment (RAS System)Documento54 pagineUnderway Replenishment (RAS System)Thiha BoBoNessuna valutazione finora

- 750 DWT GA-ModelDocumento1 pagina750 DWT GA-ModelHanzalah NaufalNessuna valutazione finora

- MO Aluminium Catamarans Rule Developments Supporting Document V1.0Documento37 pagineMO Aluminium Catamarans Rule Developments Supporting Document V1.0tyu100% (2)

- 19th Century Merchant ShipsDocumento23 pagine19th Century Merchant Shipsjanellee73100% (2)

- PT Boats: The Fast & Furious of WWII: Did You Know?Documento1 paginaPT Boats: The Fast & Furious of WWII: Did You Know?Hartford CourantNessuna valutazione finora

- Structure and features of bulk carriersDocumento2 pagineStructure and features of bulk carriersVijay Damley100% (1)

- An Analysis of Slocum 37 YawlDocumento14 pagineAn Analysis of Slocum 37 YawlMarian IgescuNessuna valutazione finora

- Nimitz-Class CarriersDocumento25 pagineNimitz-Class Carriersmahajan73100% (2)

- Specifications of A Naval ShipDocumento13 pagineSpecifications of A Naval ShipSiddharth Narayanan ChidambareswaranNessuna valutazione finora

- Reducing Underwater Noise Pollution From Large Commercial VesselsDocumento44 pagineReducing Underwater Noise Pollution From Large Commercial VesselsInternational Fund for Animal WelfareNessuna valutazione finora

- Adventures in Boating Washington HandbookDocumento116 pagineAdventures in Boating Washington HandbookvaldesasNessuna valutazione finora

- Calculation Barge Stab PDFDocumento31 pagineCalculation Barge Stab PDFMartinus OktaNessuna valutazione finora

- Safety Guidelines For Design, Construction & Operation of TugsDocumento50 pagineSafety Guidelines For Design, Construction & Operation of TugsTomash Verbitsky100% (2)

- OVPQ Master FullDocumento40 pagineOVPQ Master FullFaidzy RahmanNessuna valutazione finora

- Crew Service Centre IndonesiaDocumento10 pagineCrew Service Centre IndonesiaResha Rofi'ah100% (1)