Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Project Standards and Specifications Spherical Vessels Rev01

Caricato da

hiyeonDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Project Standards and Specifications Spherical Vessels Rev01

Caricato da

hiyeonCopyright:

Formati disponibili

Page : 1 of 14

KLM Technology Group

Project Engineering Standard

Rev: 01 April 2012

www.klmtechgroup.com

KLM Technology Group #03-12 Block Aronia, Jalan Sri Perkasa 2 Taman Tampoi Utama 81200 Johor Bahru Malaysia

SPECIFICATION FOR SPHERICAL VESSELS (PROJECT STANDARDS AND SPECIFICATIONS)

TABLE OF CONTENTS

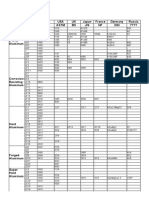

1. 2. GENERAL 1.1 Scope DESIGN 2.1 Shell Design 2.2 Support Column Design 2.3 Opening Reinforcement 2.4 Nozzles and Manholes 2.5 Internals and Externals 2.6 Stairways and Platforms FABRICATION 3.1 General 3.2 Plate 3.3 Welding 3.4 Postweld Heat Treatment (PWHT) 3.5 Site Assembling Work INSPECTION AND TESTING 4.1 General 4.2 Impact Requirement 4.3 Non Destructive Examination 4.4 Hydrostatic Test PAINTING AND MARKING 5.1 Painting 5.2 Marking PACKING AND SHIPPING 5.3 Packing 5.4 Shipping DELIVERY CONDITIONS 7.1 Plate 7.2 Columns 7.3 Nozzles and Manholes 7.4 Platform, Ladders and Stairway 7.5 Accessories, Erection Tools and Welding Rods 2 2 2 2 2 4 4 4 5 6 6 6 6 7 7 8 8 8 8 9 9 9 9 9 9 10 10 10 10 10 11 11

3.

4.

5. 6.

7.

Page : 2 of 14

KLM Technology Group

Project Engineering Standard

Rev: 01 April 2012

www.klmtechgroup.com

KLM Technology Group #03-12 Block Aronia, Jalan Sri Perkasa 2 Taman Tampoi Utama 81200 Johor Bahru Malaysia

SPECIFICATION FOR SPHERICAL VESSELS (PROJECT STANDARDS AND SPECIFICATIONS)

1. 1.1

GENERAL Scope

1.1.1 This specification covers additional requirements for engineering in regard to the design, material, fabrication, inspection, testing and supply of Section VIII Div.1 Spherical Vessels. 2. 2.1 DESIGN Shell Design

2.1.1 Sphere shells shall be calculated according to the requirements of ASME Section VIII, Division 1, using the required design temperature, design pressure, and corrosion allowance. 2.1.2 No fatigue analysis is required in the design of the spheres. 2.1.3 In the design of sphere supports, special attention shall be given to the loads imposed on the spherical shell. Consideration shall be given to secondary forces resulting from service temperatures or changes in temperature; test and operating pressure; liquid loads, both with and without pressure application; piping reactions, and normal supporting loads. Consideration shall be given to loads resulting from differential settlement of foundations where this is anticipated . 2.2 Support Column Design 2.2.1 Spheres shall have suitably numbered support columns constructed of steel pipe and rigidly welded to the shell. 2.2.2 Support columns shall be capable of supporting the sphere filled with water.

Page : 3 of 14

KLM Technology Group

Project Engineering Standard

Rev: 01 April 2012

www.klmtechgroup.com

KLM Technology Group #03-12 Block Aronia, Jalan Sri Perkasa 2 Taman Tampoi Utama 81200 Johor Bahru Malaysia

SPECIFICATION FOR SPHERICAL VESSELS (PROJECT STANDARDS AND SPECIFICATIONS)

2.2.3

Support columns shall be sufficiently large to ensure stability, taking into consideration of external loads and deflections due to pressure expansion or thermal expansion and the weight of the sphere plus contents.

2.2.4 Calculations for support column including induced shell stresses shall be submitted to PURCHASER. 2.2.5 The design of support columns shall be done according to Appendix G, ASME Section VIII, Division 1. 2.2.6 Whenever possible, support columns shall be attached to equatorial zones by a reinforcing plate large enough to ensure even distribution of loads. 2.2.7 Diagonal bracing members shall not be attached directly to a sphere unless adequate provisions are made for such loads in the design of the sphere. 2.2.8 Support columns and their members shall be designed and fabricated so as to prevent accumulation of water. Where this is impracticable, adequate drainage openings shall be provided to prevent such accumulation. 2.2.9 Attachment welds to shell shall be full penetration type of ASME Section VIII Division1. 2.2.10 Support columns welds on the shell shall clear the meridional and latitudinal shell plate welds by at least 50 mm. 2.2.11 If postweld heat treatment after erection is required by the code, a sufficient clearance shall be provided in the anchor bolt holes in the footings, to allow for expansion of the sphere. 2.2.12 At the base of each column a slide plate to the required dimension shall be provided.

Page : 4 of 14

KLM Technology Group

Project Engineering Standard

Rev: 01 April 2012

www.klmtechgroup.com

KLM Technology Group #03-12 Block Aronia, Jalan Sri Perkasa 2 Taman Tampoi Utama 81200 Johor Bahru Malaysia

SPECIFICATION FOR SPHERICAL VESSELS (PROJECT STANDARDS AND SPECIFICATIONS)

2.2.13 VENDOR shall submit the expected final settlement of foundation measured after hydrostatic test in the following manner for PURCHASER's approval: 1) Even settlement 2) Tilting of tank 3) Out of plane settlement 2.3 Opening Reinforcement

2.3.1 Nozzles shall be constructed as integrally reinforced forged nozzles. 2.3.2 Neither nozzle nor its reinforcement shall straddle a weld joint at a shell. All welded accessories shall be at least 50 mm removed from weld joints. 2.3.3 For nozzle larger than 1-1/2 inch which have longer projection than 400 mm, appropriate reinforcement shall be considered. 2.4 Nozzles and Manholes

2.4.1 For temperature connection located below maximum liquid level, thermo well installation shall be provided on shell using flanged connection. 2.4.2 Basically, manhole shall be provided only at top of sphere. However, for construction convenience, bottom manhole may be provided, but seal weld or welded cap shall be provided after erection work completed. Top manhole shall be provided with davit to facilitate removal of the cover. 2.4.3 Spheres to be fully post weld heat treated in the field shall be provided with an enlarged filling 1 discharge connection of sufficient size for access of post weld heat treat equipment. See Figure 2A. 2.4.4 After post weld heat treatment of the sphere, the filling 1 discharge line shall be welded to the connection with a tapered dollar plate. See Figure 2B.

Page : 5 of 14

KLM Technology Group

Project Engineering Standard

Rev: 01 April 2012

www.klmtechgroup.com

KLM Technology Group #03-12 Block Aronia, Jalan Sri Perkasa 2 Taman Tampoi Utama 81200 Johor Bahru Malaysia

SPECIFICATION FOR SPHERICAL VESSELS (PROJECT STANDARDS AND SPECIFICATIONS)

2.4.5 Butt weld between the tapered dollar plate and the sphere cap plate shall be locally post weld heat treated thereafter. 2.5 Internals and Externals

2.5.1 Removable internal parts shall be able to disassemble into pieces to pass through manhole. 2.5.2 When water spray system is specified on the data sheet or drawings, the tank shall be provided with the spray nozzles for water spray system and riser pipes with supports. 2.5.3 External lugs such as pipe support lugs, insulation lugs shall be provided on sphere shell or their support. 2.5.4 Sphere shall have fireproof clips attached on their support columns and shell. 2.6 Stairways and Platforms

2.6.1 Stairways and platforms shall be provided to allow access to operating valves and instruments. Auxiliary structures to services instruments, connections, shall be provided where required. 2.6.2 A stairway shall be provided from grade to the top of the sphere and shall have handrails. 2.6.3 Stairways shall have the following provisions: 1) 2) 3) 4) Maximum angle with a horizontal line shall be 45" Minimum effective tread width shall be 235 mm. Minimum effective width of stairways shall be 760 mm. Stair landings shall not be less than 750 mm in the direction of the stairway.

Potrebbero piacerti anche

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDa Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsValutazione: 4 su 5 stelle4/5 (1)

- Dry Bulk Storage Tank SpecificationDocumento7 pagineDry Bulk Storage Tank SpecificationMohamed Mostafa IbrahimNessuna valutazione finora

- Allstate Specification For Astm PDFDocumento12 pagineAllstate Specification For Astm PDFZaendals JepitNessuna valutazione finora

- SPC Occ 221423 MeDocumento4 pagineSPC Occ 221423 Metarekhisham1234Nessuna valutazione finora

- Awwa d100 PotableDocumento8 pagineAwwa d100 PotableOnatNessuna valutazione finora

- Potable Water Storage Tank SpecificationDocumento7 paginePotable Water Storage Tank SpecificationTeguh Setiono100% (2)

- Pipe Supports Design CriteriaDocumento11 paginePipe Supports Design CriteriaJaykumar75% (4)

- Specification For Cathodic Protection DesignDocumento39 pagineSpecification For Cathodic Protection Designhezron7771% (7)

- Elevated Water Storage Tank Specification Composite Pedestal DesignDocumento11 pagineElevated Water Storage Tank Specification Composite Pedestal DesignashwiniNessuna valutazione finora

- Elevated SpecsDocumento14 pagineElevated SpecsSure ConsultancyNessuna valutazione finora

- ElevatedDocumento11 pagineElevatedSebastián ReyesNessuna valutazione finora

- Technical Specification Section: StructureDocumento10 pagineTechnical Specification Section: StructurePremBhushanNessuna valutazione finora

- Technical Specification Section StructureDocumento10 pagineTechnical Specification Section StructurePremBhushanNessuna valutazione finora

- 331615-Water Storage Steel TanksDocumento14 pagine331615-Water Storage Steel TanksinstrengNessuna valutazione finora

- Aluminum Dome Roof Installation: Chevron Specification TAM-EG-4812Documento7 pagineAluminum Dome Roof Installation: Chevron Specification TAM-EG-4812Burak GülenNessuna valutazione finora

- SECTION 13200 Specification For Bolted Tank UIGDocumento11 pagineSECTION 13200 Specification For Bolted Tank UIGEman Ismail HalawiNessuna valutazione finora

- Double Deck Floating RoofDocumento16 pagineDouble Deck Floating RoofInamullah Khan100% (3)

- 33 05 23.16 Pipe JackingDocumento3 pagine33 05 23.16 Pipe JackingisaacalvareztejanoNessuna valutazione finora

- Cold Box PackageDocumento5 pagineCold Box PackageAleem QureshiNessuna valutazione finora

- ES-1652 Shell and Tube Heat Exchangers r0Documento14 pagineES-1652 Shell and Tube Heat Exchangers r0Raul García (INNTELLIA)Nessuna valutazione finora

- Tender No: RCC/NR/UPSO-II/ENG/PT-07/19-20 Public Tender:-: Page 76 of 200Documento7 pagineTender No: RCC/NR/UPSO-II/ENG/PT-07/19-20 Public Tender:-: Page 76 of 200Shilpa SinghNessuna valutazione finora

- Alumina DaDocumento7 pagineAlumina DaBurak GülenNessuna valutazione finora

- Is: 10987Documento14 pagineIs: 10987tarangtushar100% (2)

- Section - Multi-Column Elevated Water Storage TankDocumento6 pagineSection - Multi-Column Elevated Water Storage Tankali gholiaNessuna valutazione finora

- DLT 5039-95 Specification For Design of Steel Gate in Hydropower and Water Conservancy ProjectsDocumento64 pagineDLT 5039-95 Specification For Design of Steel Gate in Hydropower and Water Conservancy Projectssaliyarumesh2292Nessuna valutazione finora

- Cooling TowersDocumento4 pagineCooling TowersHerlys PereiraNessuna valutazione finora

- Bolted Tank Specifications Final 11-5-15Documento6 pagineBolted Tank Specifications Final 11-5-15Rodrigo ZapataNessuna valutazione finora

- AWWA D100 Guide Specification PDFDocumento8 pagineAWWA D100 Guide Specification PDFDaniel Marín100% (1)

- Echnical Larification: Project Parts ApprovalDocumento4 pagineEchnical Larification: Project Parts ApprovalRatha ThanNessuna valutazione finora

- Project Standards and Specifications Shell and Tube Heat Exchangers Rev01Documento9 pagineProject Standards and Specifications Shell and Tube Heat Exchangers Rev01amitgoel1989Nessuna valutazione finora

- Guide Specification - SDP 200: GeneralDocumento10 pagineGuide Specification - SDP 200: GeneralhbookNessuna valutazione finora

- 39FX Guide PDFDocumento8 pagine39FX Guide PDFonspsnonsNessuna valutazione finora

- Design Criteria StructuralDocumento56 pagineDesign Criteria Structuralvenkiee100% (1)

- 331615-Water Storage Steel TanksDocumento14 pagine331615-Water Storage Steel TanksAdelmo Filho50% (2)

- Mesan MXR-KM (F-K) Guide Specs r2Documento4 pagineMesan MXR-KM (F-K) Guide Specs r2Renu TekumudiNessuna valutazione finora

- Aci523 - ImportanteDocumento5 pagineAci523 - ImportanteCledson2Nessuna valutazione finora

- 60-8001 - Check List For E-House & Topside Switchgear RFQDocumento3 pagine60-8001 - Check List For E-House & Topside Switchgear RFQDinesh RajNessuna valutazione finora

- Tam-Sc-2-B Doorsheet Removal and Reinstallation: February 2003 © Chevrontexaco 1 of 9Documento9 pagineTam-Sc-2-B Doorsheet Removal and Reinstallation: February 2003 © Chevrontexaco 1 of 9Herlys Pereira100% (1)

- 33 16 13 - Ground Storage TankDocumento6 pagine33 16 13 - Ground Storage TankBelford AbuhNessuna valutazione finora

- Tower PipingDocumento40 pagineTower PipingenjoygurujiNessuna valutazione finora

- NDCT SpecsDocumento121 pagineNDCT Specsthexp0werNessuna valutazione finora

- Offshore Structures: General IntroductionDocumento258 pagineOffshore Structures: General IntroductionAnonymous WCG2HjPybJNessuna valutazione finora

- Transmission Construction Standard: Saudi ElectricitycompanyDocumento12 pagineTransmission Construction Standard: Saudi ElectricitycompanyTori Small0% (1)

- Fabrication of Vessel StandardDocumento1 paginaFabrication of Vessel StandardAnonymous T0y70SNessuna valutazione finora

- Multi-Column Water Tank Construction SpecificationsDocumento8 pagineMulti-Column Water Tank Construction SpecificationsJorge León IllanesNessuna valutazione finora

- HPCL STD Spec For Storage TanksDocumento16 pagineHPCL STD Spec For Storage TanksnagtummalaNessuna valutazione finora

- ABS 2005 Steel Vessels Corrigenda March 2005Documento14 pagineABS 2005 Steel Vessels Corrigenda March 2005Erick Cruz MontañezNessuna valutazione finora

- Iqwq-ce1092-Mpere-00-0001 - 1 Static Equipement Installation Plan (Tank)Documento17 pagineIqwq-ce1092-Mpere-00-0001 - 1 Static Equipement Installation Plan (Tank)Ali MajeedNessuna valutazione finora

- Draft IS 4721Documento10 pagineDraft IS 4721rajfabNessuna valutazione finora

- Expansion Joint Technical Specification and Data SheetDocumento9 pagineExpansion Joint Technical Specification and Data SheetAhmad Dzulfiqar RahmanNessuna valutazione finora

- La91 Fabrication of PipingDocumento11 pagineLa91 Fabrication of PipingandyNessuna valutazione finora

- Operations ManualDocumento19 pagineOperations ManuallogesniceNessuna valutazione finora

- SEPL-Boiler Erection Instruction ManualDocumento14 pagineSEPL-Boiler Erection Instruction ManualKartheek Ramishetti100% (2)

- Ethane Furnace Erection SequenceDocumento5 pagineEthane Furnace Erection SequenceAleem QureshiNessuna valutazione finora

- Thermal Energy Storage TankDocumento24 pagineThermal Energy Storage Tankfahimafroz0% (1)

- Cyclones For Fluidized Bed ProcessesDocumento4 pagineCyclones For Fluidized Bed ProcessesswatkoolNessuna valutazione finora

- Expansion Joint Technical Specification and Data Sheet1Documento9 pagineExpansion Joint Technical Specification and Data Sheet1RAPHAEL suzartNessuna valutazione finora

- A Guide to Ship Repair Estimates in Man-hoursDa EverandA Guide to Ship Repair Estimates in Man-hoursValutazione: 4.5 su 5 stelle4.5/5 (5)

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeDa EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNessuna valutazione finora

- Lateral Capacity of Helix PiersDocumento8 pagineLateral Capacity of Helix PiershiyeonNessuna valutazione finora

- Gas Composition Examples TransportDocumento1 paginaGas Composition Examples TransporthiyeonNessuna valutazione finora

- D.F.I. Helical Presentation 7Documento68 pagineD.F.I. Helical Presentation 7hiyeonNessuna valutazione finora

- Perko-Helical Piles FlierDocumento2 paginePerko-Helical Piles FlierhiyeonNessuna valutazione finora

- Gas Composition ExamplesDocumento1 paginaGas Composition ExampleshiyeonNessuna valutazione finora

- IS 4995 (Part 2) 1974Documento25 pagineIS 4995 (Part 2) 1974Nagaraju ChintaNessuna valutazione finora

- Chemical Engineering - Plant Engineering 2 Ideal Gas - RevisionDocumento4 pagineChemical Engineering - Plant Engineering 2 Ideal Gas - RevisionhiyeonNessuna valutazione finora

- Corrosion of Helix PiersDocumento7 pagineCorrosion of Helix PiershiyeonNessuna valutazione finora

- Chemical Engineering - Plant Engineering 2 Power RequirementDocumento2 pagineChemical Engineering - Plant Engineering 2 Power RequirementhiyeonNessuna valutazione finora

- 8042306Documento99 pagine8042306Darshan KashiNessuna valutazione finora

- Storage Tanks and SilosDocumento9 pagineStorage Tanks and SiloshiyeonNessuna valutazione finora

- Calculations in Natural Gas CourseDocumento6 pagineCalculations in Natural Gas CourseHilmi ScpgzNessuna valutazione finora

- Compressors IntroductionDocumento12 pagineCompressors Introductionhiyeon100% (1)

- PT Concrete Storage StructuresDocumento51 paginePT Concrete Storage StructurescavnqnNessuna valutazione finora

- The Design of Natural Gas PipelinesDocumento7 pagineThe Design of Natural Gas PipelineshiyeonNessuna valutazione finora

- EC201 (Rev) Tcm92 22934kompressDocumento12 pagineEC201 (Rev) Tcm92 22934kompressJoe GoparNessuna valutazione finora

- 9 MultiphaseDocumento26 pagine9 MultiphaseAshrafNamamuTeratasNessuna valutazione finora

- NG. Compressor StationDocumento12 pagineNG. Compressor StationBrian MayNessuna valutazione finora

- Vol2 Appendix QDocumento314 pagineVol2 Appendix QhiyeonNessuna valutazione finora

- 8.1 Physical Properties of The Gas: 8.1.1 Pressure and VolumeDocumento16 pagine8.1 Physical Properties of The Gas: 8.1.1 Pressure and VolumehiyeonNessuna valutazione finora

- 11gas LiftDocumento18 pagine11gas LifthiyeonNessuna valutazione finora

- Cd5796 Emma OlgaDocumento26 pagineCd5796 Emma OlgahiyeonNessuna valutazione finora

- Transient two-phase flow insightsDocumento6 pagineTransient two-phase flow insightshiyeonNessuna valutazione finora

- Appendix T Route Selection MatrixDocumento9 pagineAppendix T Route Selection MatrixhiyeonNessuna valutazione finora

- Landfall Valve Installation: Sru Wad Dac Onb AyDocumento1 paginaLandfall Valve Installation: Sru Wad Dac Onb AyhiyeonNessuna valutazione finora

- Addendum Part 3Documento16 pagineAddendum Part 3hiyeonNessuna valutazione finora

- 03 COR 25 1MDR0470 Route Selection C Butler FINALDocumento17 pagine03 COR 25 1MDR0470 Route Selection C Butler FINALhiyeonNessuna valutazione finora

- Conversions UnitsDocumento1 paginaConversions UnitshiyeonNessuna valutazione finora

- Beregninger Gass Z-FaktorDocumento8 pagineBeregninger Gass Z-FaktorhiyeonNessuna valutazione finora

- Calculations in Natural Gas CourseDocumento6 pagineCalculations in Natural Gas CourseHilmi ScpgzNessuna valutazione finora

- Activity6 2c More Engineering ProblemsDocumento7 pagineActivity6 2c More Engineering ProblemsChristianNessuna valutazione finora

- Cooling Tower Noise Control Silencers Reduce SoundDocumento37 pagineCooling Tower Noise Control Silencers Reduce SoundUllas EK100% (1)

- IRC-78-2014 Standard Specifications and Code of Practice For Road Bridges, Section VII - Foundations and Substructure (Revised Edition)Documento100 pagineIRC-78-2014 Standard Specifications and Code of Practice For Road Bridges, Section VII - Foundations and Substructure (Revised Edition)Saroon Afshan76% (29)

- Highway Materials & Mix Design Ppt. MMHDocumento35 pagineHighway Materials & Mix Design Ppt. MMHMd Mehedi HasnatNessuna valutazione finora

- Sequential Load Analysis For Tall BuildingsDocumento10 pagineSequential Load Analysis For Tall BuildingsharisleeNessuna valutazione finora

- DBR - Fire Fighting - HPMC ParalaDocumento16 pagineDBR - Fire Fighting - HPMC ParalaKiran LokhandeNessuna valutazione finora

- Gan Band STRDocumento18 pagineGan Band STRitshotandfreeNessuna valutazione finora

- VRF Reporte - SpecificationsDocumento10 pagineVRF Reporte - SpecificationsKolor TécnologicoNessuna valutazione finora

- Climbing Formwork: Instructions For Assembly and Use - Standard Confi GurationDocumento92 pagineClimbing Formwork: Instructions For Assembly and Use - Standard Confi Gurationsyaiful bahtiarNessuna valutazione finora

- Installation and Maintenance Guide for Kenmore 2500 15 Gallon Central HumidifierDocumento13 pagineInstallation and Maintenance Guide for Kenmore 2500 15 Gallon Central HumidifierjsedlockNessuna valutazione finora

- Laminar Flow in ChannelsDocumento15 pagineLaminar Flow in ChannelsNeybilNessuna valutazione finora

- Carbide Banding - Effect On FatigueDocumento15 pagineCarbide Banding - Effect On FatigueSteve Green100% (1)

- Sylobloc Silica Anti-Blocking Additives: Product Portfolio & Selection GuideDocumento4 pagineSylobloc Silica Anti-Blocking Additives: Product Portfolio & Selection Guide360907219Nessuna valutazione finora

- Doha Clinic-Revised (7 Months)Documento4 pagineDoha Clinic-Revised (7 Months)DU A NENessuna valutazione finora

- Electrical Checklist Plan Review ChecklistDocumento13 pagineElectrical Checklist Plan Review ChecklistCB100% (1)

- Vibrations in Steam TurbinesDocumento11 pagineVibrations in Steam TurbinesAnudeep Chittluri100% (1)

- DAIKIN VAM VRV HVE ModelDocumento5 pagineDAIKIN VAM VRV HVE ModelPads PrietoNessuna valutazione finora

- Design of EHV SwitchyardDocumento47 pagineDesign of EHV Switchyardpraveen_1324100% (1)

- China (GB) USA UK Japan France Germany Russia Old New Astm BS JIS NF DIN ????Documento2 pagineChina (GB) USA UK Japan France Germany Russia Old New Astm BS JIS NF DIN ????payara111Nessuna valutazione finora

- Pipefill PDFDocumento8 paginePipefill PDFAlaa RamadanNessuna valutazione finora

- Chapter 6 Introduction To Thermodynamics PDFDocumento17 pagineChapter 6 Introduction To Thermodynamics PDFSaurav PaulNessuna valutazione finora

- Standard One-Storey School Building: (2 - Classrooms)Documento16 pagineStandard One-Storey School Building: (2 - Classrooms)Prime Agritech EngineeringNessuna valutazione finora

- Commissioning of Plumbing SystemsDocumento7 pagineCommissioning of Plumbing SystemsNadeesha BandaraNessuna valutazione finora

- Bolt Tightening Handbook Linear Motion ADocumento44 pagineBolt Tightening Handbook Linear Motion AMarcos MorachickNessuna valutazione finora

- PipeWrap BTDocumento2 paginePipeWrap BTPrashantBaruaNessuna valutazione finora

- Enthalpy / Entropy DiagramDocumento34 pagineEnthalpy / Entropy DiagramMara TrofinNessuna valutazione finora

- OECSwceDocumento12 pagineOECSwceChristopher WeeksNessuna valutazione finora

- FE 3300 The Use of Fans in Pneumatic ConveyingDocumento4 pagineFE 3300 The Use of Fans in Pneumatic ConveyingAvery OppegardNessuna valutazione finora

- Construction of 2 Storey Multi Purpose Building - TS Cruz Ville Subdivision - KaligayahanDocumento53 pagineConstruction of 2 Storey Multi Purpose Building - TS Cruz Ville Subdivision - KaligayahanBobbles D LittlelionNessuna valutazione finora

- Pup Main Building: West Wing FloorDocumento19 paginePup Main Building: West Wing FloorDhenil ManubatNessuna valutazione finora