Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Linear Coefficients of Expansion

Caricato da

VBT1Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Linear Coefficients of Expansion

Caricato da

VBT1Copyright:

Formati disponibili

17

Material Expansion Coefficients

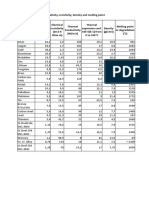

Chapter 17 Material Expansion Coefficients Linear Thermal Expansion Coefficients of Metals and Alloys

Linear Thermal Expansion Coefficients of Metals and Alloys

Table 17-1 provides the linear thermal expansion coefficients of the most frequently used metals and allows. Table 17-1. Linear thermal expansison coefficients of metals and alloys

Coefficient of Expansion Alloys ALUMINUM AND ALUMINUM ALLOYS ppm/C ppm/F

Aluminum (99.996%)

23.6

13.1

Wrought Alloys EC 1060 and 1100 2011 and 2014 2024 2218 3003 23.6 23.0 22.8 22.3 23.2 13.1 12.8 12.7 12.4 12.9

4032 5005, 5050, and 5052 5056 5083 5086

19.4 23.8 24.1 23.4 23.9

10.8 13.3 13.4 13.0 13.3

5154 5357 5456 6061 and 6063 6101 and 6151

23.9 23.7 23.9 23.4 23.0

13.3 13.2 13.3 13.0 12.8

7075 7090 and 7178

23.2 23.4

12.9 13.0

17-2

Users Manual

Chapter 17 Material Expansion Coefficients Linear Thermal Expansion Coefficients of Metals and Alloys

Table 17-1. Linear thermal expansison coefficients of metals and alloys (Cont.)

Coefficient of Expansion Alloys ALUMINUM AND ALUMINUM ALLOYS (Continued) Casting Alloys A13 43 and 108 A108 A132 D132 20.4 22.0 21.5 19.0 20.5 11.4 12.3 12.0 10.6 11.4 ppm/C ppm/F

F132 138 142 195 B195

20.7 21.4 22.5 23.0 22.0

11.5 11.9 12.5 12.8 12.3

214 220 319 355 356

24.0 25.0 21.5 22.0 21.5

13.4 13.9 12.0 12.3 12.0

360 750 40E COPPER AND COPPER ALLOYS Wrought Coppers Pure Copper Electrolytic Tough Pitch Copper (ETP) Deoxidized Copper, High Residual Phosphorous (DHP) Oxygen-Free Copper Free-Machining Copper 0.5% Te or 1% Pb

21.0 23.1 24.7

11.7 12.9 13.8

16.5 16.8 17.7 17.7 17.7

9.2 9.4 9.9 9.9 9.9

Users Manual

17-3

Chapter 17 Material Expansion Coefficients Linear Thermal Expansion Coefficients of Metals and Alloys

Table 17-1. Linear thermal expansison coefficients of metals and alloys (Cont.)

Coefficient of Expansion Alloys COPPER AND COPPER ALLOYS (Continued) Wrought Alloys (Continued) Gilding, 95% Commercial Bronze, 90% Jewelry Bronze, 87.5% Red Brass, 85% Low Brass, 80% 18.1 18.4 18.6 18.7 19.1 10.1 10.3 10.4 10.4 10.6 ppm/C ppm/F

Cartridge Brass, 70% Yellow Brass Muntz Metal Leaded Commercial Bronze Low-Leaded Brass

19.9 20.3 20.8 18.4 20.2

11.1 11.2 11.5 10.2 11.3

Medium-Leaded Brass High-Leaded Brass Extra-High-Leaded Brass Free-Cutting Brass Leaded Muntz Metal

20.3 20.3 20.5 20.5 20.8

11.3 11.3 11.4 11.4 11.6

Forging Brass Architectural Bronze Inhibited Admiralty Naval Brass Leaded Naval Brass

20.7 20.9 20.2 21.2 21.2

11.5 11.6 11.3 11.8 11.8

Manganese Bronze (A) Phosphorous Bronze, 5% (A) Phosphorous Bronze, 8% (C) Phosphorous Bronze, 10%(D) Phosphorous Bronze, 1.25%

21.2 17.8 18.2 18.4 17.8

11.8 9.9 10.1 10.3 9.9

17-4

Users Manual

Chapter 17 Material Expansion Coefficients Linear Thermal Expansion Coefficients of Metals and Alloys

Table 17-1. Linear thermal expansison coefficients of metals and alloys (Cont.)

Coefficient of Expansion Alloys COPPER AND COPPER ALLOYS (Continued) Wrought Alloys (Continued) Free-Cutting Phosphorous Bronze Cupro-Nickel, 30% Cupro-Nickel, 10% Nickel Silver, 65-18 Nickel Silver, 55-18 17.3 16.2 17.1 16.2 16.7 9.6 9.0 9.5 90 9.3 ppm/C ppm/F

Nickel Silver, 65.12 High-Silicon Bronze (A) Low-Silicon Bronze (B) Aluminum Bronze (3) Aluminum-Silicon Bronze

16.2 18.0 179 16.4 18.0

9.0 10.0 10.0 9.2 10.0

Aluminum Bronze Beryllium Copper

16.8 17.8

9.4 9.9

Casting Alloys 88 Cu-8 SN-4 Zn 88 Cu-11 Sn 88 Cu-6 Sn-1.5 Pb-4.5 Zn 87 Cu-8 Sn-1 Pb-4 Zn 87 Cu-10 Sn-1 Pb-2 Zn 18.0 18.4 18.5 18.0 18.0 10.0 10.3 10.3 10.0 10.0

80 Cu-10 Sn-10 Pb 78 Cu-7 Sn-15 Pb 85 Cu-5 Sn-5 Pb-5 Zn 72 Cu-1 Sn-3 Pb-24 Zn 67 Cu-1 Sn-3 Pb-29 Zn

18.5 18.5 18.1 20.7 20.2

10.3 10.3 10.0 11.5 11.3

61 Cu-1 Sn-1 Pb-37 Zn Manganese Bronze (60,000 psi)

21.6 20.5

12.0 11.4

Users Manual

17-5

Chapter 17 Material Expansion Coefficients Linear Thermal Expansion Coefficients of Metals and Alloys

Table 17-1. Linear thermal expansison coefficients of metals and alloys (Cont.)

Coefficient of Expansion Alloys COPPER AND COPPER ALLOYS (Continued) Casting Alloys (Continued) Manganese Bronze (65,000 psi) Manganeze Bronze (110,000 psi) Aluminum Bronze (Alloy 9A) Aluminum Bronze (Alloy 9B) Aluminum Bronze (Alloys 9C & 9D) IRON AND IRON ALLOYS Pure Iron 11.7 6.5 21.6 19.8 17.0 17.0 16.2 12.0 11.0 9.5 9.5 9.0 ppm/C ppm/F

Fe-C Alloys 0.06% C 0.22% C 0.40% C 0.56% C 1.08% C 1.45% C 11.7 11.7 11.3 11.0 10.8 10.1 6.5 6.5 6.3 6.1 6.0 5.6

Invar (36 Ni) 13 Mn-1.2 C 13 Cr-0.35 C 12.0 Cr-0.4 Ni-0.09 C 17.7 Cr-9.6 Ni-0.06 C

0 to 2 18.0 10.0 9.8 16.5

to 1.1 10.0 5.6 5.5 9.2

18. W-4 Cr-1 V Gray Cast Iron Malleable Iron (Pearlitic) LEAD AND LEAD ALLOYS Corroding Lead (99.73+% Pb) 5-95 Solder 20-80 Solder 50-50 Solder

11.2 10.5 12.0

6.2 5.7 6.7

29.3 28.7 26.5 23.4

16.3 16.0 14.8 13.0

17-6

Users Manual

Chapter 17 Material Expansion Coefficients Linear Thermal Expansion Coefficients of Metals and Alloys

Table 17-1. Linear thermal expansison coefficients of metals and alloys (Cont.)

Coefficient of Expansion Alloys LEAD AND LEAD ALLOYS (Continued) 1% Antimonial Lead Hard Lead (96 Pb, 4 Sb) Hard Lead (94Pb, 6 Sb) 8% Antimonial Lead 9% Antimonial Lead 28.8 27.8 27.2 26.7 26.4 16.1 15.5 15.2 14.9 14.7 ppm/C ppm/F

Lead-Base Babbitt: SAE 14 Alloy 8 MAGNESIUM AND MAGNESIUM ALLOYS Magnesium (99.8%) Casting Alloys AM100A AZ63A AZ91A, B, C AZ92A HZ32A 25.2 26.1 26.0 25.2 26.7 14.1 14.6 14.5 14.1 14.9 25.2 14.1 19.6 24.0 10.9 13.4

ZH42 ZH62A AK51A EZ33A EK30A and EK41A Wrought Alloys M1A and A3A AZ31B and PE AZ61A and AZ80A ZK60A, B HM31A

27.0 27.1 26.1 26.1 26.1

15.1 15.1 14.6 14.6 14.6

26.0 26.0 26.0 26.0 26.1

14.5 14.5 14.5 14.5 14.6

Users Manual

17-7

Chapter 17 Material Expansion Coefficients Linear Thermal Expansion Coefficients of Metals and Alloys

Table 17-1. Linear thermal expansison coefficients of metals and alloys (Cont.)

Coefficient of Expansion Alloys NICKEL AND NICKEL ALLOYS Nickel (99.95% Ni-+Co) Duranickel Monel Monel (cast) Inconel 13.3 13.0 14.0 12.9 11.5 7.4 7.2 7.8 7.2 6.4 ppm/C ppm/F

Ni-o-nel Hastelloy B Hastelloy C Hastelloy D Hastelloy F

12.9 10.0 11.3 11.0 14.2

7.2 5.6 6.3 6.1 7.9

Hastelloy N Hastelloy W Hastelloy X Illium G Illium R

10.4 11.3 13.8 12.19 12.0

5.8 6.3 7.7 6.8 26.7

80 Ni-20 Cr 60 Ni-24 Fe-16Cr 35 Ni-45 Fe-20 Cr Constantan STAINLESS STEELS 301 302 302B 303 304

17.3 17.0 15.8 18.8

9.6 9.5 8.8 10.5

16.9 17.3 16.2 17.3 17.3

9.4 9.6 9.0 9.6 9.6

305 308

17.3 17.3

9.6 9.6

17-8

Users Manual

Chapter 17 Material Expansion Coefficients Linear Thermal Expansion Coefficients of Metals and Alloys

Table 17-1. Linear thermal expansison coefficients of metals and alloys (Cont.)

Coefficient of Expansion Alloys STAINLESS STEELS (Continued) 309 310 314 316 317 14.9 14.4 15.1 16.0 16.0 8.3 8.0 8.4 8.9 8.9 ppm/C ppm/F

321 347 501 502

16.7 16.7 11.15 11.15

9.3 9.3 6.2 6.2

403 405 410 416 420

9.9 10.8 11.0 9.9 10.25

5.5 6.0 6.1 5.5 5.7

430 430F 431 440A 440B

10.45 10.45 11.7 10.1 10.1

5.8 5.8 6.5 5.6 5.6

440C 446 TITANIUM AND TITANIUM ALLOYS 99.9% Ti 99.0% Ti Ti-5 A1-2.5 Sn Ti-8 Mn

10.1 10.6

5.6 5.9

8.41 8.55 9.36 8.64

4.7 4.76 5.2 4.8

Users Manual

17-9

Chapter 17 Material Expansion Coefficients Linear Thermal Expansion Coefficients of Metals and Alloys

Table 17-1. Linear thermal expansison coefficients of metals and alloys (Cont.)

Coefficient of Expansion Alloys ZINC AND ZINC ALLOYS Pure Zinc AG40A Alloy AC41A Alloy Commercial Rolled Zinc: 0.08 Pb 03 Pb, 0.3 Cd 32.5 33.9* 18.1 18.9 39.7 27.4 27.4 22.1 15.3 15.3 ppm/C ppm/F

Rolled Zinc Allow (1Cu, 0.010 Mg) An-Cu-Ti Alloy (0.8 Cu, 0.15 Ti)

34.8** 24.9***

*With the grain; 23.4 across the grain ** With the grain; 21.1 across the grain ***With the grain; 19.4 across the grain

19.4 13.9

PURE METALS Beryllium Cadmium Calcium Chromium Cobalt 11.6 29.8 22.3 6.2 13.8 6.5 16.6 12.4 3.5 7.7

Gold Iridium Lithium Manganese Palladium

14.2 6.8 56.0 22.0 11.76

7.9 3.8 31.0 12.3 6.6

Platinum Rhenium Rhodium Ruthenium Silicon

8.9 6.7 8.3 9.1 5.0

5.0 3.7 4.6 5.1 2.8

17-10

Users Manual

Chapter 17 Material Expansion Coefficients Linear Thermal Expansion Coefficients of Metals and Alloys

Table 17-1. Linear thermal expansison coefficients of metals and alloys (Cont.)

Coefficient of Expansion Alloys PURE METALS (Continued) Silver Tungsten Vanadium Zirconium 19.68 4.6 8.3 5.85 11.0 2.7 4.6 3.3 ppm/C ppm/F

Users Manual

17-11

Chapter 17 Material Expansion Coefficients Linear Thermal Expansion Coefficients of Metals and Alloys

Product specifications and descriptions in this document subject to change without notice. Copyright (C) 2002 Agilent Technologies Printed in U.S.A. 07/02 This is a chapter from the manual titled: Laser and Optics User's Manual For complete manual, order: Paper version: p/n 05517-90045 CD version: p/n 05517-90063 This chapter is p/n 05517-90143

17-12

Users Manual

Potrebbero piacerti anche

- Relationship Between E and TDocumento3 pagineRelationship Between E and Tvande_852001Nessuna valutazione finora

- Composition and Physical Properties of AlloysDocumento22 pagineComposition and Physical Properties of Alloysmohsen_267Nessuna valutazione finora

- Valve Spec.Documento15 pagineValve Spec.koner_debasishNessuna valutazione finora

- Useful Information For The Valve IndustryDocumento9 pagineUseful Information For The Valve Industryhummingbird4uNessuna valutazione finora

- List of Copper AlloysDocumento8 pagineList of Copper AlloysspahicdaniloNessuna valutazione finora

- Lead Anodes for Copper ElectrowinningDocumento28 pagineLead Anodes for Copper Electrowinningvictor perez villegasNessuna valutazione finora

- AlloysDocumento27 pagineAlloysranvir_rajNessuna valutazione finora

- 5 - Duplex Stainless Steels and Nickel AlloysDocumento44 pagine5 - Duplex Stainless Steels and Nickel AlloysdennykvgNessuna valutazione finora

- P Numbers: Grouping of Base Metals For Qualification (No. 1Documento5 pagineP Numbers: Grouping of Base Metals For Qualification (No. 1Lim DongseopNessuna valutazione finora

- Alloy Steels Nickel Cobalt AlloysDocumento1 paginaAlloy Steels Nickel Cobalt AlloysMichaelben MichaelbenNessuna valutazione finora

- Performance Analysis of A Smelting ReactDocumento6 paginePerformance Analysis of A Smelting ReactMARCELO HINOJOSA HERNANDEZNessuna valutazione finora

- NSR Factors Calculation ExampleDocumento9 pagineNSR Factors Calculation ExampleRolando QuispeNessuna valutazione finora

- Corrosion Resistance of Nickel Containing Alloys in Organic Acids and Related CompoundsDocumento0 pagineCorrosion Resistance of Nickel Containing Alloys in Organic Acids and Related CompoundsrickrobbinsNessuna valutazione finora

- Zhang 2018Documento11 pagineZhang 2018dilla zainudinNessuna valutazione finora

- P1 To P8Documento9 pagineP1 To P8Pat AuffretNessuna valutazione finora

- Thermal Expansion Data Table Tb06Documento4 pagineThermal Expansion Data Table Tb06Brandon HillNessuna valutazione finora

- Thermocouple S: Thermoelectric EffectDocumento3 pagineThermocouple S: Thermoelectric EffectAnonymous 01rI0sNessuna valutazione finora

- Electrical or Thermal CondutivityDocumento1 paginaElectrical or Thermal CondutivityDan SabadusNessuna valutazione finora

- How To Weld Fully Austenitic Stainless SteelsDocumento20 pagineHow To Weld Fully Austenitic Stainless SteelsCarlos Bermejo AlvarezNessuna valutazione finora

- CuniDocumento32 pagineCunikampit100% (1)

- FontargenDocumento282 pagineFontargenMIHAINessuna valutazione finora

- P92 Paper IIW Conference GrazDocumento13 pagineP92 Paper IIW Conference GrazzhangxingzydNessuna valutazione finora

- Introduction To The Family of Stainless SteelsDocumento29 pagineIntroduction To The Family of Stainless Steelspipedown456Nessuna valutazione finora

- AOD Chapter12 PDFDocumento4 pagineAOD Chapter12 PDFNguyễn Văn ThanhNessuna valutazione finora

- Properties of NickelDocumento60 pagineProperties of NickelchodekiranNessuna valutazione finora

- Aluminium SpecificationDocumento2 pagineAluminium SpecificationklhlNessuna valutazione finora

- Table of MetalsDocumento26 pagineTable of MetalsAkramNessuna valutazione finora

- Metal Injection Molding Material PropertiesDocumento12 pagineMetal Injection Molding Material Propertiesdbfreelancer1195Nessuna valutazione finora

- Asme b31.3 - Coef C-3 - EjemploDocumento4 pagineAsme b31.3 - Coef C-3 - EjemploEduardo GironNessuna valutazione finora

- Metal Dusting in A Laboratory Environment - Alloying Addition EffectsDocumento15 pagineMetal Dusting in A Laboratory Environment - Alloying Addition EffectsClaudia MmsNessuna valutazione finora

- Modulus of Rigidity of Some Common MaterialsDocumento5 pagineModulus of Rigidity of Some Common MaterialsSathisKumaarNessuna valutazione finora

- HIC Resistance SteelDocumento180 pagineHIC Resistance SteelArash Ilbagi100% (1)

- The Welding of Structural Steels Without PreheatDocumento10 pagineThe Welding of Structural Steels Without PreheatHouman HatamianNessuna valutazione finora

- USPAS 2002 Materials, Fabrication TechniquesDocumento46 pagineUSPAS 2002 Materials, Fabrication Techniquesgangappa birajadarNessuna valutazione finora

- Presentation - 1 Energy Use in Metal Production: Keywords: Metals, Embodied Energy, Primary Metals, Recycling, GreenhouseDocumento3 paginePresentation - 1 Energy Use in Metal Production: Keywords: Metals, Embodied Energy, Primary Metals, Recycling, GreenhouseNitin RautNessuna valutazione finora

- Corrosion Engineering Course Forms of CorrosionDocumento138 pagineCorrosion Engineering Course Forms of CorrosionAnupam Chowdhury100% (1)

- Ferrous Alloys Metallurgy ReviewDocumento80 pagineFerrous Alloys Metallurgy ReviewAlvin Garcia PalancaNessuna valutazione finora

- Carbone 2191 ISO Graphite Spec SheetDocumento6 pagineCarbone 2191 ISO Graphite Spec Sheetmichaelstarr1969Nessuna valutazione finora

- Studying The Effect of Tramp Elements inDocumento7 pagineStudying The Effect of Tramp Elements inmohit madaviNessuna valutazione finora

- Jasinski 1987Documento5 pagineJasinski 1987Het DedhiaNessuna valutazione finora

- Materials Form Final Product ClassificationDocumento30 pagineMaterials Form Final Product ClassificationBalakumarNessuna valutazione finora

- WPS - EngineerDocumento20 pagineWPS - Engineerhunghoanglong100% (1)

- Raffmetal: UNI EN 1676 and 1706Documento2 pagineRaffmetal: UNI EN 1676 and 1706Anshuman RoyNessuna valutazione finora

- Abreviaturas Comunes en La Industria ValvuleraDocumento10 pagineAbreviaturas Comunes en La Industria Valvulerataz_007Nessuna valutazione finora

- SS - Filler Wire SelectionDocumento26 pagineSS - Filler Wire SelectionBaraa AzebNessuna valutazione finora

- Welding Stainless SteelDocumento4 pagineWelding Stainless SteelJohan ZraghozNessuna valutazione finora

- 171020Documento27 pagine171020lort1971Nessuna valutazione finora

- MgO Based Inclusions in Aluminum Killed SteelsDocumento19 pagineMgO Based Inclusions in Aluminum Killed SteelsEstéfano Aparecido VieiraNessuna valutazione finora

- Cast Alloys for Advanced Ultra Supercritical Steam TurbinesDocumento14 pagineCast Alloys for Advanced Ultra Supercritical Steam TurbinesAnonymous lmCR3SkPrKNessuna valutazione finora

- Corrosion Resistance of Nickel and Nickel Containing Alloys in Caustic Soda and Other AlkaliesDocumento42 pagineCorrosion Resistance of Nickel and Nickel Containing Alloys in Caustic Soda and Other AlkaliesrickrobbinsNessuna valutazione finora

- Metal Alloys Guide: Properties and Applications of Aluminum, Copper, Nickel, Titanium and Their AlloysDocumento31 pagineMetal Alloys Guide: Properties and Applications of Aluminum, Copper, Nickel, Titanium and Their AlloysAsyiqotul UlyaNessuna valutazione finora

- CDA110 Specifaction SheetDocumento5 pagineCDA110 Specifaction SheetGendakensNessuna valutazione finora

- Material PropertiesDocumento93 pagineMaterial Propertiessachin_sawant1985Nessuna valutazione finora

- Callister 8th Edition - Chapter 11 - Applications and Processing of Metal AlloysDocumento35 pagineCallister 8th Edition - Chapter 11 - Applications and Processing of Metal AlloysRini ArtikaNessuna valutazione finora

- High Temperature Corrosion: Fundamentals and EngineeringDa EverandHigh Temperature Corrosion: Fundamentals and EngineeringNessuna valutazione finora

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Da EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Valutazione: 5 su 5 stelle5/5 (1)

- Extractive Metallurgy 3: Processing Operations and RoutesDa EverandExtractive Metallurgy 3: Processing Operations and RoutesNessuna valutazione finora

- Materials Data for Cyclic Loading: Low-Alloy SteelsDa EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsValutazione: 5 su 5 stelle5/5 (2)

- Die Casting Metallurgy: Butterworths Monographs in MaterialsDa EverandDie Casting Metallurgy: Butterworths Monographs in MaterialsValutazione: 3.5 su 5 stelle3.5/5 (2)

- Core Competency Qualification Requirements Handbook: Master Training SpecialistDocumento71 pagineCore Competency Qualification Requirements Handbook: Master Training SpecialistVBT1Nessuna valutazione finora

- Dept. of Energy - Chemistry 2of2Documento138 pagineDept. of Energy - Chemistry 2of2shivadogNessuna valutazione finora

- US Navy Course NAVEDTRA 134 - Navy Instructor ManualDocumento134 pagineUS Navy Course NAVEDTRA 134 - Navy Instructor ManualGeorges100% (6)

- Metrology HandbookDocumento159 pagineMetrology Handbookdj1702Nessuna valutazione finora

- How buffers maintain pH levelsDocumento4 pagineHow buffers maintain pH levelsManP13Nessuna valutazione finora

- Improved Conductivity and Mechanism of Carrier Transport in Zinc Oxide With Embedded Silver LayerDocumento8 pagineImproved Conductivity and Mechanism of Carrier Transport in Zinc Oxide With Embedded Silver LayerAbdul BasitNessuna valutazione finora

- Profile Prince Decoware Furniture HandlesDocumento54 pagineProfile Prince Decoware Furniture HandlesRushabh ShahNessuna valutazione finora

- Galvanic Series: Why Metals Corrode?Documento7 pagineGalvanic Series: Why Metals Corrode?Rey Francis FamulaganNessuna valutazione finora

- Bio HGHDocumento19 pagineBio HGHapi-240332064Nessuna valutazione finora

- Photos of Defects Found in RadiographyDocumento14 paginePhotos of Defects Found in RadiographyKavipriyan KaviNessuna valutazione finora

- Cassida Chain Oil 150-SdsDocumento5 pagineCassida Chain Oil 150-SdsInggil Budi PekertiNessuna valutazione finora

- Alkyl HalideDocumento54 pagineAlkyl HalideNelvianaNessuna valutazione finora

- Spontaneous Combustion ConversionDocumento68 pagineSpontaneous Combustion ConversionRizwan Ullah BaigNessuna valutazione finora

- BioreactorsDocumento32 pagineBioreactorskhadeeja vjfndnNessuna valutazione finora

- Zuellig Pharma Corporation: Item Name of Medicine Brand Name Principal Name Quantity Unit PriceDocumento2 pagineZuellig Pharma Corporation: Item Name of Medicine Brand Name Principal Name Quantity Unit PriceJZik SibalNessuna valutazione finora

- Fosroc Solvent 102 resin cleaning solventDocumento2 pagineFosroc Solvent 102 resin cleaning solventShaikhRizwanNessuna valutazione finora

- As 2278.1-2008 Aerosol Containers Metal Aerosol Dispensers of Capacity 50 ML To 1000 ML InclusiveDocumento7 pagineAs 2278.1-2008 Aerosol Containers Metal Aerosol Dispensers of Capacity 50 ML To 1000 ML InclusiveSAI Global - APAC50% (2)

- MScSYChem18 19Documento40 pagineMScSYChem18 19kumarNessuna valutazione finora

- Insect PestsDocumento164 pagineInsect PestsKenneth100% (11)

- CHM1207 Lab 3 2023 - DRAKES, Tameica (1042436) PDFDocumento6 pagineCHM1207 Lab 3 2023 - DRAKES, Tameica (1042436) PDFNikoli MajorNessuna valutazione finora

- Toxic Substances and Disease Registry MRLs for March 2016Documento16 pagineToxic Substances and Disease Registry MRLs for March 2016KodeChandrshaekharNessuna valutazione finora

- Name of Elements Properties Use/S 1. ZinkDocumento13 pagineName of Elements Properties Use/S 1. ZinkNora Alfaro BalsakiNessuna valutazione finora

- Food Preservatives and Their Harmful EffDocumento2 pagineFood Preservatives and Their Harmful EffJo ShuNessuna valutazione finora

- Liquefied Gas HandbookDocumento38 pagineLiquefied Gas HandbookAndri Suharto100% (1)

- Nucleic Acids BrochureDocumento2 pagineNucleic Acids BrochureCring-cring NavarroNessuna valutazione finora

- Flashing CalculationsDocumento8 pagineFlashing CalculationsjcmarabouNessuna valutazione finora

- C.02 - Gas-Freeing and Cleaning of TanksDocumento7 pagineC.02 - Gas-Freeing and Cleaning of TanksmkkamarajNessuna valutazione finora

- Review of Essential Oils from Annonaceae PlantsDocumento13 pagineReview of Essential Oils from Annonaceae PlantsroxanaNessuna valutazione finora

- Expwb3ans eDocumento67 pagineExpwb3ans eOlivia LinNessuna valutazione finora

- Concrete Strength by Brick ChipsDocumento10 pagineConcrete Strength by Brick ChipsHamayet RaselNessuna valutazione finora

- Drug Price Control Order 2013 As Good as a Leaky BucketDocumento3 pagineDrug Price Control Order 2013 As Good as a Leaky Bucketcat100percentileNessuna valutazione finora

- Volcanic Eruptions NotesDocumento24 pagineVolcanic Eruptions NotesKarthikesan MakNessuna valutazione finora

- Lubricant Properties CalculatorDocumento14 pagineLubricant Properties CalculatorzamijakaNessuna valutazione finora

- Hodson G - Methanol in WineDocumento5 pagineHodson G - Methanol in WinePhaimNessuna valutazione finora