Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SampleCalculationspipingB3132008 PDF

Caricato da

sosatlantiqueDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SampleCalculationspipingB3132008 PDF

Caricato da

sosatlantiqueCopyright:

Formati disponibili

Ph: 520-265-3657 Fax: 888-241-3035 mailto:info@keydesigneng.com http://www.keydesigneng.

com/

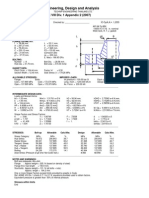

Piping Calculation per ASME B31.3-2008

Drawing Description: Sample P&ID Drawing Name: KEY-026 P&ID

These are Sample Calculations, For Demonstration Purposes only.

Prepared by: Michael Rodgers, P.Eng. Date: July 9, 2010 Project: KEY-026

Sample Calculations piping B31.3-2008.xls

Page 2 of 13

Table of Contents

Table of Contents Piping Calculations: Summary Item 1: 1/2" SCH.80 Item 2: 1" SCH.80 Item 3: 2" SCH.80 Item 4: 3" SCH.40 Item 5: 4" SCH.40 Item 6: Tube 0.5"x0.035" Item 8: 1" x 2" Threadolet Item 9: 1" x 3" Threadolet Sheet # 2 3 4 5 6 7 8 9 10 12

Sample Calculations For Demonstration only

Sample Calculations piping B31.3-2008.xls

Page 3 of 13

Piping Calculations: Summary

Code of construction: Material: Design Pressure Internal: Operating Internal Pressure: Design Temperature: Operating Temperature: PWHT: NDE: Corrosion Allowance: Test Pressure: ASME B31.3-2008 316 Stainless (see BOM) 90 psig 65 psig 150F 150F None 100% Visual 0" 135 psig

Discussion & Conclusion:

Tube: 1/2" Tubing: The limiting MAWP is 2,576 PSI for the 1/2", given a Corrosion Allowance of 0.00". This is greater than the design pressure of 90 PSI. Acceptable Pipe: 1/2" to 4" Pipe: For piping in this size range, the limiting MAWP is 1,531 PSI for the 4.0"-Sch40, given a Corrosion Allowance of 0.00". This is greater than the design pressure of 90 PSI. Acceptable Fittings: Buttweld All elbows, tees, bushings and similar fittings are ASME B16.9 compliant, and as such are subject to the pressure rating of pipe, which has been calculated and is acceptable. Furthermore, they are all CRN-registered for the province of installation.

Acceptable Fittings: Olets Olets are calculated conservatively per ASME B31.3-2006 on the following sheets as a Branch connection, per Figure 328.5.4D(1). All connections are acceptable for the design condition of 90 psi at 150F and no additional reinforcement is required beyond the external fillet weld that has been specified on the drawing notes. Acceptable Flanges: All Flanges are B16.5 RFWN & bear a CRN from ABSA for Alberta. The pressure rating for A182 F316 @ 150F is 255 PSI, which is greater than the design pressure of 90 PSI. Acceptable

Sample Calculations For Demonstration only

Sample Calculations piping B31.3-2008.xls

Page 4 of 13

Pipe and Shell Calculation, B31.3, Rev.4.3

Ref: ASME B31.3, 2008 Edition, para. 304.1 Item 1: 1/2" Sch.80 Item: Design Temperature: 150F Material= A312 TP316 Do = 0.84 in, Outside Diameter t= CA = P= S= E= UTP = W= Y= 0.147 in, Nominal wall thickness 0 in, Corrosion allowance 90 psi, Design Pressure 20000 psi, Allowable stress at temperature 0.80 Longitudinal Efficiency 0.125 Undertolerance Allowance, as a decimal 1.00 Weld joint Reduction Factor (para 302.3.5(e)) 0.4 Coefficient, Table 304.1.1

Calculation of Variables UT= 0.018375 in, for UT=t*UTP nt= 0.128625 in, for nt=(t-CA-UT) Ri= 0.291375 in, for Ri=Do/2-nt d= 0.58275 in, for d=Ri*2 304.1.2: Straight Pipe under Internal Pressure, Minimum Required Thickness

These values don't include corrosion allowance and any other mechanical allowances

3a

t3a= 90*0.84/(2(20000*0.8*1+90*0.4)) t3a= 0.002 in t3b= 90*(0.58275+ 2*0)/(2(20000*0.8*1-90*(1-0.4)) t3b= 0.002 in Check: Is MAX(t3a,t3b)<=nt? Yes MAX(0.002, 0.001)<= 0.128 Therefore thickness is Acceptable MAWP= 5,584 psi

3b

304.1.2 Check for applicability

Conditions below are checked to ensure that the calculations performed above are applicable to the geometry and the pressure range. Additional verification would otherwise be required.

Diameter Pressure

tmin<(Do/6) P/(S*E)<0.385

Geometry is Acceptable Pressure Range is Acceptable

Sample Calculations For Demonstration only

Sample Calculations piping B31.3-2008.xls

Page 5 of 13

Pipe and Shell Calculation, B31.3, Rev.4.3

Ref: ASME B31.3, 2008 Edition, para. 304.1 Item 2: 1" Sch.80 Item: Design Temperature: 150F Material= A312 TP316 Do = 1.315 in, Outside Diameter t= CA = P= S= E= UTP = W= Y= 0.179 in, Nominal wall thickness 0 in, Corrosion allowance 90 psi, Design Pressure 20000 psi, Allowable stress at temperature 0.80 Longitudinal Efficiency 0.125 Undertolerance Allowance, as a decimal 1.00 Weld joint Reduction Factor (para 302.3.5(e)) 0.4 Coefficient, Table 304.1.1

Calculation of Variables UT= 0.022375 in, for UT=t*UTP nt= 0.156625 in, for nt=(t-CA-UT) Ri= 0.500875 in, for Ri=Do/2-nt d= 1.00175 in, for d=Ri*2 304.1.2: Straight Pipe under Internal Pressure, Minimum Required Thickness

These values don't include corrosion allowance and any other mechanical allowances

3a

t3a= 90*1.315/(2(20000*0.8*1+90*0.4)) t3a= 0.004 in t3b= 90*(1.00175+ 2*0)/(2(20000*0.8*1-90*(1-0.4)) t3b= 0.003 in Check: Is MAX(t3a,t3b)<=nt? Yes MAX(0.003, 0.002)<= 0.156 Therefore thickness is Acceptable MAWP= 4,213 psi

3b

304.1.2 Check for applicability

Conditions below are checked to ensure that the calculations performed above are applicable to the geometry and the pressure range. Additional verification would otherwise be required.

Diameter Pressure

tmin<(Do/6) P/(S*E)<0.385

Geometry is Acceptable Pressure Range is Acceptable

Sample Calculations For Demonstration only

Sample Calculations piping B31.3-2008.xls

Page 6 of 13

Pipe and Shell Calculation, B31.3, Rev.4.3

Ref: ASME B31.3, 2008 Edition, para. 304.1 Item 3: 2" Sch.80 Item: Design Temperature: 150F Material= A312 TP316 Do = 2.375 in, Outside Diameter t= CA = P= S= E= UTP = W= Y= 0.218 in, Nominal wall thickness 0 in, Corrosion allowance 90 psi, Design Pressure 20000 psi, Allowable stress at temperature 0.80 Longitudinal Efficiency 0.125 Undertolerance Allowance, as a decimal 1.00 Weld joint Reduction Factor (para 302.3.5(e)) 0.4 Coefficient, Table 304.1.1

Calculation of Variables UT= 0.02725 in, for UT=t*UTP nt= 0.19075 in, for nt=(t-CA-UT) Ri= 0.99675 in, for Ri=Do/2-nt d= 1.9935 in, for d=Ri*2 304.1.2: Straight Pipe under Internal Pressure, Minimum Required Thickness

These values don't include corrosion allowance and any other mechanical allowances

3a

t3a= 90*2.375/(2(20000*0.8*1+90*0.4)) t3a= 0.007 in t3b= 90*(1.9935+ 2*0)/(2(20000*0.8*1-90*(1-0.4)) t3b= 0.006 in Check: Is MAX(t3a,t3b)<=nt? Yes MAX(0.006, 0.005)<= 0.19 Therefore thickness is Acceptable MAWP= 2,747 psi

3b

304.1.2 Check for applicability

Conditions below are checked to ensure that the calculations performed above are applicable to the geometry and the pressure range. Additional verification would otherwise be required.

Diameter Pressure

tmin<(Do/6) P/(S*E)<0.385

Geometry is Acceptable Pressure Range is Acceptable

Sample Calculations For Demonstration only

Sample Calculations piping B31.3-2008.xls

Page 7 of 13

Pipe and Shell Calculation, B31.3, Rev.4.3

Ref: ASME B31.3, 2008 Edition, para. 304.1 Item 4: 3" Sch.40 Item: Design Temperature: 150F Material= A312 TP316 Do = 3.5 in, Outside Diameter t= CA = P= S= E= UTP = W= Y= 0.216 in, Nominal wall thickness 0 in, Corrosion allowance 90 psi, Design Pressure 20000 psi, Allowable stress at temperature 0.80 Longitudinal Efficiency 0.125 Undertolerance Allowance, as a decimal 1.00 Weld joint Reduction Factor (para 302.3.5(e)) 0.4 Coefficient, Table 304.1.1

Calculation of Variables UT= 0.027 in, for UT=t*UTP nt= 0.189 in, for nt=(t-CA-UT) Ri= 1.561 in, for Ri=Do/2-nt d= 3.122 in, for d=Ri*2 304.1.2: Straight Pipe under Internal Pressure, Minimum Required Thickness

These values don't include corrosion allowance and any other mechanical allowances

3a

t3a= 90*3.5/(2(20000*0.8*1+90*0.4)) t3a= 0.010 in t3b= 90*(3.122+ 2*0)/(2(20000*0.8*1-90*(1-0.4)) t3b= 0.009 in Check: Is MAX(t3a,t3b)<=nt? Yes MAX(0.009, 0.008)<= 0.189 Therefore thickness is Acceptable MAWP= 1,806 psi

3b

304.1.2 Check for applicability

Conditions below are checked to ensure that the calculations performed above are applicable to the geometry and the pressure range. Additional verification would otherwise be required.

Diameter Pressure

tmin<(Do/6) P/(S*E)<0.385

Geometry is Acceptable Pressure Range is Acceptable

Sample Calculations For Demonstration only

Sample Calculations piping B31.3-2008.xls

Page 8 of 13

Pipe and Shell Calculation, B31.3, Rev.4.3

Ref: ASME B31.3, 2008 Edition, para. 304.1 Item 5: 4" Sch.40 Item: Design Temperature: 150F Material= A312 TP316 Do = 4.5 in, Outside Diameter t= CA = P= S= E= UTP = W= Y= 0.237 in, Nominal wall thickness 0 in, Corrosion allowance 90 psi, Design Pressure 20000 psi, Allowable stress at temperature 0.80 Longitudinal Efficiency 0.125 Undertolerance Allowance, as a decimal 1.00 Weld joint Reduction Factor (para 302.3.5(e)) 0.4 Coefficient, Table 304.1.1

Calculation of Variables UT= 0.029625 in, for UT=t*UTP nt= 0.207375 in, for nt=(t-CA-UT) Ri= 2.042625 in, for Ri=Do/2-nt d= 4.08525 in, for d=Ri*2 304.1.2: Straight Pipe under Internal Pressure, Minimum Required Thickness

These values don't include corrosion allowance and any other mechanical allowances

3a

t3a= 90*4.5/(2(20000*0.8*1+90*0.4)) t3a= 0.013 in t3b= 90*(4.08525+ 2*0)/(2(20000*0.8*1-90*(1-0.4)) t3b= 0.012 in Check: Is MAX(t3a,t3b)<=nt? Yes MAX(0.012, 0.011)<= 0.207 Therefore thickness is Acceptable MAWP= 1,531 psi

3b

304.1.2 Check for applicability

Conditions below are checked to ensure that the calculations performed above are applicable to the geometry and the pressure range. Additional verification would otherwise be required.

Diameter Pressure

tmin<(Do/6) P/(S*E)<0.385

Geometry is Acceptable Pressure Range is Acceptable

Sample Calculations For Demonstration only

Sample Calculations piping B31.3-2008.xls

Page 9 of 13

Pipe and Shell Calculation, B31.3, Rev.4.3

Ref: ASME B31.3, 2008 Edition, para. 304.1 Item 6: 1/2"x0.035" tube Item: Design Temperature: 150F Material= A269 TP316 Do = 0.5 in, Outside Diameter t= CA = P= S= E= UTP = W= Y= 0.035 in, Nominal wall thickness 0 in, Corrosion allowance 90 psi, Design Pressure 20000 psi, Allowable stress at temperature 1.00 Longitudinal Efficiency 0.125 Undertolerance Allowance, as a decimal 1.00 Weld joint Reduction Factor (para 302.3.5(e)) 0.4 Coefficient, Table 304.1.1

Calculation of Variables UT= 0.004375 in, for UT=t*UTP nt= 0.030625 in, for nt=(t-CA-UT) Ri= 0.219375 in, for Ri=Do/2-nt d= 0.43875 in, for d=Ri*2 304.1.2: Straight Pipe under Internal Pressure, Minimum Required Thickness

These values don't include corrosion allowance and any other mechanical allowances

3a

t3a= 90*0.5/(2(20000*1*1+90*0.4)) t3a= 0.001 in t3b= 90*(0.43875+ 2*0)/(2(20000*1*1-90*(1-0.4)) t3b= 0.001 in Check: Is MAX(t3a,t3b)<=nt? Yes MAX(0.001, 0.001)<= 0.03 Therefore thickness is Acceptable MAWP= 2,576 psi

3b

304.1.2 Check for applicability

Conditions below are checked to ensure that the calculations performed above are applicable to the geometry and the pressure range. Additional verification would otherwise be required.

Diameter Pressure

tmin<(Do/6) P/(S*E)<0.385

Geometry is Acceptable Pressure Range is Acceptable

Sample Calculations For Demonstration only

Sample Calculations piping B31.3-2008.xls

Page 10 of 13

Branch Reinforcement, B31.3, ver.3.3

ASME B31.3, 2008 Edition, para. 304.3

Item:

Item 8: 1" Threadolet on 2"

For Header/Run: Material= A312 TP316 P= 90 psi, system design pressure Do = 2.375 in, outside diameter of header/run Th = 0.218 in, wall thickness S= 20,000 psi, allowable stress E= 1 efficiency of header at branch UTP = 0.125 undertolerance, as a decimal Y= 0.4 Y, Table 304.1.1 CA= 0 in, corrosion allowance. W= 1 Weld joint strength reduction factor For Branch: Material= Do = Tb = S= E= UTP = Y= CA= B= Weld=

Fig 328.5.4D(1)

A403 WP316 1.315 in, outside diameter of branch 0.179 in, wall thickness 20,000 psi, allowable stress 1 efficiency of nozzle shell 0.125 undertolerance, as a decimal 0.4 Y, Table 304.1.1 0 in, corrosion allowance. 90 degrees, nozzle angle 0.1875 in, External Fillet weld leg size

External fillet size is Acceptable

Please note the following limitations on the applicability of these equations; (b) The rules in paras. 304.3.2 through 304.3.4 are minimum requirements, valid only for branch connections in which (using the nomenclature of Fig. 304.3.3): (1) the run pipe diameter-to-thickness ratio (Dh/Th) is less than 100 and the branch-to-run diameter ratio (Db/Dh) is not greater than 1.0 (2) for run pipe with Dh/Th 100, the branch diameter, Db, is less than one-half the run diameter, Dh; (3) angle is at least 45 deg (4) the axis of the branch intersects the axis of the run.

Calculation of Variables T, header= 0.191 T, branch= 0.157 L4= 0.393 d1= 1.001 d2= 1.001 tc= 0.125 Leg41= 0.177

in, actual thickness with undertolerance removed. in, actual thickness with undertolerance removed. in, height of reinforcement zone outside of run pipe in, effective length removed from pipe at branch in, half width of reinforcement zone in, minimum weld throat requirement in, Minimum weld leg requirement

Required Pipe Thicknesses: t, header= 90*2.375/(2*(20000*1*1+90*0.4)) 0.005 in, required header thickness, for pressure t, branch= 90*1.315/(2*(20000*1*1+90*0.4)) 0.003 in, required branch thickness, for presure Area calculations: A1= 0.0053*1.001*(2-SIN(90/180*3.14)) 0.005 sq.in, Reinforcement area required A2= (2*1.001-1.001)*(0.19075-0.0053-0) 0.186 sq.in, Reinf. Area available in run pipe wall A3= 2*0.3925*(0.157-0.003-0)/SIN(90/180*3.14) 0.121 sq.in, Reinf. Area available in branch pipe wall

Sample Calculations For Demonstration only

Sample Calculations piping B31.3-2008.xls

Page 11 of 13

A4= 2*0.5*0.1875^2 0.035 sq.in, Reinf. Area due to welds and other reinforcement

In order for the joint to be acceptable: Area Required, A1 <= Area Available, A2+A3+A4 0.005 <=(0.186+0.121+0.035=0.3417)

ACCEPTABLE, NO ADDITIONAL REINFORCEMENT REQUIRED

Sample Calculations For Demonstration only

Sample Calculations piping B31.3-2008.xls

Page 12 of 13

Branch Reinforcement, B31.3, ver.3.3

ASME B31.3, 2008 Edition, para. 304.3

Item:

Item 9: 1" Threadolet on 3"

For Header/Run: Material= A312 TP316 P= 90 psi, system design pressure Do = 3.5 in, outside diameter of header/run Th = 0.216 in, wall thickness S= 20,000 psi, allowable stress E= 1 efficiency of header at branch UTP = 0.125 undertolerance, as a decimal Y= 0.4 Y, Table 304.1.1 CA= 0 in, corrosion allowance. W= 1 Weld joint strength reduction factor For Branch: Material= Do = Tb = S= E= UTP = Y= CA= B= Weld=

Fig 328.5.4D(1)

A403 WP316 1.315 in, outside diameter of branch 0.179 in, wall thickness 20,000 psi, allowable stress 1 efficiency of nozzle shell 0.125 undertolerance, as a decimal 0.4 Y, Table 304.1.1 0 in, corrosion allowance. 90 degrees, nozzle angle 0.1875 in, External Fillet weld leg size

External fillet size is Acceptable

Please note the following limitations on the applicability of these equations; (b) The rules in paras. 304.3.2 through 304.3.4 are minimum requirements, valid only for branch connections in which (using the nomenclature of Fig. 304.3.3): (1) the run pipe diameter-to-thickness ratio (Dh/Th) is less than 100 and the branch-to-run diameter ratio (Db/Dh) is not greater than 1.0 (2) for run pipe with Dh/Th 100, the branch diameter, Db, is less than one-half the run diameter, Dh; (3) angle is at least 45 deg (4) the axis of the branch intersects the axis of the run.

Calculation of Variables T, header= 0.189 T, branch= 0.157 L4= 0.393 d1= 1.001 d2= 1.001 tc= 0.125 Leg41= 0.177

in, actual thickness with undertolerance removed. in, actual thickness with undertolerance removed. in, height of reinforcement zone outside of run pipe in, effective length removed from pipe at branch in, half width of reinforcement zone in, minimum weld throat requirement in, Minimum weld leg requirement

Required Pipe Thicknesses: t, header= 90*3.5/(2*(20000*1*1+90*0.4)) 0.008 in, required header thickness, for pressure t, branch= 90*1.315/(2*(20000*1*1+90*0.4)) 0.003 in, required branch thickness, for presure Area calculations: A1= 0.0079*1.001*(2-SIN(90/180*3.14)) 0.008 sq.in, Reinforcement area required A2= (2*1.001-1.001)*(0.189-0.0079-0) 0.181 sq.in, Reinf. Area available in run pipe wall A3= 2*0.3925*(0.157-0.003-0)/SIN(90/180*3.14) 0.121 sq.in, Reinf. Area available in branch pipe wall

Sample Calculations For Demonstration only

Sample Calculations piping B31.3-2008.xls

Page 13 of 13

A4= 2*0.5*0.1875^2 0.035 sq.in, Reinf. Area due to welds and other reinforcement

In order for the joint to be acceptable: Area Required, A1 <= Area Available, A2+A3+A4 0.008 <=(0.181+0.121+0.035=0.3373)

ACCEPTABLE, NO ADDITIONAL REINFORCEMENT REQUIRED

Sample Calculations For Demonstration only

Potrebbero piacerti anche

- Bobcat Manual PDFDocumento292 pagineBobcat Manual PDFAhmed MagedNessuna valutazione finora

- Welcome To Presentation On: Pipe Support Systems & Piping FlexibilityDocumento67 pagineWelcome To Presentation On: Pipe Support Systems & Piping Flexibilitysids8292% (24)

- UBC 1997 UBC Code StructuralDocumento510 pagineUBC 1997 UBC Code Structuralkurokandas83% (6)

- Standard Practice For Direct Design of Buried Precast Concrete Pipe Using Standard InstallDocumento51 pagineStandard Practice For Direct Design of Buried Precast Concrete Pipe Using Standard Installsandeep100% (2)

- Questions For Stress AnalysisDocumento3 pagineQuestions For Stress AnalysisSunday PaulNessuna valutazione finora

- Thermal Design Considerations For Centrifugal Compressor Piping SystemsDocumento5 pagineThermal Design Considerations For Centrifugal Compressor Piping SystemsSerge Rinaudo100% (1)

- Trunnion Calcualtion SheetDocumento22 pagineTrunnion Calcualtion SheetAbhijit0% (1)

- Design & Construction of Piping SystemsDocumento115 pagineDesign & Construction of Piping SystemsSuresh Babu100% (13)

- G 32 - 16Documento20 pagineG 32 - 16juan fNessuna valutazione finora

- Piping Spring HangersDocumento2 paginePiping Spring HangersyogacruiseNessuna valutazione finora

- Pipe cap thickness and coupling rating calculationsDocumento2 paginePipe cap thickness and coupling rating calculationsmasaminathanNessuna valutazione finora

- Swimming Pool Calculation: To Calculate Pipe SizingDocumento2 pagineSwimming Pool Calculation: To Calculate Pipe SizingBenjamin YusuphNessuna valutazione finora

- MF 440 Xtra Narrow (Tier II) PDFDocumento2 pagineMF 440 Xtra Narrow (Tier II) PDFlmn_grss100% (1)

- Basis For Deciding Stress Critical LinesDocumento3 pagineBasis For Deciding Stress Critical LinesRomner Cordova100% (1)

- Pipeline Calculations - ASAB Gas Lift LinesDocumento11 paginePipeline Calculations - ASAB Gas Lift LinesSaqib LaeeqNessuna valutazione finora

- Significance of Two-phase flow in Piping SystemsDocumento4 pagineSignificance of Two-phase flow in Piping SystemssindalvaleriNessuna valutazione finora

- Hvac BomDocumento6 pagineHvac BomTagel MarkosNessuna valutazione finora

- ASME B31 3 Calculator V2Documento11 pagineASME B31 3 Calculator V2gerrydimayuga100% (3)

- Hilti Calculation ExamplesDocumento10 pagineHilti Calculation ExamplesNgoc TruongNessuna valutazione finora

- Pipe Branch Connection CalculationDocumento3 paginePipe Branch Connection Calculationsaravoot_jNessuna valutazione finora

- Thickness CalculationDocumento6 pagineThickness CalculationBuddy EkoNessuna valutazione finora

- Overview of Drill BitsDocumento153 pagineOverview of Drill BitsJohnSmithNessuna valutazione finora

- Wall Thickness Calculation of 36in Gas PipelineDocumento1 paginaWall Thickness Calculation of 36in Gas PipelineLU1228100% (3)

- Above Ground Piping Wall Thickness CalculationsDocumento7 pagineAbove Ground Piping Wall Thickness Calculationslutfi awn100% (1)

- ASME B31 8 Riser CalcDocumento12 pagineASME B31 8 Riser CalcEmmanuel LawrenceNessuna valutazione finora

- General Physics 1 Week 3Documento5 pagineGeneral Physics 1 Week 3Levi AckermanNessuna valutazione finora

- Modeling of Internal Pressure and Thrust Load On Nozzles Using WRC 368Documento5 pagineModeling of Internal Pressure and Thrust Load On Nozzles Using WRC 368m5416Nessuna valutazione finora

- Stress Analysis of GRPDocumento5 pagineStress Analysis of GRPRomner CordovaNessuna valutazione finora

- Pipe Thickness CalculationDocumento1 paginaPipe Thickness Calculationananyo_senguptaNessuna valutazione finora

- Pipe Stress Amp SupportDocumento24 paginePipe Stress Amp SupportShilpa GanganNessuna valutazione finora

- Pipe Support DetailsDocumento8 paginePipe Support DetailsGodwinNessuna valutazione finora

- Structural Analysis of Pipeline and Piping SystemsDocumento58 pagineStructural Analysis of Pipeline and Piping SystemsDushyant VarshneyNessuna valutazione finora

- Flange Leakage CheckDocumento1 paginaFlange Leakage CheckPhornlert WanaNessuna valutazione finora

- Minimum Pipe Wall Thickness and MAWP SI Final ProtectedDocumento11 pagineMinimum Pipe Wall Thickness and MAWP SI Final Protectedjsfscibd100% (1)

- Cswip 3.1 (Welding Inspector) Multiple Choice QuestionsDocumento18 pagineCswip 3.1 (Welding Inspector) Multiple Choice QuestionsRajkumar ANessuna valutazione finora

- SampleCalculationspipingB3132008 PDFDocumento13 pagineSampleCalculationspipingB3132008 PDFsosatlantiqueNessuna valutazione finora

- SampleCalculationspipingB3132008 PDFDocumento13 pagineSampleCalculationspipingB3132008 PDFsosatlantiqueNessuna valutazione finora

- Pipe Wall Thickness CalculationDocumento8 paginePipe Wall Thickness CalculationRAGHVENDRA PRATAP SINGH0% (1)

- Baby Mait PDFDocumento2 pagineBaby Mait PDFChris LuNessuna valutazione finora

- Taller1 Hanger Sizing in CaesarDocumento37 pagineTaller1 Hanger Sizing in CaesarAnkithNessuna valutazione finora

- Line Stop Welded To Shoe CalculationDocumento16 pagineLine Stop Welded To Shoe CalculationmohdnazirNessuna valutazione finora

- Code Comparison ASME B31.1 Vs B31.3 Vs B31.8Documento27 pagineCode Comparison ASME B31.1 Vs B31.3 Vs B31.8khaireddinNessuna valutazione finora

- Virtual Anchor Length - KBRDocumento22 pagineVirtual Anchor Length - KBRSammar Adhikari100% (2)

- ASME B31.3 wall thickness calcDocumento11 pagineASME B31.3 wall thickness calcAnonymous wIPMQ5rhNessuna valutazione finora

- Pipe Thickness Calculation PDFDocumento1 paginaPipe Thickness Calculation PDFHeny Martha67% (3)

- Internal CoilDocumento2 pagineInternal CoilwhngomjNessuna valutazione finora

- Expansion Joint in CAESARDocumento5 pagineExpansion Joint in CAESARkaruna346Nessuna valutazione finora

- Piping Stress Critical Lines - Basis For Piping Critical Line ListDocumento4 paginePiping Stress Critical Lines - Basis For Piping Critical Line Listashish.mathur1Nessuna valutazione finora

- Design of Piping Systems by Tengku SyahdilanDocumento115 pagineDesign of Piping Systems by Tengku SyahdilanRagerishcire KanaalaqNessuna valutazione finora

- Spring SelectionDocumento12 pagineSpring SelectionNitesh KumarNessuna valutazione finora

- Expansion LoopDocumento54 pagineExpansion Loopsteepa22Nessuna valutazione finora

- Implementing Expansion Loops to Absorb Thermal StressDocumento13 pagineImplementing Expansion Loops to Absorb Thermal StressAan DamaiNessuna valutazione finora

- Wall Thickness Calculation for Piping SystemsDocumento47 pagineWall Thickness Calculation for Piping Systemsthinhvipro100% (1)

- Sizing Pressure Regulators & Control ValvesDocumento16 pagineSizing Pressure Regulators & Control ValvesCH1253Nessuna valutazione finora

- Modeling Procedure of Rigid Strut in Caesar IIDocumento5 pagineModeling Procedure of Rigid Strut in Caesar IIHmd MokhtariNessuna valutazione finora

- Mitigations To Flow Induced Vibration (FIV) in Control Valve Piping System Using Visco-Elastic Dampers & Neoprene PadsDocumento7 pagineMitigations To Flow Induced Vibration (FIV) in Control Valve Piping System Using Visco-Elastic Dampers & Neoprene PadsIJSTENessuna valutazione finora

- FluidFlow Designer HandbookDocumento78 pagineFluidFlow Designer Handbooksosatlantique100% (4)

- Compressors Classification Types ReciprocatingDocumento139 pagineCompressors Classification Types Reciprocatingrgopinath5100% (1)

- PIPE THICKNESS CALCULATIONDocumento11 paginePIPE THICKNESS CALCULATIONvazzoleralex6884100% (1)

- Calculation For Reinforced PadDocumento4 pagineCalculation For Reinforced Padjsridhar_34750% (2)

- Types of Stresses in Piping Systems - Pressure Vessel EngineeringDocumento7 pagineTypes of Stresses in Piping Systems - Pressure Vessel EngineeringLorenzoNessuna valutazione finora

- SPC-0804.02-50.08 Rev D2 Pipe Stress AnalysisDocumento11 pagineSPC-0804.02-50.08 Rev D2 Pipe Stress Analysisrajabi_m100% (1)

- 10speed EatonDocumento2 pagine10speed EatonChristopherNessuna valutazione finora

- H H Optimum 0,2: Instructions For Using NomogramDocumento4 pagineH H Optimum 0,2: Instructions For Using NomogrammithunjobsNessuna valutazione finora

- SIF Calculation For Piping ConnectionsDocumento6 pagineSIF Calculation For Piping ConnectionsManuelNessuna valutazione finora

- L&T Double Block and Bleed Plug ValvesDocumento12 pagineL&T Double Block and Bleed Plug Valvesvijay10484Nessuna valutazione finora

- API 650 Tank Design 1Documento5 pagineAPI 650 Tank Design 1robertantoreni100% (9)

- Piping Stress Handbook - by Victor Helguero - Part 2 PDFDocumento121 paginePiping Stress Handbook - by Victor Helguero - Part 2 PDFCESAR100% (2)

- System design: Calculating pipe expansion and contractionDocumento3 pagineSystem design: Calculating pipe expansion and contractionreach_arindomNessuna valutazione finora

- Noise Control Engineering Conference Paper EvaluationDocumento2 pagineNoise Control Engineering Conference Paper EvaluationbehnazrzNessuna valutazione finora

- 9819 0067 09 Instruction Book Compressor GAR 5 HDocumento25 pagine9819 0067 09 Instruction Book Compressor GAR 5 HCesar Eduardo100% (1)

- Stress Analysis On Offshore PlatformsDocumento45 pagineStress Analysis On Offshore PlatformsMalarNessuna valutazione finora

- Design of Piping SystemsDocumento115 pagineDesign of Piping SystemsDushyant Varshney100% (2)

- Application of Bellows Expansion Joints in Piping SystemDocumento5 pagineApplication of Bellows Expansion Joints in Piping Systemjlcheefei9258Nessuna valutazione finora

- 8 AS4041 ASME B31 3 Pipe Wall ThicknessDocumento12 pagine8 AS4041 ASME B31 3 Pipe Wall Thicknesswhah11Nessuna valutazione finora

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Documento1 paginaPipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadNessuna valutazione finora

- Mechanical Operation Slurry TransportDocumento113 pagineMechanical Operation Slurry TransportIsrarulHaqueNessuna valutazione finora

- Mathcad Tutorial: by Colorado State University StudentDocumento51 pagineMathcad Tutorial: by Colorado State University StudentDiana ScodreanuNessuna valutazione finora

- Pipe Wall Thickness Sample CalculationDocumento1 paginaPipe Wall Thickness Sample CalculationjkahamedNessuna valutazione finora

- Orifice Plate Showing VenaDocumento6 pagineOrifice Plate Showing VenahugepotatoNessuna valutazione finora

- Surge Analysis: What Is Pressure Surge?Documento2 pagineSurge Analysis: What Is Pressure Surge?Yang Gul Lee100% (1)

- 650 741rev3Documento2 pagine650 741rev3sosatlantiqueNessuna valutazione finora

- Piping Codes PDFDocumento47 paginePiping Codes PDFsosatlantiqueNessuna valutazione finora

- Cadworx 2013 Quick Start GuideDocumento17 pagineCadworx 2013 Quick Start GuideEric LyonNessuna valutazione finora

- Flexiable AnalysisDocumento12 pagineFlexiable AnalysismohamedeliasNessuna valutazione finora

- Flexiable AnalysisDocumento12 pagineFlexiable AnalysismohamedeliasNessuna valutazione finora

- Flexiable AnalysisDocumento12 pagineFlexiable AnalysismohamedeliasNessuna valutazione finora

- C 2 QuickDocumento30 pagineC 2 QuicksosatlantiqueNessuna valutazione finora

- Gas Well TestingDocumento49 pagineGas Well TestingSofiaNessuna valutazione finora

- Manual de Partes - Torito 2T FL PDFDocumento54 pagineManual de Partes - Torito 2T FL PDFJuan José Falcon PonceNessuna valutazione finora

- V. Jovicic and M. R. Coop1997 - Stiffness, Coarse Grained Soils, Small StrainsDocumento17 pagineV. Jovicic and M. R. Coop1997 - Stiffness, Coarse Grained Soils, Small StrainsxiangyugeotechNessuna valutazione finora

- Siemens SPPA P3000Documento2 pagineSiemens SPPA P3000shahin_bNessuna valutazione finora

- SIMTOS2014 Exhibitors DirectoryDocumento14 pagineSIMTOS2014 Exhibitors DirectoryctyvteNessuna valutazione finora

- Edexcel GCE: Tuesday 7 June 2005 Afternoon Time: 1 Hour 30 MinutesDocumento4 pagineEdexcel GCE: Tuesday 7 June 2005 Afternoon Time: 1 Hour 30 MinutesMargarita SatrakiNessuna valutazione finora

- Three Phase Alternator SynchorinizingDocumento11 pagineThree Phase Alternator SynchorinizingSud JoshNessuna valutazione finora

- Vibration Study - Electromontaj - 400kV Tantareni-Kozlodui - ACSR 160 - 95-Rev. ADocumento14 pagineVibration Study - Electromontaj - 400kV Tantareni-Kozlodui - ACSR 160 - 95-Rev. ALiciu CiprianNessuna valutazione finora

- DNV-CG-0037 2021-11Documento74 pagineDNV-CG-0037 2021-11wfxNessuna valutazione finora

- FluidDocumento84 pagineFluidVishal SalveNessuna valutazione finora

- TCR User Manual TCR Part 3 Iss3 15.01.19Documento21 pagineTCR User Manual TCR Part 3 Iss3 15.01.19ASEM NjadatNessuna valutazione finora

- SENR5672Documento2 pagineSENR5672Gilvan JuniorNessuna valutazione finora

- Example 24.1. Determine The Maximum, Minimum and Average Pressure in A PlateDocumento7 pagineExample 24.1. Determine The Maximum, Minimum and Average Pressure in A PlateFajar Pamungkas100% (1)

- Mesurement and Inspection SheetDocumento3 pagineMesurement and Inspection SheetSaifur RahmanNessuna valutazione finora

- Pin MillingDocumento16 paginePin MillingBhavik NagdaNessuna valutazione finora

- The Laws and Velocity of Planetary Motion: Section - 10 FDocumento3 pagineThe Laws and Velocity of Planetary Motion: Section - 10 FFiyory TassewNessuna valutazione finora

- Service N ValveDocumento30 pagineService N ValvesenamotoNessuna valutazione finora