Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Resolution Enhancement Techniques

Caricato da

Smitha KollerahithluDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Resolution Enhancement Techniques

Caricato da

Smitha KollerahithluCopyright:

Formati disponibili

Resolution enhancement techniques: Mask engineering or wavefront engineering

Sharp features are lost because higher frequencies are lost due to diffraction. These effects are calculable and can be compensated for. The resolution of an optical system can be improved by increasing the numerical aperture and reducing the wavelength. Increasing the numerical aperture and reducing the wavelength, however, decrease the depth of the focus. Further reduction in the wavelength requires the development of new optical systems and resist compositions.

It is known that in the sub 0.5m range, a perfect image on the mask can, from diffraction effect, result in a distorted pattern in the resist. OPC mask attempt to reverse the situation by having a distorted image on the mask that is design to, produce a perfect image on the resist. A computer is used to analyze exposure process conditions. However, the use of OPC are so difficult that they are unlikely to be implemented on a large scale in the near future.

Resolution enhancement techniques: (1) Optical proximity corrections (OPC)

Resolution enhancement techniques:

OPC

(3)

Resolution enhancement techniques: (2) Optical Phase Shifting

Diffraction problem could be more pronounced as two mask patterns get closer together OPS uses phase shifting to sharpen printed images. These techniques can allow existing exposure tools to be used in manufacturing at least one more technology generation.

Unresolved pattern

(4)

Off-axis Illumination technique

Next Generation lithographic methods

Why is optical lithography so widely used and what makes it such a promising method? It has high throughput, good resolution, low cost and ease in operation. However, due to deep submicron IC process requirements, optical lithography has limitation that have not yet been solved. Therefore, it is required to find alternatives to optical lithography. The possible promising techniques are: Electron beam lithography Extreme Ultraviolet Lithography X-ray lithography Ion beam lithography

When the angle of illumination and the angle of diffraction are well matched, the amount of light diffracted can be enhanced and the contrast of the image improved.

Schematic of an electron beam lithography machine.

In raster scan system The beam scan sequentially over every possible location (pixel) on the mask and is Turned off where no exposure Is required. In a vector scan system The beam is directed only to the Requested pattern features and jumps from features to Features.

Advantage: Generation of submicron Resist geometries Greater depth of focus Direct patterning on a Semiconductor without Using a mask. Currently EBL is the Technology of choice for Mask generation due to Its ability to accurately define small features.

Issue associated with EBL: Proximity effect

In EBL scattering causes the electron beam to broaden and expose a large volume of resist then expected.

(a) Raster scan writing scheme. (b) Vector scan writing schemes. (c) Shapes of electron beam: round, variable, and

cell projection.

Scattering with angular limitation projection electron beam lithography (SCALPEL)

Challenges: EUV is strangely absorbed In all materials. Lithography process must be performed in vacuum Mask blank must also be multilayer coated to minimize Its reflection.

This approach has not yet been in a full scale manufacturing environment, but It appears to have significant promise for future lithography needs.

Schematic representation of an extreme ultraviolet (EUV) lithography system.

Schematic representation of a proximity x-ray lithography system.

The primary factor limiting resolution in optical lithography is diffraction. However, because of advancement in excimer lasers, photoresist chemistry and resolution enhancement techniques , optical lithography will remain the main stream technology , at least to the 100nm generation.

Although all non optical lithography techniques have 100 nm or better resolution , each process has its own limitations: Proximity effect in electron beam lithography Mask blank production difficulties in EUV lithography Mask fabrication complexity in X-ray lithography Random space charge effect in ion beam lithography

Potrebbero piacerti anche

- Thomas Calculus 11th (Textbook + Solutions)Documento140 pagineThomas Calculus 11th (Textbook + Solutions)Sendhilkumar Alalasundaram76% (33)

- Kool & the Gang Backline RequirementsDocumento11 pagineKool & the Gang Backline RequirementsPaul GunterNessuna valutazione finora

- Line 6 - Spider 3 - 1508-3012-HD75Documento68 pagineLine 6 - Spider 3 - 1508-3012-HD75Francisco PerezNessuna valutazione finora

- Installation QualificationDocumento17 pagineInstallation Qualificationtrinath16198067% (6)

- Circuit Design Concepts For Esd Protection 2008 PDFDocumento32 pagineCircuit Design Concepts For Esd Protection 2008 PDFNguyen Van ToanNessuna valutazione finora

- Millimicrosecond Pulse Techniques: International Series of Monographs on Electronics and InstrumentationDa EverandMillimicrosecond Pulse Techniques: International Series of Monographs on Electronics and InstrumentationNessuna valutazione finora

- Some Techniques of Problem Solving: Work Out The Major Factors InvolvedDocumento19 pagineSome Techniques of Problem Solving: Work Out The Major Factors InvolvedRahul M PatilNessuna valutazione finora

- 1 Basic Concepts of Diagnostic X Ray Equipment PDFDocumento48 pagine1 Basic Concepts of Diagnostic X Ray Equipment PDFahmed_galal_waly1056Nessuna valutazione finora

- The Normal CSFDocumento2 pagineThe Normal CSFUm MahmoudNessuna valutazione finora

- 3DICDocumento148 pagine3DICnoorevNessuna valutazione finora

- CSF Flowmetry MriDocumento5 pagineCSF Flowmetry MribricklaneNessuna valutazione finora

- Retrohepatic Gallbladder Masquerading As Hydatid Cyst in ADocumento18 pagineRetrohepatic Gallbladder Masquerading As Hydatid Cyst in AMadalina BlagaNessuna valutazione finora

- Liquor CerebrospinalisDocumento25 pagineLiquor CerebrospinalisIhda ParidahNessuna valutazione finora

- Ultrasound Și DopplerDocumento3 pagineUltrasound Și DopplerAurelia AlexandraNessuna valutazione finora

- Gas Manager W-FM54Documento104 pagineGas Manager W-FM54Rodolfo Tinajero Preciado100% (1)

- Fluid CerebrospinalDocumento3 pagineFluid CerebrospinalAurelia AlexandraNessuna valutazione finora

- Understanding About CMOS Fabrication TechnologyDocumento4 pagineUnderstanding About CMOS Fabrication TechnologyJayesh RaghuwanshiNessuna valutazione finora

- Computed TomographyDocumento86 pagineComputed TomographysolomongNessuna valutazione finora

- X-Ray Reveals Skull Lesions in Multiple Myeloma PatientDocumento63 pagineX-Ray Reveals Skull Lesions in Multiple Myeloma Patient李建明Nessuna valutazione finora

- Pre PlaceDocumento13 paginePre Placesree yarasiNessuna valutazione finora

- Imaging With X-RaysDocumento107 pagineImaging With X-RaysNipunNessuna valutazione finora

- Single-Mask Double-Patterning Lithography BenefitsDocumento21 pagineSingle-Mask Double-Patterning Lithography BenefitsRenju TjNessuna valutazione finora

- Surface Movement Radar 0Documento6 pagineSurface Movement Radar 0rainatkmNessuna valutazione finora

- Unit 5 Medical UltrasoundDocumento6 pagineUnit 5 Medical Ultrasoundtwy113Nessuna valutazione finora

- Implementing Best Practices For Vlan Topologies: Defining VlansDocumento66 pagineImplementing Best Practices For Vlan Topologies: Defining VlansArun JoyNessuna valutazione finora

- Nanotechnology in Agriculture Scope and ApplicationsDocumento26 pagineNanotechnology in Agriculture Scope and ApplicationsSmitha KollerahithluNessuna valutazione finora

- Wilson M., Kannangara K., Smith G., Simmons M. Nanotechnology.. Basic Science and Emerging Technologies (CRC, 2002) (ISBN 1584883391) (O) (288s) - EEDocumento288 pagineWilson M., Kannangara K., Smith G., Simmons M. Nanotechnology.. Basic Science and Emerging Technologies (CRC, 2002) (ISBN 1584883391) (O) (288s) - EESmitha Kollerahithlu70% (10)

- Wilson M., Kannangara K., Smith G., Simmons M. Nanotechnology.. Basic Science and Emerging Technologies (CRC, 2002) (ISBN 1584883391) (O) (288s) - EEDocumento288 pagineWilson M., Kannangara K., Smith G., Simmons M. Nanotechnology.. Basic Science and Emerging Technologies (CRC, 2002) (ISBN 1584883391) (O) (288s) - EESmitha Kollerahithlu70% (10)

- 14 NM Process Technology PDFDocumento53 pagine14 NM Process Technology PDFGabriel DonovanNessuna valutazione finora

- X-Ray GridsDocumento21 pagineX-Ray GridsA-42 Aditya PandeNessuna valutazione finora

- SOIDocumento25 pagineSOIDavis AbrahamNessuna valutazione finora

- Horizon - APC - M61 - D001 PDFDocumento136 pagineHorizon - APC - M61 - D001 PDFomar tlebNessuna valutazione finora

- MOSFET Scaling: Dr. Rajan Pandey Associate Professor, SENSEDocumento6 pagineMOSFET Scaling: Dr. Rajan Pandey Associate Professor, SENSEVibha M VNessuna valutazione finora

- Applications of Nanotechnology in AerospaceDocumento7 pagineApplications of Nanotechnology in AerospaceSmitha KollerahithluNessuna valutazione finora

- Radiographic Testing FundamentalsDocumento30 pagineRadiographic Testing FundamentalsMohamed ElfawalNessuna valutazione finora

- Nano Green Building ExDocumento116 pagineNano Green Building ExAdalberto SosaNessuna valutazione finora

- SSI Basic System Notes PDFDocumento8 pagineSSI Basic System Notes PDFBambang Soegeng0% (1)

- w3css Tutorial2Documento54 paginew3css Tutorial2RajuNessuna valutazione finora

- BIST Algorithm For Embedded-DRAM CoresDocumento4 pagineBIST Algorithm For Embedded-DRAM CoresespskcNessuna valutazione finora

- 2 Fault Modeling OverviewDocumento10 pagine2 Fault Modeling Overviewsamantha223Nessuna valutazione finora

- D2A1-1-3-DV VCD Based Power SignoffDocumento17 pagineD2A1-1-3-DV VCD Based Power SignoffRaj Shekhar ReddyNessuna valutazione finora

- Design Techniques For Low Noise Cmos Operational AmplifiersDocumento4 pagineDesign Techniques For Low Noise Cmos Operational AmplifiersChandra Praveen MahalingamNessuna valutazione finora

- LC Ladder Matching NetworksDocumento33 pagineLC Ladder Matching NetworksCarriceiros TourNessuna valutazione finora

- Ee 215 ADocumento8 pagineEe 215 AArjun Singhal100% (1)

- Putational Electromagnetics and Engineering PDFDocumento245 paginePutational Electromagnetics and Engineering PDFjNessuna valutazione finora

- EE 658 Lecture 1: Introduction to Testing of Digital CircuitsDocumento112 pagineEE 658 Lecture 1: Introduction to Testing of Digital CircuitsAmandeep VaishNessuna valutazione finora

- Scan Chain ReorderDocumento48 pagineScan Chain ReorderPrasanna KumarNessuna valutazione finora

- Lower Limb: Fig. (1) : A Photoradiograph of A Plain X Ray of The Pelvis (Antero-Posterior View) ShowingDocumento8 pagineLower Limb: Fig. (1) : A Photoradiograph of A Plain X Ray of The Pelvis (Antero-Posterior View) ShowingAmany AliNessuna valutazione finora

- CMOS Translinear CellsDocumento4 pagineCMOS Translinear CellsSumitChoudharyNessuna valutazione finora

- VLSIDocumento43 pagineVLSIGuruKPONessuna valutazione finora

- Vlsi Design Test and TestabilityDocumento17 pagineVlsi Design Test and TestabilitySuravarapu ArunaNessuna valutazione finora

- EC 1401 - VLSI Design QuestionsDocumento18 pagineEC 1401 - VLSI Design QuestionsChaitanya PrabhuNessuna valutazione finora

- Chapter A 1Documento3 pagineChapter A 1Kiran ShettyNessuna valutazione finora

- D-Band Frequency Tripler For Passive Imaging - Final 13th JulyDocumento4 pagineD-Band Frequency Tripler For Passive Imaging - Final 13th JulyTapas SarkarNessuna valutazione finora

- LOwpower Verification For UVMDocumento1 paginaLOwpower Verification For UVMThi NguyenNessuna valutazione finora

- VLSI Lab ManualDocumento83 pagineVLSI Lab ManualSri SandhiyaNessuna valutazione finora

- Development of TSMC 0.25 M Standard Cell LibraryDocumento3 pagineDevelopment of TSMC 0.25 M Standard Cell Libraryhex0x1Nessuna valutazione finora

- Research Notes On VlsiDocumento70 pagineResearch Notes On VlsiMohit GirdharNessuna valutazione finora

- Low Power Techniques For VLSI DesignDocumento6 pagineLow Power Techniques For VLSI DesignjainatinNessuna valutazione finora

- Nanoparticles For Diagnostic Imaging andDocumento12 pagineNanoparticles For Diagnostic Imaging andBrunaNessuna valutazione finora

- WCNDocumento102 pagineWCNVinaY ChowdaryNessuna valutazione finora

- Vlsi FabDocumento8 pagineVlsi FabhaheNessuna valutazione finora

- DR Kaushal Cerebral Blood FlowDocumento52 pagineDR Kaushal Cerebral Blood Flowoddie333Nessuna valutazione finora

- ISSC 2011 Vector Divergence Considerations For Latency Optimized High Speed Asynchronous CDC v0 7 Camera Ready SubmissionDocumento6 pagineISSC 2011 Vector Divergence Considerations For Latency Optimized High Speed Asynchronous CDC v0 7 Camera Ready SubmissionSandeep BoyinaNessuna valutazione finora

- Basics of Inductor Design and Simulation in ADSDocumento35 pagineBasics of Inductor Design and Simulation in ADSpatarinwNessuna valutazione finora

- MMIC Design Course OverviewDocumento207 pagineMMIC Design Course OverviewA Mohan BabuNessuna valutazione finora

- Clock Distribution Power Dissipation Optimization TechniquesTITLEDocumento24 pagineClock Distribution Power Dissipation Optimization TechniquesTITLEMike PotterNessuna valutazione finora

- DDR SdramDocumento36 pagineDDR Sdramajmalpm333Nessuna valutazione finora

- Signal Integrity in The Real WorldDocumento52 pagineSignal Integrity in The Real WorldpatarinwNessuna valutazione finora

- Cmos ReportDocumento25 pagineCmos ReportNaveen KumarNessuna valutazione finora

- Prepared by Guided by K.S.Vaghosi Prof. G.D.Karadkar M.E.Part - Ii (Production) Roll No - 139 Mech. DepttDocumento42 paginePrepared by Guided by K.S.Vaghosi Prof. G.D.Karadkar M.E.Part - Ii (Production) Roll No - 139 Mech. DepttKetan VaghosiNessuna valutazione finora

- Process sequence of the lithography processDocumento176 pagineProcess sequence of the lithography processlinjefNessuna valutazione finora

- Extreme Ultra Violet LithographyDocumento44 pagineExtreme Ultra Violet Lithographysanketh07Nessuna valutazione finora

- LITHOGRAPHY PPT TITLEDocumento38 pagineLITHOGRAPHY PPT TITLENarayan Mishra MishraNessuna valutazione finora

- Nr-40 Multiferroics MaterialsZSurowiakDBochenekDocumento49 pagineNr-40 Multiferroics MaterialsZSurowiakDBochenekSmitha KollerahithluNessuna valutazione finora

- Magnetic Nano Particles PDFDocumento20 pagineMagnetic Nano Particles PDFSmitha KollerahithluNessuna valutazione finora

- BiomaterialDocumento50 pagineBiomaterialSmitha KollerahithluNessuna valutazione finora

- Wach 2015 SeeDocumento44 pagineWach 2015 SeeSmitha KollerahithluNessuna valutazione finora

- Metallic ImplantsDocumento38 pagineMetallic ImplantsSmitha Kollerahithlu100% (1)

- Nano Tech BookDocumento112 pagineNano Tech BookKenneth LeeNessuna valutazione finora

- Nano TechDocumento3 pagineNano TechChethan R S GowdaNessuna valutazione finora

- Nano Particles in Waste Water TreatmentDocumento17 pagineNano Particles in Waste Water TreatmentkoppadNessuna valutazione finora

- Nano Tech BookDocumento112 pagineNano Tech BookKenneth LeeNessuna valutazione finora

- PolymersDocumento24 paginePolymersSmitha KollerahithluNessuna valutazione finora

- 2Documento13 pagine2VNSAramakiNessuna valutazione finora

- Nanotechnologies in AgricultureDocumento10 pagineNanotechnologies in AgricultureSmitha KollerahithluNessuna valutazione finora

- Nanotechnologies in AgricultureDocumento10 pagineNanotechnologies in AgricultureSmitha KollerahithluNessuna valutazione finora

- Pre Regulatory MedicineDocumento14 paginePre Regulatory MedicineSmitha KollerahithluNessuna valutazione finora

- PiezoelectricDocumento19 paginePiezoelectricSmitha KollerahithluNessuna valutazione finora

- NasaDocumento35 pagineNasaSmitha KollerahithluNessuna valutazione finora

- Ynano Assessment of Nanotechnology in Automotive and Aerospace Sectors Final ReportDocumento65 pagineYnano Assessment of Nanotechnology in Automotive and Aerospace Sectors Final ReportSmitha KollerahithluNessuna valutazione finora

- Dna Based NanotechnologyDocumento7 pagineDna Based NanotechnologySmitha KollerahithluNessuna valutazione finora

- BiomaterialsDocumento5 pagineBiomaterialsSmitha KollerahithluNessuna valutazione finora

- Ijftr 33 (3) 304-317Documento14 pagineIjftr 33 (3) 304-317Dulce BaezaNessuna valutazione finora

- ThermodynamicsDocumento15 pagineThermodynamicsSmitha KollerahithluNessuna valutazione finora

- Materials Science & Engineering Introductory E-BookDocumento13 pagineMaterials Science & Engineering Introductory E-BookSmitha KollerahithluNessuna valutazione finora

- Health Efects of NanoparticlesDocumento57 pagineHealth Efects of NanoparticlesSmitha KollerahithluNessuna valutazione finora

- DNA biosensors detect genetic diseasesDocumento22 pagineDNA biosensors detect genetic diseasesSmitha KollerahithluNessuna valutazione finora

- Trigonometric Formula Sheet: Definition of The Trig FunctionsDocumento10 pagineTrigonometric Formula Sheet: Definition of The Trig Functionsmonelmetal100% (1)

- 36.331 RRCDocumento217 pagine36.331 RRCBilal AwanNessuna valutazione finora

- Circuit Construction Kit Ac Virtual Lab HTML Guide - enDocumento4 pagineCircuit Construction Kit Ac Virtual Lab HTML Guide - enkavithaNessuna valutazione finora

- H-330 Field Installation Manual IndexDocumento11 pagineH-330 Field Installation Manual IndexRamon JimenezNessuna valutazione finora

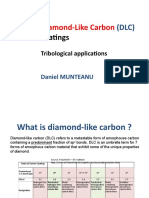

- Diamond Like CoatingsDocumento24 pagineDiamond Like CoatingscecilchifticaNessuna valutazione finora

- Manual FunctionBlock TersusDocumento122 pagineManual FunctionBlock TersusFabiano Chaves SilvaNessuna valutazione finora

- Sony - HCD rg110, MHC rg110Documento21 pagineSony - HCD rg110, MHC rg110Marin VlahovićNessuna valutazione finora

- AIS 038 Rev2F PDFDocumento105 pagineAIS 038 Rev2F PDFRohit KumarNessuna valutazione finora

- DatasheetDocumento5 pagineDatasheetMuharrem ŞişliNessuna valutazione finora

- Geoeel Manual Export Rev GDocumento318 pagineGeoeel Manual Export Rev GJoshuaOrieroNessuna valutazione finora

- Institute of Aeronautical Engineering (Autonomous) : Electronics and Communication EngineeringDocumento40 pagineInstitute of Aeronautical Engineering (Autonomous) : Electronics and Communication EngineeringMano HarNessuna valutazione finora

- Thesis Power Amplifier DesignDocumento8 pagineThesis Power Amplifier Designleslylockwoodpasadena100% (2)

- User Manual: - Installation - OperationDocumento61 pagineUser Manual: - Installation - OperationKasun WeerasingheNessuna valutazione finora

- Horizon Tech ManualDocumento5 pagineHorizon Tech Manualwolf125Nessuna valutazione finora

- Em InductionDocumento51 pagineEm InductionAmy DavisNessuna valutazione finora

- Lightning Characterization For Flashover Rate Calculation of Overhead Transmission LinesDocumento6 pagineLightning Characterization For Flashover Rate Calculation of Overhead Transmission LinessunitharajababuNessuna valutazione finora

- SCCOverview PDFDocumento3 pagineSCCOverview PDFdevriesenNessuna valutazione finora

- Multistage Air Bubble Detection and Fluid Analysis For Dialysis MachinesDocumento3 pagineMultistage Air Bubble Detection and Fluid Analysis For Dialysis MachinesInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Surface Roughness Parameters and MeasurementDocumento11 pagineSurface Roughness Parameters and MeasurementHafiz Ghulam NabiNessuna valutazione finora

- ZVA Service ManualDocumento226 pagineZVA Service Manualrf2011Nessuna valutazione finora

- Fuji-Electric Fujitsu Rs9lb Rs12lbDocumento16 pagineFuji-Electric Fujitsu Rs9lb Rs12lbAlain ClementeNessuna valutazione finora