Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Technical Specifications of Aluminium Rivets or Steel Mandrel

Caricato da

mutualscrewCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Technical Specifications of Aluminium Rivets or Steel Mandrel

Caricato da

mutualscrewCopyright:

Formati disponibili

Rivets

180

L

E

H

W

D

P

F

Aluminum Rivet/

Steel Mandrel

Dome Head

Blind Rivet

Description

An aluminum blind fastener which has a self-contained steel mandrel which permits the formation of an upset on the blind end of

the rivet and expansion of the rivet shank during rivet setting to join the component parts of an assembly. The steel mandrel is

pulled into or against the rivet body, breaking at or near the junction of the mandrel shank and its upset end. The head of the body

is slightly rounded and twice as wide as the body diameter.

Applications/

Advantages

Dome head is the most commonly specified head style because of its low profile and neat, finished appearance. The steel mandrel

gives this style rivet greater tensile and shear values than aluminum rivets with aluminum mandrels. They should be used when

fastening materials with similar mechanical and physical properties.

Material

Rivet: Aluminum Alloy 5056 or 5154 or equivalent alloy. Rivets have no additional finish except for sizes #42 & 44 which are also

available painted white. Note: Some manufacturers use aluminum alloy 5052 which is acceptable but will lower the shear, tensile

and mandrel break load standards to those of aluminum rivets with aluminum mandrels (see page 144).

Mandrel: Carbon steel 1006 or equivalent. May be furnished plain or with a protective coating, at the option of the manufacturer.

Shear Strength

Rivets shall have ultimate shear loads not less than the minimum ultimate shear loads specified for the applicable size given in the

above table.

Tensile Strength

Rivets shall have ultimate tensile loads not less than the minimum ultimate tensile loads specified for the applicable size given in

the above table.

Mandrel Break

Load

While the rivet is being set, the axially applied load necessary to break the mandrel shall be within the limits specified for the

applicable rivet size given in the above table.

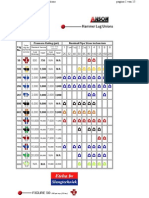

ALUMINUM BODY/STEEL MANDREL DOME HEAD BREAK-STEM BLIND RIVETS

SAE J-1200

Nominal

Rivet

Diameter

D H E W P F

Ultimate

Shear

Load

Ultimate

Tensile

Load

Mandrel Break

Load

Rivet Shank

Diameter

Head Diameter

Head

Height

Mandrel

Diameter

Mandrel

Protrusion

Blind Side

Protrusion

Max Min Max Min Max Nom Min Max Min, lb. Min, lb. Max Min

3/32 0.096 0.090 0.198 0.178 0.032 0.057 1.00 L + 0.100 90 120 275 175

1/8 0.128 0.122 0.262 0.238 0.040 0.076 1.00 L + 0.120 170 220 600 400

5/32 0.159 0.153 0.328 0.296 0.050 0.095 1.06 L + 0.140 260 350 850 600

3/16 0.191 0.183 0.394 0.356 0.060 0.114 1.06 L + 0.160 380 500 1050 750

1/4 0.255 0.246 0.525 0.475 0.080 0.151 1.25 L + 0.180 700 920 1850 1450

www.mutualscrew.com

Contact: 800.222.0324/201.845.5700

Email ID: bill@mutualscrew.com

Rivets

181

Dome Head

Blind Rivet

Aluminum Rivet/

Steel Mandrel

PART NUMBER COMPARISON - ALUMINUM RIVET/STEEL MANDREL

Kanebridge

Huck/

Automatic

Pop

Marson/

Creative

Star Celus

Cherry Gesipa

ADS31 - - - - - - -

ADS32 ABS32 AD32BS AB3-2 - A/S 32D BSP-32 GSMD32A

ADS34 ABS34 AD34BS AB3-4 - A/S 34D BSP-34 GSMD34A

ADS41 ABS41 AD41BS AB4-1 4-1ASD A/S 41D BSP-41 GSMD41A

ADS42 ABS42 AD42BS AB4-2 4-2ASD A/S 42D BSP-42 GSMD42A

ADS43 ABS43 AD43BS AB4-3 4-3ASD A/S 43D BSP-43 GSMD43A

ADS44 ABS44 AD44BS AB4-4 4-4ASD A/S 44D BSP-44 GSMD44A

ADS45 ABS45 AD45BS AB4-5 4-5ASD A/S 45D BSP-45 GSMD45A

ADS46 ABS46 AD46BS AB4-6 4-6ASD A/S 46D BSP-46 GSMD46A

ADS48 ABS48 AD48BS AB4-8 4-8ASD A/S 48D BSP-48 GSMD48A

ADS52 ABS52 AD52BS AB5-2 5-2ASD A/S 52D BSP-52 GSMD52A

ADS53 ABS53 AD53BS AB5-3 5-3ASD A/S 53D - GSMD53A

ADS54 ABS54 AD54BS AB5-4 5-4ASD A/S 54D BSP-54 GSMD54A

ADS56 ABS56 AD56BS AB5-6 5-6ASD A/S 56D BSP-56 GSMD56A

ADS58 ABS58 AD58BS AB5-8 - A/S 58D BSP-58 GSMD58A

ADS510 ABS510 - - - A/S510D BSP-510 -

ADS512 - - - - - - -

ADS516 - - - - - - -

ADS62 ABS62 AD62BS AB6-2 6-2ASD A/S 62D BSP-62 GSMD62A

ADS64 ABS64 AD64BS AB6-4 6-4ASD A/S 64D BSP-64 GSMD64A

ADS66 ABS66 AD66BS AB6-6 6-6ASD A/S 66D BSP-66 GSMD66A

ADS68 ABS68 AD68BS AB6-8 6-8ASD A/S 68D BSP-68 GSMD68A

ADS610 ABS610 AD610BS AB6-10 6-10ASD A/S610D BSP-610 GSMD610A

ADS612 ABS612 AD612BS AB6-12 6-12ASD A/S612D BSP-612 GSMD612A

ADS614 ABS614 AD614BS - - A/S614D BSP-614 GSMD614A

ADS616 ABS616 AD616BS AB6-16 - A/S616D BSP-616 GSMD616A

ADS618 ABS618 - - - - - -

ADS620 - - - - - - -

ADS622 - - - - - - -

ADS84 ABS84 AD84BS AB8-4 - A/S 84D BSP-84 GSMD84A

ADS86 ABS86 AD86BS AB8-6 - A/S 86D BSP-86 GSMD86A

ADS88 ABS88 AD88BS AB8-8 - A/S 88D BSP-88 GSMD88A

ADS810 ABS810 AD810BS - - A/S810D BSP-810 GSMD810A

Celus is a registered trademark of Celus Fasteners Manufacturing Inc..

Gesipa is a registered trademark of Gesipa Fasteners USA Inc..

Pop is a registered trademark of Pop Fastening Systems, Emhart Fastening Teknologies, a Black & Decker Company.

Kanebridges rivets are not manufactured by or connected with the producers of Gesipa or Pop rivets. www.mutualscrew.com

Contact: 800.222.0324/201.845.5700

Email ID: bill@mutualscrew.com

Rivets

189

Application

Data

Part Number Key

Notes on Rivet Selection

Strength- The tensile and shear strengths required for an application must be determined and a rivet selected that

meets those requirements.

Materials- Choose a rivet that is made of a metal with similar mechanical and physical properties as the materials

being joined. This is especially critical in assemblies where higher temperatures and/or corrosive elements are present.

Metal compatability helps reduce the risks of galvanic corrosion and material fatigue.

Grip Range- Measure the total thickness of the materials being fastened. This is known as the rivet grip. The grip

ranges of the most commonly available rivets are listed in the table below. Sufficient rivet length is necessary for

proper formation of the secondary head on the blind side of the assembly. Multi-grip rivets have wider grip ranges

than standard break-stem blind rivets.

ADS64L

Rivet Material: A = Aluminum; S = Steel; SS = Stainless; K = Copper

Mandrel Material: A = Aluminum; S = Steel; SS = Stainless

Grip Range: In 16ths of an inch (4/16 = 1/4)

L - This "L" indicates that the dome head is the Large Flange style.

Rivet Diameter: In 32nd's of an inch (6/32 = 3/16)

Head Style: D = Dome

*

*Kanebridge Part Number

APPLICATION DATA FOR STANDARD BREAK-STEM BLIND RIVETS

SAE J-1200

Rivet

Number

Grip Range

Barrel

Length

Recommended

Hole Size

Drill Size

Rivet

Number

Grip Range

Barrel

Length

Recommended

Hole Size

Drill Size

Max Max Min Max Max Min

31 .020-.062 .187

0.100 0.097 #41

62 .020-.125 .325

0.196 0.192 #11

32 .020-.125 .250 63 .126-.187 .387

33 .087-.187 .312 64 .188-.250 .450

34 .126-.250 .375 66 .251-.375 .575

41 .020-.062 .212

0.133 0.129 #30

68 .376-.500 .700

42 .063-.125 .275 610 .510-.625 .825

43 .126-.187 .337 612 .626-.750 .950

44 .188-.250 .400 614 .751-.875 1.075

45 .251-.312 .462 616 .876-1.000 1.200

46 .313-.375 .525 618 1.001-1.125 1.325

48 .376-.500 .650 620 1.126-1.250 1.450

52 .020-.125 .300

0.164 0.160 #20

622 1.251-1.375 1.575

53 .125-.187 .362 84 .126-.250 .500

0.261 0.257 F

54 .188-.250 .425 86 .251-.375 .625

56 .251-.375 .550 88 .376-.500 .750

58 .376-.500 .675 810 .501-.625 .875

510 .501-.625 .800 812 .626-.750 .990

512 .626-.750 .925 816 .751-1.000 1.240

516 .876-1.000 1.175

www.mutualscrew.com

Contact: 800.222.0324/201.845.5700

Email ID: bill@mutualscrew.com

Potrebbero piacerti anche

- High-Performance GM LS-Series Cylinder Head GuideDa EverandHigh-Performance GM LS-Series Cylinder Head GuideValutazione: 4.5 su 5 stelle4.5/5 (2)

- Example Vessel Re RatingDocumento9 pagineExample Vessel Re RatingRBKUMARNessuna valutazione finora

- Tool HoldersDocumento35 pagineTool HoldersCarlos Santos Ramirez MarañonNessuna valutazione finora

- Armor RodsDocumento4 pagineArmor RodsJonathan McNallyNessuna valutazione finora

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDa EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsValutazione: 4.5 su 5 stelle4.5/5 (10)

- Inertia Dynamics 2011 CatalogDocumento40 pagineInertia Dynamics 2011 CatalogElectromateNessuna valutazione finora

- Roberts Oxygen Welding Industrial Catalog 2011Documento104 pagineRoberts Oxygen Welding Industrial Catalog 2011sanjibkrjanaNessuna valutazione finora

- Jeep, Dana & Chrysler Differentials: How to Rebuild the 8-1/4, 8-3/4, Dana 44 & 60 & AMC 20Da EverandJeep, Dana & Chrysler Differentials: How to Rebuild the 8-1/4, 8-3/4, Dana 44 & 60 & AMC 20Nessuna valutazione finora

- Cast Steel Gate Valve - VS01 (ASME 150)Documento4 pagineCast Steel Gate Valve - VS01 (ASME 150)sghinausNessuna valutazione finora

- Hydraulic Hose SelectionDocumento16 pagineHydraulic Hose Selectiondavo87Nessuna valutazione finora

- Weld Like a Pro: Beginning to Advanced TechniquesDa EverandWeld Like a Pro: Beginning to Advanced TechniquesValutazione: 4.5 su 5 stelle4.5/5 (6)

- Victaulic W07 Rigid Cplg.20.02Documento4 pagineVictaulic W07 Rigid Cplg.20.02dan_capitanNessuna valutazione finora

- Fragola Performance CatalogDocumento64 pagineFragola Performance CatalogChad MarNessuna valutazione finora

- Faslt 0020 enDocumento6 pagineFaslt 0020 enshashikanth79Nessuna valutazione finora

- Condensadora Westinghouse 5TR Mod DS3BA - DS5BADocumento4 pagineCondensadora Westinghouse 5TR Mod DS3BA - DS5BAOscar Sanchez Velasquez0% (1)

- Burndy CatalogDocumento79 pagineBurndy CatalogRoger Carlos100% (1)

- DSM PDFDocumento8 pagineDSM PDFSlobodan AnticNessuna valutazione finora

- Hamerlug Unions (Anson)Documento15 pagineHamerlug Unions (Anson)Leonardo ViannaNessuna valutazione finora

- Wiring AccessoriesDocumento56 pagineWiring AccessoriesKrizia De PeraltaNessuna valutazione finora

- H 1104Documento2 pagineH 1104Madirley PimentaNessuna valutazione finora

- Section Q: Splined Hubs, Drive KitsDocumento8 pagineSection Q: Splined Hubs, Drive KitshaggNessuna valutazione finora

- Copper Bonded Grounding Rod ManufacturerDocumento7 pagineCopper Bonded Grounding Rod ManufacturerUjjwal ShahNessuna valutazione finora

- Classif AçosDocumento7 pagineClassif AçoslavascudoNessuna valutazione finora

- Pulleys TechDocumento8 paginePulleys TechashkansoheylNessuna valutazione finora

- FusesDocumento8 pagineFusesmohanNessuna valutazione finora

- Conductor SizeDocumento1 paginaConductor SizeBilal AhmadNessuna valutazione finora

- ButterflyDocumento6 pagineButterflysachin2010Nessuna valutazione finora

- KVC 01Documento35 pagineKVC 01hamidreza_m85Nessuna valutazione finora

- BSP 05 UK (Nov-11) PDFDocumento20 pagineBSP 05 UK (Nov-11) PDFhepcomotionNessuna valutazione finora

- AmeritoolBroch Aug21Documento12 pagineAmeritoolBroch Aug21hiscoke69Nessuna valutazione finora

- MasterSeries 850 Specification SheetDocumento2 pagineMasterSeries 850 Specification SheetFEBCONessuna valutazione finora

- 16620YDocumento17 pagine16620YbalajivangaruNessuna valutazione finora

- Simplex Type S Filter 1" & 1 " (25 & 40mm) Screwed (Cast Iron Only)Documento1 paginaSimplex Type S Filter 1" & 1 " (25 & 40mm) Screwed (Cast Iron Only)Deddy IrawanNessuna valutazione finora

- Mi Ether CatalogDocumento76 pagineMi Ether CatalogcirclelineNessuna valutazione finora

- Power Stream Couplings-Specn SheetsDocumento6 paginePower Stream Couplings-Specn SheetsAmol PatkiNessuna valutazione finora

- 11502Documento9 pagine11502balajivangaruNessuna valutazione finora

- 03 Inside Page 2021 EarthingDocumento49 pagine03 Inside Page 2021 Earthingtest4you2222Nessuna valutazione finora

- Comeval Cast Steel Gate Valve ANSI 150 PDFDocumento5 pagineComeval Cast Steel Gate Valve ANSI 150 PDFblizanacNessuna valutazione finora

- Alloy Chain Sling Working Load LimitsDocumento14 pagineAlloy Chain Sling Working Load LimitsjillianixNessuna valutazione finora

- Copper Bonded Earthing Rod ManufacturerDocumento7 pagineCopper Bonded Earthing Rod ManufacturerUjjwal ShahNessuna valutazione finora

- Thomson Roundrail 1BC SpecsheetDocumento2 pagineThomson Roundrail 1BC SpecsheetElectromateNessuna valutazione finora

- Automotive Cable-Single Core: Colours 30M 100M 500MDocumento0 pagineAutomotive Cable-Single Core: Colours 30M 100M 500Mppanagos5664Nessuna valutazione finora

- Mercedes 04 WDocumento6 pagineMercedes 04 WDoszlop DiannaNessuna valutazione finora

- Helium SLA Disc 7E1 Passport 2017 PDFDocumento8 pagineHelium SLA Disc 7E1 Passport 2017 PDFPieter Baobab BoomNessuna valutazione finora

- NT, NSHD, NB & DV End-Suction Centrifugal Pumps To En733 (Din 24255)Documento28 pagineNT, NSHD, NB & DV End-Suction Centrifugal Pumps To En733 (Din 24255)jorgeNessuna valutazione finora

- CTRLDocumento57 pagineCTRLpbontyNessuna valutazione finora

- Butterfly Valves Series BF-03-M2 Full Lug and BF-04-M2 Wafer Specification SheetDocumento2 pagineButterfly Valves Series BF-03-M2 Full Lug and BF-04-M2 Wafer Specification SheetWattsNessuna valutazione finora

- 11422Documento10 pagine11422balajivangaruNessuna valutazione finora

- Kobelco Welding HandbookDocumento76 pagineKobelco Welding HandbookChulita IntaratutNessuna valutazione finora

- NOV Elmar ICT WL Tools Poster A4Documento95 pagineNOV Elmar ICT WL Tools Poster A4AjayNessuna valutazione finora

- AS3 / AS6: SAE-Flange / Weld ButtDocumento5 pagineAS3 / AS6: SAE-Flange / Weld ButtHuy NguyễnNessuna valutazione finora

- Advance Advenger Part DocumentDocumento50 pagineAdvance Advenger Part DocumentJim KelleyNessuna valutazione finora

- Series 77F-DI-250 Specification SheetDocumento2 pagineSeries 77F-DI-250 Specification SheetWattsNessuna valutazione finora

- GWC Valve International - Forged Steel Gate, Globe, and Check ValvesDocumento28 pagineGWC Valve International - Forged Steel Gate, Globe, and Check ValvesGWC Valve InternationalNessuna valutazione finora

- Pernos Huck C50LDocumento4 paginePernos Huck C50LAngelina Santiago JimenezNessuna valutazione finora

- Thin Layer ChromatographyDocumento497 pagineThin Layer ChromatographyFrancimauroNessuna valutazione finora

- Chapter 3.1 - CoagulationDocumento51 pagineChapter 3.1 - CoagulationHanif NifNessuna valutazione finora

- 1-6 Chemical Reactions of Alkanes and AlkenesDocumento2 pagine1-6 Chemical Reactions of Alkanes and AlkenesBryan100% (1)

- 118 Worm Gear LubesDocumento4 pagine118 Worm Gear LubesWajahat RasoolNessuna valutazione finora

- Guideline For Butt Saddle and Socket FusionDocumento10 pagineGuideline For Butt Saddle and Socket FusionKenNessuna valutazione finora

- Merck Index Front MatterDocumento14 pagineMerck Index Front MatterCristian Meneguzzi100% (1)

- Determine PH by PH Indicator and Universal IndicatorDocumento3 pagineDetermine PH by PH Indicator and Universal IndicatorhaleelNessuna valutazione finora

- ULO TempDocumento7 pagineULO TempcnacevedoNessuna valutazione finora

- Resin Screening To Optimize Chromatographic SeparaDocumento5 pagineResin Screening To Optimize Chromatographic SeparamohanNessuna valutazione finora

- Glazing A - IKA Group - Silicone Sealant Indonesia 1Documento4 pagineGlazing A - IKA Group - Silicone Sealant Indonesia 1Riry SuprianaNessuna valutazione finora

- Experiment 2 - ELECTROCHEMICAL CELLSDocumento5 pagineExperiment 2 - ELECTROCHEMICAL CELLSFroz ChickenNessuna valutazione finora

- Civil Engineering Interview QuestionsDocumento123 pagineCivil Engineering Interview QuestionsSoni Mishra Tiwari89% (9)

- 2007 - Huber Et Al. - Synergies Between Bio and Oil Refineries For The Production of Fuels From Biomass PDFDocumento18 pagine2007 - Huber Et Al. - Synergies Between Bio and Oil Refineries For The Production of Fuels From Biomass PDFMayank KumarNessuna valutazione finora

- Cryogenic GrindingDocumento21 pagineCryogenic GrindingRahul Yadav100% (1)

- Vacuum Regulator Gas Feed Systems Theory and MaintenanceDocumento62 pagineVacuum Regulator Gas Feed Systems Theory and Maintenancezhigang dingNessuna valutazione finora

- 2jz Ecu TerminalsDocumento4 pagine2jz Ecu TerminalsJp Da Silva100% (1)

- Arabinose + Tryptophan OperonDocumento58 pagineArabinose + Tryptophan OperonLucy ZuluNessuna valutazione finora

- Post Weld Heat TreatmentDocumento3 paginePost Weld Heat TreatmentpvdrameshNessuna valutazione finora

- VAG Control ValvesDocumento12 pagineVAG Control ValvesVignesh NadimuthuNessuna valutazione finora

- ID Senyawa Antibakteri Yang Diproduksi OlehDocumento8 pagineID Senyawa Antibakteri Yang Diproduksi OlehNurawaliah RezkyNessuna valutazione finora

- Goldmix PC110 TDS PDFDocumento1 paginaGoldmix PC110 TDS PDFRafael Obusan IINessuna valutazione finora

- Stycast 1264 A/B: Low Viscosity, Transparent, Epoxy EncapsulantDocumento2 pagineStycast 1264 A/B: Low Viscosity, Transparent, Epoxy EncapsulantRosli YaacobNessuna valutazione finora

- HamzaDocumento20 pagineHamzaHamza KhakwaniNessuna valutazione finora

- Brazing PrinciplesDocumento118 pagineBrazing PrinciplesKingsman 86100% (1)

- Chapter 8 Ionic Chain PolymerizationDocumento34 pagineChapter 8 Ionic Chain PolymerizationelnurorucluNessuna valutazione finora

- Methods For Testing Antioxidant Activity: The Analyst February 2002Documento17 pagineMethods For Testing Antioxidant Activity: The Analyst February 2002Boas WayneNessuna valutazione finora

- Pollutants and Its MeasurementDocumento70 paginePollutants and Its MeasurementECRDNessuna valutazione finora

- Ocr Gateways c1c2c3Documento36 pagineOcr Gateways c1c2c3Jatinder BathNessuna valutazione finora

- Anchor Bolt For Brick MasonryDocumento11 pagineAnchor Bolt For Brick MasonryEdmond Chow100% (1)

- GGBSDocumento20 pagineGGBSratnakar0% (1)

- Arizona, Utah & New Mexico: A Guide to the State & National ParksDa EverandArizona, Utah & New Mexico: A Guide to the State & National ParksValutazione: 4 su 5 stelle4/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoDa EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoValutazione: 5 su 5 stelle5/5 (1)

- New York & New Jersey: A Guide to the State & National ParksDa EverandNew York & New Jersey: A Guide to the State & National ParksNessuna valutazione finora

- The Bahamas a Taste of the Islands ExcerptDa EverandThe Bahamas a Taste of the Islands ExcerptValutazione: 4 su 5 stelle4/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensDa EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNessuna valutazione finora

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptDa EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptValutazione: 5 su 5 stelle5/5 (1)