Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bearing Failure Due To Current

Caricato da

T S VirdiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Bearing Failure Due To Current

Caricato da

T S VirdiCopyright:

Formati disponibili

Vo l .

3 , D e c e m b e r 2 0 0 2

Ask the experts

Current Trends

Bearing Down On Electrical Stress Can Protect A Motor

In the past few years, there has been a significant increase in motor problems associated with shaft voltages and currents. Voltage discharge from current passing through the bearings can cause the bearings to be damaged or fail if not properly insulated. Shaft voltages have long been associated with medium and large electric

Q: A:

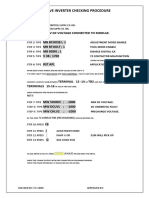

Is there a specific

procedure to follow when insulating bearings? If so, what is the procedure?

Apply sufficient

machines; however, the increased use of variable frequency drives has resulted in shaft voltages in much smaller motors. It is theorized that the terminal motor voltage supplied by the drive is not balanced or symmetrical in some aspect. In standard machines, any break from uniformity in the rotor or stator can cause shaft voltages. Shorted laminations, gaps in the stator laminations, variations in air gap or spacing for fields or interpoles in a DC machine can result in shaft voltages in rotating equipment. Shaft voltages may also result from static electric discharge from the driven equipment or process. Other abnormalities in sine wave power supply are associated with grounding, unbalances or harmonics which may also result in induced shaft voltages. Noisy bearings or repeated bearing failures can be an indication of electrical stress. Only after the bearings have been removed and inspected can this problem be diagnosed. Otherwise, the motor will continue to operate until the bearings fail and the motor is so severely damaged that any evidence of shaft currents is destroyed. Indications of shaft voltages include fluting or a picket-fence signature on the race of the bearing. Fluting due

continued on back >

alumina oxide coating to allow for finished grinding to original bearing journal dimensions with 63 RMS, or better, surface finish. A phenolic sealer must be applied after the initial machining, but before the finish grind. Suggested insulation material: Alumina oxide Bonding material Sealer

Have a question for the experts? Contact us at jim.bryan@emotors.com

Fluting due to shaft currents on both a roller bearing, above, and a ball bearing, below.

product service BULLETIN

inverter duty motors. Any product manufactured by US Motors can be requested to be modified with insulation, at an additional cost. EASA shops receiving a US Motors brand motor for repair are encouraged to re-coat the materials before installing new bearings, if the ceramic was dam-

When rotational speed varies, the shaft currents may cause a dull, frosted appearance instead of fluting.

< continued from belt watch

aged. Keep in mind that when insulating a bearing housing, you must also insulate the face of the bearing cap. The bearing cap could come into contact with the face of the bearing, bypassing any insulation on the bearing housing. Be sure to take special care when applying the ceramic coating because ceramic chips easily. Care should also be taken when balancing a shaft with ceramic-coated journals because the layer of ceramic is relatively thin. The rotor weight should not be placed on the journals for balancing or inspection because the point-loading is likely to break the ceramic loose from the shaft. The damage does not show up until the motor is in service, at which time the ceramic fractures, leaving the bearing with a loose shaft fit. Other recommended measures for protecting bearings from shaft voltages include: Use bearings with ceramic balls. Insulate both bearing housings. Install ground brushes on both ends. Insulate both shaft journals. Install in-line filters between the motor and VFD to reduce the problem. Improve grounding of the motor and drive. Some experimental products are also being reviewed. Various bearing lubricants alter the impedance to ground, which reduces the current flow through the bearings. The use of the epoxy putties such as Devcon and Belzona are also being used by other manufacturers, but load capacity and use in oil lubrication is still an issue. The shaft grounding brush system is an acceptable method, but follow-up maintenance is required. In some hostile environments, the grounding brush system is not successful. The decision on which bearing protective system to use is often up to the end-user since cost is usually the deciding factor. For more information about bearing protection, contact Cheri Newman, Senior Product Service Engineer with US Motors, at 314-553-2653 or cheri.newman@emotors.com.

to shaft currents can occur on both a roller bearing and a ball bearing. The spacing of the fluting marks depends on the rpm, diameter, radial load and magnitude of the shaft voltage. In some cases, the appearance of the balls offers the best clue. Instead of a highly-polished finish, the rolling elements may have a dull grey or smoky appearance. The standard voltage limits for ball bearings is 100mV and 200mV for sleeve bearings. Variable frequency drives can result in shaft voltages as high as 20 to 25 volts. Because of capacitive coupling between the rotor and stator, both bearings must be electrically isolated. The standard method of insulating only one bearing will not protect bearings in a machine operated from a variable frequency drives. US Motors suggests using a protective ceramic coating on the bearings when the bearings indicate shaft currents are present and have caused the failure. This approach may not be practical on smaller size motors, however, some bearing manufacturers do offer an anti-friction bearing with an insulated outer race or rolling element. The practice at US Motors is to insulate the non-drive end shaft bearing journal with a ceramic (aluminum oxide) coating. Insulated sleeve bearings are purchased with the outer diameter insulated by the bearing manufacturer. Insulated bearings are provided as a standard feature on all US Motors products in the 5800 through 9600 frame series, all Titan 6 pole motors, Titan sleeve bearings motors and Titan

Ceramic or aluminum oxide spray is one method of insulating. Above, an opposite drive end bearing journal, and below, vertical motor bearing carriers, all of which have been insulated with ceramic spray.

Photos Wanted

Emerson Motor Technologies NEMA Winding Failure Return Program was successful in identifying application-related functions. At this time, the Product Service Department would like photos of 440 frame winding failures. Our intent is to focus on application errors, improper installation and other conditions that can severely damage a motor. Please e-mail your pictures to the Product Service Engineer you are coordinating the warranty repairs with. Thank you for your assistance.

Potrebbero piacerti anche

- MI199 Training Combustion AdjustmentDocumento11 pagineMI199 Training Combustion AdjustmentT S VirdiNessuna valutazione finora

- SOP-Hitachi DrivesDocumento2 pagineSOP-Hitachi DrivesT S VirdiNessuna valutazione finora

- Backup ProcedureDocumento36 pagineBackup ProcedureT S Virdi100% (1)

- PS Controller Implimentation PDFDocumento123 paginePS Controller Implimentation PDFT S VirdiNessuna valutazione finora

- Tata CGL Sj700 Bitmapping v02Documento1 paginaTata CGL Sj700 Bitmapping v02T S VirdiNessuna valutazione finora

- MI199 Training Flow MeasurementDocumento9 pagineMI199 Training Flow MeasurementT S VirdiNessuna valutazione finora

- Rockwell Automation - Basics of Circuit BreakersDocumento102 pagineRockwell Automation - Basics of Circuit Breakersrobertspiteri100% (1)

- SMP DrivesDocumento3 pagineSMP DrivesT S VirdiNessuna valutazione finora

- SJ-700 Parameter ListDocumento3 pagineSJ-700 Parameter ListT S VirdiNessuna valutazione finora

- BOM Incomer Panels FINALDocumento19 pagineBOM Incomer Panels FINALT S VirdiNessuna valutazione finora

- Welder Iba SignalsDocumento3 pagineWelder Iba SignalsT S VirdiNessuna valutazione finora

- Spare Checked From HV PanelsDocumento1 paginaSpare Checked From HV PanelsT S VirdiNessuna valutazione finora

- SMP DrivesDocumento3 pagineSMP DrivesT S VirdiNessuna valutazione finora

- Drives 1.0Documento10 pagineDrives 1.0T S VirdiNessuna valutazione finora

- APG Non HealthDocumento14 pagineAPG Non HealthT S VirdiNessuna valutazione finora

- Checklists JobsDocumento3 pagineChecklists JobsT S VirdiNessuna valutazione finora

- Commissioning Test Report: Tata Steel LTD, Jamshedpur Cgl2 RevampingDocumento6 pagineCommissioning Test Report: Tata Steel LTD, Jamshedpur Cgl2 RevampingT S VirdiNessuna valutazione finora

- Model Work Place Check ListDocumento5 pagineModel Work Place Check ListT S VirdiNessuna valutazione finora

- Voice of VillagersDocumento7 pagineVoice of VillagersT S VirdiNessuna valutazione finora

- Cgl2 Revamping: Commissioning Test ReportDocumento7 pagineCgl2 Revamping: Commissioning Test ReportT S VirdiNessuna valutazione finora

- Hall Effect Sensors TheoryDocumento12 pagineHall Effect Sensors TheoryPrateek BhatnagarNessuna valutazione finora

- QuenchDocumento17 pagineQuenchT S VirdiNessuna valutazione finora

- Grounding Matrix Grounding DiagramDocumento3 pagineGrounding Matrix Grounding DiagramT S VirdiNessuna valutazione finora

- Adolescent Girl 24.8 Part 2Documento9 pagineAdolescent Girl 24.8 Part 2T S VirdiNessuna valutazione finora

- Template For Capturing Drive Failure Data - R1Documento1 paginaTemplate For Capturing Drive Failure Data - R1T S VirdiNessuna valutazione finora

- ABB ACS 600 DC Bus OvervoltageDocumento2 pagineABB ACS 600 DC Bus OvervoltageT S VirdiNessuna valutazione finora

- Overflux InrushcurrDocumento4 pagineOverflux InrushcurrT S VirdiNessuna valutazione finora

- Spoken LanguageDocumento13 pagineSpoken LanguageT S VirdiNessuna valutazione finora

- Sop For Motor Changing JobDocumento10 pagineSop For Motor Changing JobT S Virdi50% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Brochure Makita 18v Cordless Impact WrenchDocumento36 pagineBrochure Makita 18v Cordless Impact WrenchHidaayah Ngabas NoorNessuna valutazione finora

- Caterpillar 320 ELDocumento2 pagineCaterpillar 320 ELSantiago GuayasamínNessuna valutazione finora

- Powertronic D QS VerA Installation QuickshifterDocumento7 paginePowertronic D QS VerA Installation QuickshifterGauravNessuna valutazione finora

- Power Systems CH - 9 (Zub)Documento37 paginePower Systems CH - 9 (Zub)Dale SteynNessuna valutazione finora

- TRSM0990 PumpRemovalDocumento46 pagineTRSM0990 PumpRemovalHamilton MirandaNessuna valutazione finora

- Krombach Strainers & GGCDocumento35 pagineKrombach Strainers & GGCMeanRatNessuna valutazione finora

- IM107Documento36 pagineIM107Stefano Di LuccaNessuna valutazione finora

- 00-110 - Balder PDFDocumento3 pagine00-110 - Balder PDFMoe Latt0% (1)

- SYL956H5 SYL956H5: Brand NewDocumento12 pagineSYL956H5 SYL956H5: Brand NewGuillermo HerreraNessuna valutazione finora

- EIM 7 - 8-Module 1Documento24 pagineEIM 7 - 8-Module 1Donna Shane ReyesNessuna valutazione finora

- Aircraft Maintenance ManualDocumento10 pagineAircraft Maintenance ManualPPC LINE9Nessuna valutazione finora

- Caldina Electrical Wiring DiagramDocumento73 pagineCaldina Electrical Wiring DiagramAdam80% (10)

- Diagrama CD PDFDocumento9 pagineDiagrama CD PDFCarlos AranedaNessuna valutazione finora

- rd-m592 2Documento1 paginard-m592 2faizgpNessuna valutazione finora

- Control Panel O&m ManualDocumento9 pagineControl Panel O&m Manualhari kiranNessuna valutazione finora

- TM 55-1520-210-CL PDFDocumento5 pagineTM 55-1520-210-CL PDFEagle1968Nessuna valutazione finora

- Detroit DD15 Engine: Horsepower LB-FT Torque LitersDocumento10 pagineDetroit DD15 Engine: Horsepower LB-FT Torque Litersfdpc198792% (13)

- Rounding MachinesDocumento4 pagineRounding Machinesarbnor_morinaNessuna valutazione finora

- 6BT (210, 2600, 2891, INT, Nov 00, M-90761) PDFDocumento2 pagine6BT (210, 2600, 2891, INT, Nov 00, M-90761) PDFCrespo Jorge100% (1)

- Parts Manual - EH02-1Documento12 pagineParts Manual - EH02-1Văn ĐạtNessuna valutazione finora

- Snchronous Motor 1 20Documento11 pagineSnchronous Motor 1 20Niño James CagatNessuna valutazione finora

- 3126Documento5 pagine3126Ebied Yousif AlyNessuna valutazione finora

- MTC-650 A: Marine Temperature CalibratorDocumento8 pagineMTC-650 A: Marine Temperature CalibratorSof TalhacNessuna valutazione finora

- PT6 Component Repair ListingDocumento6 paginePT6 Component Repair ListingAman LynNessuna valutazione finora

- SSS CLUTCH 10T S Short Shaft Instructions 270907 PDFDocumento4 pagineSSS CLUTCH 10T S Short Shaft Instructions 270907 PDFferayiNessuna valutazione finora

- FW6A Manual CuerpoDocumento11 pagineFW6A Manual CuerpoHenrry trespalaciosNessuna valutazione finora

- trsl0261 0510Documento2 paginetrsl0261 0510Darrinel Perez CcordovaNessuna valutazione finora

- Xby2 I5601e-0-Initial Startup - Rev 0 - 15 Apr 09Documento35 pagineXby2 I5601e-0-Initial Startup - Rev 0 - 15 Apr 09llaiskonis2725100% (3)

- PDI TEE 165 Manual BookDocumento34 paginePDI TEE 165 Manual BookRiswan Park'Chu Young50% (2)

- DPO Repair ManualDocumento72 pagineDPO Repair ManualHugo Ramos Trejo100% (9)