Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SB 2K9 0027 C236

Caricato da

dclynesTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SB 2K9 0027 C236

Caricato da

dclynesCopyright:

Formati disponibili

(Page.

1/7)

Service Bulletin

Subject Model

Ref. No.

2K9-0027 (C236)

<Date> September 18, 2012

Measures against Fuser Belt Damage (Measures against the Service Calls C6200/C6600/C6720) TASKalfa 7550ci, TASKalfa 6550ci, TASKalfa 8000i, TASKalfa 6500i

Entire Stock Rework In-Field modification by case In-Field modification at next visit No modification necessary

l:

KMCs Classification

Field Measures: When the fuser belt edge is torn, please replace the fuser unit with the new one. On your next visit, please check if the flange key of the bush is not in the U-shape groove. If it is in the groove, please replace the fuser unit with the new one. (For more details on the check, please refer to the pages 4 and 5.) Serial Nos. of the Affected Machines: Please refer to the pages 6 and 7.

Phenomenon

The following service calls may appear if the fuser belt is torn. - C6200 (Broken fuser edge heater wire) - C6600 (Fuser belt rotation error) - C6720 (Fuser IH belt rotation error)

Causes

A) If the flange key of the bush comes into the U-shape groove of the heat roller when rotating since the depth of the joint between the U-shape groove and the flange key to stop the rotation is shallow, the edge of the Ushape groove may be rolled up and the fuser belt edge may be torn by the rolled up part of the U-shape groove. B) The fuser belt edge may be momentarily bent and then torn if the fuser belt is pulled in the rotating direction of the bush due to the contact of the bush flange with the fuser belt edge.

Content of Changes

For the cause A) The joint shape between the U-shape groove of the heat roller and the flange key of the bush was changed to increase the depth of the joint. For the cause B) The round shape of the bush flange was changed in order to prevent the fuser belt edge from being bent (from R4.4 to R7). Cause A OK NG

Fuse belt edge scratched by the rolled-up leading edge of the U-shape groove

Flange key of the bush surely fits in the U-shape groove

When the leading edge of the U-shape groove is rolled up as the flange key of the bush comes into the Ushape groove.

KYOCERA Document Solutions Europe Technical Customer Service Division (TCSD)

(Page.2/7)

Service Bulletin

Cause B X

Ref. No.

2K9-0027 (C236)

<Date> September 18, 2012

Fuser belt edge scratched by the bush flange (indicated in yellow) and it may be bent.

(Cross section of the figure to the left) View from X View from Y

Heat roller

Belt

Flange of the bush

Fuser belt momentarily bent if the fuser belt is pulled in the rotating direction of the bush

No.

Old Part No.

New Part No.

Description

Qty Old New

Com patibi lity Old New

Remarks

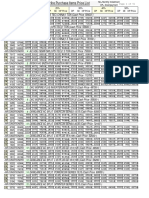

TASKalfa 7550ci/6550ci 1 2 3 4 302K993124 2K993124 302K993134 2K993134 302K99C134 2K99C134 302K99K134 2K99K134 302LF93054 2LF93054 302LF93064 2LF93064 302LF9C064 2LF9C064 302LF9K064 2LF9K064 302K993125 2K993125 302K993135 2K993135 302K99C135 2K99C135 302K99K135 2K99K135 302LF93055 2LF93055 302LF93065 2LF93065 302LF9C065 2LF9C065 302LF9K065 2LF9K065 FK-8706 FK-8707 FK-8707 FK-8707(KR) 1 1 1 1 1 1 1 1 X X X X O O O O For 120V For 220V to 240V (Except KDCN/KDKR) For KDCN For KDKR

TASKalfa 8000i/6500i 5 6 7 8 FK-6706 FK-6707 FK-6707 FK-6707(KR) 1 1 1 1 1 1 1 1 X X X X O O O O For 120V For 220V to 240V (Except KDCN/KDKR) For KDCN For KDKR

KYOCERA Document Solutions Europe Technical Customer Service Division (TCSD)

(Page.3/7)

Service Bulletin

Changes for the cause A State of the bush and the heat roller (attached) State of the bush and the heat roller (separated)

Ref. No.

2K9-0027 (C236)

<Date> September 18, 2012

Cross section of the heat roller and the bush

Heat roller

Old

Bush Depth of the joint between the U-shape groove and the flange key shallow

New

Depth of the joint between the U-shape groove and the flange key deepened

Bent added to the edge of the Ushape groove of the heat roller as stopper

Changes for the cause B (Old)

0.7+/-0.1 mm

R4.4

Heat roller

Belt

Bush flange

Fuser belt may be momentarily bent if it is pulled in the rotating direction of the bush.

1+/-0.1 mm

(New) R7

Heat roller

Belt

Round shape of the bush flange changed

Contact area of the bush flange with the fuser belt edge becomes smaller after this change. Accordingly, the stress caused by the bent fuser belt is reduced since the fuser belt is hardly pulled in the rotating direction of the bush. KYOCERA Document Solutions Europe Technical Customer Service Division (TCSD)

(Page.4/7)

Service Bulletin

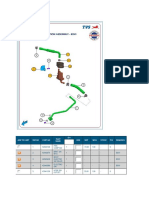

[Procedure to check the position of the flange key] No. 1 2 3

Ref. No.

2K9-0027 (C236)

<Date> September 18, 2012

Procedures Open the paper conveying unit. Remove the screw (3X8B(S) III SR) and then remove the COVER WIRE FUSER. Disconnect the connector (x2) and remove the screw (4X12B(S) III SR)(x4). Then, detach the FUSER UNIT. Rotate the gear while twisting the FUSER UNIT to align the fuser belt toward the machine front side. (*) Please watch the video issued together with this service bulletin for the alignment of the belt. Video: [Fuser_belt_shifting_method_Video_E]

Machine rear side Align the fuser belt toward the machine front side.

Rotate the gear while applying the force to the unit by twisting it.

Gear

Machine front side

Fuser unit

Check if the flange key of the bush at the machine rear side of the fuser unit is not getting under the heat roller. (Attention) If the heat roller is hot, please cover it with cloth. Do not directly touch it by hand.

Machine rear side Normal Machine front side

NG: Key on the flange gets under the inside of the heat roller.

Heat roller

Heat roller

Flange key

Flange key

If the flange key is getting under the inside of the heat roller, --> Replace the FUSER UNIT with the new one and go to No.10. If the flange key was not inside of the heat roller, --> Please go to No.7.

KYOCERA Document Solutions Europe Technical Customer Service Division (TCSD)

(Page.5/7)

Service Bulletin

No. Procedures

Machine rear side

Ref. No.

2K9-0027 (C236)

<Date> September 18, 2012

Rotate the gear while twisting FUSER UNIT for aligning the fuser belt toward the machine rear side.

Align the fuser belt toward the machine front side.

Rotate the gear while adding the force to the unit by twisting it to the opposite direction of the procedure 4.

Gear

Machine front side

Fuser unit

Check if the flange key at the machine front side is getting under the inside of the heat roller. (Attention) If the heat roller is hot, please cover it with cloth instead of directly touching it by hand.

Machine rear side Normal Machine front side NG if the flange key is inside of the heat roller.

Heat roller

Heat roller

Flange key

Flange key

9 10 11 12 13

If the flange key is getting under the inside of the heat roller, --> Replace the FUSER UNIT with the new one and go to No.10. If the flange key does not get under the heat roller, --> Please go to No.10. Reattach the FUSER UNIT by tightening the screw (4X12B(S) III SR)(x4). Connect the connector of the FUSER UNIT (x2) to the machine. Reattach the COVER WIRE FUSER by tightening the screw (3X8B(S) III SR). Close the paper conveying unit.

KYOCERA Document Solutions Europe Technical Customer Service Division (TCSD)

(Page.6/7)

Service Bulletin

Serial Nos. of the Affected Machines

<Main units> 7550ci

KDJ 1102K99JP0 N4C2900042 UTAX 1102K93UT0 N4G2800063 KDA 1102K92US0 N4D Next KDAU 1102K93AS0 N4F2800104 CPY 1102K92CS0 NH62800085 KDCN 1102K93KS0 NY3 Next KDA GSA 1102K92US1 NLM Next KDTW 1102K9TTW0 NQ8 Next KDBR 1102K92BR0 NJG Next KDAS 1102K93AX0 NQ32800022

Ref. No.

2K9-0027 (C236)

<Date> September 18, 2012

KDA 220V 1102K94US0 NH7 Next

KDE 1102K93NL0 N4E2800399

6550ci

KDJ 1102LB9JP0 N4H Next UTAX 1102LB3UT0 N4M2800138 KDA 1102LB2US0 N4J2800685 KDAU 1102LB3AS0 N4L2800108 CPY 1102LB2CS0 NH92800262 KDCN 1102LB3KS0 NY42800012 KDA GSA 1102LB2US1 NLN Next KDTW 1102LBTTW0 NQ7 Next KDBR 1102LB2BR0 NJF Next KDAS 1102LB3AX0 NQ22800025 KDA 220V 1102LB4US0 NHC Next KDE 1102LB3NL0 N4K2800397

8000i

KDJ 1102LF9JP0 N4N2900318 UTAX 1102LF3UT0 N4S2800172 KDA 120V 1102LF2US0 N4P2801355 Olivetti 1102LF3LV0 NK12800121 CPY 1102LF2CS0 NHE2800393 KDAU 1102LF3AS0 N4R2900089 KDA GSA 1102LF2US1 NLP Next KDCN 1102LF3KS0 NKP Next KDBR 1102LF2BR0 NJE Next KDKR 1102LF3KR0 NMQ Next KDA 220V 1102LF4US0 NHF Next KDTW 1102LFTTW0 NJQ Next KDE 1102LF3NL0 N4Q2800913 KDSG 1102LF3SG0 NJK2800098

6500i

KDJ 1102LG9JP0 N4T2900172 UTAX 1102LG3UT0 N4X2800301 KDA 1102LG2US0 N4U2802047 Olivetti 1102LG3LV0 NK22800115 CPY 1102LG2CS0 NHG2800659 KDAU 1102LG3AS0 N4W Next KDA GSA 1102LG2US1 NLQ Next KDCN 1102LG3KS0 NKQ2800129 KDBR 1102LG2BR0 NJD Next KDKR 1102LG3KR0 NMR Next KDA 220V 1102LG4US0 NHH Next KDTW 1102LGTTW0 NJR Next KDE 1102LG3NL0 N4V2801186 KDSG 1102LG3SG0 NJL2800116

KYOCERA Document Solutions Europe Technical Customer Service Division (TCSD)

(Page.7/7)

Service Bulletin

<MK kits>

MK-8705C 120V 1702K97US0 NEX2800427 220V to 240V 1702K98KL0 NLU2800315 KDAS 1702K98AX0 NQ6 Next KDCN 1702K98KS0 NY7 Next

Ref. No.

2K9-0027 (C236)

<Date> September 18, 2012

MK-6705C 120V 1702LF7US1 L552800721 220V to 240V 1702LF8KL1 L532800310 KDKR 1702LF8KR3 L56 Next KDCN 1702LF8KS2 L57 Next KDTW 1702LFTTW1 L58 Next

<Fuser units> 7550ci/6550ci 120V No.1 M13052803946 8000i/6500i 120V No.5 KX9052811593

220V to 240V No.2

KDCN No.3 M14052802719

KDKR No.4

220V to 240V No.6

KDCN No.7 KX8052807103

KDKR No.8

KYOCERA Document Solutions Europe Technical Customer Service Division (TCSD)

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Priport Platinum (C267) : Parts CatalogDocumento98 paginePriport Platinum (C267) : Parts CatalogNhã BáNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Grupo Electrogeno Con Motor 3412-Coripuno PDFDocumento4 pagineGrupo Electrogeno Con Motor 3412-Coripuno PDFDEYNERNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- CCTV Pole EarthingDocumento2 pagineCCTV Pole EarthingJoselin Leo100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Lifting Equipment 04 11 2023Documento22 pagineLifting Equipment 04 11 2023rome reyesNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- EST2 RS-232 Optical Isolator CardDocumento2 pagineEST2 RS-232 Optical Isolator CardDavid TieuNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- SW EotE Gear CardsDocumento4 pagineSW EotE Gear Cardsgr1bble100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- 02 05 PDFDocumento177 pagine02 05 PDFImagex Raios xNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Pec Answers 701 To 800Documento7 paginePec Answers 701 To 800RICHARD BARGONessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Electricity - Level 5 - QuestionsDocumento19 pagineElectricity - Level 5 - QuestionsThe PassionNessuna valutazione finora

- PEO Soldier Portfolio FY2012Documento298 paginePEO Soldier Portfolio FY2012Nickchios100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Power System Protection QPDocumento2 paginePower System Protection QPmaniNessuna valutazione finora

- Split Type Air Conditioner: Models Indoor Unit Outdoor UnitDocumento17 pagineSplit Type Air Conditioner: Models Indoor Unit Outdoor Unitbigor2Nessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- 688 Level Switch For Pressure Vessels Up To 2000 Psig: SeriesDocumento2 pagine688 Level Switch For Pressure Vessels Up To 2000 Psig: SeriesDante Cabrera GuzmanNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Taylor's Firearm Mini Catalog 2022Documento2 pagineTaylor's Firearm Mini Catalog 2022albazabduNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Service Manual - Lid45w13n (7312d)Documento37 pagineService Manual - Lid45w13n (7312d)jupecas matosinhosNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Input, Output Devices - AssignmentDocumento16 pagineInput, Output Devices - AssignmentZacardious DhanrajNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Datasheet Hanersun 585WDocumento2 pagineDatasheet Hanersun 585WAlexandre VieiraNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- Tma - Installation Instruction PDFDocumento14 pagineTma - Installation Instruction PDFRaimundo MouraNessuna valutazione finora

- Ul 62368 - 2014Documento116 pagineUl 62368 - 2014mstampekNessuna valutazione finora

- Nissan 370Z BCSDocumento85 pagineNissan 370Z BCSHendrick Cepeda0% (1)

- PriceListHirePurchase NormalDocumento51 paginePriceListHirePurchase NormalMuhammad AtifNessuna valutazione finora

- ECP Safe T Pull SSB-DIP (2019)Documento2 pagineECP Safe T Pull SSB-DIP (2019)Guang ChenzNessuna valutazione finora

- 2003 Taurus Catalog Pages SMDocumento9 pagine2003 Taurus Catalog Pages SMmfNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Handbook in Rigging and LiftingDocumento50 pagineHandbook in Rigging and LiftingGunawan Hagun100% (2)

- Differential Pressure Control, Types MP 54, MP 55 and MP 55ADocumento8 pagineDifferential Pressure Control, Types MP 54, MP 55 and MP 55AMilosgl100% (1)

- Prince Prince Prince Prince Prince: Pressure SwitchesDocumento2 paginePrince Prince Prince Prince Prince: Pressure Switchesersanjeeb_456100% (1)

- Parts list with stock detailsDocumento2 pagineParts list with stock detailsSoroj BiswasNessuna valutazione finora

- What Is A Search and Rescue Transponder (SART)Documento4 pagineWhat Is A Search and Rescue Transponder (SART)Ertan KoseNessuna valutazione finora

- GURPS Armas de Fogo NT8+Documento2 pagineGURPS Armas de Fogo NT8+Guilherme PanseriniNessuna valutazione finora

- S-AAA-ELMS-CRANE (Rev.0-2015)Documento7 pagineS-AAA-ELMS-CRANE (Rev.0-2015)Swathish SivaprasadNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)