Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Discharge Capacity Check

Caricato da

kolioskiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Discharge Capacity Check

Caricato da

kolioskiCopyright:

Formati disponibili

Using Darcy-Weisbach

2

2 5 4

8

f

l

Q L K

h

g D D t

( | | | |

= +

| |

(

\ . \ .

5 4

8 f

l

g h

Q

L K

D D

t =

( | | | |

+

| |

(

\ . \ .

f l m i nor

h h h = +

4 2

2

8

D g

Q

K h

minor

t

=

2

2 5

8

f

f

L Q

h

g D t

=

2

2 5 4

8

f

l

Q L K

h

g D D t

( | | | |

= +

| |

(

\ . \ .

5 4

8 f

l

g h

Q

L K

D D

t =

( | | | |

+

| |

(

\ . \ .

2

2 5

8

f

f

L Q

h

g D t

=

The friction factor doesnt vary greatly

If Q is known assume f is 0.02, if D is known

assume rough pipe law

Use Darcy Weisbach and minor loss equations

Solve for Q or D

Calculate Re and c/D

Find new f on Moody diagram

Iterate

The friction factor doesnt vary greatly

If Q is known assume f is 0.02, if D is known

assume rough pipe law

Use Darcy Weisbach and minor loss equations

Calculate Re and c/D

Find new f on Moody diagram

1 3 . 7

2 lo g

f

D

c

| |

=

|

\ .

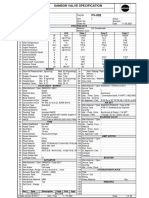

DATA INPUT

Kb

0

o

rad 0.131 x q

0.660

Weir 0 903.29 0 0.00 0.00000

0+100 10.00 676.73 16.00 0.28 0.05645

0+200 12.00 676.46 8.00 0.14 0.03572

0+300 24.00 676.19 42.00 0.73 0.10672

0+400 6.40 675.92 36.00 0.63 0.09640

0+500 5.00 675.65 53.00 0.93 0.12443

0+600 7.40 892.06 53.00 0.93 0.12443

Total Length 2435.06 0.54415

Total Kb = 0.54

Select Entrance type Perpendicular square Entrance

Entrance Loss, Ki = 0.5

Select Outlet Type Submerge outlet

Outlet Loss, Ko = 1

Losses due to sudden contractions

D

1

/D

2

1.0 1.5 2.0 2.5

Kc 0 0.25 0.35 0.40

Where D

1

/D

2

is the ratio of the larger diameter to that of the smaller diameter

If D

1

/D

2

is not found in the table

By interpolation

D

1

= 1.86

D

2

= 1.86

D

1

/D

2

Kc

Higher value 1.5 0.25

Your value 1 0

Lower value 1 0

D

1

= 1.86

D

2

= 1.86

D

1

/D

2

Kc

Higher value 1.5 0.25

Your value 1 0

Lower value 1 0

Sudden Contraction

Loss, Kc = 0

Losses through fully opened valves

Select Type of Valve GATE

Kv = 0.1

Total Value of K = 2.14

Minor Headloss Coefficient Computation

Point Location Elevation

Deflection angle

Pipe length

SOURCE OF INFORMATION

"Study of Bend Losses in Large Pipes" (SML)

From AWWA M11 Manual:

Inlet losses

Perpendicular square Entrance 0.5

Inward Projecting Inlet 0.8

Slightly Rounded 0.2

Bell Mouth Inlet 0.1

Outlet loss

Submerge outlet 1 `

Drop outlet 0

Losses through fully opened valves

TYPE Kv

SPHERICAL 0

GATE 0.1

BUTTERFLY

(t/D = 0.2) 0.3

Minor Headloss Coefficient Computation

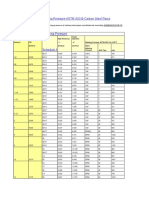

Inputs: Source of Information:

Diameter 1.61 m

Water Level at Desander 903.29 mASL

Headrace Pipe Top Elevation 892.06 mASL

Pipe Length, L 2,435.06 m

Headloss 11.23 m

Gravitational acceleration, g 9.810 m

2

/s

Pipe Centerline at Surgetank 889.833 mASL

Pipe submergence 1.48 m

Calculation:

A.1 Assume Turbulent flow, compute for f:

Pipe Roughness, 2.5000 mm

Friction factor, f 0.1286 m

Minor Headloss Coefficient, K 14.45

(K/D

4

) 2.15 m 3.40

(fL/D

5

) 28.95 m 7.8273562

Actual Headloss, Hl

actual

11.23 m 11.229981

Discharge Capacity 2.090530876 m

3

/s

Velocity 1.026868786 m/s

A.2 Compute final friction factor using initial diameter:

Kenimatic Viscocity 0.000001007 m

2

/s

Reynolds Number 1,641,766.38

Type of Flow Turbulent

New Friction Factor 0.021977844

A.3 Recompute final diameter using new friction factor:

(fL/D

5

) 4.95 m

Dischargecap 4.38 m

Velocity, V 2.149426576 m/s

Pipe Roughness, 0.0025 m

Pipe Length, L 2,435.06 m

Minor Headloss, hm 3.40 m

Friction Headloss, hf 7.83 m

Friction Loss, Hlactual 11.23 m

Reynolds Number, Re 3,433,455.37

Friction Factor, f 0.02202

Discharge Capacity 4.37 m

3

/s

Velocity, V 2.15 m/s

Checking Swamee-Jain Limits:

Check: /D 0.001552795 >> OK 10

-6

< /D < x10

-2

Check: Re 3,433,455.4 >> OK 5000<Re<10

8

A. Darcy-Weisbach Equation:

B. Swamee-Jain Equation:

Discharge Computation

Goal Seek

From To From To

Brass and Glass pipe 0.009 0.013 0.009 0.011

Asbestos-cement pipe 0.010 0.012

Wrought-iron and weleded steel pipe 0.010 0.014 0.011 0.013

Wood stave pipe 0.010 0.014 0.011 0.013

Clean cast-iron pipe 0.010 0.015 0.011 0.013

Concrete pipe 0.010 17.000

very smooth 0.011 0.012

"wet mix", steel forms 0.012 0.014

"dry mix", rough forms 0.015 0.016

with rough joints 0.016 0.017

Common-clay drainage tile 0.011 0.017 0.012 0.014

Vitrified sewer pipe 0.010 0.017 0.013 0.015

Riveted-steel pipe 0.013 0.017 0.015 0.017

Dirty or tuberculated cast-iron pipe 0.015 0.035

Corrugated-iron pipe 0.020 0.022

pg 199.., HYDRAULICS By H.W. King, C.O. Wisler, J.G. Woodburn

Viscocity Table

Type of channel and description Min. Normal Max. T

A. Closed conduits flowing partly full 0

A-1. Metal 5

a. Brass, smooth 0.009 0.010 0.013 10

b. Steel 15

1. Lockbar and welded 0.010 0.012 0.014 20

2. Riveted and spiral 0.013 0.016 0.017 25

c. Cast-iron 30

1. Coated 0.010 0.013 0.014 35

2. Uncoated 0.011 0.014 0.016 40

d. Wrought iron 45

1. Black 0.012 0.014 0.015 50

2. Galvanized 0.013 0.016 0.017 55

e. Corrugated metal 60

1. Subdrain 0.017 0.019 0.021 65

2. Strom drain 0.021 0.010 0.030 70

75

80

85

90

95

100

References

Grade Input Values

Values of n to Be used with the Manning Formula

Values of the Roughness Coefficient, n (Chow, 1959)

Kind of Pipe

Variation Use in Designing

ASTM Material Designation Grade Minimum

Yield

Strength

ksi (MPa)

Minimum

Tensile

Strength

ksi (MPa)

A139 B 35 (242) 60 (415) B

C 42 (290) 60 (415) C

D 46 (315) 60 (415) D

E 52 (360) 66 (455) E

55

A36/A36M 36 (248) 58 (400) 60

A516/A516M 55 30 (205) 55 (380) 65

60 32 (220) 60 (415) 70

65 35 (240) 65 (450)

70 38 (260) 70 (485)

Steel Sheet (Flat Coil)

Steel Plate

Moody Diagram

Viscocity Table

kinematic viscosity (m

2

/s)

0.000001792

0.000001519

0.000001308

0.000001141

0.000001007

0.000000897

0.000000804

0.000000727

0.000000661

0.000000605

0.000000556

0.000000513

0.000000477

0.000000444

0.000000415

0.00000039

0.000000367

0.000000347

0.000000328

0.000000311

0.000000296

References

Potrebbero piacerti anche

- Sizing Calculation FCVDocumento3 pagineSizing Calculation FCVYawar QureshiNessuna valutazione finora

- 5 3 17Documento14 pagine5 3 17Raymond de WeeverNessuna valutazione finora

- High Pressure Flange Design 236313199Documento133 pagineHigh Pressure Flange Design 236313199Karthikeyan VisvakNessuna valutazione finora

- Samson Valve Specification: Process DataDocumento49 pagineSamson Valve Specification: Process DataMuhammed TamerNessuna valutazione finora

- 6 23 0Documento13 pagine6 23 0hlagos123Nessuna valutazione finora

- Valve Sizing Calculation Sheet: Version: V3.1.0 Date: 20/01/2016Documento4 pagineValve Sizing Calculation Sheet: Version: V3.1.0 Date: 20/01/2016JOSE MARTIN MORA RIVEROSNessuna valutazione finora

- Old Noise ManualDocumento28 pagineOld Noise ManualChristo KellermanNessuna valutazione finora

- Ballot Fugitive Emission TestsDocumento33 pagineBallot Fugitive Emission TestsMemoNessuna valutazione finora

- Analisis of Stress in BellowsDocumento101 pagineAnalisis of Stress in BellowsOswaldo GuerraNessuna valutazione finora

- Control Valve Sizing - Steam or Vapor Rev 2Documento2 pagineControl Valve Sizing - Steam or Vapor Rev 2dilip matalNessuna valutazione finora

- Surge CalculationsDocumento7 pagineSurge CalculationsSameer MinhajNessuna valutazione finora

- NaturalConvectionHeatTransferCoefficients SI Units Final ProtectedDocumento44 pagineNaturalConvectionHeatTransferCoefficients SI Units Final ProtectedFabio MiguelNessuna valutazione finora

- Orifice SizingDocumento1 paginaOrifice SizingMarco D'OnofrioNessuna valutazione finora

- Nonboiling Liq Outflow F Vertical Cyl VesselDocumento26 pagineNonboiling Liq Outflow F Vertical Cyl VesselSrihari KodimelaNessuna valutazione finora

- Calculate Pressure Drop in Basket & Tee Strainers ReferenceDocumento5 pagineCalculate Pressure Drop in Basket & Tee Strainers Referencebrock100% (1)

- Pressure DropDocumento19 paginePressure DropGigis Kintan MyarthalunaNessuna valutazione finora

- Orifice PlatesDocumento20 pagineOrifice PlatesAntonio GallegosNessuna valutazione finora

- Current BrochureDocumento41 pagineCurrent BrochureArlanNessuna valutazione finora

- Firsa Catalog 2009Documento53 pagineFirsa Catalog 2009alankar2050Nessuna valutazione finora

- Control Valve Sizing 1Documento23 pagineControl Valve Sizing 1Enerprec SASNessuna valutazione finora

- Calculation of Orifice CoefficientDocumento18 pagineCalculation of Orifice Coefficientvinayjoshi270586Nessuna valutazione finora

- Pipeline Size CalculationDocumento6 paginePipeline Size CalculationharyjbiNessuna valutazione finora

- Engineering Services by KBR Technical Services, IncDocumento12 pagineEngineering Services by KBR Technical Services, IncgfgfNessuna valutazione finora

- Pipe Size CalculationDocumento22 paginePipe Size CalculationShaik FaridhNessuna valutazione finora

- Pipe SizeDocumento9 paginePipe SizezniperxNessuna valutazione finora

- Flow Calculation: II. Constants I. Flow EquationDocumento1 paginaFlow Calculation: II. Constants I. Flow EquationAndrey Pachón FrancoNessuna valutazione finora

- 17-1cs-Normal Tightening and Loosening of Flange BoltsDocumento3 pagine17-1cs-Normal Tightening and Loosening of Flange Boltsyulianus_sr100% (1)

- Sizing of Control Valves For Non-Turbulent Flow (Laminar and Transitional)Documento14 pagineSizing of Control Valves For Non-Turbulent Flow (Laminar and Transitional)JOSE MARTIN MORA RIVEROSNessuna valutazione finora

- IEC Aero Noise Mass 4C R2Documento23 pagineIEC Aero Noise Mass 4C R2JeromeNessuna valutazione finora

- 2 Inch OutputPCVDocumento1 pagina2 Inch OutputPCVDuy Nguyễn VănNessuna valutazione finora

- Orifice Plate Sizing CalculatorDocumento11 pagineOrifice Plate Sizing Calculatormyself_riteshNessuna valutazione finora

- Maximum Working Pressure-ASTM A53 B Carbon Steel PipesDocumento2 pagineMaximum Working Pressure-ASTM A53 B Carbon Steel PipesBFEVietnamNessuna valutazione finora

- Calculs CV & KVDocumento13 pagineCalculs CV & KVradiopascalgeNessuna valutazione finora

- Dike Wall Height Calculation Sheet (For SYMMETRICAL TANKS)Documento7 pagineDike Wall Height Calculation Sheet (For SYMMETRICAL TANKS)Saqib LaeeqNessuna valutazione finora

- Valve Failure ConsequencesDocumento10 pagineValve Failure ConsequencesThomas MazzoleniNessuna valutazione finora

- Analytical Considerations The Code Qualification Piping SystemsDocumento17 pagineAnalytical Considerations The Code Qualification Piping SystemsMahendra RathoreNessuna valutazione finora

- Ancor Flanges Asme Viii PDFDocumento3 pagineAncor Flanges Asme Viii PDFLizbeth Fiallos AvilaNessuna valutazione finora

- DOT Pipeline SpecificationsDocumento20 pagineDOT Pipeline Specificationssect349Nessuna valutazione finora

- AERODYNAMIC NOISE Worksheet InstructionsDocumento6 pagineAERODYNAMIC NOISE Worksheet InstructionsMuhammad Adil KhanNessuna valutazione finora

- Hdpe Wall Thick ChartDocumento3 pagineHdpe Wall Thick ChartSushil GambhirNessuna valutazione finora

- Z - Peng RobinsonDocumento1 paginaZ - Peng RobinsonMuhammadTanzeeLUsmanNessuna valutazione finora

- Press "CTRL+M" To Calculate C: Calculation of Theoretical Orifice Flow and C For Sharp Edged OrificeDocumento14 paginePress "CTRL+M" To Calculate C: Calculation of Theoretical Orifice Flow and C For Sharp Edged Orificehardik033Nessuna valutazione finora

- Orifice Calculation Sheet Service Fluid Oxygen: G Mass Flow RateDocumento2 pagineOrifice Calculation Sheet Service Fluid Oxygen: G Mass Flow RateGovind RaoNessuna valutazione finora

- Volum Water HydrotestDocumento2 pagineVolum Water HydrotestFerinoviardi100% (1)

- Fluid Engineering Flow in P.Documento6 pagineFluid Engineering Flow in P.sunilkumar2685Nessuna valutazione finora

- Fisher Et Valve Manual December 2010Documento36 pagineFisher Et Valve Manual December 2010LeonardNessuna valutazione finora

- Line Single PhaseDocumento2 pagineLine Single PhasehussamNessuna valutazione finora

- Relief 5Documento5 pagineRelief 5Mo ZeroNessuna valutazione finora

- Control Valve Sizing - Gas Rev 2aDocumento2 pagineControl Valve Sizing - Gas Rev 2aMahmoud ShaheenNessuna valutazione finora

- Deu PointDocumento2 pagineDeu PointP.S.J.SarmaNessuna valutazione finora

- Orifice Calc Gas Rev 0Documento1 paginaOrifice Calc Gas Rev 0edufragaNessuna valutazione finora

- Elementary Mechanics of Fluids: Flow in PipesDocumento23 pagineElementary Mechanics of Fluids: Flow in PipesAndre Amba MatarruNessuna valutazione finora

- Viscous Flow in Pipes: CEE 331 Fluid Mechanics March 11, 2014Documento40 pagineViscous Flow in Pipes: CEE 331 Fluid Mechanics March 11, 2014Paulo BuenoNessuna valutazione finora

- Hydraulics 6713 Tutorials and SolutionsDocumento42 pagineHydraulics 6713 Tutorials and SolutionsAsun RajaNessuna valutazione finora

- Ch8 Steady Incompressible Flow in Pressure Conduits (PartB)Documento66 pagineCh8 Steady Incompressible Flow in Pressure Conduits (PartB)avinash_friends21Nessuna valutazione finora

- Indo 1Documento29 pagineIndo 1Michael TinambunanNessuna valutazione finora

- Major Losses in PipesDocumento7 pagineMajor Losses in PipesMd. Tariqul Islam MunnaNessuna valutazione finora

- Calculation Pressure DropDocumento9 pagineCalculation Pressure DropdasubhaiNessuna valutazione finora

- Friction Loss CalculationDocumento50 pagineFriction Loss CalculationDhruv RamaniNessuna valutazione finora

- Hydraulic Calculations Safe RainDocumento20 pagineHydraulic Calculations Safe RainCastherperConsultoríaEnConstrucciónNessuna valutazione finora

- LubricantsDocumento42 pagineLubricantsNo Mercy GamingNessuna valutazione finora

- Applications in Convective Heat Transfer With Emphasis On Blade Cooling Flows Part I, Background & MethodologiesDocumento26 pagineApplications in Convective Heat Transfer With Emphasis On Blade Cooling Flows Part I, Background & MethodologiesDhesa HidayatNessuna valutazione finora

- מספרים חסרי מימדDocumento1 paginaמספרים חסרי מימדA.b Te'enaNessuna valutazione finora

- Norpar Pipenet PresentationDocumento35 pagineNorpar Pipenet PresentationTON0% (1)

- Hydro GraphDocumento52 pagineHydro GraphSamer ElabdNessuna valutazione finora

- Orifice, Nozzle and Venturi Flow Rate MetersDocumento9 pagineOrifice, Nozzle and Venturi Flow Rate MetersDian Ahmad HapidinNessuna valutazione finora

- Saturations: Lecture 5: Microscopic Displacement in Porous Media (Part 1)Documento34 pagineSaturations: Lecture 5: Microscopic Displacement in Porous Media (Part 1)Faraj NabiyevNessuna valutazione finora

- I. Fittings Input: Spreadsheet Calculation of Pressure Drop in Open or Single-Loop Hydraulic SystemsDocumento5 pagineI. Fittings Input: Spreadsheet Calculation of Pressure Drop in Open or Single-Loop Hydraulic SystemskakoullisgNessuna valutazione finora

- CD 33 FDocumento7 pagineCD 33 FGrecella Marliyani SinagaNessuna valutazione finora

- Tut 1Documento2 pagineTut 1wilson0% (1)

- Ihp Microproject 2Documento38 pagineIhp Microproject 2Vishal SahaneNessuna valutazione finora

- Multiphase Well Testing SolutionsDocumento22 pagineMultiphase Well Testing SolutionsSlim.BNessuna valutazione finora

- BNP 20103 Ex 3Documento6 pagineBNP 20103 Ex 3aoi_chiepNessuna valutazione finora

- Assignment 2 - Head and Fluid FlowDocumento3 pagineAssignment 2 - Head and Fluid FlowRN Builder IpohNessuna valutazione finora

- ENV315 - Online Air Pollution Control Lecture 12Documento35 pagineENV315 - Online Air Pollution Control Lecture 12Samim JubayerNessuna valutazione finora

- Yokogawa - PMCA - FlowDocumento42 pagineYokogawa - PMCA - Flowhon choong chongNessuna valutazione finora

- WWW - Vidyarthiplus.In: Fluid Mechanics and Machinery Lab - Viva QuestionDocumento3 pagineWWW - Vidyarthiplus.In: Fluid Mechanics and Machinery Lab - Viva QuestionAkash Kumar DevNessuna valutazione finora

- Chap 9 Differential Analysis of Fluid Flow - CompleteDocumento70 pagineChap 9 Differential Analysis of Fluid Flow - CompleteMusa Van SarNessuna valutazione finora

- CVEN 3323 Weirs LabDocumento5 pagineCVEN 3323 Weirs LabJJ Sean CruzNessuna valutazione finora

- Combined Transient Analysis Report 04092017Documento19 pagineCombined Transient Analysis Report 04092017imamtaNessuna valutazione finora

- WQ2 Current Status and Water Production OverviewDocumento16 pagineWQ2 Current Status and Water Production Overviewحسين رامي كريم A 12Nessuna valutazione finora

- ESO204 TEXT Book PDFDocumento516 pagineESO204 TEXT Book PDFshubhi kesarwaniNessuna valutazione finora

- Microemulsion Utility in Pharmaceuticals - Implications For Multi-Drug Delivery PDFDocumento18 pagineMicroemulsion Utility in Pharmaceuticals - Implications For Multi-Drug Delivery PDFAnonymous nioO6GQxlNessuna valutazione finora

- Hydraulic Machines TextbookDocumento370 pagineHydraulic Machines TextbookAli HegaigNessuna valutazione finora

- HydrodynamicsDocumento122 pagineHydrodynamicsIustin Cristian100% (2)

- Autocad Aca User Guide SpanishDocumento554 pagineAutocad Aca User Guide Spanishjol87Nessuna valutazione finora

- 41 - Southern Cross - Iso Pump - 125 X 100 - 315 - 1450-2980 RPMDocumento1 pagina41 - Southern Cross - Iso Pump - 125 X 100 - 315 - 1450-2980 RPMAndreas B KresnawanNessuna valutazione finora

- Analysis of Flow Around A Ship Propeller Using OpenFOAMDocumento60 pagineAnalysis of Flow Around A Ship Propeller Using OpenFOAMbinho58Nessuna valutazione finora