Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

THPS 75

Caricato da

dalton2003Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

THPS 75

Caricato da

dalton2003Copyright:

Formati disponibili

THPS 75%

MOT 7175 Iron Sulfide Reduction/Cleaner

Physical Properties Specific Gravity 1.37+/-.03 Bulk Density 11.3 lbs./gal. Form Liquid Color Colorless Odor Characteristic pH 3.2+/-1.0 Solubility Soluble in water Flash Point (F) N/A Freeze Point (F) -45F Boiling Point 226F

Product Description MOT 7175 is a multifunctional product used in the oil producing and refining industry. This product is excellent for dissolving iron sulfide deposits. Significant cost reductions can be achieved by applying this product in the oil drilling and refining industry. MOT 7175 combines with problematic FeS to form soluble and stable complexes without releasing hydrogen sulfide gas or colloidal sulfur. This product is effective in controlling sulfate reducing bacteria that cause down hole souring and the generation of hydrogen sulfide, a flammable, corrosive and toxic gas. This product is very effective in controlling sulfate reducing bacteria in cooling water systems. Feed Method This product can be fed directly from the container. For oil field applications the feed rates will vary. Initial shock treatment can range from 70 to 700 ppm with subsequent dosages of 30 to 200 ppm, drilling muds from 70 to 3000 ppm, oil and gas pipelines typically at 10 to 70 ppm.

MOT 7175 Iron Sulfide Reduction/Cleaner

Physical Properties Specific Gravity 1.37+/-.03 Bulk Density 11.3 lbs./gal. Form Liquid Color Colorless Odor Characteristic pH 3.2+/-1.0 Solubility Soluble in water Flash Point (F) N/A Freeze Point (F) -45F Boiling Point 226F

Product Description

MOT 7175 is a multifunctional product used in the oil producing and refining industry. This product is excellent for dissolving iron sulfide deposits. Significant cost reductions can be achieved by applying this product in the oil drilling and refining industry. MOT 7175 combines with problematic FeS to form soluble and stable complexes without releasing hydrogen sulfide gas or colloidal sulfur. This product is effective in controlling sulfate reducing bacteria that cause down hole souring and the generation of hydrogen sulfide, a flammable, corrosive and toxic gas. This product is very effective in controlling sulfate reducing bacteria in cooling water systems. Feed Method This product can be fed directly from the container. For oil field applications the feed rates will vary. Initial shock treatment can range from 70 to 700 ppm with subsequent dosages of 30 to 200 ppm, drilling muds from 70 to 3000 ppm, oil and gas pipelines typically at 10 to 70 ppm. Special Information This product is very user and environmentally friendly in that it biodegrades to inert components and upon discharge it degrades to environmentally benign products. First Aid Procedures Eyes: Flush immediately with large amounts of water for 15 minutes and get immediate medical attention. Skin: Wash with soap and water, remove contaminated clothing, and get medical attention. Prolonged contact may cause allergic reactions in some individuals. Swallowed: Promptly drink large quantities of water. Do not induce vomiting, avoid alcohol, and contact a physician immediately. Special Information This product is very user and environmentally friendly in that it biodegrades to inert components and upon discharge it degrades to environmentally benign products. First Aid Procedures Eyes: Flush immediately with large amounts of water for 15 minutes and get immediate medical attention. Skin: Wash with soap and water, remove contaminated clothing, and get medical attention. Prolonged contact may cause allergic reactions in some individuals.

Swallowed: Promptly drink large quantities of water. Do not induce vomiting, avoid alcohol, and contact a physician immediately.

Potrebbero piacerti anche

- Biogas Plant: Biogas Digester Design, Gas Production and PurificationDa EverandBiogas Plant: Biogas Digester Design, Gas Production and PurificationValutazione: 3 su 5 stelle3/5 (1)

- BIOCOR 7175 Iron Sulfide Reduction/Cleaner: Physical PropertiesDocumento4 pagineBIOCOR 7175 Iron Sulfide Reduction/Cleaner: Physical Propertiesdalton2003Nessuna valutazione finora

- Technical Data Sheet: Trichrome HB 1700Documento3 pagineTechnical Data Sheet: Trichrome HB 1700LuuThiThuyDuongNessuna valutazione finora

- Technical Bulletin: Sodium Metabisulfite (SMBS)Documento2 pagineTechnical Bulletin: Sodium Metabisulfite (SMBS)மதன் குமார்.மNessuna valutazione finora

- CatalogDocumento26 pagineCatalogJonny DenNessuna valutazione finora

- Oxygen Control 25 LTRDocumento2 pagineOxygen Control 25 LTRPlinio José Gálvez PerníaNessuna valutazione finora

- Sodium HypochloriteDocumento7 pagineSodium HypochloriteEdison Cheong100% (1)

- Heavy Duty Powdered Detergent: Big BiteDocumento1 paginaHeavy Duty Powdered Detergent: Big BiteAsimNessuna valutazione finora

- Gardobond 159 M: Technical Service Data SheetDocumento3 pagineGardobond 159 M: Technical Service Data SheetSamNessuna valutazione finora

- Orgastab SWL: Technical Data SheetDocumento2 pagineOrgastab SWL: Technical Data SheetxbaakNessuna valutazione finora

- Gardobond® G 4098/10: ScopeDocumento5 pagineGardobond® G 4098/10: ScopeAhmed OusamaNessuna valutazione finora

- DuPont Oil Well Productivity GlicolicoDocumento12 pagineDuPont Oil Well Productivity GlicolicoFederico ArqueroNessuna valutazione finora

- Bright Acid Copper For Wire and Grounding Rods: E-Brite 202GDocumento6 pagineBright Acid Copper For Wire and Grounding Rods: E-Brite 202GUsman ali Cheema100% (1)

- WTP CD1000Documento2 pagineWTP CD1000alexNessuna valutazione finora

- MTBE-Data and Safety SheetDocumento5 pagineMTBE-Data and Safety SheetDr.AhmedNessuna valutazione finora

- Stabilol PDocumento2 pagineStabilol PMuhammad Aasim HassanNessuna valutazione finora

- Crystal Cut 322 BACDocumento2 pagineCrystal Cut 322 BACMiguel Lobos CofreNessuna valutazione finora

- Du-Zinc 019Documento7 pagineDu-Zinc 019KaRenthLuNaNessuna valutazione finora

- DURFERRIT2Documento22 pagineDURFERRIT2Kyle BennettNessuna valutazione finora

- Technical Data Sheet: Goldbond TNDocumento3 pagineTechnical Data Sheet: Goldbond TNCicero Gomes de SouzaNessuna valutazione finora

- Cipton VC11- Giới ThiệuDocumento2 pagineCipton VC11- Giới ThiệuTâm TrươngNessuna valutazione finora

- SorbitolDocumento9 pagineSorbitolPanneerselvam DhanushkodiNessuna valutazione finora

- TDS No 520BDocumento2 pagineTDS No 520Bhyeryeon ohNessuna valutazione finora

- TDS No 30Documento2 pagineTDS No 30Sasitharan YellapanNessuna valutazione finora

- Tissocyl RLBDocumento2 pagineTissocyl RLBRezoanul Haque100% (1)

- Blue GoldDocumento9 pagineBlue GoldDinesh RajNessuna valutazione finora

- Natech Kolseal MO2Documento8 pagineNatech Kolseal MO2marlon_3gsNessuna valutazione finora

- Boiler Sludge Conditioner PDFDocumento2 pagineBoiler Sludge Conditioner PDFShashi Naganur100% (1)

- Rossari Biotech Limited-Company ProfileDocumento17 pagineRossari Biotech Limited-Company ProfileGajendra SharmaNessuna valutazione finora

- Preservatives For Hair Products and Cosmetics - IngreCoreDocumento23 paginePreservatives For Hair Products and Cosmetics - IngreCorekh.srm.ukNessuna valutazione finora

- Divoflow 185 enDocumento2 pagineDivoflow 185 enHau SinâuđaNessuna valutazione finora

- TDS PippoDocumento3 pagineTDS PippoAzizMitraNessuna valutazione finora

- 9zero Liquid Discharge Plant - Multiple Effect Evaporator-Khatav PDFDocumento29 pagine9zero Liquid Discharge Plant - Multiple Effect Evaporator-Khatav PDFहरिओम हरी100% (2)

- Met-Kleen 140 (7.8.13)Documento1 paginaMet-Kleen 140 (7.8.13)tribolasNessuna valutazione finora

- Formulating-Cleaning Products High Performing Vehicle Shampoos CleanersDocumento8 pagineFormulating-Cleaning Products High Performing Vehicle Shampoos CleanersAnh HoangNessuna valutazione finora

- BROSUR DG-Boiller TreatmentDocumento8 pagineBROSUR DG-Boiller TreatmentGerry HandoyoNessuna valutazione finora

- Manufacture of Alpha Olefin Sulphonate 3Documento22 pagineManufacture of Alpha Olefin Sulphonate 3Hari Om Kumar VNessuna valutazione finora

- Safety Data Sheet: JohnsondiverseyDocumento2 pagineSafety Data Sheet: JohnsondiverseySteve ForsterNessuna valutazione finora

- LABSA ProposalDocumento10 pagineLABSA ProposalMichelle MendozaNessuna valutazione finora

- Acid Thickener Tech DataDocumento3 pagineAcid Thickener Tech Dataanneleiaaa62% (21)

- Aquacid 1054 DataSheetDocumento2 pagineAquacid 1054 DataSheetArgentus Asesorías QuímicasNessuna valutazione finora

- Enzyme Treatment For Polluted WaterDocumento46 pagineEnzyme Treatment For Polluted WaterTuanNessuna valutazione finora

- Aluminium ChlorohydrateDocumento2 pagineAluminium ChlorohydrateAnandNessuna valutazione finora

- Bisulphite 25 LTR Liquid 38-40%Documento2 pagineBisulphite 25 LTR Liquid 38-40%Eliete ArrudaNessuna valutazione finora

- "We Take Care of Your and Your Emoloyees' Health!": Aliquo IndustrialDocumento6 pagine"We Take Care of Your and Your Emoloyees' Health!": Aliquo IndustrialMilan JovanovicNessuna valutazione finora

- (Chemistry Drugs Poisons) Homemade Cyanide and RicinDocumento7 pagine(Chemistry Drugs Poisons) Homemade Cyanide and Ricinapi-3699610100% (9)

- Cyanide and Ricin Homemade PDFDocumento7 pagineCyanide and Ricin Homemade PDFСергей ЯрмолаNessuna valutazione finora

- Blue Sapphire Information and Directions of Use-1Documento10 pagineBlue Sapphire Information and Directions of Use-1glorongaiNessuna valutazione finora

- DOALL-MSDS F KleenKoolDocumento6 pagineDOALL-MSDS F KleenKoolJAY CORTEZ MAMABICHONessuna valutazione finora

- Technical Data Sheet: Trichrome HB 1700 TDocumento3 pagineTechnical Data Sheet: Trichrome HB 1700 TLuuThiThuyDuong100% (1)

- CHEMICAL - Golden Tower - Cambodia - COMIN 0208Documento9 pagineCHEMICAL - Golden Tower - Cambodia - COMIN 0208Abdulvasea SaaitNessuna valutazione finora

- Tile and Grout CleanerDocumento6 pagineTile and Grout CleanerKalai Selvan100% (2)

- PT025Documento2 paginePT025RASHID SHAMIMNessuna valutazione finora

- Specialty Clarification & Coagulation Solutions: Chemistry For A Greener WorldDocumento6 pagineSpecialty Clarification & Coagulation Solutions: Chemistry For A Greener Worldnithinc10100% (1)

- Antifoulant and BiodispersantDocumento1 paginaAntifoulant and BiodispersantsourajpatelNessuna valutazione finora

- Manual of Formulas - Recipes, Methods & Secret ProcessesDa EverandManual of Formulas - Recipes, Methods & Secret ProcessesValutazione: 4.5 su 5 stelle4.5/5 (2)

- Everyday Natural Cleaning Solutions: Innovative Green Cleaning Recipes And Tips For Your HomeDa EverandEveryday Natural Cleaning Solutions: Innovative Green Cleaning Recipes And Tips For Your HomeValutazione: 3 su 5 stelle3/5 (1)

- Organic and Sulfate Free Melt and Pour Glycerin Soap Crafting RecipesDa EverandOrganic and Sulfate Free Melt and Pour Glycerin Soap Crafting RecipesValutazione: 5 su 5 stelle5/5 (1)

- BT 35 PDFDocumento6 pagineBT 35 PDFdalton2003Nessuna valutazione finora

- PBDocumento6 paginePBdalton2003100% (1)

- Am Fsropro e Cell enDocumento2 pagineAm Fsropro e Cell endalton2003Nessuna valutazione finora

- BT 31Documento9 pagineBT 31dalton2003Nessuna valutazione finora

- PBDocumento6 paginePBdalton2003100% (1)

- BT 25Documento8 pagineBT 25dalton2003Nessuna valutazione finora

- Table To Play OutDocumento1 paginaTable To Play Outdalton2003Nessuna valutazione finora

- Water Treating Panel Discussion Monday, February 4, 2008 2:00p To 3:45pDocumento4 pagineWater Treating Panel Discussion Monday, February 4, 2008 2:00p To 3:45pdalton2003Nessuna valutazione finora

- BT 58Documento7 pagineBT 58dalton2003Nessuna valutazione finora

- Flocon 285Documento2 pagineFlocon 285dalton2003Nessuna valutazione finora

- 2011 Seminar EducationDocumento1 pagina2011 Seminar Educationdalton2003Nessuna valutazione finora

- Forugh Farrokhzad 2012 3Documento71 pagineForugh Farrokhzad 2012 3Eliana Galanda100% (1)

- Owner/Operator Seminar Tuesday, February 7, 10:00a - 2:00p (Lunch Will Be Included)Documento1 paginaOwner/Operator Seminar Tuesday, February 7, 10:00a - 2:00p (Lunch Will Be Included)dalton2003Nessuna valutazione finora

- 2006 Winter WT MinutesDocumento2 pagine2006 Winter WT Minutesdalton2003Nessuna valutazione finora

- Appendix: Ionization of CO Solutions As Function of TH PH at 25 CDocumento1 paginaAppendix: Ionization of CO Solutions As Function of TH PH at 25 Cdalton2003Nessuna valutazione finora

- Stabrom 909 MSDSDocumento6 pagineStabrom 909 MSDSdalton2003Nessuna valutazione finora

- CTSM 2 MSDS 1Documento2 pagineCTSM 2 MSDS 1dalton2003Nessuna valutazione finora

- EDTMP Na5Documento1 paginaEDTMP Na5dalton2003Nessuna valutazione finora

- BWA Belcor 575 Replaces Molybdate USA WF 0Documento2 pagineBWA Belcor 575 Replaces Molybdate USA WF 0dalton2003Nessuna valutazione finora

- Material Safety Data Sheet: U.S. Department of LaborDocumento2 pagineMaterial Safety Data Sheet: U.S. Department of Labordalton2003Nessuna valutazione finora

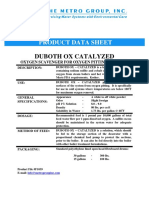

- Duboth OX Catalyzed - Product DataDocumento1 paginaDuboth OX Catalyzed - Product Datadalton2003Nessuna valutazione finora

- Onion Drying Using Catalytic Infrared Dryer PDFDocumento45 pagineOnion Drying Using Catalytic Infrared Dryer PDFSteve DennisNessuna valutazione finora

- O&M BW213dh, PDH, PDBH-3 10158027000 Up 00814011Documento102 pagineO&M BW213dh, PDH, PDBH-3 10158027000 Up 00814011Flavio VerNessuna valutazione finora

- Chanel ConnectivityDocumento15 pagineChanel ConnectivityAlfian AminNessuna valutazione finora

- How Sediment Filters WorkDocumento6 pagineHow Sediment Filters WorkWaleed EmaraNessuna valutazione finora

- Design of Contour Bunds - Runoff RatesDocumento6 pagineDesign of Contour Bunds - Runoff RatesClifford Ryan GalenzogaNessuna valutazione finora

- Unit 1 EnvironmentDocumento54 pagineUnit 1 EnvironmentRUSHIL SHAHNessuna valutazione finora

- Marine Engineering KnowledgeDocumento1.055 pagineMarine Engineering KnowledgebalajimeieNessuna valutazione finora

- Antox 71 E Plus: Safety Data SheetDocumento15 pagineAntox 71 E Plus: Safety Data SheetMohamed AdelNessuna valutazione finora

- Alpha Purified Water Refilling StationDocumento50 pagineAlpha Purified Water Refilling StationJong Dollente Jr.Nessuna valutazione finora

- Mech Conexiones RoscadasDocumento12 pagineMech Conexiones RoscadasGuillermo Catter FarroNessuna valutazione finora

- Viqua Sterilight Uv Disinfection SystemDocumento4 pagineViqua Sterilight Uv Disinfection SystemMuhammad EsamNessuna valutazione finora

- Self Curing and Self Compacted ConcreteDocumento64 pagineSelf Curing and Self Compacted ConcretedhwaniNessuna valutazione finora

- Quarter 4 Summative Test No.2Documento1 paginaQuarter 4 Summative Test No.2Krislyn Joy MalbataanNessuna valutazione finora

- APA Technical Note - Condensation Causes and ControlDocumento4 pagineAPA Technical Note - Condensation Causes and ControlLJD211Nessuna valutazione finora

- Garbera Flower Project Report SampleDocumento8 pagineGarbera Flower Project Report SampleVamshi KrishnaNessuna valutazione finora

- EcoGeo C 27.03.2013 English ManualDocumento106 pagineEcoGeo C 27.03.2013 English ManualBradz TalpoNessuna valutazione finora

- Inspection and Testing Program Fire Protection Equipment: A. Statement of ProblemDocumento12 pagineInspection and Testing Program Fire Protection Equipment: A. Statement of ProblemdinduntobzNessuna valutazione finora

- SEP Zooz: 401 "M" St. S.W. Waobin"",n, D.C. 20460Documento5 pagineSEP Zooz: 401 "M" St. S.W. Waobin"",n, D.C. 20460Zaenal Islam Abdul RochimNessuna valutazione finora

- The Effect of Fertilizer On Lead Resistance in Brassica RapaDocumento7 pagineThe Effect of Fertilizer On Lead Resistance in Brassica Rapaapi-300104326Nessuna valutazione finora

- Boat and StreamDocumento4 pagineBoat and StreamAllin 1Nessuna valutazione finora

- Final Communication Strategy Framework For ODMPDocumento39 pagineFinal Communication Strategy Framework For ODMPAse JohannessenNessuna valutazione finora

- 2.5 Best Available Techniques For The Production of Soda Ash by The Solvay ProcessDocumento4 pagine2.5 Best Available Techniques For The Production of Soda Ash by The Solvay ProcessSajjad Ahmed100% (1)

- L2 Soil Stress and Pore Water PressureDocumento17 pagineL2 Soil Stress and Pore Water PressureVinayaka Ram100% (3)

- Basic Principles of Landscape Design ReportDocumento34 pagineBasic Principles of Landscape Design ReporttejaswiniNessuna valutazione finora

- Assessment of Heavy Metals Concentration in Togona River of Goba Town Oromia RegionethiopiaDocumento8 pagineAssessment of Heavy Metals Concentration in Togona River of Goba Town Oromia RegionethiopiaTiruneh GANessuna valutazione finora

- Article 5 Normal Baseline: I. BaselinesDocumento7 pagineArticle 5 Normal Baseline: I. BaselinesKing BangngayNessuna valutazione finora

- Dam Removal Full ReportDocumento236 pagineDam Removal Full ReportArnab Nirendra GhoshNessuna valutazione finora

- 55-Offshore Wind Power BasicsDocumento38 pagine55-Offshore Wind Power BasicsYoyok SetyoNessuna valutazione finora

- Channel MaintenanceDocumento11 pagineChannel MaintenancenNessuna valutazione finora

- State of The Art Landfill Leachate PDFDocumento93 pagineState of The Art Landfill Leachate PDFPatricia SegoviaNessuna valutazione finora