Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Good Flat Slab Example Acc To EC2 (The Concrete Centre)

Caricato da

Nitish RamdaworTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Good Flat Slab Example Acc To EC2 (The Concrete Centre)

Caricato da

Nitish RamdaworCopyright:

Formati disponibili

71

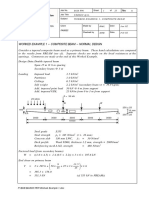

33 Cont|nuous r|||ed s|a|

The slab is for an ofce where the specied load is 1.0 kN/m

2

for

nishes and 4.0 kN/m

2

imposed (no partitions). Perimeter load is

assumed to be 10 kN/m. Concrete is C30/37. The slab is 300 mm

thick and columns are 400 mm square. The oor slabs are at 4.50 m

vertical centres. A 2 hour re rating is required.

E

D

C

A

4.0

8.0

9.6

200 x 200

hole

200 x 200

hole

300 mm flat slabs

All columns 400 mm sq.

8.6

8.0

4.0 4.0

6

.0

1

2

3

B Bb

Figure 3.18 Part plan of flat slab p

3.4.1 Actions

kN/m

2

Permanent:

EC1-1-1:

Table A1

Self-weight 0.30 25 = 7.5

Finishes = 1.0

Total g

k

= 8.5

Variable:

Offices j

k

= 4.0

Client requirement. See also BS EN 199111, Tables 6.1, 6.2, Cl. 6.3.2.1(8) & NA.

3.4 Flat slab

h|s examp|e |s or the des|gn o a re|norced concrete |at s|a| w|thout co|umn heads he s|a|

|s part o a |arger |oor p|ate and |s ta|en rom @nb]^mhma^]^lb`gZg]\hglmkn\mbhgh_k^bg_hk\^]

\hg\k^m^_eZmleZ[l

|2/|

, where |n|te e|ement ana|ys|s and des|gn to lurocode 2 |s |||ustrated As

w|th the @nb]^, gr|d ||ne C w||| |e des|gned |ut, or the sa|e o |||ustrat|on, coe|c|ents w||| |e

used to esta|||sh des|gn moments and shears |n th|s cr|t|ca| area o the s|a|

lro|ect deta||s

Ca|cu|ated |y chg o| no CCIP 041

Chec|ed |y web Sheet no 1

C||ent TCC Late Oct 09

Flat slab

72

3.4.2 Cover

c

nom

:

c

nom

= c

min

+ Dc

dev

where

c

min

= max[c

min,b

; c

min,dur

; 10 mm]

where

c

min,b

= 20 mm, assuming 20 mm diameter reinforcement

c

min,dur

= 15 mm for XC1 and using C30/37

Dc

dev

= 10 mm

Exp. (4.1)

Cl. 4.4.1.2(3)

Table 4.1.

BS 8500-1:

Table A4.

Fire:

For 2 hours resistance, a

min

= 35 mm = not critical

= c

nom

= 20 + 10 = 30 mm

EC2-1-2:

Table 5.9

3.4.3 Load combination and arrangement

q

k

= 4.0 kN/m

2

g

k

= 8.5 kN/m

2

9600 8600

2 3 1

Figure 3.19 Panel centred on grid C

Ultimate load, n:

By inspection, Exp. (6.10b) is critical.

n = 1.25 8.50 + 1.5 4.0 = 16.6 kN/m

2

Fig. 2.5

EC0: Exp. (6.10b)

Arrangement:

Choose to use all-and-alternate-spans-loaded load cases and

coefcients

.

Cl. 5.1.3(1) & NA:

Table NA.1

(option b)

3.4.4 Analysis grid line C

Consider grid line C as a bay 6.0 m wide. (This may be conservative

for grid line C but is correct for grid line D etc.)

M

Ed

Effective spans:

9600 2 400/2 + 2 300/2 = 9500 mm

8600 2 400/2 + 2 300/2 = 8500 mm

Cl. 5.3.2.2(1)

Check applicability of moment coefcients:

8500/9500 = 0.89 = as spans differ by less than 15% of larger

span, coefcients are applicable.

Tables C2 & C3

The all-spans-loaded case with 20% redistribution of support moments would

also have been acceptable but would have involved some analysis. The use of Table

5.9 in BS EN 199212 (Fire resistance of solid at slabs) is restricted to where

redistribution does not exceed 15%; the coefcients presume 15% redistribution

at supports.

Cl. 5.3.1 & NA

Table C3

73

34 l|at s|a|

As two span, use table applicable to beams and slabs noting

increased coefcients for central support moment and shear.

Table C3

Design moments in bay.

Spans:

M

Ed

= (1.25 8.5 0.090 + 1.5 4.0 0.100) 6.0 9.5

2

= 842.7 kNm

Support:

M

Ed

= 16.6 0.106 6.0 9.5

2

= 952.8 kNm

C D

Column

strip

Column

strip

Column strip Column strip

Middle

strip

Middle strip

6000

1500

1500

1500

15001500 1500 3000 1500

1

2

Figure 3.20 Column and middle strips p

Apportionment of moments between column strips and middle strips:

Apportionment (as %)

Column strip Middle strip

ve (hogging) Long span = 70%

Short span = 75%

Long span = 30%

Short span = 25%

+ve (sagging) 50% 50%

Table I.1;

CS Flat slab

guide

[27]

Table I.1

NA.3

[1a]

; Fig. I.1

Parallel to grid C, column strip is l

y

/2 = 3 m wide. The middle strip is

also 3 m wide.

Long span moments:

M

Ed

Column strip, 3 m wide Middle strip, 3 m wide

ve (hogging) 0.70 952.8/3.0 = 222.3 kNm/m 0.30 952.8/3.0 = 95.3 kNm/m

+ve (sagging) 0.50 842.7/3.0 = 140.5 kNm/m 0. 50 842.7/3.0 = 140.5 kNm/m

The Concrete Societys TR 64

[27]

recommends a percentage, k

1

, based on l

y

/l

z

Assuming l

y

/l

z

= 1.5 the distribution of moments in the long span between column

strips and middle strips is given as 70% and 30%.

74

Punching shear force, V

Ed

VV :

At C2,

V

Ed

VV = 16.6 6.0 9.6

0.63 2 = 1204.8 kN Table C3 Table C3

At C1 (and C3)

V

Ed

VV = 16.6 6.0 9.6 0.45 + (10 + 0.2 0.3 25)

1.25 6.0

= 516.5 kN

Table C3 Table C3

3.4.5 Design grid line C

Effective depth, d:

d = 300 30 20/2 = 260 mm d

a) Flexure: column strip and middle strip, sagging

M

Ed

= 140.5 kNm/m

K = M

Ed

/bd

2

f

ck

f = 140.5 10

6

/(1000 260

2

30) = 0.069

z/ zz d = 0.94 d Table C5 Table C5

z = 0.94 260 = 244 mm

A

s

= M

Ed

/f

yd

ff z = 140.5 10 z

6

/(244 500/1.15) = 1324 mm

2

/m

(r = 0.51%) r

Try H20 @ 200 B1 (1570 mm

2

/m)

b) Deection: column strip and middle strip

Check span-to-effective-depth ratio. Appendix B Appendix B

Allowable l/ ll d = d N N K F1 F2 F3

where

Cl. 7.4.2(2)

Appendix C Appendix C

N = 20.3 ( N r = 0.51%, r f

ck

f = 30)

Tables C10C13 Tables C10C13

K = 1.2 (at slab)

F1 = 1.0 (b

eff

/b

w

bb = 1.0)

w

F2 = 1.0 (no brittle partitions)

#

F3 = 310/s

s

s 1.5

Cl. 7.4.2, Exp. (7.17)

Table 7.4N, &

NA, Table NA.5

Note 5

Fig. C3 Fig. C3

where*

s

s

s = s

su

s (A

s,req

/

q

A

s,prov

) 1/d

where

s

su

s = (500/1.15) (8.5 + 0.3 4.0)/16.6 = 254 MPa

(or 253 MPa; from Figure C3

G

k

/Q

k

= 2.1, c

2

cc = 0.3 and g

G

gg = 1.25)

d = redistribution ratio = 1.03 d

= s

s

s 253 (1324/1570)/1.03 = 207

= F3 = 310/207 = 1.50

= Allowable l/ ll d = 20.3 1.2 1.50 = 36.5 d

Fig. C14 Fig. C14

As punching shear force (rather than a beam shear force) effective span is not

appropriate.

Cladding and strip of slab beyond centre of support.

#

Otherwise for at slabs 8.5/9.5 = 0.89 as span > 8.5 m.

* See Appendix B1.5

In line with Note 5 to Table NA.5, 1.50 is considered to be a maximum for 310/s

s

s .

Cl. 7.4.2(2)

75

34 l|at s|a|

Actual l/d = 9500/260 = 36.5 = OK

Use H20 @ 200 B1 (1570)

c) Flexure: column strip, hogging

M

Ed

= 222.3 kNm/m

K = M

Ed

/bd

2

f

ck

= 222.3 10

6

/(1000 260

2

30) = 0.109

z/d = 0.89

z = 0.89 260 = 231 mm

A

s

= M

Ed

/f

yd

z = 222.3 10

6

/(231 500/1.15) = 2213 mm

2

/m

(r = 0.85%)

Try H20 @ 125 T1 (2512 mm

2

/m)

#

Table C5

d) Flexure: middle strip, hogging

M

Ed

= 95.3 kNm/m

K = M

Ed

/bd

2

f

ck

= 95.3 10

6

/(1000 260

2

30) = 0.069

z/d = 0.95

z = 0.95 260 = 247 mm

A

s

= M

Ed

/f

yd

z = 95.3 10

6

/(247 500/1.15) = 887 mm

2

/m

(r = 0.34%)

Try H16 @ 200 T1 (1005 mm

2

/m)

Table C5

e) Requirements

i) In column strip, inside middle 1500 mm

There is a requirement to place 50% of A

t

within a width equal to

0.125 of the panel width on either side of the column.

Cl. 9.4.1(2)

Area required = (3 2213 + 3 887)/2 mm

2

= 4650 mm

2

Over width = 2 0.125 6.0 m = 1500 mm

i.e. require 4650/1.5 = 3100 mm

2

/m for 750 mm either side of the

column centreline.

Use H20 @ 100 T1 (3140 mm

2

/m)

750 mm either side of centre of support (16 no. bars)

(r = 0.60%)

ii) In column strip, outside middle 1500 mm

Area required = 3.0 2213 16 314 mm

2

= 1615 mm

2

Over width = 3000 2 750 mm = 1500 mm

i.e. 1077 mm

2

/m

Use H20 @ 250 T1 (1256 mm

2

/m)

in remainder of column strip

Note: Continuity into columns will reduce sagging moments and criticality of

deection check (see Figures 3.26 and 3.27).

Note requirement for at least 2 bars in bottom layer to carry through column.

#

The hogging moment could have been considered at face of support to reduce the

amount of reinforcement required.

Cl. 9.4.1(3)

76

iii) In middle strip Use H16 @ 200 T1 (1005 mm

2

/m)

iv) Perpendicular to edge of slab at edge column

Design transfer moment to column M

t

= 0.17 b

e

d

2

f

ck

where

Cl. 9.4.2(1),

I.1.2(5)

b

e

= c

z

+ y = 400 + 400 = 800 mm

M

t

= 0.17 800 260

2

30 10

6

= 275.8 kNm

K = M

Ed

/bd

2

f

ck

= 275.8 10

6

/(800 260

2

30) = 0.170

z/d = 0.82

z = 0.82 260 = 213 mm

A

s

= M

Ed

/f

yd

z = 275.8 10

6

/(213 500/1.15) = 2978 mm

2

/m

This reinforcement to be placed within c

x

+ 2c

y

= 1100 mm

Fig. 9.9

SMDSC

[9]

Try 10 no. H20 T1 U-bars in pairs @ 200 (3140 mm

2

) local to column

(max. 200 mm from column)

Note:

Where a 200 200 hole occurs on face of column, b

e

becomes 600 mm

and pro rata, A

s,req

becomes 2233 mm

2

i.e. use 4 no. H20 each side

of hole (2512 mm

2

).

v) Perpendicular to edge of slab generally

Assuming that there is partial xity along the edge of the slab, top

reinforcement capable of resisting 25% of the moment in the

adjacent span should be provided

0.25 2213 = 553 mm

2

/m OK

Cl. 9.3.1.2(2),

9.2.1.4(1) & NA

vi) Check minimum area of reinforcement

A

s,min

= 0.26 (f

ctm

/f

yk

) b

t

d 0.0013 b

t

d

where

b

t

= width of tension zone

f

ctm

= 0.30 f

ck

0.666

A

s,min

= 0.26 0.30 30

0.666

1000 260/500 = 390 mm

2

/m

(r = 0.15%)

Use H12 @ 200 (565 mm

2

/m)

Cl. 9.3.1.1, 9.2.1.1

Table 3.1

The reinforcement should extend 0.2h from edge = 600 mm Cl. 9.3.1.4(2)

3.4.6 Analysis grid line 1 (grid 3 similar)

Consider grid line 1 as being 9.6/2 + 0.4/2 = 5.0 m wide with

continuous spans of 6.0 m. Column strip is 6.0/4 + 0.4/2 = 1.7 m

wide. Consider perimeter load is carried by column strip only. Cl. 5.1.1(4)

77

34 l|at s|a|

q

k

slab = 20.0 kN/m

g

k

cladding = 10.0 kN/m

g

k

slab = 42.5 kN/m

6000 6000 6000

F E D C

p

Actions:

Permanent from slab g

k

= 5 8.5 kN/m

2

= 42.5 kN/m

Variable from slab q

k

= 5 4.0 kN/m

2

= 20.0 kN/m

Permanent perimeter load g

k

= 10.0 kN/m

Load combination and arrangement:

As before, choose to use all-spans-loaded case and coefcients

Cl. 5.1.3(1) &

NA: Table NA.1

(option c)

Ultimate load, n:

By inspection, Exp. (6.10b) is critical. Fig. 2.5

n = 1.25 (42.5 +10) + 1.5 20 = 95.6 kN/m EC0: Exp. (6.10b)

Perimeter load, 10 1.25 = 12.5 kN/m

Effective span, l

eff

Effective span = 6000 2 400/2 + 2 300/2 = 5900 Cl. 5.3.2.2(1)

Design moments in bay, M

Ed

:

In spans (worst case, end span assuming pinned support)

M

Ed

= 0.086 83.0 5.9

2

= 248.5 kNm Table C2

At supports (worst case 1st support)

M

Ed

= 0.086 83.0 5.9

2

= 248.5 kNm

Additional moment in column strip only due to perimeter load,

spans (and supports, worst case)

M

Ed

= 0.086 12.5 5.9

2

= 37.4 kNm

Table C2

Apportionment to column strips and middle strips: NA.3

[1a]

: Fig. I.1

Apportionment (as %)

Column strip, 1.7 m wide Middle strip

ve (hogging) Short span = 75% Short span = 25%

+ve (sagging) 50% 50%

Table I.1

CS Flat slab

guide

[27]

Short span moments:

M

Ed

Column strip, 1.7 m wide Middle strip, 3.3 m wide

ve (hogging) (0.75 248.5 + 37.4)/1.70

= 131.6 kNm/m

0.25 248.5/3.3

= 18.8 kNm/m

+ve (sagging) (0.50 248.5 + 37.4)/1.70

= 95.1 kNm/m

0.50 248.5/3.3

= 37.6 kNm/m

78

Punching shear force, V

Ed

For internal supports, as before = 516.5 kN

For penultimate support, 516.5 1.18 = 609.5 kN Table C3

3.4.7 Design grid line 1 (grid 3 similar)

Cover:

c

nom

= 30 mm as before

d = 300 30 20 20/2 = 240 mm

a) Flexure: column strip, sagging

M

Ed

= 95.1 kNm/m

K = M

Ed

/bd

2

f

ck

= 95.1 10

6

/(1000 240

2

30) = 0.055 Table C5

z/d = 0.95

z = 0.95 240 = 228 mm

A

s

= M

Ed

/f

yd

z = 95.1 10

6

/(228 500/1.15) = 959 mm

2

/m

(r = 0.40%)

Try H16 @ 200 B2 (1005 mm

2

/m)

b) Deection: column strip

Check span-to-effective-depth ratio. Appendix B

Allowable l/d = N K F1 F2 F3

where

Appendix C7

Tables C10C13

N = 26.2 (r = 0.40%, f

ck

= 30) Cl. 7.4.2, Exp.

(7.17), Table 7.4N

& NA,

Table NA.5:

Note 5

K = 1.2 (at slab)

F1 = 1.0 (b

eff

/b

w

= 1.0)

F2 = 1.0 (no brittle partitions)

F3 = 310/ s

s

1.5

where

s

s

= s

su

(A

s,req

/A

s,prov

) 1/d

where

s

su

283 MPa (from Figure C3 and G

k

/Q

k

= 3.6, c

2

= 0.3, g

G

= 1.25)

d = redistribution ratio = 1.08

Fig. C3

= s

s

283 (959/1005)/1.08 = 250 Table C14

= F3 = 310/250 = 1.24 Fig. C3

=Allowable l/d = 26.2 1.2 1.24 = 39.0

Actual l/d = 5900/240 = 24.5 = OK

Use H16 @ 200 B2 (1005 mm

2

/m)

c) Flexure: middle strip, sagging

M

Ed

= 37.6 kNm/m

By inspection, z = 228 mm

A

s

= M

Ed

/f

yd

z = 37.6 10

6

/(228 500/1.15) = 379 mm

2

/m

(r = 0.56%)

79

34 l|at s|a|

By inspection, deection OK.

Check minimum area of reinforcement.

A

s,min

= 0.26 (f

ctm

/f

yk

) b

t

d 0.0013 b

t

d Cl. 9.3.1.1, 9.2.1.1

where

b

t

= width of tension zone

f

ctm

= 0.30 f

ck

0.666

Table 3.1

A

s,min

= 0.26 0.30 30

0.666

1000 240/500 = 361 mm

2

/m

(r = 0.15%)

Use H12 @ 300 T2 (376 mm

2

/m)

d) Flexure: column strip, hogging

M

Ed

= 131.6 kNm/m

K = M

Ed

/bd

2

f

ck

= 131.6 10

6

/(1000 240

2

30) = 0.076

z/d = 0.928

z = 0.928 240 = 223 mm

A

s

= M

Ed

/f

yd

z = 131.6 10

6

/(223 500/1.15) = 1357 mm

2

/m

(r = 0.56%)

Try H20 @ 200 T2 (1570 mm

2

/m)

Table C5

e) Flexure: middle strip, hogging

M

Ed

= 18.8 kNm/m

By inspection, z = 228 mm Table C5

A

s

= M

Ed

/f

yd

z = 18.8 10

6

/(228 500/1.15) = 190 mm

2

/m

(r = 0.08%)

A

s,min

as before = 361 mm

2

/m

(r = 0.15%)

Try H12 @ 300 T2 (376 mm

2

/m)

Cl. 9.3.1.1, 9.2.1.1

f) Requirements

There is a requirement to place 50% of A

t

within a width equal to 0.125

of the panel width on either side of the column. As this column strip is

adjacent to the edge of the slab, consider one side only:

Area required = (1.5 1357 + 3.3 190)/2 mm

2

= 1334 mm

2

Within = 0.125 6.0 m = 750 mm of the column centreline,

i.e. require 1334/0.75 = 1779 mm

2

/m for 750 mm from the column

centreline.

Cl. 9.4.1(2)

The hogging moment could have been considered at face of support to reduce

the amount of reinforcement required. This should be balanced against the

effect of the presence of a 200 200 hole at some supports which would

have the effect of increasing K but not unduly increasing the total amount of

reinforcement required in the column strip (a 1.5% increase in total area would

been required).

80

Allowing for similar from centreline of column to edge of slab:

Use 6 no. H20 @ 175 T2(1794 mm

2

/m)

(r = 0.68%)

between edge and to 750 mm from centre of support

In column strip, outside middle 1500 mm, requirement is for

1.7 1357 6 314 = 422 mm

2

in 750 mm, i.e. 563 mm

2

/m

Use H12 @ 175 T2 (646 mm

2

/m) in remainder of column strip

In middle strip Use H12 @ 300 T2 (376 mm

2

/m)

3.4.8 Analysis grid line 2

Consider panel on grid line 2 as being 9.6/2 + 8.6/2 = 9.1 m wide

and continuous spans of 6.0 m. Column strip is 6.0/2 = 3.0 m wide.

(See Figure 3.20).

q

k

slab = 36.4 kN/m

g

k

slab = 77.4 kN/m

6000 6000 6000

F E D C

Figure 3.22 Internal panel on grid 2 p

Slab g

k

= 9.1 8.5 kN/m

2

= 77.4 kN/m

Slab q

k

= 9.1 4.0 kN/m

2

= 36.4 kN/m

Actions, load combination and arrangement:

Choose to use all-spans-loaded case.

Cl. 5.1.3(1) &

NA: Table NA.1

(option c)

Ultimate load, n:

By inspection, Exp. (6.10b) is critical.

n = 1.25 77.4 + 1.5 36.4 = 151.4 kN/m

Fig. 2.5

EC0: Exp. (6.10b)

Effective span, l

eff

:

Effective span = 5900 mm as before.

Cl. 5.3.2.2(1)

Design moments in bay, M

Ed

:

Spans (worst case, end span assuming pinned support)

M

Ed

= 0.086 151.4 5.9

2

= 453.2 kNm Table C2

Support (worst case 1st support)

M

Ed

= 0.086 151.4 5.9

2

= 453.2 kNm

Additional moment in column strip only due to perimeter load.

Table C2

81

34 l|at s|a|

Apportionment to column strips and middle strips:

M

Ed

Column strip, 3.0 m wide Middle strip, 6.1 m wide

ve (hogging) 0.75 453.2/3.0

= 113.3 kNm/m

0.25 453.2/6.1

= 18.5 kNm/m

+ve (sagging) 0.50 453.2/3.0

= 75.5 kNm/m

0.50 453.2/6.1

= 37.1 kNm/m

Punching shear force, V

Ed

, as before.

3.4.9 Design grid line 2

Effective depth, d

d = 300 30 20 20/2 = 240 mm

a) Flexure: column strip, sagging

M

Ed

= 75.5 kNm/m

By inspection, z = 228 mm

A

s

= M

Ed

/f

yd

z = 75.5 10

6

/(228 500/1.15) = 761 mm

2

/m

(r = 0.32%)

Try H16 @ 250 B2 (804 mm

2

/m)

Table C5

Deection: column strip

By inspection, OK.

b) Flexure: column strip, sagging

M

Ed

= 37.1 kNm/m

By inspection, z = 228 mm

A

s

= M

Ed

/f

yd

z = 37.1 10

6

/(228 500/1.15) = 374 mm

2

/m

(r = 0.55%)

By inspection, deection OK. Try H10 @ 200 B2 (393 mm

2

/m)

c) Flexure: column strip, hogging

M

Ed

= 113.3 kNm/m

K = M

Ed

/bd

2

f

ck

= 113.3 10

6

/(1000 240

2

30) = 0.065

z/d = 0.94

z = 0.928 240 = 225 mm

Table C5

A

s

= M

Ed

/f

yd

z = 113.3 10

6

/(225 500/1.15) = 1158 mm

2

/m

(r = 0.48%)

Try H20 @ 250 T2 (1256 mm

2

/m)

d) Flexure: middle strip, hogging

M

Ed

= 18.5 kNm/m

By inspection, z = 228 mm

The hogging moment could have been considered at face of support to reduce

the amount of reinforcement required.

82

A

s

= M

Ed

/f

yd

z = 18.5 10

6

/(228 500/1.15) = 187 mm

2

/m

(r = 0.08%) Table C5

As before minimum area of reinforcement governs

A

s,min

= 0.26 0.30 30

0.666

1000 240/500 = 361 mm

2

/m

(r = 0.15%)

Try H12 @ 300 B2 (376 mm

2

/m)

Cl. 9.3.1.1, 9.2.1.1

e) Requirements

Regarding the requirement to place 50% of A

t

within a width equal

to 0.125 of the panel width on either side of the column:

Area required = (3.0 1158 + 6.1 187)/2 mm

2

= 2307 mm

2

Within = 2 0.125 6.0 m = 1500 mm centred on the column

centreline,

i.e. require 2307/1.5 = 1538 mm

2

/m for 750 mm either side of the

column centreline.

Use H20 @ 200T2 (1570 mm

2

/m)

750 mm either side of centre of support

(r = 0.60%)

In column strip, outside middle 1500 mm, requirement is for

3.0 1158 1.5 1570 = 1119 mm

2

in 1500 mm, i.e. 764 mm

2

/m

Use H16 @ 250 T2 (804 mm

2

/m) in remainder of column strip

In middle strip: Use H12 @ 300 T2 (376 mm

2

/m)

3.4.10 Punching shear, central column, C2

At C2, applied shear force, V

Ed

= 1204.8 kN

a) Check at perimeter of column

v

Ed

= bV

Ed

/u

i

d < v

Rd,max

where

Cl. 6.4.3(2),

6.4.5(3)

b = factor dealing with eccentricity; recommended value 1.15

V

Ed

= applied shear force Fig. 6.21N & NA

u

i

= control perimeter under consideration.

For punching shear adjacent to interior columns Cl. 6.4.5(3)

u

0

= 2(c

x

+ c

y

) = 1600 mm

d = mean effective depth = (260 + 240)/2 = 250 mm Exp. (6.32)

v

Ed

= 1.15 1204.8 10

3

/1600 250 = 3.46 MPa

v

Rd,max

= 0.5vf

cd

Cl. 6.4.5(3) Note

Column C2 is taken to be an internal column. In the case of a penultimate

column, an additional elastic reaction factor should have been considered.

83

34 l|at s|a|

where

v = 0.6(1 f

ck

/250) = 0.528

f

cd

= a

cc

lf

ck

/g

C

= 1.0 1.0 30/1.5 = 20

= 0.5 0.528 20 = 5.28 MPa = OK Table C7

b) Check shear stress at control perimeter u

1

(2d from face of column)

v

Ed

= bV

Ed

/u

1

d < v

Rd,c

where

b, V

Ed

and d as before

Cl. 6.4.2

u

1

= control perimeter under consideration.

For punching shear at 2d from interior columns

u

1

= 2(c

x

+ c

y

) + 2Q 2d = 4741 mm

Fig. 6.13

v

Ed

= 1.15 1204.8 10

3

/4741 250 = 1.17 MPa

v

Rd,c

= 0.18/ g

C

k (100 r

l

f

ck

)

0.333

Exp. (6.47) & NA

where

g

C

= 1.5

k = 1 + (200/d)

0.5

2 k = 1 + (200/250)

0.5

= 1.89

r

l

= (r

ly

r

lz

)0.5 = (0.0085 0.0048)

0.5

= 0.0064 Cl. 6.4.4.1(1)

where

r

|y

, r

lz

= Reinforcement ratio of bonded steel in the y and

z direction in a width of the column plus 3d each

side of column

#

f

ck

= 30

v

Rd,c

= 0.18/1.5 1.89 (100 0.0064 30)

0.333

= 0.61 MPa

= Punching shear reinforcement required Table C5*

c) Perimeter at which punching shear links are no longer required

u

out

= V

Ed

b/(d v

Rd,c

)

u

out

= 1204.8 1.15 10

3

/(250 0.61) = 9085 mm

Exp. (6.54)

Length of column faces = 4 400 = 1600 mm

Radius to u

out

= (9085 1600)/2Q = 1191 mm from face of column

Perimeters of shear reinforcement may stop 1191 1.5 250 = 816 m

from face of column Cl. 6.4.5(4) & NA

Shear reinforcement (assuming rectangular arrangement of links):

s

r,max

= 250 0.75 = 187, say = 175 mm Cl. 9.4.3(1)

At the perimeter of the column, v

Rd,max

assumes the strut angle is 45, i.e. that

cot y = 1.0. Where cot y = < 1.0, v

Rd,max

is available from Table C7.

#

The values used here for r

ly

, r

lz

ignore the fact that the reinforcement is

concentrated over the support. Considering the concentration would have given a

higher value of V

Rd,c

at the expense of further calculation to determine r

ly

, r

lz

at

3d from the side of the column.

* v

Rd,c

for various values of d and r

l

is available from Table C6.

84

Inside 2d control perimeter, s

t,max

= 250 1.5 = 375, say 350 mm Cl. 9.4.3(2)

Outside control perimeter s

t,max

= 250 2.0 = 500 mm

Assuming vertical reinforcement:

At the basic control perimeter, u

1

, 2d from the column

:

A

sw

(v

Ed

0.75v

Rd,c

) s

r

u

1

/1.5f

ywd,ef

) Exp. (6.52)

where

f

ywd,ef

= effective design strength of reinforcement

= (250 + 0.25d) < f

yd

= 312 MPa Cl. 6.4.5(1)

For perimeter u

1

A

sw

= (1.17 0.75 0.61) 175 4741/(1.5 312)

= 1263 mm

2

per perimeter

A

sw,min

0.08f

ck

0.5

(s

r

s

t

)/(1.5 f

yk

sin a + cos a) Exp. (9.11)

where

A

sw,min

= minimum area of a single leg of link

a = angle between main reinforcement and shear

reinforcement; for vertical reinforcement sin a = 1.0

A

sw,min

0.08 30

0.5

(175 350)/(1.5 500) = 36 mm

2

= Try H8 legs of links (50 mm

2

)

A

sw

/u

1

1263/4741 = 0.266 mm

2

/mm

Using H8 max. spacing = min[50/0.266; 1.5d]

= min[188; 375] = 188 mm cc

= Use min. H8 legs of links at 175 mm cc around perimeter u

1

Cl. 9.4.3

Perimeters at 0.75d = 0.75 250 = 187.5 mm

say = 175 mm centres

Cl. 9.4.3(1)

d) Check area of reinforcement > 1263 mm

2

in perimeters inside u

1

1st perimeter to be > 0.3d but < 0.5d from face of column. Say

0.4d = 100 mm from face of column.

By inspection of Figure 3.23 the equivalent of 10 locations are available

at 0.4d from column therefore try 2 10 no. H10 = 1570 mm

2

.

Fig. 9.10,

Cl. 9.4.3(4)

By inspection of Figure 3.23 the equivalent of 18 locations are

available at 1.15d from column therefore try 18 no. H10 = 1413 mm

2

.

By inspection of Figure 3.23 the equivalent of 20 locations are available

at 1.90d from column therefore try 20 no. H10 = 1570 mm

2

.

By inspection of Figure 3.23 beyond u

1

to u

out

grid of H10 at 175 x 175 OK.

Clause 6.4.5 provides Exp. (6.52), which by substituting v

Ed

for v

Rd,c

, allows

calculation of the area of required shear reinforcement, A

sw

, for the basic control

perimeter, u

1

.

The same area of shear reinforcement is required for all perimeters inside or

outside perimeter u

1

. See Commentary on design, Section 3.4.14. Punching shear

reinforcement is also subject to requirements for minimum reinforcement and

spacing of shear reinforcement (see Cl. 9.4.3).

Cl. 6.4.5

Exp. 6.5.2

Cl. 9.4.3

Potrebbero piacerti anche

- Drop Panel CalculationDocumento2 pagineDrop Panel Calculationsandiok86Nessuna valutazione finora

- Bending Strength: Overall Buckung Check L R - R at - o - 5 X 7 o o o - . o T Y - 5 T F - o / ' UDocumento8 pagineBending Strength: Overall Buckung Check L R - R at - o - 5 X 7 o o o - . o T Y - 5 T F - o / ' UReef20Nessuna valutazione finora

- Basement Wall DesignDocumento2 pagineBasement Wall DesignArindam RoyNessuna valutazione finora

- Shear Walls - An OverviewDocumento6 pagineShear Walls - An OverviewTabish IslamNessuna valutazione finora

- CompositeDocumento11 pagineCompositeluuvandong48xf396100% (1)

- 2 Way SlabDocumento22 pagine2 Way SlabAhmed Al-AmriNessuna valutazione finora

- Fig. 1: Types of Shear Wall, (A) Single Storey, (B) Multi-StoreyDocumento3 pagineFig. 1: Types of Shear Wall, (A) Single Storey, (B) Multi-StoreyAmer GonzalesNessuna valutazione finora

- Deltabeam EngDocumento20 pagineDeltabeam EngAmir OmeraševićNessuna valutazione finora

- Reinforced Concrete Rectangular Beam Design To AS3600-2009Documento4 pagineReinforced Concrete Rectangular Beam Design To AS3600-2009Rron de GuzmanNessuna valutazione finora

- Pages From PCA Notes On ACI318-08Documento4 paginePages From PCA Notes On ACI318-08Jorge Rubén TorresNessuna valutazione finora

- Minimum Edge Distances As Identified in BS 5950Documento1 paginaMinimum Edge Distances As Identified in BS 5950Jagdish DhanuskarNessuna valutazione finora

- Waffle SlabDocumento2 pagineWaffle SlabKasun Geenath Vithanage100% (1)

- Fin Plate ConnectionDocumento70 pagineFin Plate Connectionfloi dNessuna valutazione finora

- Analysis and Design of A Continuous R. C. Raker Beam Using Eurocode 2Documento13 pagineAnalysis and Design of A Continuous R. C. Raker Beam Using Eurocode 2Ubani Obinna Ranks100% (7)

- Example 1 ': σ σ on faces near water face) on faces away σ water faceDocumento4 pagineExample 1 ': σ σ on faces near water face) on faces away σ water faceyenebeb tarikuNessuna valutazione finora

- Vertical Reinforcement (Walls BS 8110)Documento4 pagineVertical Reinforcement (Walls BS 8110)dhanya1995100% (1)

- Week 9 - Session 1 - Concrete Design - Punching Shear in RC Flat SlabsDocumento5 pagineWeek 9 - Session 1 - Concrete Design - Punching Shear in RC Flat SlabsengkjNessuna valutazione finora

- Example Simply Supported IPE Profile PurlinDocumento10 pagineExample Simply Supported IPE Profile PurlinAjay GargNessuna valutazione finora

- Shear Wall in ACIDocumento26 pagineShear Wall in ACIMeirzhan YerzhanovNessuna valutazione finora

- Structural Design - Post Tensioned Slab Design1Documento12 pagineStructural Design - Post Tensioned Slab Design1Chamil MahagamageNessuna valutazione finora

- Comparative Design of Biaxial RC ColumnsDocumento14 pagineComparative Design of Biaxial RC ColumnsMouhamad WehbeNessuna valutazione finora

- Watertight Roof Slabs Guidelines & General PrinciplesDocumento29 pagineWatertight Roof Slabs Guidelines & General PrinciplesGoanengineerNessuna valutazione finora

- Strengthening Design of Concrete Beams by Adition of Steel PlatesDocumento10 pagineStrengthening Design of Concrete Beams by Adition of Steel PlatesgparratNessuna valutazione finora

- RCC61 Basement WallDocumento15 pagineRCC61 Basement WallMUTHUKKUMARAMNessuna valutazione finora

- Steelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiesDocumento56 pagineSteelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiessubamanivelNessuna valutazione finora

- Worked Example 1 - Composite Beam - Normal DesignDocumento26 pagineWorked Example 1 - Composite Beam - Normal DesignTudor Tudor100% (1)

- Worked Example 1 - Composite Beam - Normal Design PDFDocumento26 pagineWorked Example 1 - Composite Beam - Normal Design PDFtudor2786Nessuna valutazione finora

- Composite Beams and Slabs1Documento9 pagineComposite Beams and Slabs1rameshbabu_1979100% (1)

- Slab With OpeningDocumento16 pagineSlab With OpeningTomislav Šimag100% (1)

- ComFlor® ManualDocumento132 pagineComFlor® ManualAhmedNessuna valutazione finora

- Pad Foundation With Two Columns ExampleDocumento10 paginePad Foundation With Two Columns ExampleakankwasaNessuna valutazione finora

- Chapter 3 Shear ExamplesDocumento30 pagineChapter 3 Shear ExamplesRefisa JiruNessuna valutazione finora

- CP 114 - Concrete CoverDocumento2 pagineCP 114 - Concrete CoverJibeesh CMNessuna valutazione finora

- Raft Foundation DesignDocumento5 pagineRaft Foundation Designafiq100% (2)

- Engg/10/s4 Reinforced Concrete Design To Bs 8110: Contract RefDocumento3 pagineEngg/10/s4 Reinforced Concrete Design To Bs 8110: Contract RefGodfrey James MachotaNessuna valutazione finora

- Design of Flat Slabs For PunchingDocumento8 pagineDesign of Flat Slabs For PunchingAli Alskeif100% (1)

- Ipt Design WorkDocumento43 pagineIpt Design WorkMorice RwakataleNessuna valutazione finora

- Types of Ties For and Placement of Reinforcing SteelDocumento8 pagineTypes of Ties For and Placement of Reinforcing Steelइंजि कौस्तुभ पवार100% (1)

- MasterSeries Student Masonry Retaining EtcDocumento21 pagineMasterSeries Student Masonry Retaining EtcekaNessuna valutazione finora

- A1 - Composite Beam PDFDocumento6 pagineA1 - Composite Beam PDFNaim YaqeenNessuna valutazione finora

- Design Parameters For Longitudinal Bars (Beams - BS 8110)Documento4 pagineDesign Parameters For Longitudinal Bars (Beams - BS 8110)Lavanyan Satchithananthan100% (1)

- Ramset Specifiers Anchoring Resource Book ANZ - TruBolt Mechanical AnchoringDocumento10 pagineRamset Specifiers Anchoring Resource Book ANZ - TruBolt Mechanical AnchoringjlolhnpNessuna valutazione finora

- RC Design I ColumnsDocumento32 pagineRC Design I Columnseph100% (1)

- Punching ShearDocumento7 paginePunching SheardagetzNessuna valutazione finora

- BS8110 Span-Depth Ratios PDFDocumento1 paginaBS8110 Span-Depth Ratios PDFRezart PogaceNessuna valutazione finora

- AS3600-2009 Wall DesignDocumento14 pagineAS3600-2009 Wall DesignMREFAATNessuna valutazione finora

- Slab Design ExcelDocumento5 pagineSlab Design ExcelVinod RevankarNessuna valutazione finora

- Detailing MembersDocumento43 pagineDetailing Memberschithirai10Nessuna valutazione finora

- Truss DesignDocumento16 pagineTruss DesignRabindraUpretiNessuna valutazione finora

- End Plates - Worked Examples With Partial Depth End Plate - Example 5Documento1 paginaEnd Plates - Worked Examples With Partial Depth End Plate - Example 5Kimutai Kirui AlphonceNessuna valutazione finora

- Design of Reinforced Concrete Shear WallDocumento8 pagineDesign of Reinforced Concrete Shear WallklynchelleNessuna valutazione finora

- 16 Selection of Concrete Filled Steel Pipe Columns 23052014Documento1 pagina16 Selection of Concrete Filled Steel Pipe Columns 23052014Ahmad Badsha QuadriNessuna valutazione finora

- RCC51 Column Load Take-Down DesignDocumento7 pagineRCC51 Column Load Take-Down DesignBst PerchatNessuna valutazione finora

- EC2 - Concrete Centre (Flat Slabs - 2007)Documento21 pagineEC2 - Concrete Centre (Flat Slabs - 2007)florincinciNessuna valutazione finora

- Faculty of Applied Engineering and Urban PlanningDocumento22 pagineFaculty of Applied Engineering and Urban PlanningHazem Almasry100% (1)

- 11 Lecture 11 - Beam - Design - ExamplesDocumento65 pagine11 Lecture 11 - Beam - Design - ExamplesManoj SharmaNessuna valutazione finora

- Design of Rectangular Water TankDocumento268 pagineDesign of Rectangular Water Tankchetanmale89% (28)

- Isolated Sloped Footing SpreadsheetDocumento283 pagineIsolated Sloped Footing Spreadsheetarif_rubin100% (3)

- Plastic AnalysisDocumento31 paginePlastic Analysisgaiagmr100% (1)

- Lightweight ConcreteDocumento98 pagineLightweight ConcreteNitish RamdaworNessuna valutazione finora

- Minimising Crack Control Reinforcement - Design BookletDocumento21 pagineMinimising Crack Control Reinforcement - Design BookletNitish Ramdawor100% (1)

- Orn 19Documento94 pagineOrn 19rajithfernando50% (2)

- Shear EnhancedDocumento8 pagineShear Enhancedunitedfc9612Nessuna valutazione finora

- Wall Calculation Example EC2Documento15 pagineWall Calculation Example EC2Kristjan Igasta88% (8)

- Example 3 Rectangular SiloDocumento7 pagineExample 3 Rectangular SiloAhmed Said50% (2)

- Design of Elevated Service ReservoirDocumento88 pagineDesign of Elevated Service ReservoirNitish Ramdawor86% (7)

- RCC11 Element DesignDocumento6 pagineRCC11 Element DesignYannick PrattNessuna valutazione finora

- Design of Deep BeamsDocumento5 pagineDesign of Deep BeamsNitish Ramdawor50% (2)

- RC ColumnsDocumento42 pagineRC Columnsyenrai100% (1)

- Civil Engineering Design (1) : Analysis and Design of SlabsDocumento40 pagineCivil Engineering Design (1) : Analysis and Design of SlabsMuhammad Saqib Abrar83% (6)

- Notes 17 - Slope Deflection DerivationDocumento7 pagineNotes 17 - Slope Deflection DerivationNitish RamdaworNessuna valutazione finora

- Consultancy Services For The Feasibility Study of A Second Runway at SSR International AirportDocumento6 pagineConsultancy Services For The Feasibility Study of A Second Runway at SSR International AirportNitish RamdaworNessuna valutazione finora

- Ag 42Documento9 pagineAg 42Nitish RamdaworNessuna valutazione finora

- Feng ShuiDocumento1 paginaFeng ShuiNitish RamdaworNessuna valutazione finora

- ABB MNS IAC Additional Test ReportDocumento14 pagineABB MNS IAC Additional Test ReportSheik100% (1)

- Carbon Compounds: Standard/ Class/ Grade - 10 SSC, CBSE - 8 ICSEDocumento53 pagineCarbon Compounds: Standard/ Class/ Grade - 10 SSC, CBSE - 8 ICSEsaintEmNessuna valutazione finora

- Relayoperationprinciples 141126065914 Conversion Gate01Documento43 pagineRelayoperationprinciples 141126065914 Conversion Gate01kenlavie2Nessuna valutazione finora

- SB 234Documento9 pagineSB 234JolettitoNessuna valutazione finora

- Recent Developments On The Interpretation of Dissolved Gas Analysis in TransformersDocumento33 pagineRecent Developments On The Interpretation of Dissolved Gas Analysis in TransformersputrasejahtraNessuna valutazione finora

- How To Find Equilibrium Price and Quantity MathematicallyDocumento2 pagineHow To Find Equilibrium Price and Quantity MathematicallyJoshua S Mjinja100% (1)

- Class 10 Science Chapter 2 Revision NotesDocumento16 pagineClass 10 Science Chapter 2 Revision NotesKriish RatnaniNessuna valutazione finora

- Upstream Process Engineering Course: 5. Produced WaterDocumento27 pagineUpstream Process Engineering Course: 5. Produced WaterMohamed SelimNessuna valutazione finora

- Slab DesignDocumento96 pagineSlab Designdilrangi100% (2)

- Solution Manual For Modern Quantum Mechanics 2nd Edition by SakuraiDocumento13 pagineSolution Manual For Modern Quantum Mechanics 2nd Edition by Sakuraia440706299Nessuna valutazione finora

- Consumer Surplus:: at K Chabveka Economics NotesDocumento28 pagineConsumer Surplus:: at K Chabveka Economics NotesShawn DzingayiNessuna valutazione finora

- From-To Chart ExampleDocumento22 pagineFrom-To Chart Exampleajeng.saraswatiNessuna valutazione finora

- DREHMO Matic-C ENDocumento36 pagineDREHMO Matic-C ENsimbamikeNessuna valutazione finora

- RS 385SHDocumento3 pagineRS 385SHshahpinkalNessuna valutazione finora

- VSF2 ND EdDocumento345 pagineVSF2 ND EdRyanNessuna valutazione finora

- Pspice Project-BJT AmplifierDocumento4 paginePspice Project-BJT AmplifierSerdar7tepe100% (1)

- Aloe (Aloe Barbadensis Miller) Gel As An Agent in Delaying The Physical DETERIORATION OF EGGPLANT (Solanum Melongena), TOMATO (LycopersicumDocumento20 pagineAloe (Aloe Barbadensis Miller) Gel As An Agent in Delaying The Physical DETERIORATION OF EGGPLANT (Solanum Melongena), TOMATO (LycopersicumCyrus BautistaNessuna valutazione finora

- Statistics Hand NotesDocumento16 pagineStatistics Hand NotesAtul VermaNessuna valutazione finora

- Calculation of Section Modulus PDFDocumento4 pagineCalculation of Section Modulus PDFAnthony Gravagne40% (5)

- EMDCSS DatasheetDocumento5 pagineEMDCSS DatasheetHoracio UlloaNessuna valutazione finora

- Slide 1: No-Churn TelecomDocumento11 pagineSlide 1: No-Churn Telecomleongladxton100% (1)

- Stars and Galaxies 9th Edition Seeds Test BankDocumento20 pagineStars and Galaxies 9th Edition Seeds Test Bankngocalmai0236h100% (32)

- Estimation of Microbial GrowthDocumento25 pagineEstimation of Microbial GrowthziaiitdNessuna valutazione finora

- FMC - Novolastic Subsea Thermal Insulation - LOW RESDocumento3 pagineFMC - Novolastic Subsea Thermal Insulation - LOW RESalphading50% (2)

- LSMW To Update Customer Master Records With Standard ObjectDocumento9 pagineLSMW To Update Customer Master Records With Standard ObjectShahid_ONNessuna valutazione finora

- FluidsDocumento10 pagineFluidslara alghamdiNessuna valutazione finora

- Lab 9: Standard Plate Count: How Do We Know How Many Bacteria Are in A Liquid?Documento4 pagineLab 9: Standard Plate Count: How Do We Know How Many Bacteria Are in A Liquid?Penelope MeloNessuna valutazione finora

- Simultaneous Equations - Word ProblemsDocumento27 pagineSimultaneous Equations - Word ProblemsSandy Wong0% (1)

- Clayton, R., Chen, S., & Lefort, G. (2005) - New Bit Design, Cutter Technology Extend PDC Applications To Hard Rock Drilling PDFDocumento9 pagineClayton, R., Chen, S., & Lefort, G. (2005) - New Bit Design, Cutter Technology Extend PDC Applications To Hard Rock Drilling PDFadeelsnNessuna valutazione finora

- Automotive Solutions: Setting The Pace For InnovationDocumento36 pagineAutomotive Solutions: Setting The Pace For InnovationAda TopanNessuna valutazione finora