Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

18 Ni CR Mo 5

Caricato da

lavius_mTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

18 Ni CR Mo 5

Caricato da

lavius_mCopyright:

Formati disponibili

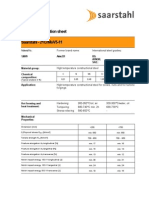

Quality

18NiCrMo5

According to standards

Number

UNI 7846: 1978

--

Technical card

Trafilix

Lucefin Group

Chemical composition

C%

Si%

Mn%

P%

S%

Cr%

Mo%

Ni%

max

max

0,15-0,21

0,15-0,40

0,60-0,90

0,035

0,035

0,70-1,00 0,15-0,25 1,20-1,50 Permissible deviations

on the product

0.02

0.03

0.04

+ 0.005 + 0.005

0.05

0.03

0.05

By agreement this steel can be supplied with the addition of lead (Pb) 0.15-0.35% or sulphur (S) 0.020-0.035%

Calcium (Ca) treatment may be supplied on request

Temperature C

Hot forming

Normalizing

Core

hardening

Carbonitriding

1100-900

880

air

--

Soft

annealing

Isothermal

annealing

840-870

oil-polymer

salt bath

Transformation

annealing +FP

950-1000

quick cooling

850

water

700 slowly 15C/h 850 furnace

until 600 after air cooling to

650 after, air

(HB max 240)

(HB 150-220)

Carburizing

Hardening

Tempering

carburizing

surf.

880-930

800-830

150-180

oil-polymer

salt bath

Preheating

Stress relieving

welding

after welding

welding must be made on the annealing and before

the carburizing

150-350

600 furnace cooling

AC1

AC3

MS * core

** carburizing surface

730

815

360* 180**

End quench

Hardenability

test

Mechanical and physical properties

Hot rolled mechanical properties obtained from test blanks after core hardening + stress relieving UNI 7846: 1978

dimension

Testing at room temperature (longitudinal)

mm

R

Rp 0.2

A%

C%

Kcu

HB

test blanks

N/mm2

N/mm2 min.

min.

min.

J min.

11

1230-1520

980

8

-30

363-432

30

980-1270

735

9

-32.5

295-373

for information

63

830-1130

635

10

-35

249-339

for information

Table of tempering values

HB

415

HRC

44.5

R

N/mm2

1460

Rp 0.2 N/mm2

1070

A

%

13.5

C

%

57.0

Kv

J

64

HRC carburizing

64

surface

Tempering at C 50

at room temperature for round 10 mm after quenching oil at 850C

415

415

409

404

395

381

362

344

327

44.5 44.5 44

43.5 42.5 41

39

37

35

1460 1450 1430 1400 1360 1300 1230 1150 1080

1120 1170 1210 1210 1190 1150 1100 1040 960

13.6 13.5 13.2 13.0 12.8 12.8 12.9 13.8 15.0

58.0 59.0 60.0 60.0 60.0 60.0 60.0 61.0 63.0

64

62

62

64

46

46

46

75

94

63.5 62

60

59

56

-----

301

32

1000

860

17.0

65.0

125

--

271

28

900

790

19.5

68.0

148

--

237

22

790

700

22.0

72.0

166

--

218

-710

610

24.0

74.0

180

--

100

550

600

650

700

150

200

250

300

350

400

450

500

Technical card Trafilix

18NiCrMo5

Cold drawn +C (815M17) BS 970-3: 1991

dimension

Testing at room temperature (longitudinal)

mm

R

Rp 0.2

A%

Kv

HB

over

to

N/mm2 min

N/mm2 min

min

J min

min

-19

1080

-8

22

327

------------testing after quenching, carburizing surface. Quenching 830C oil tempering 200C air

Forged UNI 8550: 1984

dimension

Testing at room temperature (longitudinal)

mm

R

Rp 0.2

A% L

A% T

A% Q

over

to

N/mm2

N/mm2 min

min

min

min

11

1225-1520

980

8

--11

25

1030-1325

785

9

--25

40

930-1230

735

9

--40

100

785-1080

590

10

-mechanical properties obtained from test blanks after core hardening + stress relieving

L = longitudinal T = tangential Q = radial

Kcu L

J min

30

32.5

32.5

35

Kcu T

J min

-----

Kv L

J min

-----

HB

361-432

311-384

278-363

234-327

UNI 7846:1978 Jominy test HRC (grain size G 5 min. according to UNI 3245)

distance in mm from quenched end

min

max

1.5

11

13

15

20

25

30

35

40

45

50

39

49

38

48.5

36

48

34

46.5

31

45

29

43.5

27

41

25.5

40

23

37

21

35.5

20.5

34.5

20

33.5

-33

-32.5

-32

Temperature

Testing at C

20

Mod. of elasticity N/mm2

E long.

G tang.

210000

80000

Specific heat capacity

J/(KgK)

460

EUROPE EN

17NiCrMo6-4

ITALY UNI

18NiCrMo5

Density

Kg/dm3

7.85

Rp 0.2 N/mm2

< 250 mm

250-500

--

--

Thermal conductivity

W/(mK)

41

CHINA

--

GERMANY DIN

--

----

Thermal expansion

[(m/mK) 10-6 C-1 ]

-Specific electric resist.

Ohmmm2/m

0.16

FRANCE AFNOR

18NCD6

U.K. B.S.

815M17

Conductivity

Siemensm/mm2

6.25

RUSSIA

19HNM

USA AISI/SAE

4317

Potrebbero piacerti anche

- 40NiCrMo7 PDFDocumento2 pagine40NiCrMo7 PDFAmy GriffinNessuna valutazione finora

- 39 Ni CR Mo 3Documento2 pagine39 Ni CR Mo 3Lokesh Krishnappa100% (1)

- Din 17100Documento4 pagineDin 17100Sheby SandyNessuna valutazione finora

- QU AL ITY: Material Data SheetDocumento5 pagineQU AL ITY: Material Data SheetAlex007Nessuna valutazione finora

- BS3100 CastingDocumento1 paginaBS3100 Castingrakesh100% (1)

- 803 Aluminum Alloys For Chill Casting and Low Pressure CastingDocumento4 pagine803 Aluminum Alloys For Chill Casting and Low Pressure Castingketan1965Nessuna valutazione finora

- Sew 555-2001 - 7.5.2018Documento12 pagineSew 555-2001 - 7.5.2018Nav Talukdar100% (1)

- General Documentation - RecrystallizationDocumento11 pagineGeneral Documentation - RecrystallizationAlbokeaNessuna valutazione finora

- EN8 Steel: BS970: 1955 EN8, BS970/PD970: 1970 OnwardsDocumento1 paginaEN8 Steel: BS970: 1955 EN8, BS970/PD970: 1970 Onwardsgowtham_venkat_4Nessuna valutazione finora

- Heat Resitant Steel Castings MaterialsDocumento2 pagineHeat Resitant Steel Castings MaterialssusisaravananNessuna valutazione finora

- AISI 410 Martensitic Stainless Steel: Gloria Material Technology CorpDocumento1 paginaAISI 410 Martensitic Stainless Steel: Gloria Material Technology CorppvdangNessuna valutazione finora

- Sa 351Documento6 pagineSa 351Anil0% (1)

- 21 CR Mo V511Documento1 pagina21 CR Mo V511uksrajNessuna valutazione finora

- 253MA High Temperature Resistant TubesDocumento2 pagine253MA High Temperature Resistant TubesBerkan FidanNessuna valutazione finora

- Weldability of Thermo-Mechanically Rolled Steels Used in Oil and Gas Offshore StructuresDocumento8 pagineWeldability of Thermo-Mechanically Rolled Steels Used in Oil and Gas Offshore StructurestheijesNessuna valutazione finora

- A319Documento2 pagineA319malika_000% (1)

- Aerospace Material Specification: Plating, Nickel General PurposeDocumento8 pagineAerospace Material Specification: Plating, Nickel General PurposeSURYAS63Nessuna valutazione finora

- Book - Creep High Temperature Component Analysis Overview of Assesment and Design ProceduresDocumento89 pagineBook - Creep High Temperature Component Analysis Overview of Assesment and Design ProceduresHamdani NurdinNessuna valutazione finora

- Tool Steel Alloy Cr12MoVDocumento5 pagineTool Steel Alloy Cr12MoVMujjo Sahb100% (1)

- TL-DSV 2012-05 Engl Br-1Documento5 pagineTL-DSV 2012-05 Engl Br-1Dorota HONessuna valutazione finora

- Supraform S315-700 MC / EN10149-2 S315-700 MC: Hot Rolled High Strength Low Alloy Structural Steel CoilDocumento2 pagineSupraform S315-700 MC / EN10149-2 S315-700 MC: Hot Rolled High Strength Low Alloy Structural Steel CoilHugo RodriguezNessuna valutazione finora

- 253 MA Austenitic - High - Temperature - Grades - Datasheet PDFDocumento12 pagine253 MA Austenitic - High - Temperature - Grades - Datasheet PDFAbdulNessuna valutazione finora

- 2370 Ed1 ENDocumento5 pagine2370 Ed1 ENanhthoNessuna valutazione finora

- Aisi 4140 Alloy Steel (Uns g41400)Documento4 pagineAisi 4140 Alloy Steel (Uns g41400)Deepak ChaurasiaNessuna valutazione finora

- Din 1.4003Documento2 pagineDin 1.4003Dhaniel100% (1)

- Alloy286 - ASTM A453 660 DatasheetDocumento2 pagineAlloy286 - ASTM A453 660 Datasheetn1ghtfallNessuna valutazione finora

- 50 CR Mo 4Documento4 pagine50 CR Mo 4Diogo NascimentoNessuna valutazione finora

- Al Busbar 6060 DatasheetDocumento1 paginaAl Busbar 6060 DatasheetpiirsaluNessuna valutazione finora

- Maleable Cast IronsDocumento0 pagineMaleable Cast IronsGilang Miky Pratama AlwianNessuna valutazione finora

- en 10213 2007 Steel Castings For Pressure Purposes PDFDocumento29 pagineen 10213 2007 Steel Castings For Pressure Purposes PDFPramod NautiyalNessuna valutazione finora

- Material Equivalents Table: Werkstoffnr. DIN Aisi/Astm/Sae BS Afnor Cast IronDocumento3 pagineMaterial Equivalents Table: Werkstoffnr. DIN Aisi/Astm/Sae BS Afnor Cast IronGohilakrishnan ThiagarajanNessuna valutazione finora

- Minfm32202 Din 17445 Grade G X5crni13 4 Quenched and Tempered qt1Documento3 pagineMinfm32202 Din 17445 Grade G X5crni13 4 Quenched and Tempered qt1Biraj SahooNessuna valutazione finora

- SIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Documento5 pagineSIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Rajoo PrajapatiNessuna valutazione finora

- A580A580M-15 Standard Specification For Stainless Steel WireDocumento5 pagineA580A580M-15 Standard Specification For Stainless Steel Wiretjt4779Nessuna valutazione finora

- Thermanit 17-06 (Boehler)Documento1 paginaThermanit 17-06 (Boehler)queno1Nessuna valutazione finora

- Afnor 28 CDV 5-08 SteelDocumento1 paginaAfnor 28 CDV 5-08 SteelMagoroku D. YudhoNessuna valutazione finora

- 1 2312 PDFDocumento4 pagine1 2312 PDFFrancisco CarrascoNessuna valutazione finora

- ASTM 213, t22Documento22 pagineASTM 213, t22amolgadgikar100% (1)

- Salt Bath FurnaceDocumento7 pagineSalt Bath FurnacehavejsnjNessuna valutazione finora

- Aisi 4340 Alloy Steel (Uns g43400)Documento4 pagineAisi 4340 Alloy Steel (Uns g43400)Muhamad Ikbal TrismanaNessuna valutazione finora

- Duplex Stainless Steel 329 or 1.4460 PDFDocumento2 pagineDuplex Stainless Steel 329 or 1.4460 PDFtien100% (1)

- Steel IndexDocumento24 pagineSteel IndexAnonymous AlhzFE9EVNNessuna valutazione finora

- Powder Components Heat Treatment PDFDocumento47 paginePowder Components Heat Treatment PDFsmani170Nessuna valutazione finora

- Nfa 49 310 Grade Tu 52 B Tubes PDFDocumento1 paginaNfa 49 310 Grade Tu 52 B Tubes PDFMitul MehtaNessuna valutazione finora

- GX300CrMo15 3Documento1 paginaGX300CrMo15 3jdash0904Nessuna valutazione finora

- Comparison List Copper Bronze 2011 1Documento7 pagineComparison List Copper Bronze 2011 1NaldoVicenteNessuna valutazione finora

- Interlloy 440C MartensiticDocumento4 pagineInterlloy 440C MartensiticGuillaume BoyerNessuna valutazione finora

- A723A723M-18a 1.05 PDFDocumento5 pagineA723A723M-18a 1.05 PDFist93993Nessuna valutazione finora

- 16MnCr5 1.7131 16MnCrS5 1.7139 RM16 ENGDocumento2 pagine16MnCr5 1.7131 16MnCrS5 1.7139 RM16 ENGJerzy RistujczinNessuna valutazione finora

- Alloy Process Data Sheet - 105-85Documento3 pagineAlloy Process Data Sheet - 105-85Ugur KayaNessuna valutazione finora

- Bearing Steel Material Specification Sheet SAE52100Documento1 paginaBearing Steel Material Specification Sheet SAE52100Christy Vijay Roy HenryNessuna valutazione finora

- Astm A447Documento3 pagineAstm A447quality kslNessuna valutazione finora

- 13-8 MoDocumento2 pagine13-8 MofedaquiNessuna valutazione finora

- Aluminium - Specifications, Properties, Classifications and Classes, Supplier Data by AalcoDocumento2 pagineAluminium - Specifications, Properties, Classifications and Classes, Supplier Data by Aalcowongtathong1987Nessuna valutazione finora

- Schallater Gaas80 Gaa100 DownloadDocumento4 pagineSchallater Gaas80 Gaa100 DownloadRakesh SrivastavaNessuna valutazione finora

- 42 Crmo 4Documento2 pagine42 Crmo 4Shiva Kumar MNessuna valutazione finora

- En10083-2 - 1996 - C35eDocumento3 pagineEn10083-2 - 1996 - C35ealextentwentyNessuna valutazione finora

- C45EDocumento3 pagineC45ETrương Định100% (1)

- 42 CR Mo 4Documento2 pagine42 CR Mo 4niladriprasadrNessuna valutazione finora

- 42CrMo4 Datos Tecnicos PDFDocumento2 pagine42CrMo4 Datos Tecnicos PDFjlplazaolaNessuna valutazione finora

- FoxitPDFEditor20 ManualDocumento204 pagineFoxitPDFEditor20 Manuallavius_mNessuna valutazione finora

- Specifications For Aluminum Ingot Alloys (ASTM B179-03) : Alloy SI FE CU MN MG CR NI ZN TI SN OE OTDocumento1 paginaSpecifications For Aluminum Ingot Alloys (ASTM B179-03) : Alloy SI FE CU MN MG CR NI ZN TI SN OE OTlavius_mNessuna valutazione finora

- CuZn 39 PB 3Documento2 pagineCuZn 39 PB 3lomas34Nessuna valutazione finora

- Rockwell Brin Dell Hardness ConvDocumento1 paginaRockwell Brin Dell Hardness Convlavius_mNessuna valutazione finora

- Quality 18nicrmo5: Applications: High-Stress Gearwheels Components and CamshaftsDocumento1 paginaQuality 18nicrmo5: Applications: High-Stress Gearwheels Components and Camshaftslavius_mNessuna valutazione finora

- Materialcomprison GHISADocumento3 pagineMaterialcomprison GHISAlavius_mNessuna valutazione finora

- Quality: Astm A 105Documento1 paginaQuality: Astm A 105lavius_mNessuna valutazione finora

- JIG Level-A Banned Substances Threshold, Homogeneous LevelDocumento1 paginaJIG Level-A Banned Substances Threshold, Homogeneous Levellavius_mNessuna valutazione finora

- PA12GDocumento1 paginaPA12Glavius_mNessuna valutazione finora

- Hostaform® POM Processing: Automotive IndustryDocumento1 paginaHostaform® POM Processing: Automotive Industrylavius_mNessuna valutazione finora

- 20NiCrMo2 2 PDFDocumento2 pagine20NiCrMo2 2 PDFlavius_mNessuna valutazione finora

- Arun Et al-2019-ChemistrySelectDocumento8 pagineArun Et al-2019-ChemistrySelectRavi Kumar ARunNessuna valutazione finora

- PhillipsDocumento22 paginePhillipsArthur RodriguezNessuna valutazione finora

- Tramlink Low-Floor Light Rail Vehicle: Rostocker Strassenbahn Ag, Rostock, GermanyDocumento2 pagineTramlink Low-Floor Light Rail Vehicle: Rostocker Strassenbahn Ag, Rostock, GermanyLuca Marius CristianNessuna valutazione finora

- Lighting Layout Power Layout: Single Line Diagram LegendDocumento1 paginaLighting Layout Power Layout: Single Line Diagram LegendAnieken AyoNessuna valutazione finora

- Workstation-Sub Micro Space PlanDocumento21 pagineWorkstation-Sub Micro Space Planarnella_hNessuna valutazione finora

- Cardox-Blockage Removal SystemDocumento5 pagineCardox-Blockage Removal SystemNaelNessuna valutazione finora

- EmpanelHospList HelpFAQDocumento13 pagineEmpanelHospList HelpFAQaditi001Nessuna valutazione finora

- Image AnalysisDocumento404 pagineImage Analysisholyfreeman34Nessuna valutazione finora

- Online Bank SynopsisDocumento7 pagineOnline Bank SynopsisPrashant VermaNessuna valutazione finora

- An Introduction To Error-Correcting Codes: The Virtues of RedundancyDocumento38 pagineAn Introduction To Error-Correcting Codes: The Virtues of RedundancyKrish Cs20Nessuna valutazione finora

- NFC Reader LibrarayDocumento63 pagineNFC Reader Libraraysekhar479Nessuna valutazione finora

- Dehp 780 MPDocumento104 pagineDehp 780 MPVitorNessuna valutazione finora

- GCC TutorialDocumento4 pagineGCC Tutorialistanbulizma5803100% (5)

- Heat ConductionDocumento11 pagineHeat ConductionAlex Samuel SilvaNessuna valutazione finora

- Contactor HassDocumento1 paginaContactor Hassecaldera10Nessuna valutazione finora

- On Pressure and Velocity Boundary Conditions For The Lattice Boltzmann BGK ModelDocumento9 pagineOn Pressure and Velocity Boundary Conditions For The Lattice Boltzmann BGK Modelamin110110Nessuna valutazione finora

- Ece T 2012 ToppersDocumento13 pagineEce T 2012 ToppersRajesh LingamalluNessuna valutazione finora

- Lexus Brand BrochureDocumento40 pagineLexus Brand Brochurejammypops100% (1)

- The Relevance of YS/UTS RatioDocumento21 pagineThe Relevance of YS/UTS RatiocarrespmNessuna valutazione finora

- Chapter 13: Worksheet Mark SchemeDocumento2 pagineChapter 13: Worksheet Mark SchemeAdam DanialNessuna valutazione finora

- Agroforestry: A Sustainable Land-Use System For Food and WoodDocumento72 pagineAgroforestry: A Sustainable Land-Use System For Food and WoodAlok PatraNessuna valutazione finora

- En 10268Documento4 pagineEn 10268Alex LacerdaNessuna valutazione finora

- PHP Practicals With SolutionDocumento31 paginePHP Practicals With SolutionBharti100% (3)

- Memory QVL 3rd Gen AMD Ryzen Processors PDFDocumento14 pagineMemory QVL 3rd Gen AMD Ryzen Processors PDFნიკო ქარცივაძეNessuna valutazione finora

- 7-2-c Form - Gen Consultant PQ Summary Rev-0Documento4 pagine7-2-c Form - Gen Consultant PQ Summary Rev-0Tori SmallNessuna valutazione finora

- Ch2 Snapshot 20 LightingDocumento4 pagineCh2 Snapshot 20 Lightinggarych72Nessuna valutazione finora

- The Scientist PDFDocumento68 pagineThe Scientist PDFPetcu Adrian100% (1)

- TIA Workshop ITBDocumento48 pagineTIA Workshop ITBFirman Suhendra100% (1)

- V8 Pro BRDocumento20 pagineV8 Pro BRwtn2013Nessuna valutazione finora

- Braemar ApplicationDocumento2 pagineBraemar Applicationjoemedia0% (1)