Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bearing Number Codes

Caricato da

DSGCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Bearing Number Codes

Caricato da

DSGCopyright:

Formati disponibili

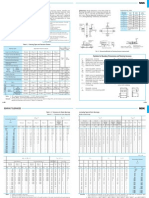

Boundary Dimensions and Bearing Number Codes

5. Boundary Dimensions and Bearing Number Codes

5.1 Boundary dimensions

A rolling bearing's major dimensions, known as "boundary dimensions," are shown in Figs. 5.1 - 5.3. To facilitate international bearing interchangeability and economical bearing production, bearing boundary dimensions have been standardized by the International Standards Organization (ISO). In Japan, rolling bearing boundary dimensions are regulated by Japanese Industrial Standards (JIS B 1512). Those boundary dimensions which have been standardized include: bearing bore diameter, outside diameter, width/height, and chamfer dimensions - all important dimensions when considering the compatibility of shafts, bearings, and housings. However, as a general rule,

B r r r r1 r1 r r r r r d D E B d D D1 D r r T r T C d1 d r r

bearing internal construction dimensions are not covered by these dimensions. For metric series rolling bearings there are 90 standardized bore diameters (d) ranging in size from 0.6mm - 2,500mm. Outer diameter dimensions (D) for radial bearings with standardized bore diameter dimensions are covered in the "diameter series;" their corresponding width dimensions (B) are covered in the "width series." For thrust bearings there is no width series; instead, these dimensions are covered in the "height series." The combination of all these series is known as the "dimension series." All series numbers are shown in Table 5.1. Although many rolling bearing dimensions are standardized, and have been listed here for purposes of

Fig. 5.1 Radial bearings (excluding tapered roller bearings) Table 5.1 Dimension series numbers

Fig. 5.2 Tapered roller bearings

Fig. 5.3 Single direction thrust bearings

Dimension series Diameter series (outer diameter dimensions) Radial bearings (excluding tapered roller bearings) Tapered roller bearings Width series (width dimensions) Height series Reference (height dimensions) diagram Diagram 5.4

number 7, 8, 9, 0, 1, 2, 3, 4 8, 0, 1, 2, 3, 4, 5, 6 dimensions small number large small 0, 1, 2, 3 small large 7, 9, 1, 2 small large large

9, 0, 1, 2, 3 large

Diagram 5.5

dimensions small number

Thrust bearings

0, 1, 2, 3, 4 large

dimensions small

Diagram 5.6

Dimension Diameter series series Height series

Width series Diameter series

8

4 3 2 1 0 9 8

6 01 2 3 4

70 71 72 73 08 09 00 01 02 03 18 19 10 12 11 13 74 29 20 22 38 39 30 31 32 23 24 41 42 58 59 50 68 69 33 48 49 40 60 90 92 91 93 94 83

28

21

Dimension series

82

04

Fig. 5.4 Dimension series for radial bearings (excluding tapered roller bearings; diameter series 7 has been omitted)

3

10 11 12 13 14

Diameter series

2 1 0 9

22 2 23

0 2

Width series

24

Fig. 5.5 Dimension series for tapered roller bearings

Fig. 5.6 Dimension series for thrust bearings (excluding diameter series 5)

A-30

Boundary Dimensions and Bearing Number Codes

future standardization, there are many standard bearing dimensions which are not presently manufactured. Boundary dimensions for radial bearings (excluding tapered roller bearings) are shown in the attached tables.

"basic number" followed by "supplementary codes." The makeup and order of bearing numbers is shown in Table 5.2. The basic number indicates general information about a bearing, such as its fundamental type, boundary dimensions, series number, bore diameter code and contact angle. The supplementary codes derive from prefixes and suffixes which indicate a bearing's tolerances, internal clearances, and related specifications.

5.2 Bearing numbers

Rolling bearing part numbers indicate bearing type, dimensions, tolerances, internal construction, and other related specifications. Bearing numbers are comprised of a

(Bearing number examples)

6205ZZC32AS

Shell Alvania S2 grease Radial internal clearance C3 Shielded (both) Nominal bore diameter 25mm Diameter series 2 Deep groove ball bearing

23034BD1

Lubrication hole/lubrication groove (when outer diameter is less than 320mm) Type B Nominal bore diameter 170mm Dimension series 0 Width series 3 Spherical roller bearing

7012BDBGMP6

Tolerances JIS Class 6 Medium preload Back-to-back duplex arrangement Contact angle 40 Nominal bore diameter 60mm Dimension series 0 Angular contact ball bearing

240750BK30

Bore diameter: tapered inner ring bore, standard taper ratio 1:30 Type B Bore diameter 750mm Dimension series 0 Width series 4 Spherical roller bearing

NU320G1C3

Radial internal clearance C3 High strength machined brass rivetless cage with square holes Nominal bore diameter 100mm Dimension series 3 Cylindrical roller bearing NU type

51120L1P5

Tolerances JIS Class 5 High strength, machined brass cage Nominal bore diameter 100mm Diameter series 1 Height series 1 Thrust ball bearing

4T30208

Nominal bore diameter 40mm Diameter series 2 Width series 0 Tapered roller bearing Spec. 4T

A-31

Boundary Dimensions and Bearing Number Codes

Table 5.2 Bearing number composition and arrangement Basic number Supplementary prefix code Special application/material/ heat treatment code 4T: ET: 4T tapered roller bearings ET tapered roller bearings Bearing series code Bearing series Dimension series code Width/height series

1

Diameter series

Bore diameter code bore Code diameter mm

Contact angle code Code

1

Contact angle

Deep groove ball bearings (type code 6)

68 69 60 62 63 78 79 70 72 73 (1) (1) (1) (0) (0) (1) (1) (1) (0) (0) 8 9 0 2 3 8 9 0 2 3

/0.6 /1.5 /2.5 1

0.6 1.5 2.5 1

ETA: ET+special heat treatment E: EA: Bearing using case hardened steel Bearing made of nitride-treated case hardened steel Bearing made of nitride-treated bearing steel (SUJ3) Bearing made of special heat-treated bearing steel (SUJ3) Stainless steel bearings High speed steel bearings Plated bearings Ceramic rolling element bearings HL roller bearings

Angular contact ball bearings A Standard contact angle 30 B Standard contact angle 40 Standard contact angle 15 C Tapered roller bearings B Contact angle over 10 C to/including 17 D Contact angle over 17 to/including 24 Contact angle over 24 to/including 32

Angular contact ball bearings (type code 7)

9 00 01 02 03 /22 /28 /32 04 05 06

9 10 12 15 17 22 28 32 20 25 30

TA:

Self-aligning ball bearings (type code 1,2)

12 13 22 23 NU10 NU2 NU22 NU3 NU23 NU4 NNU49 NN30 329X 320X 302 322 303 303D 313X 323 239 230 240 231 241 222 232 213 223 511 512 513 514 811 812 893 (0) (0) (2) (2) 1 (0) 2 (0) 2 (0) 4 3 2 2 0 2 0 0 1 2 3 3 4 3 4 2 3 1 2 1 1 1 1 1 1 9 2 3 2 3 0 2 2 3 3 4 9 0 9 0 2 2 3 3 3 3 9 0 0 1 1 2 2 3 3 1 2 3 4 1 2 3

TM:

Cylindrical roller bearings (type code NU, N, NF, NNU, NN, etc.)

F: N: M: 5S: HL:

88 92 96 /500 /530 /560 /2,360 /2,500

440 460 480 500 530 560

Tapered roller bearings (type code 3)

ECO: ECO-Top tapered roller bearings LH: Bearing made of bearing steel that provides long life at high temperatures (STJ2), which is treated to stabilize dimensions at temperatures up to 250C Dimension stabilized bearing for high temperature use (to 200C) Dimension stabilized bearing for high temperature use (to 250C)

2,360 2,500

Spherical roller bearings (type code 2)

TS3:

TS4:

Single direction thrust ball bearings (type code 5)

Cylindrical roller thrust bearings (type code 8)

Spherical thrust roller bearings (type code 2) 292 9 2 293 9 3 294 9 4

1 Codes in ( ) are not shown in nominal numbers. Note: Please consult NTN Engineering concerning bearing series codes, and supplementary prefix/suffix codes not listed in the above table.

A-32

Boundary Dimensions and Bearing Number Codes

Supplementary suffix codes Internal modifications code U: Internationally interchangeable tapered roller bearings R: Noninternationally interchangeable tapered roller bearings ST: Low torque tapered roller bearings HT: High axial load use cylindrical roller bearings Seal / Shield code LLB: Synthetic rubber seal (noncontact type) External configuration code K: Tapered inner ring bore, standard taper ratio 1:12 Duplex Internal clearance arrangement code /preload code DB: Back-to-back arrangement DF: Face-to-face arrangement DT: Tandem arrangement D2: Two matched, paired bearings C2: Internal clearance less than normal (CN): Normal clearance C3: Internal clearance greater than normal

1

cage code L1: High strength, machined brass cage F1: Machined carbon steel cage G1: High strength machined brass rivetless cage with square holes, G2: Pin type cage J: Pressed steel cage T2: Plastic mold cage

Tolerance code Lubrication code P6: JIS Class 6 P5: JIS Class 5 P4: JIS Class 4 P2: JIS Class 2 2: ABMA Class 2 3: ABMA Class 3 0: ABMA Class 0 00: ABMA Class 00 /2AS: Shell Alvania S2 grease /3AS: Shell Alvania S3 grease /8A: Shell Alvania EP2 grease /5K: MULTEMP SRL /LX11: Barierta JFE552 /LP03: Thermosetting grease (grease for poly-lube bearings)

LLU: Synthetic rubber K30: seal Tapered inner (contact type) ring bore, standard taper LLH: ratio 1:30 Synthetic rubber seal N: (low-torque type) With snap ring groove ZZ: Steel shield NR: With snap ring D: With oil hole D1: Lubrication hole/lubrication groove

C4: Internal G: Flush ground clearance greater than C3 : Spacer C5: (= spacers Internal standard width clearance dimensions) greater than C4 CM: Radial internal clearance for electric motor use /GL: Light preload /GN: Normal preload /GM: Medium preload /GH: Heavy preload

A-33

Potrebbero piacerti anche

- Adobe Photoshop 9 Cs2 Serial + Activation Number & Autorization Code ADocumento1 paginaAdobe Photoshop 9 Cs2 Serial + Activation Number & Autorization Code ARd Fgt36% (22)

- Bearing Size Chart GuideDocumento17 pagineBearing Size Chart Guideocchitya100% (15)

- 7 - Lakhs Bank EstimateDocumento8 pagine7 - Lakhs Bank Estimatevikram Bargur67% (3)

- MockupDocumento1 paginaMockupJonathan Parra100% (1)

- Rolling Element Bearing BasicsDocumento3 pagineRolling Element Bearing BasicssubbusenthilNessuna valutazione finora

- Dryer-Pulveriser Powder PerfectionDocumento8 pagineDryer-Pulveriser Powder PerfectionEmre AfacanNessuna valutazione finora

- DSR Aor For Wet Riser and Sprinkler System 2019Documento110 pagineDSR Aor For Wet Riser and Sprinkler System 2019Sambit Pattanaik50% (2)

- Day / Month / Year: Certificate of No Criminal Conviction Applicant Data Collection Form (LOCAL)Documento4 pagineDay / Month / Year: Certificate of No Criminal Conviction Applicant Data Collection Form (LOCAL)Lhea RecenteNessuna valutazione finora

- Infor Mashup SDK Developers Guide Mashup SDKDocumento51 pagineInfor Mashup SDK Developers Guide Mashup SDKGiovanni LeonardiNessuna valutazione finora

- 2011 REV SAE Suspension Kiszco PDFDocumento112 pagine2011 REV SAE Suspension Kiszco PDFRushik KudaleNessuna valutazione finora

- Catalogo SKFDocumento546 pagineCatalogo SKFa508593780% (5)

- Bearing Number CodesDocumento3 pagineBearing Number CodesgksamyNessuna valutazione finora

- SKF Bearing Types and Nomenclature GuideDocumento19 pagineSKF Bearing Types and Nomenclature GuidesordelaflorNessuna valutazione finora

- SKF Ball Bearing DimensionsDocumento44 pagineSKF Ball Bearing Dimensionsmobax1Nessuna valutazione finora

- SKF NameDocumento26 pagineSKF NameIslam Fawzy100% (1)

- Bearing TypesDocumento7 pagineBearing TypesMaintenance Circle100% (1)

- Fag Rolling BearingsDocumento56 pagineFag Rolling BearingsmgkalfasNessuna valutazione finora

- Basic Knowledge For Using Bearings SafelyDocumento40 pagineBasic Knowledge For Using Bearings SafelypibearingNessuna valutazione finora

- Worm GearboxDocumento20 pagineWorm Gearboxsonal joshi100% (1)

- EleconDocumento72 pagineEleconPranit BangeraNessuna valutazione finora

- Bearing Number Code ReferenceDocumento6 pagineBearing Number Code ReferenceIbraheem KhressNessuna valutazione finora

- Identification and Analysis of Bearing & Accessory FailureDocumento13 pagineIdentification and Analysis of Bearing & Accessory FailureAbul Ishaque Mohammed IbrahimNessuna valutazione finora

- 16699EN Spherical ShimsDocumento6 pagine16699EN Spherical ShimsCarlos PinnaNessuna valutazione finora

- Types of GearsDocumento22 pagineTypes of GearsAnonymous 2RbW9dNessuna valutazione finora

- Gates Belt For Fin FanDocumento131 pagineGates Belt For Fin FanJeffry KarundengNessuna valutazione finora

- Bearing Numbers Explained: A Guide to Prefixes, Basic Numbers and SuffixesDocumento3 pagineBearing Numbers Explained: A Guide to Prefixes, Basic Numbers and Suffixesshahadat08Nessuna valutazione finora

- BaltimoreAircoil PartsGuide 2012 PDFDocumento56 pagineBaltimoreAircoil PartsGuide 2012 PDFMichael Jordan100% (1)

- SKF Bearing DesignationsDocumento0 pagineSKF Bearing DesignationsPatrick BaridonNessuna valutazione finora

- Purpose, Types and Applications of BearingsDocumento15 paginePurpose, Types and Applications of BearingsSeanRiniFernando100% (1)

- Analysis of Bearing ClearancesDocumento8 pagineAnalysis of Bearing Clearancesbwelz100% (1)

- Bearings NomenclaturesDocumento76 pagineBearings NomenclaturesgksamyNessuna valutazione finora

- Grease Select Guide PDFDocumento12 pagineGrease Select Guide PDFeng13Nessuna valutazione finora

- Sleeve BearingsDocumento18 pagineSleeve BearingsrikumohanNessuna valutazione finora

- BearingDocumento423 pagineBearingaubd100% (2)

- BearingDocumento41 pagineBearingM.IBRAHEEMNessuna valutazione finora

- Grease Refill QtyDocumento3 pagineGrease Refill QtyParmasamy SubramaniNessuna valutazione finora

- Morgoil Bearings Used in Rolling MillsDocumento84 pagineMorgoil Bearings Used in Rolling MillsRohit chavan100% (1)

- SKF Angular Contact Ball Bearings - Your Key To Longer Service LifeDocumento44 pagineSKF Angular Contact Ball Bearings - Your Key To Longer Service LifeBrunoNessuna valutazione finora

- FAG Bearings For Rolling Mills Application PDFDocumento69 pagineFAG Bearings For Rolling Mills Application PDFPintu SarkarNessuna valutazione finora

- Bearing Failure Modes GuideDocumento4 pagineBearing Failure Modes Guideaaa2175Nessuna valutazione finora

- GearsDocumento30 pagineGearsBernard MusonaNessuna valutazione finora

- Mill GearboxDocumento428 pagineMill GearboxAli Alatas100% (1)

- Kraus ProductDocumento56 pagineKraus ProductSoemedy TanNessuna valutazione finora

- Complete CatalogDocumento651 pagineComplete CatalogFernando EscriváNessuna valutazione finora

- 2 - Rolling Bearing FundamentalsDocumento35 pagine2 - Rolling Bearing FundamentalsZiggy Gregory100% (1)

- Gear Coupling FGCDocumento4 pagineGear Coupling FGCMandar PundeNessuna valutazione finora

- Rim Face V Bs Dial On MovableDocumento1 paginaRim Face V Bs Dial On MovablereiNessuna valutazione finora

- Maintenance Troubleshooting GuideDocumento28 pagineMaintenance Troubleshooting Guidenordsmendoza100% (1)

- Encoders Catalog 2012Documento28 pagineEncoders Catalog 2012sreelakshmisnr100% (1)

- NBC Bearings TrainingDocumento23 pagineNBC Bearings TrainingChiragJoshi25% (4)

- SKF Bearing Handbook For Electric MotorsDocumento32 pagineSKF Bearing Handbook For Electric Motorskuruvillaj2217100% (2)

- Bearing Failure Analysis-V2Documento9 pagineBearing Failure Analysis-V2Anonymous omGSHUEQNessuna valutazione finora

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDa EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNessuna valutazione finora

- Boundary Dimensions and Bearing Number CodesDocumento4 pagineBoundary Dimensions and Bearing Number Codesps_07inNessuna valutazione finora

- Boundary Dimensions and Bearing Number CodesDocumento4 pagineBoundary Dimensions and Bearing Number CodesPutra Kanjeng Romo RomoNessuna valutazione finora

- Plummer Block DskatkasndfmDocumento30 paginePlummer Block DskatkasndfmVivek AradhyaNessuna valutazione finora

- Bearing tolerances explainedDocumento18 pagineBearing tolerances explainedDiego MiseNessuna valutazione finora

- NSK Cat E728g 1Documento6 pagineNSK Cat E728g 1shukhanNessuna valutazione finora

- Plummer Block Housings: FeaturesDocumento3 paginePlummer Block Housings: FeaturesrefeiNessuna valutazione finora

- Basic Knowledge of Koyo BearingsDocumento34 pagineBasic Knowledge of Koyo BearingsJinto A JNessuna valutazione finora

- 1 141227035156 Conversion Gate02 PDFDocumento52 pagine1 141227035156 Conversion Gate02 PDFPhasin ChitutsahaNessuna valutazione finora

- Iso 281:2007Documento6 pagineIso 281:2007Daniel LiawNessuna valutazione finora

- SKF Thrust BearingsDocumento20 pagineSKF Thrust BearingsBùi Văn HợpNessuna valutazione finora

- BEARING TOLERANCES TABLEDocumento12 pagineBEARING TOLERANCES TABLESandeep MatetiNessuna valutazione finora

- SKF Cylindircal Roller BearingsDocumento36 pagineSKF Cylindircal Roller Bearingskvramanan_1100% (1)

- Bearing TerminologiDocumento9 pagineBearing Terminologihengki wibowoNessuna valutazione finora

- 4rCRB Mounting and Maintenance InstructionsDocumento21 pagine4rCRB Mounting and Maintenance InstructionsNishant JhaNessuna valutazione finora

- EPRI Materials Degradation - Aging 2008 - P041.01Documento44 pagineEPRI Materials Degradation - Aging 2008 - P041.01DSGNessuna valutazione finora

- 3 APH PERFORMANCE in NTPC STATIONS AjaySharmaDocumento15 pagine3 APH PERFORMANCE in NTPC STATIONS AjaySharmaDSGNessuna valutazione finora

- Physical Metallurgy-18 Heat Treatment of SteelDocumento7 paginePhysical Metallurgy-18 Heat Treatment of SteelDSGNessuna valutazione finora

- SS - PR - PWR - PRB Guidelines P-Rod PicsDocumento47 pagineSS - PR - PWR - PRB Guidelines P-Rod PicsDSGNessuna valutazione finora

- L18 Lecture 18 Wear 1 PDFDocumento6 pagineL18 Lecture 18 Wear 1 PDFDSGNessuna valutazione finora

- Blow Down Calculation For BoilerDocumento3 pagineBlow Down Calculation For BoilerCarla RodriguesNessuna valutazione finora

- The Storage of High Volatile CoalDocumento2 pagineThe Storage of High Volatile CoalcoalspotNessuna valutazione finora

- How To Use This Severity Chart: Example Fan 625 Um (25 Mils)Documento2 pagineHow To Use This Severity Chart: Example Fan 625 Um (25 Mils)Aminul Haque SaikiaNessuna valutazione finora

- Assignment 1 Mech 321 Properties and Failure of Materials Jan 2009Documento2 pagineAssignment 1 Mech 321 Properties and Failure of Materials Jan 2009DSGNessuna valutazione finora

- Chapter Outline:: Heat Treatment (And Temperature)Documento24 pagineChapter Outline:: Heat Treatment (And Temperature)DSGNessuna valutazione finora

- Fighting Fire With CO: by Dominique Dieken, P.E., Starr Technical Risks Agency IncDocumento6 pagineFighting Fire With CO: by Dominique Dieken, P.E., Starr Technical Risks Agency IncDSGNessuna valutazione finora

- Science From 2-Chapter5Documento21 pagineScience From 2-Chapter5Kalvin Ng Chong YuNessuna valutazione finora

- Hunting Problems On Ind Drive TurbinesDocumento3 pagineHunting Problems On Ind Drive TurbinesDSGNessuna valutazione finora

- TATA Power Scaffold Safety StandardDocumento7 pagineTATA Power Scaffold Safety StandardDSG100% (1)

- Actizal Energy Audit Trials Report SummaryDocumento28 pagineActizal Energy Audit Trials Report SummaryDSGNessuna valutazione finora

- Running Hrs of Tungsten Carbide Grinding RollerDocumento1 paginaRunning Hrs of Tungsten Carbide Grinding RollerDSGNessuna valutazione finora

- Novajet: Multipurpose Self-Adhesive LabelsDocumento1 paginaNovajet: Multipurpose Self-Adhesive LabelsKartik Maheshwari HolaniNessuna valutazione finora

- Boiler Plant Mechanical EquipmentDocumento52 pagineBoiler Plant Mechanical EquipmentAriyandiNessuna valutazione finora

- SKF BRGDocumento22 pagineSKF BRGVijeth99Nessuna valutazione finora

- Running Hrs of Tungsten Carbide Grinding RollerDocumento1 paginaRunning Hrs of Tungsten Carbide Grinding RollerDSGNessuna valutazione finora

- Bowl Mill Study 1Documento10 pagineBowl Mill Study 1DSG100% (1)

- Cladding Technology Processes and ImagesDocumento7 pagineCladding Technology Processes and ImagesDSGNessuna valutazione finora

- Installation and Maintenance of SwitchgearDocumento12 pagineInstallation and Maintenance of SwitchgearcharzreeNessuna valutazione finora

- Technical Report On Electrostatic Precipitator: Geeco Enercon PVT LTD Tiruchirapalli - 620015 IndiaDocumento21 pagineTechnical Report On Electrostatic Precipitator: Geeco Enercon PVT LTD Tiruchirapalli - 620015 IndiaDSGNessuna valutazione finora

- Performance Improvement by Expert ConsultancyDocumento19 paginePerformance Improvement by Expert ConsultancyDSGNessuna valutazione finora

- FAG Bearing SuffixesDocumento4 pagineFAG Bearing SuffixesDSGNessuna valutazione finora

- KKS classification system for turbine I&CDocumento18 pagineKKS classification system for turbine I&Crawatbs2020Nessuna valutazione finora

- GEECO Seminar Spare Parts ServicesDocumento12 pagineGEECO Seminar Spare Parts ServicesDSGNessuna valutazione finora

- Battery Charger Manual - HBL PDFDocumento12 pagineBattery Charger Manual - HBL PDFDSG0% (1)

- MCQs on Defence Audit Code Chapter 9 and 10Documento2 pagineMCQs on Defence Audit Code Chapter 9 and 10Rustam SalamNessuna valutazione finora

- Accounts - User Guide: Release R15.000Documento207 pagineAccounts - User Guide: Release R15.000lolitaferozNessuna valutazione finora

- Demoversion IWE 2011Documento47 pagineDemoversion IWE 2011Burag HamparyanNessuna valutazione finora

- Papi AdbDocumento50 paginePapi AdbSilvio Figueiredo0% (1)

- (Unit) Title of The Chapter Name of FacilitatorDocumento35 pagine(Unit) Title of The Chapter Name of FacilitatorDipesh BasnetNessuna valutazione finora

- A Survey of The Advancing Use and Development of Machine Learning in Smart ManufacturingDocumento32 pagineA Survey of The Advancing Use and Development of Machine Learning in Smart Manufacturingbeben_19Nessuna valutazione finora

- Master List of Approved Vendors For Manufacture and Supply of Electrical ItemsDocumento52 pagineMaster List of Approved Vendors For Manufacture and Supply of Electrical ItemsBhoopendraNessuna valutazione finora

- PrefaceDocumento16 paginePrefaceNavaneeth RameshNessuna valutazione finora

- Operations Management For Competitive Advantage 11Th Edition Solutions Manual PDFDocumento2 pagineOperations Management For Competitive Advantage 11Th Edition Solutions Manual PDFLouis DodsonNessuna valutazione finora

- Engineered Cementitious Composites: Practical ApplicationsDocumento26 pagineEngineered Cementitious Composites: Practical Applicationsmubashir ahmedNessuna valutazione finora

- G.R. No. L-54171 October 28, 1980 JEWEL VILLACORTA, Assisted by Her Husband, GUERRERO VILLACORTA, COMPANY, Respondents. TEEHANKEE, Acting C.J.Documento6 pagineG.R. No. L-54171 October 28, 1980 JEWEL VILLACORTA, Assisted by Her Husband, GUERRERO VILLACORTA, COMPANY, Respondents. TEEHANKEE, Acting C.J.Lyra Cecille Vertudes AllasNessuna valutazione finora

- Infineon ICE3BXX65J DS v02 - 09 en PDFDocumento28 pagineInfineon ICE3BXX65J DS v02 - 09 en PDFcadizmabNessuna valutazione finora

- Constitutional Law of India-II CCSU LL.B. Examination, June 2015 K-2002Documento3 pagineConstitutional Law of India-II CCSU LL.B. Examination, June 2015 K-2002Mukesh ShuklaNessuna valutazione finora

- Supply AnalysisDocumento5 pagineSupply AnalysisCherie DiazNessuna valutazione finora

- Payment Solutions For Travel Platform: SabreDocumento2 paginePayment Solutions For Travel Platform: Sabrehell nahNessuna valutazione finora

- Mosfet PDFDocumento13 pagineMosfet PDFTad-electronics TadelectronicsNessuna valutazione finora

- DMT80600L104 21WTR Datasheet DATASHEETDocumento3 pagineDMT80600L104 21WTR Datasheet DATASHEETtnenNessuna valutazione finora

- Flex VPNDocumento3 pagineFlex VPNAnonymous nFOywQZNessuna valutazione finora

- Virtual Content SOPDocumento11 pagineVirtual Content SOPAnezwa MpetaNessuna valutazione finora

- Lessee Information StatementDocumento1 paginaLessee Information Statementmja.carilloNessuna valutazione finora

- LogDocumento85 pagineLogJo NasNessuna valutazione finora

- PhysRevResearch 4 043041Documento6 paginePhysRevResearch 4 043041marco juradoNessuna valutazione finora

- SQL DBA Mod 1 IntroDocumento27 pagineSQL DBA Mod 1 IntroDivyaNessuna valutazione finora

- Computer Application in Business NOTES PDFDocumento78 pagineComputer Application in Business NOTES PDFGhulam Sarwar SoomroNessuna valutazione finora