Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Expansion Bellows

Caricato da

Pramit ShahCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Expansion Bellows

Caricato da

Pramit ShahCopyright:

Formati disponibili

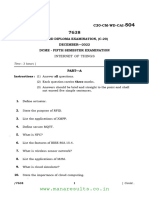

What are Expansion Bellows- The Mystery Unveiled Not everyone is really aware about the usage and

importance of metallic expansion bellows. Being a highly technical term to the industry, Vallabh Engineers decided to unveil the mystery about metallic expansion bellows. What are expansion Bellows? Metallic expansion bellows, or metallic expansion joint for pipe systems are most commonly manufactured out of stainless steel. This is to ensure that they are highly durable, can take a lot of heat and remain in good condition for a longer time. Expansion bellows are also made out of plastic, fiber or rubber. The material ordinarily depends on the purpose of the expansion bellow. How are Expansion Bellows made? Wikipedia states A bellow is made up of a series of one or more convolutions, with the shape of the convolution designed to withstand the internal pressures of the pipe, but flexible enough to accept the axial, lateral, and/or angular deflections. In simpler words, bellows are created in such a way that they can handle the pressure on the inside of the pipe. Nonetheless, they should also be flexible enough to move either way. Why are Expansion Bellows used? In most cases, expansion bellows are used to absorb movement and vibration in the process of transfer of high temperature commodities like steam, exhaust gases etc. However, expansion bellows are also used for other alternative purposes like noise absorption, anti-vibration, earthquake movement and building settlement. Expansion Bellows are auxiliary to any heavy duty, or high pressure processes. They are used in order to minimize the by-products or the process. Accessories for Expansion Bellows Now that we know the what, how and why of metallic expansion bellows, lets look a little deeper. What are the accessories needed in order to efficiently use expansion bellows. 1. Liners: Internal liners are used and needed for reducing use based erosion of the bellow as well as to reduce the turbulence across the bellows during use. 2. Covers: Temporary or permanent, covers are used to avoid damage to the bellows. They also serve the purpose of insulating the bellows. 3. Particulate Barriers or Purge Connectors: Particulate Barriers are used to avoid ceramic fiber from corroding the bellows. Particulate collection causes a restriction in the flexibility of the bellows. This purpose is also met by the purge connectors. The purge connectors are often included in the design of the liners.

4. Limit Rods: As the name suggest, the limit rods are used to restrain the bellows from expanding more than their capacity. Vallabh Engineers only use the best raw material for the manufacturing of their metallic expansion bellows and their accessories. One can rest assured that with Vallabh engineers, one will only receive the best! Visit For More information www.vallabhengineers.com

Potrebbero piacerti anche

- Colibri - DEMSU P01 PDFDocumento15 pagineColibri - DEMSU P01 PDFRahul Solanki100% (4)

- Procurement Audit PlanDocumento12 pagineProcurement Audit PlanMustafa Bilal100% (1)

- Massive X-16x9 Version 5.0 - 5.3 (Latest New Updates in Here!!!)Documento158 pagineMassive X-16x9 Version 5.0 - 5.3 (Latest New Updates in Here!!!)JF DVNessuna valutazione finora

- Elevated Swimming Pool ConstructionDocumento27 pagineElevated Swimming Pool ConstructionMon Resoco100% (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Da EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Valutazione: 5 su 5 stelle5/5 (2)

- Qualifi Level 6 Diploma in Occupational Health and Safety Management Specification October 2019Documento23 pagineQualifi Level 6 Diploma in Occupational Health and Safety Management Specification October 2019Saqlain Siddiquie100% (1)

- Expansion Joint: Road / Bridge Control JointsDocumento3 pagineExpansion Joint: Road / Bridge Control JointsMashudi FikriNessuna valutazione finora

- Back To Basics Expansion JointsDocumento5 pagineBack To Basics Expansion Jointskamal arabNessuna valutazione finora

- Basics of Small Bore FittingsDocumento9 pagineBasics of Small Bore FittingsJosh LeBlancNessuna valutazione finora

- Flex-Hose Co.-FAQ HosesDocumento3 pagineFlex-Hose Co.-FAQ Hosesadfafad gfadfNessuna valutazione finora

- Expansion JointsDocumento10 pagineExpansion JointsArun KumarNessuna valutazione finora

- Water Well Packers: Inflatable Packers International Pty LTD © 2014Documento5 pagineWater Well Packers: Inflatable Packers International Pty LTD © 2014Viller MontalicoNessuna valutazione finora

- Water StopperDocumento6 pagineWater StopperMF YousufNessuna valutazione finora

- What Is A Wear Pad? Functions of Pipe Wear PadsDocumento4 pagineWhat Is A Wear Pad? Functions of Pipe Wear PadsSanjeev KumarNessuna valutazione finora

- StentDocumento1 paginaStentFinn Dhado McCormackNessuna valutazione finora

- How Does A Mechanical Seal in A Pump Function?Documento18 pagineHow Does A Mechanical Seal in A Pump Function?Senthil Kumar PNessuna valutazione finora

- UNIT-3 (Lecture-4) Expansion JointsDocumento38 pagineUNIT-3 (Lecture-4) Expansion JointsSabbir hossainNessuna valutazione finora

- Repairs, Modifications, and Strengthening With Post-Tensioning, PTI Journal, July 2006Documento17 pagineRepairs, Modifications, and Strengthening With Post-Tensioning, PTI Journal, July 2006Viet Duc DangNessuna valutazione finora

- PHD Thesis 10 Chapter1Documento26 paginePHD Thesis 10 Chapter1araz_1985Nessuna valutazione finora

- Washers and Types of WashersDocumento5 pagineWashers and Types of WashersKaran SharmaNessuna valutazione finora

- Tensile StructureDocumento21 pagineTensile StructuresakthivisalakshiNessuna valutazione finora

- Expansion Joint On A BridgeDocumento7 pagineExpansion Joint On A BridgeDomagoj ButumovićNessuna valutazione finora

- 7Documento6 pagine7Sungo GridsawanNessuna valutazione finora

- Oilfield Casing CoreDocumento37 pagineOilfield Casing CoreRuben MejiaNessuna valutazione finora

- PIM500 Flexible HoseDocumento19 paginePIM500 Flexible HosevsvineeshNessuna valutazione finora

- OhioBrass - 27-International Suspension InsulatorsDocumento8 pagineOhioBrass - 27-International Suspension Insulatorslduong4Nessuna valutazione finora

- What Is A Wear Pad Functions of Pipe Wear PadsDocumento3 pagineWhat Is A Wear Pad Functions of Pipe Wear PadsPrabhakar KumarNessuna valutazione finora

- Viscous Dampers Save Structures From Earthquake Damage 7-2013Documento23 pagineViscous Dampers Save Structures From Earthquake Damage 7-2013Nicolas RobertoNessuna valutazione finora

- Expansion Joints & TypesDocumento4 pagineExpansion Joints & TypesgksamyNessuna valutazione finora

- Seal Assemblies (Locator, Anchor, Latch)Documento2 pagineSeal Assemblies (Locator, Anchor, Latch)Yougchu LuanNessuna valutazione finora

- Pamphlet 94 - Edition 5 - January 2018Documento2 paginePamphlet 94 - Edition 5 - January 2018Gary LiangNessuna valutazione finora

- 4page Expansion JointsDocumento4 pagine4page Expansion JointsLudi D. LunarNessuna valutazione finora

- SPE 169190 Improved Zonal Isolation in Open Hole ApplicationDocumento10 pagineSPE 169190 Improved Zonal Isolation in Open Hole ApplicationarlenNessuna valutazione finora

- Semitub DesignDocumento2 pagineSemitub DesignWero579Nessuna valutazione finora

- Assigment 1Documento3 pagineAssigment 1THUTO MOOKETSINessuna valutazione finora

- What Are Labyrinth Seals For BearingsDocumento18 pagineWhat Are Labyrinth Seals For BearingsAthiphap SrisupareerathNessuna valutazione finora

- Self-Ligating Brackets: An Overview: November 2011Documento29 pagineSelf-Ligating Brackets: An Overview: November 2011Monojit DuttaNessuna valutazione finora

- Spe 169190Documento10 pagineSpe 169190Lawrence MbahNessuna valutazione finora

- What Is A Pipe Shoe Its Types and Functions With PDFDocumento4 pagineWhat Is A Pipe Shoe Its Types and Functions With PDFPaulNessuna valutazione finora

- Thread Sealing 101 Tech ArticleDocumento4 pagineThread Sealing 101 Tech ArticleAndy ChongNessuna valutazione finora

- ss-28-4 WebDocumento4 paginess-28-4 Webbman0051401Nessuna valutazione finora

- Hydraulic and PneumaticDocumento15 pagineHydraulic and PneumaticDhvanirNessuna valutazione finora

- BellowsTech Ebook 11-15 Vs4Documento9 pagineBellowsTech Ebook 11-15 Vs4abs0001Nessuna valutazione finora

- Lecture Six Pumping Stations DesignDocumento11 pagineLecture Six Pumping Stations DesignzaidNessuna valutazione finora

- EP-Flex Brochure (LR)Documento8 pagineEP-Flex Brochure (LR)Ahmad FawazyNessuna valutazione finora

- What Is A Pipe SaddleDocumento4 pagineWhat Is A Pipe SaddleAbhishek KaliaNessuna valutazione finora

- Packers and Tubing 42Documento6 paginePackers and Tubing 42Jagdish annayaNessuna valutazione finora

- Bus DuctDocumento60 pagineBus Ductkumaratdbg100% (1)

- Sharkbite® Metal Push-Fit Plumbing Solution: Technical InformationDocumento36 pagineSharkbite® Metal Push-Fit Plumbing Solution: Technical InformationPubcrawlNessuna valutazione finora

- BAFFLESDocumento9 pagineBAFFLESSalma ChakirNessuna valutazione finora

- Expansion JointDocumento1 paginaExpansion JointRana Muhammad Abdullah WakeelNessuna valutazione finora

- PlumbingDocumento10 paginePlumbing丨ㄒ丂ᐯ乇ᗪ卂几ㄒNessuna valutazione finora

- Seal Assemblies (Locator, Anchor, Latch) PDFDocumento2 pagineSeal Assemblies (Locator, Anchor, Latch) PDFkumar abhishek singh100% (1)

- Types of FlangesDocumento12 pagineTypes of FlangesVinod GuptaNessuna valutazione finora

- Manhole CoverDocumento6 pagineManhole CoverMaria SarwatNessuna valutazione finora

- Anchor Watch 02Documento7 pagineAnchor Watch 02Janaka KarunarathnaNessuna valutazione finora

- Self Ligating Brackets: From Past To Present: IP Indian Journal of Orthodontics and Dentofacial ResearchDocumento7 pagineSelf Ligating Brackets: From Past To Present: IP Indian Journal of Orthodontics and Dentofacial Researchkarengj952Nessuna valutazione finora

- Sub Surface ToolDocumento64 pagineSub Surface ToolPrithiraj KalitaNessuna valutazione finora

- Causes and Prevention of Crevice CorrosionDocumento3 pagineCauses and Prevention of Crevice CorrosionThomasFrenchNessuna valutazione finora

- Mechanics of Rubber Bearings for Seismic and Vibration IsolationDa EverandMechanics of Rubber Bearings for Seismic and Vibration IsolationNessuna valutazione finora

- AN610 - Using 24lc21Documento9 pagineAN610 - Using 24lc21aurelioewane2022Nessuna valutazione finora

- Drug Study TemplateDocumento2 pagineDrug Study TemplateKistlerzane CABALLERONessuna valutazione finora

- Harga H2H Pula-Paket Data - Saldo EWallet v31012022Documento10 pagineHarga H2H Pula-Paket Data - Saldo EWallet v31012022lala cemiNessuna valutazione finora

- Coca-Cola Summer Intern ReportDocumento70 pagineCoca-Cola Summer Intern ReportSourabh NagpalNessuna valutazione finora

- Contemp World Module 2 Topics 1 4Documento95 pagineContemp World Module 2 Topics 1 4Miguel EderNessuna valutazione finora

- Medical Devices RegulationsDocumento59 pagineMedical Devices RegulationsPablo CzNessuna valutazione finora

- WWW - Manaresults.co - In: Internet of ThingsDocumento3 pagineWWW - Manaresults.co - In: Internet of Thingsbabudurga700Nessuna valutazione finora

- Land Degradetion NarmDocumento15 pagineLand Degradetion NarmAbdikafar Adan AbdullahiNessuna valutazione finora

- Simplified Concrete Modeling: Mat - Concrete - Damage - Rel3Documento14 pagineSimplified Concrete Modeling: Mat - Concrete - Damage - Rel3amarNessuna valutazione finora

- Characteristics of Planetary Candidates Observed by Kepler, IIDocumento106 pagineCharacteristics of Planetary Candidates Observed by Kepler, IIRick FeedNessuna valutazione finora

- WhatsNew 2019 enDocumento48 pagineWhatsNew 2019 enAdrian Martin BarrionuevoNessuna valutazione finora

- MG206 Chapter 3 Slides On Marketing Principles and StrategiesDocumento33 pagineMG206 Chapter 3 Slides On Marketing Principles and StrategiesIsfundiyerTaungaNessuna valutazione finora

- Revenue Management Session 1: Introduction To Pricing OptimizationDocumento55 pagineRevenue Management Session 1: Introduction To Pricing OptimizationDuc NguyenNessuna valutazione finora

- CE5215-Theory and Applications of Cement CompositesDocumento10 pagineCE5215-Theory and Applications of Cement CompositesSivaramakrishnaNalluriNessuna valutazione finora

- Electric Arc Furnace STEEL MAKINGDocumento28 pagineElectric Arc Furnace STEEL MAKINGAMMASI A SHARAN100% (3)

- Integrated Building Managemnt SystemDocumento8 pagineIntegrated Building Managemnt SystemRitikaNessuna valutazione finora

- Ting Vs Heirs of Lirio - Case DigestDocumento2 pagineTing Vs Heirs of Lirio - Case DigestJalieca Lumbria GadongNessuna valutazione finora

- DTMF Controlled Robot Without Microcontroller (Aranju Peter)Documento10 pagineDTMF Controlled Robot Without Microcontroller (Aranju Peter)adebayo gabrielNessuna valutazione finora

- Tank Emission Calculation FormDocumento12 pagineTank Emission Calculation FormOmarTraficanteDelacasitosNessuna valutazione finora

- How To Attain Success Through The Strength of The Vibration of NumbersDocumento95 pagineHow To Attain Success Through The Strength of The Vibration of NumberszahkulNessuna valutazione finora

- National Senior Certificate: Grade 12Documento13 pagineNational Senior Certificate: Grade 12Marco Carminé SpidalieriNessuna valutazione finora

- Modal Case Data Form: GeneralDocumento4 pagineModal Case Data Form: GeneralsovannchhoemNessuna valutazione finora

- X HM11 S Manual AUpdfDocumento228 pagineX HM11 S Manual AUpdfAntonio José Domínguez CornejoNessuna valutazione finora

- Options Trading For Beginners Aug15 v1Documento187 pagineOptions Trading For Beginners Aug15 v1Glo BerriNessuna valutazione finora

- Irrig in AfricaDocumento64 pagineIrrig in Africaer viNessuna valutazione finora

- 1 s2.0 S0304389421026054 MainDocumento24 pagine1 s2.0 S0304389421026054 MainFarah TalibNessuna valutazione finora