Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Master Thesis Civil 12

Caricato da

oxana151Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Master Thesis Civil 12

Caricato da

oxana151Copyright:

Formati disponibili

EVALUATION OF LIVE-LOAD DISTRIBUTION FACTORS (LLDFs)

OF NEXT BEAM BRIDGES

A Thesis Presented

By

ABHIJEET KUMAR SINGH

Submitted to the Graduate School of the

University of Massachusetts Amherst in partial fulfillment

Of the requirement for the degree of

MASTER OF SCIENCE IN CIVIL ENGINEERING

May 2012

CIVIL AND ENVIRONMENTAL ENGINEERING

EVALUATION OF LIVE-LOAD DISTRIBUTION FACTORS (LLDFs)

OF NEXT BEAM BRIDGES

A Thesis Presented

by

ABHIJEET KUMAR SINGH

Approved as to style and content by:

____________________________

Brea, Sergio, Chairperson

____________________________

Lardner, Thomas, Member

____________________________

Civjan, Scott, Member

____________________________________

Richard N. Palmer, Department Head

Civil and Environmental Engineering Department

iii

ACKNOWLEMDGEENT

I would like to extend my thanks to my advisor, Dr Sergio Brea for his guidance and

support throughout the project. It is his guidance and support because of which I am able

to complete my thesis. I would also like to say thank to my committee members, Dr

Lardner and Dr Civjan for their assistance and feedback on the research. I am also

thankful to the guidance provided by Kalayacki Emre in learning the advance tools SAP

2000 V14.2 in a very short duration of time. I am also thankful to my parents who were

always with me in my good and bad time and helped me to look at life in more

comprehensive and balanced manner

iv

ABSTRACT

EVALUATION OF LIVE-LOAD DISTRIBUTION FACTORS (LLDFs)

OF NEXT BEAM BRIDGES

MAY 2012

ABHIJEET KUMAR SINGH, M.S.C.E.

UNIVERSITY OF MASSACHUSETTS AMHERST

Directed by: Professor Sergio Brea

A new precast-prestressed cross section was recently developed by a consortium of

engineers from the six New England states, New York and members of the northeast

region of PCI. The northeast extreme Tee (NEXT) beam is efficient for medium Bridge

spans (50 to 80 ft long). Field formwork savings are introduced by having a flange cast

integrally during fabrication of the beams at the precasting plant. Job safety is increased

because a working platform is created. The flange width of the NEXT Beams can be

adjusted during fabrication to accommodate roadways of different widths and skew

angles. Because the section is new with complexity in its shape, the present design

guidance cannot be used to evaluate LLDFs for NEXT beams within the context of the

AASHTO LRFD. In particular, the use of live-load distribution factors (LLDFs)

equations in LRFD for NEXT beams is not straightforward. The distance between the

beam webs is variable depending on whether it is measured within a beam module or

between adjacent modules. In absence of detailed information a PCI technical committee

evaluated LLDFs (through AASHTO 2010 Bridge specification) for the NEXT beams

used in the Brimfield Bridge by two different approaches and found one of them

conservative. The conservative approach was single stem which uses the average spacing

v

(between webs ([S1+S3]/2)) for use in the LLDF equations.. The committee expressed

concerns about whether trends of LLDFs would be similar for other parametric sets, and

would like to standardize the methodology for the Bridge projects in Massachusetts with

NEXT beam as the girder. To verify the conservativeness of single stem methodology

(for the evaluation of LLDFs) for other parameters this research project was initiated.

LLDFs are evaluated based on the two approaches and compared with the LLDFs

obtained through finite element modeling.

The results of 40-3D finite element models have been used to compare the LLDFs

obtained from AASHTO 2010 Bridge design specification. The results were also used to

compare different parameters that affect LLDFs of NEXT beams including span, skew

angle, and beam end fixity. The finite element models were created using a Bridge

prototype that is being instrumented for future field verification of the analyses. The

models were created using frame elements for the beams and shell elements for the cast

in place deck. The integral abutment and foundation of the Bridges was included in the

models in which piles are created using frame elements and abutments are created using

shell elements. The results indicate that the approach taken for the design of NEXT

beams is in general conservative for interior girders of the Bridge. On the contrary such

the adopted approach was not yielding the higher value of LLDFs. The variation in

strains due to losses are compared by two methods (strains variation obtained from field

data and strain variation obtained based on AASHTO equation of losses) to verify the

AASHTO equation of losses.

vi

TABLE OF CONTENTS

Page

ACKNOWLEDGEMENT ................................................................................................. iii

ABSTRACT ....................................................................................................................... iv

LIST OF TABLES (LOT) - ................................................................................................ x

LIST OF FIGURES (LOF)- ............................................................................................. xiii

CHAPTER

1. INTRODUCTION ..1

1.1 NEXT Beam Introduction and Benefits ............................................................... 1

1.2 Motivation of Thesis ................................................................................................. 2

1.2.1 LLDF Introduction ............................................................................................. 3

1.2.2 LLDF Types ....................................................................................................... 4

1.2.3 NEXT Beam Spacings and Problem Statement ................................................ 4

1.3 Brimfield Bridge Project ........................................................................................... 7

1.4 Scope of Research ..................................................................................................... 8

1.4.1 Evaluation of LLDFs from Latest AASHTO Specification .............................. 9

1.4.2 Evaluation of LLDF from FEM Methods .......................................................... 9

1.4.3 Field Test ......................................................................................................... 10

2. LITERATURE REVIEW ............................................................................................. 12

2.1 Field Testing ........................................................................................................... 12

2.2 Laboratory testing and Analytical Modeling .......................................................... 14

3. CALCULATION OF AASHTO LIVE LOAD DISTRIBUTION FACTOR ............... 18

3.1 Super Structure Brimfield Bridge .......................................................................... 19

3.2 Sub Structure and Foundation Brimfield Bridge ................................................... 21

vii

3.3 Calculation of LLDFs for NEXT Beam Bridge ..................................................... 22

3.4 Calculation of LLDFs - Single Stem Approach (SST-type k) ............................... 23

3.5 Calculation of LLDFs - Double Stem Approach (DST - type i)............................ 24

3.6 Calculation of LLDFs for Interior Girders ............................................................. 25

3.7 Calculation of LLDFs for Exterior Girders ........................................................... 29

3.7.1 Load Position for LLDF Calculation of Exterior Girders - SST Approach ..... 30

3.7.2 Load Position for LLDF Calculation of Exterior Girders - DST Approach ... 32

3.8 LLDF Values Computed Using Single Stem Approach (type k) ........................... 34

3.9 LLDF Values Computed Using Double Stem Approach (type i) .......................... 37

3.10 Comparison between Single and Double Stem Approach .................................... 39

3.10.1 Comparison of Results for Various Spans - 0o Skew .................................... 39

3.10.2 Comparison of Results for Various Skew Angles -66.67ft (20.32m) ........... 41

3.11 Summary .............................................................................................................. 44

4 FINITE ELEMENT ANALYSIS OF NEXT BEAM BRIDGES .................................. 45

4.1 Modeling of Bridge ................................................................................................. 45

4.1.1 Modeling of the Super structure ...................................................................... 46

4.1.2 Deck width and division of lane ...................................................................... 49

4.1.3 Modeling of Foundation .................................................................................. 50

4.1.3.1 Modeling of Abutment ........................................................................... 50

4.1.3.2 Modeling of Piles .................................................................................... 51

4.2 Methodology for the Parametric Evaluation of LLDFs using FEM Analysis ........ 52

4.2.1 Bending Moment and Shear Force in Line Model ........................................... 54

4.2.2 Evaluation of LLDFs ....................................................................................... 56

viii

4.2.2.1. LLDFs for Simply Supported Bridge .......................................................... 57

4.2.2.2 LLDFs for Integral Abutment Bridge Models ............................................. 62

4.3 Summary ................................................................................................................. 68

5 PARAMETRIC STUDIES IN EVALUATION OF LLDFs ......................................... 71

5.1 Comparison of AASHTO LLDFs and FEM Analyses LLDFs ............................... 71

5.1.1 Trends Observed for Span Variations .............................................................. 72

5.1.2 Trends Observed for Skew Angle Variations .................................................. 75

5.2 Comparison of LLDFs Obtained Through Different Methods ............................... 80

5.2.1 Comparison of LLDFs for Parametric Variations in Span .............................. 80

5.2.2 Comparison of LLDFs for Parametric Variations in Skew Angle ................... 83

5.3 Summary ................................................................................................................. 85

6 STRAIN EVALAUATION AND VERIFICATION AT DIFFERENT

CONSTRUCTUION STAGES ......................................................................................... 88

6.1 Stages for Bridge Erection and Strain Evaluation .................................................. 88

6.2 Bridge Instrumentation Details ............................................................................... 89

6.3 Evaluation of Longitudinal Strain ........................................................................... 91

6.3.1 Strain Variation due to Prestress Losses Analytical Evaluation ................... 92

6.3.1.1 Strain due to Prestressing Forces ............................................................ 93

6.3.1.2 Calculation of Stresses Induced due to Prestressing Force ..................... 93

6.3.1.3 Stress Variation due to Losses and Self Weight ..................................... 96

6.3.1.4 Short-Term Loss with Relaxation Loss .................................................. 96

6.3.1.5 Time Dependent (Long-term) Losses .................................................. 100

6.3.2 Longitudinal Strains Determined from Field Data ........................................ 107

ix

6.3.2.1 Evaluation of Stage Wise Strain variation due to losses.................. 108

6.3.2.2 Cumulative Strains by Construction Stage ....................................... 110

6.4 Comparison of Measured and Calculated Strains ................................................. 111

6.5 NEXT Beam Strain Profiles at Various Construction Stages ............................... 117

6.5.1 Evaluation of Creep and Shrinkage Strains ................................................... 117

6.6 Conclusion ............................................................................................................ 123

7. SUMMARY AND CONCLUSION ........................................................................... 124

7.1 Outcome and Suggestions ..................................................................................... 125

7.1.1 Verification of outcome of PCI technical committee. ................................... 125

7.1.2 Trend Comparison Span Parameter ............................................................... 125

7.1.3 Trend comparison Skew Parameter ............................................................... 126

7.1.4 Comparison for LLDFs with different end condition .................................... 126

7.1.5 Verification of Prestress Loss Equation of AASHTO ................................... 127

APPENDICES.128

APPENDIX A: CURVE EVALUATION F0R SOIL STRUCTURE INTERACTION 128

APPENDIX B : DATE AND TIME OF RECORDED FIELD DATA .......................... 130

APPENDIX C: LOSS EVALUAION ............................................................................. 131

APPENDIX D: STAGE WISE STRESS EVALUATION ............................................. 141

APPENDIX E: STAGE WISE STRAIN EVALUATION ............................................. 145

APPENDIX F : STRAIN AND DATA IN FIELD ......................................................... 149

APPENDIX G: STRAIN VARIATION FOR DIFFERENT STAGES .......................... 172

APPENDIX H: STAGE WISE CUMULATIVE STRAIN ............................................ 179

BIBLIOGRAPHY ........................................................................................................... 185

x

LIST OF TABLES

Table Page

3.1: Cross section properties for Use in AASHTO LLDF equations ............................... 27

3.2: LLDFs-Bending Moment-Interior Girder .................................................................. 35

3.3: LLDFs-Bending Moment-Exterior Girder................................................................. 35

3.4: LLDFs-Shear Force-Interior Girder........................................................................... 36

3.5: LLDFs-Shear Force- Exterior Girder ........................................................................ 36

3.6: LLDFs-Bending Moment-Interior Girder .................................................................. 37

3.7: LLDFs-Bending Moment-Exterior Girder................................................................. 38

3.8: LLDFs-Shear Force-Interior Girder........................................................................... 38

3.9: LLDFs-Shear Force- Exterior Girder ........................................................................ 39

3.10: Bending Moment LLDFs - Different Spans, (0

o

Skew) .......................................... 40

3.11: Shear Force LLDFs - Different Spans, (0

o

skew) .................................................... 40

3.12: Bending Moment LLDFs Different Skew Angles (Span = 66.67 ft (20.32 m)) ... 42

3.13: Shear Force LLDFs Different Skew Angles (66.67 ft (20.32 m) Span) ............... 42

4.1: Section Property comparison ..................................................................................... 47

4.2: Different parameteric sets for LLDF Evaluation...53

4.3: Maximum Action for Line Model ............................................................................. 56

4.4 : LLDFs-Simply Supported Condition (Lane 1 Loaded) ............................................ 58

4.5: LLDFs-Simply Supported Condition (Lane 2 Loaded) ............................................. 59

4.6: LLDFs-Simply Supported Condition (Lane 3 Loaded) ............................................. 60

4.7: LLDFs-Simply Supported Condition (Two or more Lanes Loaded) ........................ 61

4.8: LLDFs for Bending Moment and Shear Force .......................................................... 62

xi

4.9: LLDF-IAB (Lane 1 Loaded)...................................................................................... 64

4.10: LLDF-IAB (Lane 2 Loaded).................................................................................... 65

4.11: LLDF-IAB (Lane 3 Loaded).................................................................................... 66

4.12: LLDF- IAB (Two or more than Lanes Loaded) ...................................................... 67

4.13: LLDF for Moment and Shear Force ........................................................................ 68

4.14(a-d): LLDFs Obtained From FEM........................................................................... 69

5.1: Bending Moment LLDFs - Different Spans, (0

o

Skew) ............................................ 72

5.2: Shear Force LLDFs - Different Spans, (0

o

skew)...73

5.3: Bending Moment LLDFs Different Skew Angles (Span = 66.67 ft (20.32 m)) .... 76

5.4: Shear Force LLDFs Different Skew Angles (66.67 ft (20.32 m)

Span)..77

6.1: Brimfield Bridge-Section Property ............................................................................ 93

6.2: Details of Strand Layer used in NEXT beams ........................................................... 94

6.3: Prestressing force and Stress Factor .......................................................................... 95

6.4 : Stress and Strain due to Prestressing ........................................................................ 96

6.5: Stress due to Self Weight ........................................................................................... 98

6.6: Stress and Strain at Stage 1 ....................................................................................... 99

6.7(a-f): Stage wise Creep and Shrinkage Losses ........................................................... 101

6.8: Stress due to Change in Effective Span ................................................................... 104

6.9: Stress and Strain between Stage 1 and Stage 2 ........................................................ 105

6.10: Stress Change due to Change in Effective Span.106

6.11: Stress Change Induced by Weight of Wet Concrete.............................................. 107

6.12: Field Data for NEXT Beam 1 ................................................................................ 109

xii

6.13: Strain Variation due to Creep and Shrinkage.....110

6.14: Stage Wise Cumulative Strain ............................................................................... 111

6.15 Long Term Loss Comparison for All Six NEXT Beams.....113

6.16: comparison of Strain Variation due to Time Dependent Loss............................... 122

B1 : Date of Field Data ................................................................................................... 130

C1 (a-f): Details of Time Dependent Loss for NEXT Beams ........................................ 135

D1 (a-f): Stage Wise Load Related Stress (By Analytical Method) .............................. 141

E1 (a-f): Stage Wise Cumulative Strain (By Analytical Method) .................................. 145

F1 (a-f): Field Data for NEXT Beams ............................................................................ 149

G1 (a-f): Stage Wise True Load Related Strain for NEXT Beas .................................... 173

H1 (a-f): Stage Wise Cumulative Strain for NEXT Beams ............................................ 179

xiii

LIST OF FIGURES

Figure Page

1.1 Benefits of NEXT Beam ............................................................................................... 2

1.2: NEXT Beam with Varying Spacing Between Stems. ................................................. 5

1.3: I type of Girder (Double T Beam Girder) .................................................................... 5

1.4 : K type of Girder (I Beam Girder) ............................................................................... 6

3.1: Type I Girder (Double T Beam Girder) ..................................................................... 18

3.2: Type K Girder (I Beam Girder) ................................................................................. 19

3.3: Bridge Cross Section- Brimfield Bridge .................................................................... 19

3.4: NEXT 32 Beam ......................................................................................................... 20

3.5: Arrangement Plan of the Bridge ................................................................................ 20

3.6: Elevation of the Bridge .............................................................................................. 21

3.7: Abutment on North Side ............................................................................................ 22

3.8: Abutment on South Side ............................................................................................ 22

3.9: Beam Numbering Used in Single Stem Approach .................................................... 24

3.10: Beam Numbering Used in Double Stem Approach ................................................. 24

3.11: Wheel Loading in Exterior Girder for LLDF Calculation - Single Stem Approach 31

3.12: Loading Exterior Girder Double Stem Approach .................................................... 33

3.13( a-d) Comparisons of LLDFs for Span Parameter.41

3.14(a-f) Comparisons of LLDFs for Skew Angle....43

4.1 FE model illustrating NEXT beams ............................................................................ 49

4.2 FEM model illustrating composite deck ..................................................................... 49

4.3 Bridge Section with lane division ............................................................................... 50

4.4 Non Linear Soil Modeling at three ............................................................................. 52

xiv

4.5: FEM Model of Bridge used in FEM method ............................................................. 53

4.6: Axle Placement for Maximum Bending Moment near Mid Span ............................. 55

47: Axle Placement for Maximum Shear Force near Support .......................................... 55

4.8: HS 20 truck ................................................................................................................ 55

4.9: FEM Model For Integral Abutment Bridge (Side Elevation) .................................... 63

5.1(a-b) Comparisons of LLDFs Single Stem Approach ............................................... 73

5.2 (a-b) Comparisons of LLDFs Double Stem Approach ............................................ 74

5.3(a-b) Comparisons of LLDFs FE

SS

Approach ........................................................... 74

5.4(a-b) Comparisons of LLDFs FE

IAB

Approach ......................................................... 745

5.5(a-b) LLDFs for Forces with Single Stem approach (Skew Angle Parameter) ........... 77

5.6(a-b) LLDFs for Forces with Double Stem approach .................................................. 78

5.7(a-b) LLDFs for Forces FE

SS

(Skew Angle Parameter) ............................................... 78

5.8(a-b) LLDFs for Forces FE

IAB

(Skew Angle Parameter)..79

5.9(a-b) LLDF Comparisons for 50 ft Span (0

o

Skew Angle)...82

5.10 (a-b) LLDF Comparison for 66.67 ft Spans (0

o

skew angle) ..................................... 82

5.11(a-b) LLDF Comparison for 80 ft (24.38 m)span (0

o

skew Angle)....83

5.12(a-b) LLDF Comparison for 0

o

Skew angles ............................................................. 84

5.13(a-b) LLDF Comparison for 30

o

Skew angles ........................................................... 84

5.14(a-b): LLDF Comparison for 45

o

Skew angle ............................................................ 85

6.1 Instrumentation Plan ................................................................................................... 90

6.2 Instrumentation in the NEXT Beam ........................................................................... 91

6.3 Strand Location in the NEXT Beam ........................................................................... 94

6.4 NEXT Beam with Center of Prestressing Force ....................................................... 112

xv

6.5: (a-f) Stage Wise Strain Comparison All Six NEXT Beam ................................... 116

6.6 Trapezoidal Stress Variation due to Creep ............................................................... 118

6.7 (a-f): Strain Vs Depth NEXT Beam 1to 6 ................................................................ 121

1

CHAPTER 1

INTRODUCTION

This chapter provides an introduction and benefits associated with the use of a newly

developed prestressed concrete beam section for use in short to medium span Bridges.

Because the beam does not fall into typical cross sections included in the AASHTO

LRFD specification (2010), recommendations about its design, specifically the

appropriate live-load distribution factors, need to be provided to engineers. This new

section provides several safety and economic benefits making attractive for use within the

span range for which it was intended.

1.1 NEXT Beam Introduction and Benefits

The northeast extreme tee (NEXT) beam is a prestressed double T-beam recently

developed by a consortium of engineers from all six New England states, New York and

members of the northeast region of prestressed concrete institute (PCI). Its efficient

design minimizes cost and labor in both manufacturing plant and at the job site. It also

eases the construction process and improves the safety for the workers. The lack of

draped (harped) strands is a significant benefit during fabrication. The elimination of

deck forming in the field due to its top flange (Figure 1.1a ) saves significant time during

construction and also provides an instant platform for work. The need of a diaphragm

near the supports or intermediate diaphragms is eliminated as the top flange provides

sufficient lateral stability to the NEXT beam while placing fresh concrete. The cantilever

portion of the NEXT beam (outside the stem Figure 1.1b) provides space in the exterior

girder to erect parapet wall which keeps designers and contractors away from creating

false work for the erection of parapet wall. The NEXT beam (Figure1.1c) can

2

accommodate multiple utilities such as drainage pipe and electrical wire between the

stems and there is no need to create any false work to hide them. The widths of the

NEXT beams can be adjusted readily in fabrication to accommodate roadways which are

tapered in plan. Moreover its flange can be modified readily to accommodate gentle

curve of the highway alignment. The NEXT beam is available for skew angle up to 30

o

.

(a) No Need of Formwork and diaphragm (b) No Need of false work

to cast deck and Parapet

(c) No Need of false arrangement to hide multiple utilities

Figure1.1 Benefits of NEXT Beam

1.2 Motivation of Thesis

The numerous benefits associated with the NEXT beam are going to make it a wide

spread choice for the owners in the future for the spans ranging between 50 ft (15.24 m)

to 80 ft (24.38m). Apart from the consortium states, which developed the NEXT beam

3

other states have also accepted NEXT beam due to its versatility. But the complex shape

of NEXT beam creates confusion among the members of PCI technical committee at the

front of live load analysis based on live load distribution factors (LLDFs). It is very

important to investigate all the concerns pertaining to NEXT beam so that it can be used

at widespread level in the future. To formulate the problem statement it is important to

explain LLDF, its type and formulations mentioned in AASHTO (2010 Bridge design

specification).

1.2.1 LLDF Introduction

The effect of live load in terms of actions (bending moment and shear force) on the girder

of the Bridge is obtained through LLDFs. The LLDFs make live load analysis simpler

and keeps designer of the Bridge away from complex three dimensional live load

analyses. The use of LLDFs is based on equation 1.1 in which F

I

the maximum force at

particular section of the girder of the Bridge, which can be obtained through influence

line method.

F

s

= g*F

I

.. Equation 1.1

Where,

F

s

= the maximum force at the section of concern in the girder in terms of action (bending

moment and shear force).

g = LLDFs.

F

I

= the maximum force at the section of concern obtained by running the live load of

interest on simply supported girder (only).

4

1.2.2 LLDF Types

The LLDFs can be of different types. Based on action it can be for bending moment and

shear force. Based on the division of lane it can be for one lane loaded and two or more

lanes loaded. Based on the arrangement of girders it can be for interior and exterior

girder. So there are eight different types of LLDFs and all of them are considered while

evaluation, verification and conclusion about the problems related to LLDFs of the

NEXT beams. Notation and definition of all the eight types are as follow.

gM

1

i-

= LLDF for bending moment for interior girder for one lane loaded

.

gM

2

i-

= LLDF for bending moment for interior girder for two or more lanes loaded.

gM

1

e-

= LLDF for bending moment for exterior girder for one lane loaded.

gM

2

e-

= LLDF for bending moment for exterior girder for two or more lanes loaded.

gV

1

i-

= LLDF for shear force for interior girder for one lane loaded

.

gV

2

i-

= LLDF for shear force for interior girder for two or more lanes loaded.

gV

1

e-

= LLDF for shear force for exterior girder for one lane loaded

.

gV

2

e-

= LLDF for shear force for exterior girder for two or more lanes loaded.

1.2.3 NEXT Beam Spacings and Problem Statement

Live load distribution factors in AASHTO LRFD require the use of spacing between

girders to determine values that can be used for design of Bridge girders. In NEXT

beams the spacing between girders is not uniquely defined, resulting in uncertainty about

the most appropriate value.

Figure 1.2 is one of the Bridge cross section using NEXT beams as the girder. The

nearest structure to NEXT beam is I type of cross section which is mentioned in table

4.6.2.2.1-1 of AASHTO (2010 Bridge design specification).

5

Figure1.2: NEXT Beam with Varying Spacing Between Stems.

Figure1.3: I type of Girder (Double T Beam Girder)

In the mentioned table of I type girder the spacing between the stem of individual

double T beam is similar to the spacing between the stem of adjacent double T beam.

Moreover the horizontal spacing (between the center of gravity of two adjacent girders) is

also similar to the spacing between the stems. This constant spacing has been used for the

evaluation of LLDF for double T beam.

But if we look at Bridge cross section with NEXT beam as girder in Figure 1.2 the three

spacings are different. S1 is the spacing between the stems of same NEXT beam. S2 is

the spacing between the c.g (horizontal center of gravity of NEXT beam) of two adjacent

NEXT beams, whereas S3 is spacing between stems of two adjacent NEXT beams. The

equations (Equation 3.1, 3.2, 3.4 & 3.5) mentioned in AASHTO (2010 Bridge design

specification) to evaluate LLDFs in interior girders contain only one S, the spacing

between the girder. The equations are also mentioned in Chapter 3 by Equation 3.1, 3.2,

3.4 and 3.5

The three different spacings (S1, S2, S3 Figure 1.2) in NEXT beams create a concern

among members of PCI technical committee, that what spacing should be taken while

6

evaluation of LLDFs. Based on the concern related to spacing, PCI technical committee

has contacted the original authors of the AASHTO Bridge design specification and found

that NEXT beam type of structure with varying spacing (Figure 1.2) was not specifically

investigated through any of the advanced form of analysis during development of code.

In the absence of detailed verification of LLDFs of NEXT beam type the PCI technical

committee evaluated the LLDFs for the Bridge (with NEXT beam as the girder) by single

(Type K Figure 1.4) stem (SST) approach and by double (Type I Figure 1.3) stem

approach (DST) using 2010 AASHTO Bridge design specification. In SST approach each

stem of NEXT beam was considered as K type (Figure 1.4) whereas in DST approach

NEXT beam was considered as I type (Figure 1.3). AASHTO formulation of LLDFs

contains spacing between the girders. The spacing considered in SST approach was

average spacing ([S1+S3]/2) whereas spacing considered for DST approach was S2

(spacing between horizontal center of gravity between NEXT beam).

Figure1.4: K type of Girder (I Beam Girder)

Based on the results PCI technical committee concluded that SST approach is more

conservative for some of the particular case investigated. Further verification for other

sets of parameters (varying spans and varying skew angles) is required so that the method

can be standardized for the LLDFs evaluation of NEXT beams.

The primary objective of the thesis is to ascertain whether the conclusion of PCI

technical committee extends to other sets of parameters or not. The verification has been

7

done in Chapter three in which LLDFs has been evaluated for K type (Figure1.4 SST

approach) of girder as well as for I type (Figure 1.3 DST approach) of girder. In the last

of chapter the evaluated values from both methods have been compared. It is also

important to verify the LLDFs through advance form of analysis. Chapter four is all

about creation of finite Element Model (FEM), evaluation of LLDFs for different set of

parameters and to compare the obtained LLDFs to the LLDFs obtained through latest

AASHTO (2010 Bridge design specification). The comparison will help us to check

whether the variation of LLDFs for different set of parameters obtained through FEM

analysis is in congruence with AASHTO formulations or not. The comparison will also

help us to ascertain the method to get the most conservative value of LLDFs.

The NEXT beam is a prestressed beam and therefore subjected to complex long term

effects of creep, shrinkage and relaxation of strands. It is important to verify whether the

losses taking place in the NEXT beam is in congruence with latest AASHTO (2010

Bridge design specification) or not. Instrumentation of the NEXT beam will give us strain

measurement at different stages. The strain values along the depth of NEXT beam will

help us to ascertain the behavior of NEXT beams in terms of creep and shrinkage.

Strains at different stage will also include the loss component due to long term effect of

creep, shrinkage and relaxation. Future work is based on comparison of strain component

obtained at various stages from analytical calculation and instrumentation outcome. This

comparison between strains will also help us to compare analytically evaluated value of

long term losses with long term losses obtained through instrumentation.

1.3 Brimfield Bridge Project

8

For this research, a prototype Bridge located in Brimfield, Massachusetts was selected in

order to establish typical characteristics of a NEXT beam Bridge. The Brimfield Bridge

is an integral abutment Bridge (IAB) that can be divided in to three main components: -

super structure, sub structure and foundation. The super structure portion has six NEXT

32 beams cast integrally in to the abutments. Abutments are supported on the foundation

which encompasses six HP 10x 57 piles. The Bridge is skew with 30

o

skew angle. Using

the Brimfield Bridge characteristics, three parameters importantly affecting live-load

distribution factors of NEXT beam Bridges were selected and varied systematically. The

three parameters chosen are span length, skew angle and end support conditions. The

effects of these parameters on live-load distribution factors are discussed in Chapter three

to five. Full details of the Brimfield Bridge are provided in Chapter 3.

1.4 Scope of Research

The core scope of the research can be divided in to three parts. Firstly the evaluation of

AASHTO (2010 Bridge design specification) live load distribution factor for the NEXT

beam to verify the outcome of PCI technical committee. Secondly it is important to verify

the AASHTO (2010 Bridge design specification) formulation through some advance

from of analysis in terms of variation of LLDFs with parameters and conservativeness.

Therefore FE models are created to get the LLDFs for the NEXT beam. Details from

instrumentation will be used to verify complex long term behavior of Bridge pertaining to

creep, shrinkage and relaxation. Different types of losses (short term as well as long term)

at the level of the center of prestressing force of strands has been evaluated in terms of

strains from FEM analysis and then compared from the strains obtained from field data.

9

1.4.1 Evaluation of LLDFs from Latest AASHTO Specification

LLDFs for the NEXT beam have been evaluated based on latest AASHTO (2010 Bridge

design specification) for K type (DST approach Figure 1.3) and I type (SST approach

Figure 1.4) of the girder and the obtained value has been compared for different

parametric sets. The evaluation of LLDFs has been done for five of the parametric sets to

study LLDF with varying span and skew angle of the Bridge. The spans considered are

50ft (15.24m), 66.67ft (20.32m) and 80ft (24.38m), and the skew angle considered are 0

o

,

30

o

and 45

o

. Spacing between the girders has not been considered as a parameter, as it is

fixed and marginally more than the flange width of girder. The comparison of LLDFs

obtained from both the methods will help us to ascertain whether the outcome of PCI

technical committee for particular case can be generalized for wide spectrum of

parameters or not. This whole evaluation and comparison has been done in Chapter three.

1.4.2 Evaluation of LLDF from FEM Methods

It is important to verify the LLDFs of NEXT beam with an advanced form of analysis.

LLDFs have been evaluated with the help of FEM analysis in Chapter five. Chapter five

describes the creation of two different type of FEM model with different sets of

parameters and to evaluate the LLDFs. The first model is simply supported model which

is very near to the LLDFs value obtained from the AASHTO (2010 Bridge design

specification). The second model is integral abutment Bridge model which is similar to

the actual Brimfield Bridge. Again the parametric study of LLDFs of the NEXT beam

has been done based on two of the important parameters i.e. span of the Bridge and skew

angle of the Bridge. The spans considered are similar to the previous subsection i.e. 50ft

(15.24m), 66.67ft (20.32m) and 80ft (24.38m) and the skew angle considered are 0

o

, 30

o

10

and 45

o

. Spacing between the girders has not been considered as parameter, as spacing is

fixed as and marginally more than the flange width of girder. Under FEM verification 40

FEMs are generated to evaluated LLDF for the NEXT beam with different parameter.

Out of 40 FEMs,20 FEMs are for simply supported Bridge and 20 FEMs are for IAB

models. The FEM LLDFs are evaluated for three different cases.

Evaluation of LLDFs for simply supported Bridge through AASHTO (2010

Bridge design specification).

Evaluation of LLDFs for simply supported Bridge through linear FE analysis.

Evaluation of LLDFs for Integral Abutment Bridge through non linear FE

analysis in which soil has been modeled as non liner spring.

The obtained values of LLDFs from two of the FEM have been compared in Chapter five

to ascertain the effect of inclusion of sub structure and foundation. In Chapter five

LLDFs obtained from all the four approaches are compared to verify whether the

variation of LLDFs obtained from FEM have the same nature of variation or not. The

comparison will further help us to find out which method will gives us the higher value of

LLDFs for different type of forces (bending moment and shear forces) and for different

type of components (interior girders and exterior girders).

1.4.3 Field Test

The scope of field test is to monitor the Bridge in the span of 3 years through various

strain gauges fixed at numerous locations with the intent of its long term behavior such as

Creep, Shrinkage, deflection and crack width. The strain gauge data will give the strains

at different stages of fabrication, erection and service period of the girder. These strain

11

values will be useful to evaluate creep and shrinkage loss at different time interval.

Through field testing strains were obtained before and after the following stages.

At gage installation.

20 hrs after pouring of concrete.

At the time of detentioning of strands.

At the time of placing of girder on temporary support in casting yard.

After placing the girder over abutment.

After pouring slab concrete.

At the time of live load testing.

At the interval of each three months.

In Chapter six the strain values has been evaluated from the FEM for the actual Bridge at

different stages and then compared with the strains obtained from the field

instrumentation. The strains at different stages and at different height of the girder will

help us to ascertain the behavior of NEXT beams at different stages. Moreover the strain

values obtained from the field data can help us to get the long term loss (creep loss,

shrinkage loss, relaxation loss) in the strands. This loss will be compared with the loss

obtained from analytical formulation of long terms effects from AASHTO (2010 Bridge

design specification). The comparison will help us to verify AASHTO (2010 Bridge

design specification) equations of losses in the NEXT beam.

12

CHAPTER 2

LITERATURE REVIEW

In the past many studies had been done in the area of skew Bridge. The major concerns of

the studies were to establish the behavior of skew Bridges, determine LLDF, evaluate the

influence of numerous parameters, and investigate the validity of design assumption and

many more. The studies were done through field and laboratory tests to compare the

outcome through numerical approaches which were based on advance FEM analysis from

available advanced tools. The intent of this section is to put forward all the details of

those investigations and their outcome and further utilize them in the investigation of

LLDF evaluation of NEXT beam bridges for different parametric sets.

2.1 Field Testing

Bishara et al (1993) conducted a field test of a 137feet (41.75m) span four lane composite

steel-concrete Bridge with skew angle of 58.5

o

. The main intent was to investigate the

validity of wheel load distribution factor expressions mentioned in AASHTO (2010

Bridge design specification) from FEM analyses of 36 Bridges of varying geometry. The

Bridge located in Columbus, Ohio, was tested using six dump trucks with known axle

loads. Once the field test was complete, sensitivity studies were conducted using various

parameters such as skew angles, varying spans, number of lane loaded and slab width. It

was found that skew angle has the highest impact on the wheel - load distribution factor.

However, the skew effect is negligible when the skew angle is less than 30

o

. Distribution

factors for interior and exterior girder were derived from field studies and compared to

the FEM modeling and AASHTO (2010 Bridge design specification). For skew angle

greater than 30

o

the LLDF derived from equations were found to be 5-25% higher than

13

the resulting factors from the FEM models. The LLDF for the interior girder were found

to be 30-85% that of the AASHTO specified factor of S/5.5 and 30-70% of the AASHTO

factors for the exterior girders.

Barr et al (1999): In this paper with the help of live load testing reliability of FEM model

of three span continuous Bridge was evaluated. After establishing the reliability the

model, this was used to evaluate LLDFs for flexure for 24 different variations in terms of

diaphragm, their locations, lifts, continuity and skew angles. Based on study it was

concluded that lifts, end diaphragm and skew angles affect the LLDFs whereas the effect

of intermediate diaphragm and continuity was insignificant.

Civjan et al (2007) The recent studies in 2007 were done to appreciate the behavior of

sub structure and foundation of IAB with respect to interaction with soil and to verify

various assumptions used while analysis and construction of the IAB. A three span

Bridge in Orange- Wendell, Mass. (OW) was used as the parametric study to determine

the influence of Bridge design which allows the effects of parameters to be directly

evaluated. The Bridge was extensively instrumented to provide data on the various

movements, pressures, and strains experienced by the Bridge over time. The non-Linear

FEM analysis with the help of GT STRUDL has also been used to check the congruence

of Bridge behavior with respect to output obtained from field data. The parameters used

in the paper were abutment backfill, degree of pile restraint in the top 3.0m of pile and

methods of obtaining abutment soil-spring properties and distribution of backfill

pressure.

Brena et al (2007)- In the similar line Brena et al have used various field data collected in

the span of three years of service of an integral Bridge constructed in Massachusetts for

14

better understanding of lateral movement of abutment and piles corresponds to long terms

loadings such as temperature variation along with soil structure interaction. This paper

was useful in getting the idea of related to effect of backfill and soil restraints on the piles

deformation and forces.

2.2 Laboratory testing and Analytical Modeling

Apart from various field tests laboratory studies in coordination with analytical modeling

have also been performed in the past to better appreciate the behavior of skew Bridges.

The approach was to utilize laboratory testing to validate an analytical model and to

include sensitivity studies to predict the effects of specific parameter.

Newmark et al (1948) Reported on a series of laboratory tests on straight and skewed

Bridges and based on experiments performed it was concluded that the skewed Bridge

with skew angle of 60

o

was critical in terms of shear in comparison of Bridge with

straight configuration. In addition it was concluded that the maximum moments in the

beam decreased for large angle of skew and positive moment at the centre of a panel

increased.

Helba and Kennedy et al (1995, 1996) performed laboratory studies of girder moments

and shear distribution of six simply supported skew composite steel concrete Bridges

with skew angle of 45

o

. After series of experiments and based on various experiments it

was concluded that skew angle is the most critical parameter for the distribution of shear

force and controlling factor for the design of exterior girder.

Yochia Chen (1999): This paper considered different types of Bridges (Steel I girder-

with cross bracings, prestressed concrete box girder with diaphragm, prestressed I girder

with diaphragm) for AASHTO LLDFs and FEM LLDFs. It explains the detailed process

15

to prepare the FEM model in Adina (FEM tool). Based on comparison it concluded that

FEM LLDFs are lesser than the AASHTO LLDFs and incorporating the advanced FEM

tools does not affect the sizing of the girder. The most important finding was that the load

distribution factor is not affected by the type of load considered.

Khaloo et al (2003) : This paper studied the LLDFs for simply supported skew Bridges

for varying parameters such as skew angle (0-60

o

) , varying spacing (1.8m ,2.4m ,2.7m)

between girders, varying span (25m, 30m, 35m) and different arrangement of interior

transverse diaphragm (parallel to support line, perpendicular to girder, diaphragm with

different spacing) . The comparison between AASHTO LLDFs and FEM LLDFs are in

congruence to other evaluations. For flexure, LLDFs was not varying till 30

o

. Beyond 30

o

the LLDFs for flexure reduce and variation between two comparisons was different for

interior and exterior girders. With increased spacing it was observed that LLDFs increase.

For span parameter the flexure LLDFs for interior girder was not sensitive whereas for

exterior girder it was increasing. The transverse diaphragm perpendicular to the girder

was found to be the best arrangement for even distribution of load. For this type of

diaphragm varying spacing between them does not affect the load distribution factor.

Yousif et al (2007): A comprehensive study on LLDFs, dependent parameters (span, slab

thickness, spacing between girders, longitudinal stiffness) and range of applicability of

the mentioned parameters were studied on all the six type of PCI beam I to VI. Under

study LLDFs obtained from AASHTO LRFD (2004) were compared to the LLDFs

obtained from FEM analyses in terms of their ratio. The study was done with twelve

different span between (6m to 73m) , four spacing (1.1m , 2.2m, 2.99m, 4.9m) and four

different slab thicknesses (110mm, 190mm, 240mm, 300mm ) through creation of 886

16

FEM Bridge model. The study was done on the same data base of the Bridge considered

by the Zokie et al (1991). The study concluded the ration for the flexure moment to be

greater as well as less than 1.0 for different types of PCI beam in different range of spans.

Zokaie et al (2007) This paper brief out the development of present LLDF for the

AASHTO (2010 Bridge design specification), which was based on extensive study of

previously adopted S/D formulae along with studies on several hundred actual Bridges

through numerical approach of FEM analysis. This paper was helpful in establishing

various super structure parameters such as span of the Bridge, spacing between the

girder, and skew angle of the Bridge.

Murat et al (2008): This paper was based on investigation of the effect of soil-structure

interaction on different component of IAB. Apart from soil-structure interaction variation

different properties of super structure such as stiffness of girder, spacing between the

girders were also considered. Soil properties were varied with respect to soil stiffness of

foundation. The effect of backfill and its compaction level were not considered. Sub

structure properties of abutment were varied by varying its depth and thickness. The

presence and absence of wing wall were also considered. The results from various 2

dimensional and 3 dimensional FEM model were used for the evaluation of LLDF.

Through the outcome it was concluded that varying properties in soil stiffness, sub

structure and foundation properties has negligible effect on the LLDF on the super

structure portions. However the effect was significant on sub structure and foundation.

Devin K Harris (2009): This paper discuss different type of methodologies (beam line

method, load fraction approach, S over approach, AASHTO LRFD design specification

approach, lever arm approach, in service assessment, FEM approach), used to evaluate

17

the distribution factor. It critically analyzed the strength and shortcomings of different

methods through comparison and validation through FEM. Based on study, comparison

were made on the appropriateness of different type of neutral axis for composite bridge to

get the true response are discussed. The comparison and conclusion also considered the

effect of secondary members and boundary conditions.

18

CHAPTER 3

CALCULATION OF AASHTO LIVE LOAD DISTRIBUTION FACTOR

Live load distribution factors (LLDFs) are used to calculate the live load bending

moment and shear force on Bridge girders caused by moving loads. LLDFs make not

only live load analysis simpler but also keep designers away from having to develop

complex 3-D models of simple Bridges. This chapter mainly contains the evaluation of

LLDFs for the recently developed North East Extreme Tee (NEXT) beam cross section

using AASHTO LRFD Specifications (2010).

Evaluation of LLDFs in this chapter was conducted using two generic cross sections

included in the AASHTO LRFD (2010): Type i (Figure 3.1) and Type k (Figure 3.2). In

this project, evaluation of LLDFs of a type k cross section is termed the single stem

(SST) approach, whereas evaluation of a type I cross section is termed the double stem

(DST) approach. The objective for evaluating LLDFs using two different approaches is to

verify the recommended procedure proposed by the prestressed concrete institute (PCI)

Bridge technical committee for designers. These recommendations indicated that a SST

approach would result in conservative estimates of moments and shears for most of the

cases typically encountered in practice.

Figure3.1: Type I Girder (Double T Beam Girder)

19

Figure3.2: Type K Girder (I Beam Girder)

The effect of parametric variation such as of varying span and skew on LLDFs are

studied based on actual prototype Bridge model i.e. Brimfield Bridge model which has

span of 66.67ft (20.34m) with 30

o

skew angle. Section 3.1 and 3.2 explains the detail of

Brimfield Bridges super structure, sub structure and foundation details.

3.1 Super Structure Brimfield Bridge

The super structure portion of the Bridge has six NEXT 32 beam (Figure 3.2) as shown in

Figure 3.3. The Bridge has safety curbs on the east side having the width of 1.42ft

(0.43m) and side walk in the west side with width of 4.37ft (1.33m).The spacing between

the girders is 8.08ft (2.44m). The total width of the Bridge is 48.5ft (14.78m). All the

details of mentioned dimensions are shown in Figure 3.3.

Figure3.3: Bridge Cross Section- Brimfield Bridge

The Bridge is spanning from North to South and having the span of 66.67ft (20.34m)

between the centers of gravity of the Abutment. Figure 3.5 and Figure 3.6 are showing

arrangement plan and elevation of the Bridge with other minute details. The NEXT beam

20

is further topped by 0.67ft (0.20m) thick concrete deck slab which will act compositely

with the NEXT beam.

Figure3.4: NEXT 32 Beam

Figure3.5: Arrangement Plan of the Bridge

21

Figure3.6: Elevation of the Bridge

3.2 Sub Structure and Foundation Brimfield Bridge

The NEXT beam is supported over the abutment (sub structure) in North and South side.

The abutment is reinforced cement concrete (RCC). The abutments thickness, length and

height are 4ft (1.22m), 56.97ft (17.36m) and 10.08ft (3.07m) respectively. The abutment

is attached to the wing wall (sub structure) which provides extra rigidity to the abutment

along with retaining the soils. The wing walls thickness, length and height are 1.623ft

(0.49m), 3.44ft (1.04m) and 10.08ft (3.07m) respectively. The abutment is further

supported on six HP 10x57 piles in both sides as shown in Figure 3.7 (abutment on the

North side) and Figure 3.8 (abutment of South side). Six piles of HP 10x57 sizes are used

under each abutment and are not in line with roads skew, but perpendicular to the

abutment.

22

Figure 3.7: Abutment on North Side

Figure 3.8: Abutment on South Side

3.3 Calculation of LLDFs for NEXT Beam Bridge

LLDFs for typical NEXT beam Bridges were calculated for bending moment and shear

force for interior and exterior girders. These calculations were repeated assuming one

lane loaded and two or more lanes loaded. The critical LLDFs for design is taken as the

maximum of these two lane loading cases. AASHTO equations for LLDFs (Equation 3.1

to 3.1o) are dependent on various parameters. Spacing between the girders and Bridge

span are the most important parameters as seen in these equations. NEXT beam Bridges

can be efficiently used in the range of 50 to 80ft (15.24 to 24.38m), and because of this

23

LLDFs are calculated for three different spans in the following section (50, 66.67, and

80ft [15.24, 20.32, and 24.38m]). For an individual NEXT beam, the width of the flange

is set so spacing between NEXT beams is determined by the flange width. Therefore,

girder spacing was not chosen as a parameter that could vary significantly. Bridge skew

angle was another important parameter chosen for calculation of LLDFs in NEXT beam

Bridges. Three different skew angles 0

o

, 30

o

and 45

o

have been considered for LLDFs

evaluation. A Bridge with span equal to 66.67ft (20.32m) and a skew angle of 30

o

represents a prototype Bridge from which basic structural details were drawn for this

project (Brimfield Bridge). Nine combinations of parameters were studied to assess their

influence on LLDFs. All these parameters were studied on the base model of Brimfield

Bridge which has three portions of super structure sub structure and foundation.

3.4 Calculation of LLDFs - Single Stem Approach (SST-type k)

The single stem approach (SST) was proposed by the PCI Northeast Bridge technical

committee as the conservative approach for design of NEXT beams Bridges. In a type k

cross section approximation (AASHTO 2010), each individual stem is considered as a

girder (Figure 3.2). Calculation of LLDFs must consider the spacing between stems,

which for NEXT beam Bridges is taken as the average ([S1+S3]/2) of the spacing

between stems in the same NEXT beam unit (S1-5ft [1.52m]) and the spacing between

the stems of adjacent NEXT beam units (S3-3ft [0.91m]). The value of LLDFs obtained

in this manner is multiplied by two to get the LLDFs for design of a NEXT beam.

The Brimfield Bridge is made up of six NEXT beams, of which two are exterior girders

and four are interior girders. For the SST approach, the Bridge is considered to contain

24

twelve girders, with stems B2 to B11 are representing interior girders, and B1 and B12

are representing exterior girders (Figure. 3.2).

Figure3.9: Beam Numbering Used in Single Stem Approach

The design LLDF computed for interior girder is the maximum value of LLDFs of the ten

interior girders (B2 to B11), whereas the design LLDF for exterior girder is computed

from the maximum value determined for the two exterior girders (B1 and B12).

3.5 Calculation of LLDFs - Double Stem Approach (DST - type i)

Calculation of LLDFs using the double stem approach (DST) considers the entire NEXT

beam unit as a single beam. The spacing (S2) between the center of gravity of two

adjacent NEXT beams (Figure 3.9) is used for the spacing parameter in the LLDF

equations. The LLDF values thus obtained are used directly in design for individual

NEXT beams. Using again the prototype Bridge discussed earlier (Brimfield Bridge), a

total of six NEXT 32 beams are considered making up the Bridge cross section, of which

two are exterior girders and four are interior girders (Figure 3.10). Under the DST

approach B2 to B5 are interior girders, whereas B1 and B6 are exterior girders.

Figure 3.10: Beam Numbering Used in Double Stem Approach

25

3.6 Calculation of LLDFs for Interior Girders

Calculation of LLDFs for interior girders follows equations in AASHTO LRFD (2010),

with the assumption that girder spacing in those equations is taken as the average spacing

of stems when using the SST approach (type k section), or the spacing between NEXT

beams when using the DST approach (type I section). The equations for LLDFs for

bending moment for interior girders with one lane loaded is given in Equation 3.1, and

for two or more lanes loaded by Equation 3.2.

gM

1

i-

= 0.06+[S/14]

0.4

[S/L]

0.3

[K

g

/(12Lt

s

3

)]

0.1

.. Equation 3.1

gM

2+

i-

= 0.075+[S/9.5]

0.6

[S/L]

0.2

[K

g

/(12Lt

s

3

)]

0.1

.. Equation 3.2

K

g

= n (I+Ae

g

2

)

n = E

Beam

/E

Slab

Where,

gM

1

i-

= LLDF for bending moment for interior girder with one lane loaded.

gM

2+

i-

= LLDF for bending moment for interior girder with two or more lanes loaded.

K

g

= longitudinal stiffness parameter for the composite girder (in

4

)

.

S = respective spacing between the girders (ft) for different approach.

L = span of the Bridge (ft).

t

s

= thickness of deck slab

(in)

.

n = modular ratio between the material of girder and material of deck.

e

g

= the distance between center of gravity of NEXT beam and deck slab (in).

A = Cross sectional area of the girder (in

2

).

I = Moment of inertia of NEXT beam (in

4

).

E

Beam =

Modulus of elasticity of NEXT beam (ksi)

.

26

E

Slab =

Modulus of elasticity of deck slabs (ksi).

To evaluate LLDFs, NEXT beams with different depths (24, 32, and 36in. [610, 813, and

914mm]) were considered typical for use in three different spans being investigated (50,

66.67, and 80ft [15.24, 20.32, and 24.38m]). These depths were determined using the

span ranges of different NEXT beam cross sections from available load tables. The SST

and DST approaches used to evaluate LLDFs result, therefore, in different values of K

g

depending on the cross section used. Table 3.1 lists the different values of K

g

and

relevant parameters used to calculate K

g

.

27

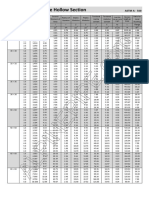

Table3.1: Cross section properties for Use in AASHTO LLDF equations

Details Unit SST DST

NEXT Beam 24F 32F 36F 24F 32F 36F

K

g

in

4

(m

4

)

158,318 (0.06) 310,661 (0.13) 417,440 (0.17) 316,635 (0.13) 621,323 (0.26) 834,881 (0.35)

N 1.41 1.41 1.41 1.41 1.41 1.41

I in

4

(m

4

) 26,481 (0.01) 58,050 (0.024) 80,142 (0.033) 52,962 (0.022) 116,100 (0.048) 160,284 (0.066)

A in

2

(m

2

) 492 (0.317) 583 (0.375) 640 (0.412) 984 (0.633) 1,166 (0.750) 1,280 (0.824)

e.g in (mm) 13.18 (334.77) 16.65 (422.91) 18.33 (465.58) 13.18 (334.77) 16.65 (422.91) 18.33 (465.58)

E

Beam

ksi (Mpa) 5,098 (35176) 5,098 (35176) 5,098 (35176) 5,098 (35176) 5,098 (35176) 5,098 (35176)

E

Slab

ksi (Mpa) 3,605 (24874) 3,605 (24874) 3,605 (24874) 3,605 (24874) 3,605 (24874) 3,605 (24874)

Notes : fc

Beam

=8000 psi, E

Beam

= 57000*sqrt (fc

Beam

)/1000 ksi, fc

Slab

=4000 psi, E

Slab

= 57000*sqrt(fc

Beam

)/1000 ksi

28

To consider the effect of skew angle on LLDFs for bending moment AASHTO LRDF

gives a correction factor (C

M

) as indicated by Equation 3.3. From Equation 3.3 it is clear

that LLDFs for bending moment decrease with increase in skew angle. This result is

consistent with results obtained from FEM analyses as discussed later.

C

M

= 1.25][(K

g

/(12Lt

s

3

)]

0.25

][S/L]

0.5

(tano)

1

.. Equation 3.3

Where,

o = skew angle of the Bridge (degree).

L = span of the Bridge (ft).

t

s

= thickness of deck slab (not including flange of NEXT beam(ft) .

S = spacing between the girders (ft).

LLDFs for the design shear force of interior girders with one lane loaded are calculated

using Equation 3.4, whereas with two or more lanes loaded is given by Equation 3.5.

gV

1

i-

= 0.36+[S/25]

.. Equation 3.4

gV

2+

i-

= 0.2+[S/12] - [S/35]

2

.. Equation 3.5

Where,

gV

1

i-

= LLDF for shear force for interior girder with one lane loaded.

gV

2+

i-

= LLDF for shear force for interior girder with two or more lanes loaded.

S = spacing between the girders (ft).

To consider the effect of skew angle on LLDFs for shear force, the LLDF shear force

correction factor (C

S

) given in Equation. 3.6 is used (AASTHO LRFD 2010). Equation

3.6 clearly shows that LLDFs for shear force increase with an increase in skew angle.

This also matches results obtained from FE analyses as discussed in Chapter 5.

C

S

= 1+ [0.2] (12Lt

s

3

/K

g

)

0.3

(tano)]

.. Equation 3.6

29

3.7 Calculation of LLDFs for Exterior Girders

LLDFs for exterior girder are computed using the lever rule according with AASHTO

LRFD (2010). The lever rule is a method of computing the distribution factors by taking

moments about the first interior girder to get the reaction at the exterior girder, assuming

there is a notional hinge in the Bridge deck directly above the first interior girder. The

design truck is placed as far away from the first interior girder towards the edge of the

Bridge to maximize the reaction computed in the exterior girder. The design truck may be

positioned transversely on the Bridge deck such that center of any wheel is not closer

than 2ft (0.94m) from the edge of the design lane.

The LLDFs for bending moment for exterior girders with one lane loaded are calculated

by the lever rule; for two or more lanes loaded the LLDFs are calculated using Equation

3.7, which is based on the LLDFs for two or more lanes loaded of interior girders.

gM

1

e-

= Lever Rule

gM

2+

e-

= e

M

*gM

2+

i-

.. Equation 3.7

e

M

= 0.77+d

e

/9.1

.. Equation 3.8

Where,

gM

1

e-

= LLDF for bending moment for exterior girder with one lane loaded.

gM

2+

e-

= LLDF for bending moment for exterior girder with two or more lanes loaded.

gM

2+

i-

= LLDF for bending moment for interior girder with two or more lanes loaded.

e

M

= correction factor for distribution, distance between design lane and the center of

gravity of girders (ft).

d

e

= horizontal distance from the centerline of the exterior web of the exterior beam

at the deck level to the interior edge of the curb or traffic barrier (in).

30

The equations for LLDF for shear force for exterior girders with one lane loaded and two

or more lanes loaded are given by lever rule and Equation 3.9 respectively.

gV

1

e-

= Lever Rule

gV

2+

e-

= e

V

* gV

2+

i-

.. Equation 3.9

e

V

= 0.6+d

e

/10

.. Equation 3.10

Where,

e

V

= Correction factor for distribution, distance between design lane and the center of

gravity of girders (ft).

To consider the effect of skew angle of the Bridge these LLDFs are multiplied by the

respective skew angle correction factors as indicated above (Equation 3.3 and 3.6).

3.7.1 Load Position for LLDF Calculation of Exterior Girders - SST Approach

For calculation of exterior girder LLDFs using the SST approach, a small curb was

considered on the edge of the Bridge to allow transverse placement of the design truck as

close to the edge as possible to maximize the reaction of the exterior girder. The width of

the curb considered was 17in. (0.43m). The first wheel of an HS20 truck load was

positioned 25.9in (0.65m) away from the edge of curb (Figure. 3.11). The second wheel

of the design truck does not appear in Figure 3.11 because it falls in the first interior

NEXT beam. The assumed location of the notional hinge above B11. The reaction

obtained in B12 in Figure 3.11 (exterior girder) is multiplied by two to determine the

LLDF for the exterior NEXT beam.

31

Figure3.11: Wheel Loading in Exterior Girder for LLDF Calculation - Single Stem

Approach

For the case of one lane loaded Applying,

EMB = 0

.. Equation 3.11

R

A

Reaction at the center of gravity of the exterior stem = 0.58P

L

F

kips The Lane fraction carried by exterior stem (0.58*P/2) = 0.29P

sM

1

e-

= m*L

F

.. Equation 3.12

gM

1

e-

= gV

1

e-

=2*sM

1

e-

.. Equation 3.13

Where,

sM

1

e-

= LLDF for bending moment of exterior Stem B12

gM

1

e-

= 2*sM

1

e-

= LLDF for bending moment for exterior NEXT beam

gV

1

e-

is LLDFs for shear force for exterior NEXT beam

m is multiple lane presence factor = 1.2 for single lane loaded.

Using Equation 3.11, Equation 3.12, Equation 3.13 we get,

gM

1

e-

= gV

1

e-

= 0.7

32

For the case of two or more lanes loaded Equations 3.7 and 3.8 are used. The eccentricity

of the center of gravity of the exterior stem to the interior edge of the curb is 0.75in

(19.05mm). The factors e

M

and e

V

for bending moment and shear force respectively, are

calculated as:

d

e

= 30.75 in.

e

M

= 0.77+d

e

/9.1 = 1.05ft (0.32m)

e

V

= 0.6+d

e

/10 = 0.88ft (0.27m)

gM

2+

e-

= e

M

*gM

1-

i-

gV

2+

e-

= e

V

*gV

1-

i-

These values are then used in Equations 3.7 and 3.9 to calculate the LLDFs for moment

and shear of exterior girders for two or more lanes loaded. These LLDF values have to be

adjusted by the respective skew angle correction factor from Equation 3.3 and Equation

3.6 for moment and shear, respectively. Results of calculated LLDFs for bending moment

and shear force are presented in tabular form in Section 3.7 (Table 3.3 and 3.5,

respectively).

3.7.2 Load Position for LLDF Calculation of Exterior Girders - DST Approach

For the evaluation of LLDFs of exterior girders using the DST approach, a narrow curb

was again assumed to allow the wheel from the design truck to be placed in a position

that generates a high force on the exterior girder. The width of the curb considered was

17in. (0.43m). The first wheel of an HS20 truck load was placed 26in. (0.65m) from the

edge of the curb. The notional hinge for application of the lever rule was placed at the

centroid of the first interior NEXT beam unit. The reaction in the exterior NEXT beam

unit is determined at the centroid of that unit as illustrated in Figure 3.12. This figure

33

illustrates B6 as a typical exterior girder; the figure also shows the notation used for

calculation of the exterior girder LLDF for a single lane loaded.

Figure3.12: Loading Exterior Girder Double Stem Approach

For the case of one lane loaded Applying,

EMB = 0

.. Equation 3.14

R

A

Reaction at the center of gravity of the exterior NEXT Beam = 1.37 P

L

F

The lane fraction carried by exterior stem (1.37*P/2) = 0.68

gM

1

e-

= gV

1

e-

=m*L

F

.. Equation 3.15

Where,

gM

1

e-

= LLDFs for bending moment for exterior NEXT beam

gV

1

e-

= LLDFs for shear force for exterior NEXT beam

m = multiple lane presence factor = 1.2

Solving Equation 3.17, with m=1.2 we get,

gM

1

e-

= gV

1

e-

= 0.82

34

Similar to the SST for two or more lanes loaded analytical equations mentioned in

AASHTO LRFD specifications (2010) are used. The eccentricity of the center of gravity

of the exterior girder to the interior edge of the narrow sided curb de is 30.75in (0.78m).

Similarly e

M

and e

V

correction factors for bending moment and shear force respectively

have been evaluated in this section. These values have to be multiplied by the respective

LLDFs of the interior girder.

d

e

= 30.75 in

e

M

= 0.77+de/9.1 = 1.05ft (0.32m)

e

V

= 0.6+de/10 = 0.88ft (0.27m)

gM

2+

e-

= e

M

*gM

1-

i-

gV

2+

e-

= e

V

*gV

1-

i-

These LLDFs have to be also multiplied by the respective skew angle correction factors

when applicable. Results of LLDFs for bending moment and shear force are listed in

Section 3.8.

3.8 LLDF Values Computed Using Single Stem Approach (type k)

This approach is assumed to be the conservative approach proposed by the PCI Bridge

technical committee and used currently by designers for design of NEXT beam Bridges.

An 8in (203.2mm). thick deck has been considered acting compositely with the NEXT

beam. Tables 3.2 through 3.5 list LLDFs for bending moment and shear force for

different assumed spans and skew angles. The spans considered are 50, 66.67, and 80ft

[15.24, 20.32, and 24.38m]. The skew angles considered are 0

o

, 30

o

and 45

o

.

35

Table 3.2: LLDFs-Bending Moment-Interior Girder

One lane loaded (gM

1

i -

) Two or more lanes loaded (gM

2+

i -

)

Span

ft (m)

Skew Span

ft (m)

Skew

0

o

30

o

45

o

0

o

30

o

45

o

50 (15.24) 0.66 0.63 0.62 50 (15.24) 0.83 0.80 0.77

66.67 (20.32) 0.63 0.61 0.59 66.67 (20.32) 0.81 0.79 0.76

80 (24.38) 0.61 0.59 0.57 80 (24.38) 0.80 0.77 0.75

Notes : 1=one lane loaded whereas, 2+= for two or more lanes loaded, i- interior girder, e- represent

exterior girder respectively, M = Bending Moment

Table 3.3: LLDFs-Bending Moment-Exterior Girder

One Lane Loaded (gM1e -) Two or more Lanes Loaded (gM2+e -)

Span

ft (m)

Skew Span

ft (m)

Skew

0

o

30

o

45

o

0

o