Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Shear Strength Calculation For Lifting Lug For Plate Flipping

Caricato da

Kim HernandezTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Shear Strength Calculation For Lifting Lug For Plate Flipping

Caricato da

Kim HernandezCopyright:

Formati disponibili

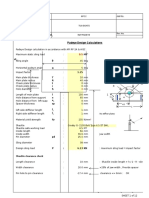

PROJECT: TITLE: Design Calculation For Lifting Lug For Plate Flipping In Panel Line Shop

Rev.: Date:

Worst Case: Material of Lifting Lug Yield Stress () SWL of Gantry Crane in Panel Line Shop = High Tensile Steel (AH36) = 36 = 20 = 2.11 = 42.2 = 21.1 = 73 = 22.07 = 6.46 (tonnes) (tonnes) () (tonnes) (tonnes) Note: 2-point lifting Note: Min. 70 to prevent lifting lug bending (kg/mm2) (tonnes)

Safety Factor

Design Load (DL) Load on Each End (F1 = DL / 2) Wire Sling Angle () Load along Wire Sling (F2 = F1 / sin ) Load along X-Axis (F3 = F1 x cos )

Check for Shear Height (H) Width (W) Shear Area (A) Allowable Shear Stress (s) Allowable Shear Force (Fas) = 56 = 30 = = = = > 1680 14.4 24192 24.2 22.07 (mm) (mm) (mm2) (kg/mm2) (kg) (tonnes) (tonnes) (mm) (mm) (mm2) (kg/mm2) (kg/mm2) (kg) (tonnes) (tonnes) Note: Shear Stress = 40% of Yield Stress Note: Hole Dia = 54 mm

Check for Weld Weld Leg Size (Hw) Weld Length (Lw) Weld Shear Area (Aw) Yield Stress Of Weld (w) Allowable Shear Stress Of Weld (sw) Allowable Shear Force (Fas) = 18 = 75 = = = = = > 3818.377 36 14.4 54984.62 54.99 21.1 Note: Fillet weld

Note: Shear Stress = 40% of Yield Stress

Check for Bending i) Lifting while Panel is Horizontal Bending load considered (F1 /2) = 10.55 (tonnes) Note: Since one edge of the plate is supported on the ground, the total load F1 is considered to be acting equally at lug and the ground support Distance from Lifting Eye to Plate (D1) Width (W) Depth (D) Section Modulus of Lifting Lug in X-axis (Zx) = 135 = 0.135 = 300 = 30 = 450000 = 450 = = = < 21.6 1.43 66.21 450 (mm) (m) (mm) (mm) (mm3) (cm3) (kg/mm2) (Tm) (cm3) (cm3) Note: Bending Stress = 60% of Yield Stress

Allowable Bending Stress (b) Bending Moment (Mb) Section Modulus Required (Zr)

ii) Lifting while Panel is Vertical Bending load considered Distance from Lifting Eye to Plate (D1) Width (W) Depth (D) Section Modulus of Lifting Lug in Y-axis (Zy) = 6.46 = 150 = 0.15 = 30 = 300 = 45000 = 45 = = = < 21.6 0.97 44.91 45 (tonnes) (mm) (m) (mm) (mm) (mm3) (cm3) (kg/mm2) (Tm) (cm3) (cm3) Note: Bending Stress = 60% of Yield Stress Note: Load considered is the horizontal load

Allowable Bending Stress (b) Bending Moment (Mb) Section Modulus Required (Zr)

Hence, SWL 25T shackles and wire slings shall be suitable for plate flipping Hence, design load of 16T lifting lugs shall be suitable for plate flipping

Actual Case 1 (B1-SP2 & SP4): Material of Lifting Lug Actual Weight of Load to be Lifted (Fa) Factored Weight (Ff = Fa x 1.25) Load on Each End (F1 = Ff / 2) Wire Sling Angle () Load along Wire Sling (F2 = F1 / sin ) Load along X-Axis (F3 = F1 x cos ) Height (H) Width (W) Shear Area (A) Yield Strength Of Mild Steel () Shear Strength Of Mild Steel (s) Allowable Shear Force (Fas)

= Mild Steel Grade A (A36) = 13.71 = 17.14 = 8.57 = 73 = 8.97 = 2.63 = 46.5 = 30 = = = = = > 1395 24 9.6 13392 13.4 8.97 (tonnes) (tonnes) (tonnes) () (tonnes) (tonnes) (mm) (mm) (mm2) (kg/mm2) (kg/mm2) (kg) (tonnes) (tonnes) (mm) (mm) (mm2) (kg/mm2) (kg/mm2) (kg) (tonnes) (tonnes) (mm) (mm) (mm3) (cm3) (mm) (m) (kg/mm2) (kg/mm2) (Tm) (cm3) (cm3) Note: Hole size = 37mm Note: 2-point lifting

Note: Shear Strength = 40% of Yield Strength

Weld Leg Size (Hw) Weld Length (Lw) Weld Shear Area (Aw) Yield Strength Of Weld (w) Shear Strength Of Weld (sw) Allowable Shear Force (Fas)

= 18 = 150 = = = = = > 3818.377 24 9.6 36656.42 36.66 17.14

Note: Fillet weld

Note: Shear Strength = 40% of Yield Strength

Width (W) Depth (D) Section Modulus of Lifting Lug in Y-axis (Z)

= 30 = 130 = 19500 = 19.5 = 100 = = = = = < 0.1 36 21.6 0.567 26.25 19.5

Distance from Lifting Eye to Plate (D1) Yield Strength Of Mild Steel () Bending Strength Of Mild Steel (b) Bending Moment (Mb) Section Modulus Required (Zr)

Note: Bending Stress = 60% of Yield Stress

Hence, SWL 12T shackles and wire slings shall be suitable for plate flipping Hence, design load of 16T lifting lugs shall be suitable for plate flipping Actual Case 2 (B1-SP5, SP6 & SP7): Material of Lifting Lug Actual Weight of Load to be Lifted (Fa) Factored Weight (Ff = Fa x 1.25) Load on Each End (F1 = Ff / 2) Wire Sling Angle () Load along Wire Sling (F2 = F1 / sin ) Load along X-Axis (F3 = F1 x cos ) Height (H) Width (W) Shear Area (A) Yield Strength Of Mild Steel () Shear Strength Of Mild Steel (s) Allowable Shear Force (Fas)

= Mild Steel Grade A (A36) = 15.76 = 19.7 = 9.85 = 73 = 10.31 = 3.02 = 46.5 = 30 = = = = = > 1395 24 9.6 13392 13.4 10.31 (tonnes) (tonnes) (tonnes) () (tonnes) (tonnes) (mm) (mm) (mm2) (kg/mm2) (kg/mm2) (kg) (tonnes) (tonnes) (mm) (mm) (mm2) (kg/mm2) (kg/mm2) (kg) (tonnes) (tonnes) (mm) (mm) (mm3) (cm3) Note: Hole size = 37mm Note: 2-point lifting

Note: Shear Strength = 40% of Yield Strength

Weld Leg Size (Hw) Weld Length (Lw) Weld Shear Area (Aw) Yield Strength Of Weld (w) Shear Strength Of Weld (sw) Allowable Shear Force (Fas)

= 18 = 150 = = = = = > 3818.377 24 9.6 36656.42 36.66 19.7

Note: Fillet weld

Note: Shear Strength = 40% of Yield Strength

Width (W) Depth (D) Section Modulus of Lifting Lug in Y-axis (Z)

= 30 = 130 = 19500 = 19.5

Distance from Lifting Eye to Plate (D1) Yield Strength Of Mild Steel () Bending Strength Of Mild Steel (b) Bending Moment (Mb) Section Modulus Required (Zr)

= 75 = = = = = < 0.075 24 14.4 0.23 15.98 19.7

(mm) (m) (kg/mm2) (kg/mm2) (Tm) (cm3) (cm3)

Note: Bending Stress = 60% of Yield Stress

Hence, SWL 12T shackles and wire slings shall be suitable for plate flipping Hence, design load of 16T lifting lugs shall be suitable for plate flipping Actual Case 3 (B1-SP8, SP9 & SP10): Material of Lifting Lug Actual Weight of Load to be Lifted (Fa) Factored Weight (Ff = Fa x 1.25) Load on Each End (F1 = Ff / 2) Wire Sling Angle () Load along Wire Sling (F2 = F1 / sin ) Load along X-Axis (F3 = F1 x cos ) Height (H) Width (W) Shear Area (A) Yield Strength Of Mild Steel () Shear Strength Of Mild Steel (s) Allowable Shear Force (Fas)

= Mild Steel Grade A (A36) = 16.82 = 21.025 = 10.52 = 73 = 11.01 = 3.22 = 46.5 = 30 = = = = = > 1395 24 9.6 13392 13.4 11.01 (tonnes) (tonnes) (tonnes) () (tonnes) (tonnes) (mm) (mm) (mm2) (kg/mm2) (kg/mm2) (kg) (tonnes) (tonnes) (mm) (mm) (mm2) (kg/mm2) (kg/mm2) (kg) (tonnes) (tonnes) (mm) (mm) (mm3) (cm3) (mm) (m) (kg/mm2) (kg/mm2) (Tm) (cm3) (cm3) Note: Hole size = 37mm Note: 2-point lifting

Note: Shear Strength = 40% of Yield Strength

Weld Leg Size (Hw) Weld Length (Lw) Weld Shear Area (Aw) Yield Strength Of Weld (w) Shear Strength Of Weld (sw) Allowable Shear Force (Fas)

= 18 = 150 = = = = = > 3818.377 24 9.6 36656.42 36.66 21.025

Note: Fillet weld

Note: Shear Strength = 40% of Yield Strength

Width (W) Depth (D) Section Modulus of Lifting Lug in Y-axis (Z)

= 30 = 130 = 19500 = 19.5 = 75 = = = = = < 0.075 24 14.4 0.25 17.37 19.5

Distance from Lifting Eye to Plate (D1) Yield Strength Of Mild Steel () Bending Strength Of Mild Steel (b) Bending Moment (Mb) Section Modulus Required (Zr)

Note: Bending Stress = 60% of Yield Stress

Hence, SWL 12T shackles and wire slings shall be suitable for plate flipping Hence, design load of 16T lifting lugs shall be suitable for plate flipping

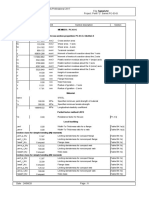

PROJECT: TITLE: Design Calculation For Lifting Lug For Plate Flipping In Panel Line Shop

Rev.: Date:

Worst Case: Material of Lifting Lug Yield Stress () SWL of Gantry Crane in Panel Line Shop Safety Factor Design Load (DL) Load on Each End (F1 = DL / 2) Wire Sling Angle () Load along Wire Sling (F2 = F1 / sin ) Load along X-Axis (F3 = F1 x cos ) = High Tensile Steel (AH36) = 36 = 20 = 1.5 = 30 = 15 = 73 = 15.69 = 4.59 (tonnes) (tonnes) () (tonnes) (tonnes) Note: 2-point lifting Note: Min. 70 to prevent lifting lug bending (kg/mm2) (tonnes)

Check for Shear Height (H) Width (W) Shear Area (A) Allowable Shear Stress (s) Allowable Shear Force (Fas) = 50 = 30 = = = = > 1500 14.4 21600 21.6 15.69 (mm) (mm) (mm2) (kg/mm2) (kg) (tonnes) (tonnes) (mm) (mm) (mm2) (kg/mm2) (kg/mm2) (kg) (tonnes) (tonnes) Note: Shear Stress = 40% of Yield Stress Note: Hole Dia = 44 mm

Check for Weld Weld Leg Size (Hw) Weld Length (Lw) Weld Shear Area (Aw) Yield Stress Of Weld (w) Allowable Shear Stress Of Weld (sw) Allowable Shear Force (Fas) = 18 = 75 = = = = = > 3818.377 36 14.4 54984.62 54.99 15 Note: Fillet weld

Note: Shear Stress = 40% of Yield Stress

Check for Bending i) Lifting while Panel is Horizontal Bending load considered (F1 /2) = 7.5 (tonnes) Note: Since one edge of the plate is supported on the ground, the total load F1 is considered to be acting equally at lug and the ground support

Distance from Lifting Eye to Plate (D1) Width (W) Depth (D) Section Modulus of Lifting Lug in X-axis (Zx)

= 135 = 0.135 = 230 = 30 = 264500 = 264.5 = = = < 21.6 1.02 47.23 264.5

(mm) (m) (mm) (mm) (mm3) (cm3) (kg/mm2) (Tm) (cm3) (cm3) Note: Bending Stress = 60% of Yield Stress

Allowable Bending Stress (b) Bending Moment (Mb) Section Modulus Required (Zr)

ii) Lifting while Panel is Vertical Bending load considered Distance from Lifting Eye to Plate (D1) Width (W) Depth (D) Section Modulus of Lifting Lug in Y-axis (Zy) = 4.59 = 150 = 0.15 = 30 = 230 = 34500 = 34.5 = = = < 21.6 0.69 31.95 34.5 (tonnes) Note: Load considered is the horizontal load (mm) (m) (mm) (mm) (mm3) (cm3) (kg/mm2) (Tm) (cm3) (cm3) Note: Bending Stress = 60% of Yield Stress

Allowable Bending Stress (b) Bending Moment (Mb) Section Modulus Required (Zr)

Hence, SWL 17T shackles and wire slings shall be suitable for plate flipping

Hence, design load of 16T lifting lugs shall be suitable for plate flipping

Potrebbero piacerti anche

- Lifting Lug Design and Stress AnalysisDocumento2 pagineLifting Lug Design and Stress AnalysisDarkvaderNessuna valutazione finora

- Lifting Eye Bolt CheckDocumento1 paginaLifting Eye Bolt Checkali akbar100% (1)

- Discussion - Design Concepts For Jib CranesDocumento2 pagineDiscussion - Design Concepts For Jib Cranesheitor29Nessuna valutazione finora

- Load analysis and strength evaluation of vessel lifting lugDocumento3 pagineLoad analysis and strength evaluation of vessel lifting lugMudasir MughalNessuna valutazione finora

- Lifting Lug CalculationsDocumento6 pagineLifting Lug CalculationsYash RamiNessuna valutazione finora

- LIFTING LUG AND LIFTING COVER DESIGN REFERENCEDocumento4 pagineLIFTING LUG AND LIFTING COVER DESIGN REFERENCERohith V VNessuna valutazione finora

- Lifting Lug CalcDocumento1 paginaLifting Lug CalcshazanNessuna valutazione finora

- Torsion Validation ShayanDocumento10 pagineTorsion Validation ShayanGicuNessuna valutazione finora

- 6a Padeye Aisc 360 2005Documento6 pagine6a Padeye Aisc 360 2005mjlazoNessuna valutazione finora

- Lifting LugDocumento4 pagineLifting LugUmmer BavaNessuna valutazione finora

- X388allegato1 2X Offshore Cranes BDocumento15 pagineX388allegato1 2X Offshore Cranes BMostafa BatourNessuna valutazione finora

- Structural Steel Design Calculations: Design of Pinnacle CrescentDocumento11 pagineStructural Steel Design Calculations: Design of Pinnacle CrescentssssNessuna valutazione finora

- Horizontal Lifting LugDocumento1 paginaHorizontal Lifting LugTushar MangratiNessuna valutazione finora

- CSA Bolted Connection FatigueDocumento3 pagineCSA Bolted Connection FatiguejurieskNessuna valutazione finora

- Transmission Line Design and Steel Pole StructuresDocumento27 pagineTransmission Line Design and Steel Pole StructuresDanNessuna valutazione finora

- Padeye .5MT CHKDocumento12 paginePadeye .5MT CHKDhanraj VasanthNessuna valutazione finora

- Design of BoltsDocumento18 pagineDesign of BoltsFunny & InformativeNessuna valutazione finora

- SEISMIC ANALYSIS KazzincDocumento14 pagineSEISMIC ANALYSIS KazzincArees KhambattaNessuna valutazione finora

- MonorailDocumento13 pagineMonorailleodegarioporralNessuna valutazione finora

- COMPARISON OF COMPOSITE BEAM DESIGNDocumento8 pagineCOMPARISON OF COMPOSITE BEAM DESIGNMohamed Abo-ZaidNessuna valutazione finora

- Lifting Beam CalculationDocumento2 pagineLifting Beam CalculationAvish ShahNessuna valutazione finora

- Lifting Lug Load Capacity Vs Crack Length CalculationDocumento26 pagineLifting Lug Load Capacity Vs Crack Length CalculationMohamed NkNessuna valutazione finora

- Welding CalculationDocumento10 pagineWelding CalculationMaqsood100% (1)

- Lifting BEAMSDocumento90 pagineLifting BEAMSGogyNessuna valutazione finora

- Checks For CompactnessDocumento15 pagineChecks For CompactnessjologscresenciaNessuna valutazione finora

- Weight&Lifting - To CheckDocumento54 pagineWeight&Lifting - To ChecknamasralNessuna valutazione finora

- Column Base Plate DesignDocumento5 pagineColumn Base Plate Design_jessecaNessuna valutazione finora

- Plywood Design Application GuideDocumento36 paginePlywood Design Application GuideHazim AffendiNessuna valutazione finora

- Pin Connected Tension MemberDocumento2 paginePin Connected Tension MemberAUNGPSNessuna valutazione finora

- Padeye Design AnalysisDocumento8 paginePadeye Design AnalysisMyatmyat SwewinNessuna valutazione finora

- PadEye Calculator: Lifting lug design and shackle compatibilityDocumento8 paginePadEye Calculator: Lifting lug design and shackle compatibilityBayari ArNessuna valutazione finora

- Bab Iii: Re-Design Dan Hasil Perhitungan Horizontal Pressure VesselDocumento36 pagineBab Iii: Re-Design Dan Hasil Perhitungan Horizontal Pressure VesselTri AgungNessuna valutazione finora

- Beam Shear & Moment DiagramDocumento8 pagineBeam Shear & Moment DiagramAnantPawarNessuna valutazione finora

- Crane Design DataDocumento4 pagineCrane Design DatapradeepqNessuna valutazione finora

- Wind Pressure Calculation As per SP-1275Documento7 pagineWind Pressure Calculation As per SP-1275Siva baalanNessuna valutazione finora

- 01 Top Running Double Girder Crane DataDocumento8 pagine01 Top Running Double Girder Crane Dataevelyn_inocenci6140Nessuna valutazione finora

- 2400 Tema DCDocumento7 pagine2400 Tema DCMasoodMiyanNessuna valutazione finora

- Vessel lifting lug design data and stress analysisDocumento3 pagineVessel lifting lug design data and stress analysismiteshpatel191100% (1)

- Connection Calculation: Dop Dop WdopDocumento2 pagineConnection Calculation: Dop Dop WdopbobbynebaNessuna valutazione finora

- Design of Curved Monorail StructureDocumento2 pagineDesign of Curved Monorail StructuredsanandaNessuna valutazione finora

- TQ-0305-R00 - Calculo Estrutura PDFDocumento4 pagineTQ-0305-R00 - Calculo Estrutura PDFPeterson MagroNessuna valutazione finora

- PadeyeDocumento14 paginePadeyeMarshall Minggat AmpiNessuna valutazione finora

- Cantilever Beam Design - I BeamDocumento1 paginaCantilever Beam Design - I Beamberylqz5878Nessuna valutazione finora

- Beam Deflections and Stresses During Lifting PDFDocumento10 pagineBeam Deflections and Stresses During Lifting PDFManoj KumarNessuna valutazione finora

- Web Yielding Is The Compressive Crushing of A Bam Web Caused by A Force Acting On The Flange Directly AboveDocumento3 pagineWeb Yielding Is The Compressive Crushing of A Bam Web Caused by A Force Acting On The Flange Directly AboveJohn Saniel J. EstacionNessuna valutazione finora

- Davit Anchor Calculation PDFDocumento14 pagineDavit Anchor Calculation PDFRiyas RafiNessuna valutazione finora

- Mi 1Documento9 pagineMi 1XNessuna valutazione finora

- Thermal Stress ExamplesDocumento10 pagineThermal Stress ExamplesVishal V BhagwatNessuna valutazione finora

- Is.4374.1980 Bollard StrengthDocumento15 pagineIs.4374.1980 Bollard Strengthaleksandar_djordjicNessuna valutazione finora

- Shackle Stress AnalysisDocumento1 paginaShackle Stress Analysisarash_mehriNessuna valutazione finora

- Lifting Lug Calculations KodDocumento2 pagineLifting Lug Calculations Kodanu radhaNessuna valutazione finora

- Earthquake load calculations as per IS1893-2002Documento9 pagineEarthquake load calculations as per IS1893-2002irshad313Nessuna valutazione finora

- Bolt Grip Length PDFDocumento1 paginaBolt Grip Length PDFmatthewwalls4386100% (2)

- Shear Strength Calculation For Lifting Lug For Plate FlippingDocumento16 pagineShear Strength Calculation For Lifting Lug For Plate FlippingKarthikeyan VisvakNessuna valutazione finora

- 참고자료 6. Shear-Strength-Calculation-for-Lifting-Lug-for-Plate-FlippingDocumento7 pagine참고자료 6. Shear-Strength-Calculation-for-Lifting-Lug-for-Plate-Flippingaoaaoa1122Nessuna valutazione finora

- DS-08 - Strip Raft With BeamDocumento21 pagineDS-08 - Strip Raft With BeamKutty MansoorNessuna valutazione finora

- Moment ConnectionsDocumento15 pagineMoment ConnectionsHector Aguana100% (1)

- Pinned and fixed base plate design calculations for I-section and tube columnsDocumento7 paginePinned and fixed base plate design calculations for I-section and tube columnsabdul karee100% (6)

- Footing Design SheetDocumento11 pagineFooting Design SheetAntonius Ajalah100% (1)

- Pressure Vessel Calculation ReportDocumento82 paginePressure Vessel Calculation ReporteeghbaliNessuna valutazione finora

- Design of Steel Structure (Chapter 2) by DR R BaskarDocumento57 pagineDesign of Steel Structure (Chapter 2) by DR R Baskarelect aksNessuna valutazione finora

- AISC member dimensions and properties viewer online databaseDocumento86 pagineAISC member dimensions and properties viewer online databaseAnghello Jeison Zavaleta De la CruzNessuna valutazione finora

- GT TableDocumento62 pagineGT Tableeuric82Nessuna valutazione finora

- Memoria Samet SimpleDocumento2 pagineMemoria Samet SimpleJuan Emanuel VenturelliNessuna valutazione finora

- Laterar Buckling Spreader Beam PDFDocumento220 pagineLaterar Buckling Spreader Beam PDFPutut SuprihartonoNessuna valutazione finora

- Design of Prestressed Concrete Beam Using Single T-BeamsDocumento7 pagineDesign of Prestressed Concrete Beam Using Single T-BeamsZohaib AhmadNessuna valutazione finora

- Body Builder Instructions: ContentsDocumento82 pagineBody Builder Instructions: ContentsJuli FitriyantoNessuna valutazione finora

- Turkish Steel Design TablesDocumento977 pagineTurkish Steel Design TablesfdsaadsfdasfNessuna valutazione finora

- Problem Set Im MechDocumento16 pagineProblem Set Im MechRomel DecenillaNessuna valutazione finora

- Curtain Wall Calculation PDFDocumento134 pagineCurtain Wall Calculation PDFAlaaBadwy100% (1)

- DIN-En-10056-01 Structural Steel Equal&Unequal Leg AnglesDocumento9 pagineDIN-En-10056-01 Structural Steel Equal&Unequal Leg AnglesbacheghoulNessuna valutazione finora

- Design of Welded Steel Plate GirdersDocumento87 pagineDesign of Welded Steel Plate GirdersHoran Malik100% (1)

- Beam StressesDocumento2 pagineBeam StressesHarsh RanaNessuna valutazione finora

- Problems 281-284: Bending Stress and Plastic Moment CalculationsDocumento17 pagineProblems 281-284: Bending Stress and Plastic Moment CalculationsMaynard Coaquira GonzalesNessuna valutazione finora

- Afd Aa 2020Documento51 pagineAfd Aa 2020Nguyen Co ThachNessuna valutazione finora

- AISC Steel Construction Manual 6th Edition.Documento780 pagineAISC Steel Construction Manual 6th Edition.Ayk Altuntopian83% (6)

- Area Moment of Inertia Section Properties Half Tube Calculator - Engineers Edge - WWW - EngineersedgeDocumento2 pagineArea Moment of Inertia Section Properties Half Tube Calculator - Engineers Edge - WWW - Engineersedgedane05Nessuna valutazione finora

- 2.Pdf3rd DiplomaDocumento23 pagine2.Pdf3rd DiplomapinkyNessuna valutazione finora

- Is 801Documento39 pagineIs 801Shashi TapsiNessuna valutazione finora

- Risa SectionDocumento63 pagineRisa Section3cesNessuna valutazione finora

- AISC Column Design Logic Makes Sense For Composite Columns, TooDocumento7 pagineAISC Column Design Logic Makes Sense For Composite Columns, TooalbertoxinaNessuna valutazione finora

- Internal II Question Bank SOMDocumento7 pagineInternal II Question Bank SOMsathyadallyNessuna valutazione finora

- AISC (ASD) Shear Connection - Cleat AngleDocumento15 pagineAISC (ASD) Shear Connection - Cleat AngleMANOJNessuna valutazione finora

- Values of C For Simply Supported Beams W-Shapes: Table 3-1 Table 3-2Documento31 pagineValues of C For Simply Supported Beams W-Shapes: Table 3-1 Table 3-2MarkNessuna valutazione finora

- Hea 140Documento2 pagineHea 140mostafa ibrahimNessuna valutazione finora

- Circular Platform Design AISCDocumento32 pagineCircular Platform Design AISCRajveer SinghNessuna valutazione finora

- Calcs for I-section beam with equal flangesDocumento18 pagineCalcs for I-section beam with equal flangesSharyn Polley100% (1)

- Calculation Sheet of Single Pile Capacity of Cgs-3 Ho Cgs Pitless Operation ProjectDocumento32 pagineCalculation Sheet of Single Pile Capacity of Cgs-3 Ho Cgs Pitless Operation Projectcharleshutabara951Nessuna valutazione finora