Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

BOLTRIGHT Tightening Procedure 6 - 2500

Caricato da

Saad Abou-ZeidDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

BOLTRIGHT Tightening Procedure 6 - 2500

Caricato da

Saad Abou-ZeidCopyright:

Formati disponibili

BOLTRIGHT Tightening Procedure

file:///C:/Program Files/Hi-Force/BOLTRIGHT/TensioningProcedure.HTM

Hi-Force Logo

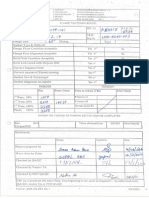

BOLTRIGHT RESULTS SUMMARY

and

TIGHTENING PROCEDURE

Date: 5/4/2011 at 05:43 PM

Name:

Organisation: TR-CCC

Joint Tag:

Remarks: Hi-Force Tool STS3-200 used.

Flange and Gasket Details

Flange Standard: ANSI Flange Nominal Size: 6 Design Pressure: 425 bar (6170 psi) Number of Bolts in Flange: 8 Bolt Material: ASTM A193 - B7M Gasket Type: Spiral Wound Gasket Gasket m Factor: 2.50 Effective Gasket Seating Width: 7.43 mm (0.293 inches) Flange Class: 2500 Operating Temperature: 20 C Test Pressure: 638 bar (9255 psi) Bolt Thread Size: 2 - 8 UN Bolt Minimum Yield Strength: 552 N/mm (80000 Lbf/in) Gasket Material: Graphite Gasket y Factor: 69 N/mm (10000 Lbf/in) Gasket Load Reaction Diameter: 194.6 mm (7.66 inches)

Tensioning Procedure

This tensioning procedure is a guide and may be needed to be adapted to suit the specific situation and circumstances. This procedure is designed to produce a residual load in each bolt of 493.0 kN (110825 Lbf) This represents 50% of the minimum yield strength of the bolt. The bolts will be tensioned during the tightening process to a higher load initially to allow for elasticity effects. The maximum loading sustained by the bolts during the tightening process represents 78%. of their minimum yield strength. Prerequisites : All personnel involved in implementing this procedure are competent in the use of the tightening equipment and joint tightening procedures. If assistance is needed, please contact Hi-Force. Important Note: This tensioning procedure is based upon using the Hi-Force hydraulic tensioner model number STS3-200 and a Pressure A = 1406 bar (20387 psi) and a Pressure B = 1125 bar (16310 psi) A. Pre-Bolting Inspection A.1 Gasket. Make sure the material is as specified, look for any possible defects or damage in the gasket such as folds or creases. A2. Flange. Inspect the gasket seating surfaces. Check for corrosion pitting, cracks, and tool marks. Any radial tool marks can directly lead to leakage regardless of the gasket material or the amount of bolt tightening. Make sure that the gasket seating surface is appropriate for the type of gasket being used. Check the areas on the flange where the nuts will seat. These should be flat and free from pitting and excessive wear. A3. Flange Alignment. It is important that the flange faces are parallel and aligned. The flange bolt holes should be lined up so that the bolts will not be bent when tightened. A4. Bolts. The bolt material specified is ASTM A193 - B7M and the thread size is 2 - 8 UN . Check each bolt to ensure that this is the case and that each bolt, nut and washer (if used) do not shown signs of corrosion, damage or excessive paint . Note : Any defects noted during the inspection must be rectified prior to starting the tensioning procedure. B. 50% Tensioning Procedure B1. Square up the Flanges. Hand tighten the bolts to square up the joint. Ensure that the flange faces are kept parallel to each other by partially tightening the bolts so that there is metal to metal contact around the full periphery of the joint. B2.1 Tensioning. The 8 bolts in the flange are to be tightened using a 50% tensioning procedure i.e. tensioners will be fitted to 4 bolts eqi-spaced around the flange. These are tightened to a high pressure (pressure A) before the remaining 4 bolts are tightened to a lower pressure (pressure B). The sequence and pressures applied are critical to achieving a leak free joint, carefully follow the instructions detailed below:

1 of 2

5/4/2011 5:43 PM

BOLTRIGHT Tightening Procedure

file:///C:/Program Files/Hi-Force/BOLTRIGHT/TensioningProcedure.HTM

B2.2 Tensioner Installation. Fit the hydraulic tensioners ( Hi-Force Model Number STS3-200) to 4 bolts eqi-spaced around the flange. B2.3 Pressure A Tensioning. Apply Pressure A (i.e. 1406 bar (20387 psi)) and tighten the nuts using a tommy bar. Release the pressure. B2.4 Pressure B Tensioning. Transfer the hydraulic tools to the 4 bolts that are yet to be tightened. Apply pressure B (i.e. 1125 bar (16310 psi)) and tighten. Release the pressure and then re-apply the pressure and ensure that the 4 nuts are tight. B2.5 Break Loose Tensioning Check. Transfer the hydraulic tools back to the 4 bolts that had been previously tightened. Increase the tensioner pressure slowly whilst attempting to rotate the tommy bar in the socket in the loosening direction of the nuts. Turn the pump off as soon as the nut first starts to rotate and make a note of the pressure (the "break loose" pressure) . If this is equal to or greater than pressure B (i.e. 1125 bar (16310 psi)) then the tensioning is complete. If this "break loose" pressure is less than pressure B then repeat steps B2.3 to B2.5. Final Check. As a final check, use a hammer to "ring" each bolt to ensure that none are slack.

ACCEPTED FOR COMPANY PRINT NAME POSITION SIGNATURE DATE

2 of 2

5/4/2011 5:43 PM

Potrebbero piacerti anche

- Ring Gasket ChartsDocumento8 pagineRing Gasket ChartsTiffany DacinoNessuna valutazione finora

- Spiral Wound Gaskets Donit TesnitDocumento0 pagineSpiral Wound Gaskets Donit Tesnitjhony1523Nessuna valutazione finora

- Nord Lock Washers InfoDocumento8 pagineNord Lock Washers InfoMaclean ArthurNessuna valutazione finora

- Ring Joint HandbookDocumento7 pagineRing Joint HandbookchiliskyNessuna valutazione finora

- 14.052 Rev. 0 - 9PE122 & 9PE123 - ECOPETROL - Cleaning Supervision, Inspection & Repair PDFDocumento11 pagine14.052 Rev. 0 - 9PE122 & 9PE123 - ECOPETROL - Cleaning Supervision, Inspection & Repair PDFVladimir Rodriguez LeonNessuna valutazione finora

- Flexitallic FlexproDocumento7 pagineFlexitallic FlexproHeryanto SyamNessuna valutazione finora

- Instrumentation Pipe & Weld Fittings: 6000psig, 10000psig and Standard RatingDocumento5 pagineInstrumentation Pipe & Weld Fittings: 6000psig, 10000psig and Standard Ratinggohjh80Nessuna valutazione finora

- Smith Gasket BrochureDocumento29 pagineSmith Gasket BrochureJeesan MathewNessuna valutazione finora

- Garlock GasketsDocumento46 pagineGarlock GasketskfchksdhbvkjhshfNessuna valutazione finora

- Slewing Bearing Installation and Maintenance Manual: Yantai Haoyang Machinery Co.,LtdDocumento22 pagineSlewing Bearing Installation and Maintenance Manual: Yantai Haoyang Machinery Co.,Ltddony ramdhaniNessuna valutazione finora

- Taper Thread TorqueDocumento1 paginaTaper Thread TorqueRichardNessuna valutazione finora

- Smooth Finish FlangesDocumento4 pagineSmooth Finish FlangessanoopvkNessuna valutazione finora

- Graphonic Garlock PDFDocumento40 pagineGraphonic Garlock PDFjbertralNessuna valutazione finora

- Flange LeakageDocumento3 pagineFlange LeakageBuiVanHop100% (1)

- Refinery InspectionDocumento44 pagineRefinery InspectiongamadiyaNessuna valutazione finora

- Compression and Recovery: The Optimum Gasket Astm F 36 JDocumento2 pagineCompression and Recovery: The Optimum Gasket Astm F 36 JTONNessuna valutazione finora

- Breather Valve - PV Valve - CNC380Documento2 pagineBreather Valve - PV Valve - CNC380mhidayat108Nessuna valutazione finora

- Difference Between Wrought Fittings and Forged Fittings - Google GroupsDocumento1 paginaDifference Between Wrought Fittings and Forged Fittings - Google Groupsim4uim4uim4uNessuna valutazione finora

- Collar Bolts: in Shell and Tube Heat ExchangersDocumento2 pagineCollar Bolts: in Shell and Tube Heat ExchangersMahdi HocineNessuna valutazione finora

- Spiral Wound GasketsDocumento3 pagineSpiral Wound GasketsHarish GundaNessuna valutazione finora

- API-1000-11 Rev 0Documento3 pagineAPI-1000-11 Rev 0Mahesh MishraNessuna valutazione finora

- Butterfly ValvesDocumento28 pagineButterfly ValvesLAWRENCENessuna valutazione finora

- Hydro Testing + Post Weld Heat TreatmentDocumento20 pagineHydro Testing + Post Weld Heat TreatmentRafia ZafarNessuna valutazione finora

- AS3788 Appendix N - Assessment of Wall Thinning: Input Data CalculationsDocumento5 pagineAS3788 Appendix N - Assessment of Wall Thinning: Input Data CalculationsGaneshNessuna valutazione finora

- Working Philosophy of A Gasket To Prevent LeakageDocumento4 pagineWorking Philosophy of A Gasket To Prevent LeakageAlfonNessuna valutazione finora

- Functioning of Flange Joints Findings From Full Scale Experiments and Fem AnalysisDocumento10 pagineFunctioning of Flange Joints Findings From Full Scale Experiments and Fem AnalysisSpecial Sicim ProcessesNessuna valutazione finora

- Troubleshooting Pumps: Pump Failure AnalysisDocumento19 pagineTroubleshooting Pumps: Pump Failure Analysispankaj vermaNessuna valutazione finora

- Torquing ManualDocumento17 pagineTorquing ManualZool HilmiNessuna valutazione finora

- Aluminium Coil / Sheet / Corrugated: Aluminium Alloy - AA 1100, 1050, 1060 - AA 3003 - AA 5005, 5052, 5754Documento1 paginaAluminium Coil / Sheet / Corrugated: Aluminium Alloy - AA 1100, 1050, 1060 - AA 3003 - AA 5005, 5052, 5754Aneesh JoseNessuna valutazione finora

- What TitleDocumento17 pagineWhat TitleBernathTurnipNessuna valutazione finora

- Socket Head Cap ScrewsDocumento1 paginaSocket Head Cap Screwsapi-3848892100% (5)

- GTS-PP-120: 3 LayerDocumento2 pagineGTS-PP-120: 3 Layershoaib1985100% (1)

- Marine Painting CourseDocumento57 pagineMarine Painting CourseMin SoeNessuna valutazione finora

- Work Instruction FOR: Tensile TestDocumento4 pagineWork Instruction FOR: Tensile TestmahendraNessuna valutazione finora

- Post Weld Heat Treatment Procedure: Doc No: STS/QAC/SOP/12Documento18 paginePost Weld Heat Treatment Procedure: Doc No: STS/QAC/SOP/12mohd as shahiddin jafriNessuna valutazione finora

- Bleed Ring - ANSI Class 150-2500 (In)Documento2 pagineBleed Ring - ANSI Class 150-2500 (In)ulfatNessuna valutazione finora

- NRL Pipeline Hydrotest Format PDFDocumento1 paginaNRL Pipeline Hydrotest Format PDFJaved Mohammed100% (1)

- Cement - API Oilwell Cement, Class 'G', Moderate Sulphate Resistant - Lehigh Cement Limited 2014 PDFDocumento6 pagineCement - API Oilwell Cement, Class 'G', Moderate Sulphate Resistant - Lehigh Cement Limited 2014 PDFAMSNessuna valutazione finora

- Bolt/hex Nut Strength MarkingsDocumento3 pagineBolt/hex Nut Strength Markings322399mk7086Nessuna valutazione finora

- Types of Flanges-Definition of FlangesDocumento4 pagineTypes of Flanges-Definition of FlangesindikumaNessuna valutazione finora

- Baking ProcedureDocumento2 pagineBaking Proceduregopuvinu4uNessuna valutazione finora

- Shell Corena S3 R 68: Performance, Features & BenefitsDocumento3 pagineShell Corena S3 R 68: Performance, Features & BenefitsjkamraNessuna valutazione finora

- Manual Torque WrenchDocumento2 pagineManual Torque WrenchVipul ShahNessuna valutazione finora

- NR494 - R01 Classification For Buoy PDFDocumento36 pagineNR494 - R01 Classification For Buoy PDFEsapermana RiyanNessuna valutazione finora

- Studding Outlet DimensionDocumento2 pagineStudding Outlet DimensionpandiangvNessuna valutazione finora

- Welder Qualification Test RecordDocumento2 pagineWelder Qualification Test RecordEngr Saeed AnwarNessuna valutazione finora

- Inspection Test Plant For Blasting Painting - Rev2Documento18 pagineInspection Test Plant For Blasting Painting - Rev2Dwikappa Asri UtamaNessuna valutazione finora

- A Pi 6 A Material Trim RatingsDocumento4 pagineA Pi 6 A Material Trim RatingsvsajuNessuna valutazione finora

- BOLTRIGHT Tightening Procedure 3 2500Documento2 pagineBOLTRIGHT Tightening Procedure 3 2500pedro ylarretaNessuna valutazione finora

- BOLTRIGHT Tightening Procedure 20-900Documento2 pagineBOLTRIGHT Tightening Procedure 20-900zeids100% (4)

- BOLTRIGHT Tightening ProcedureDocumento2 pagineBOLTRIGHT Tightening ProcedureVasilica BarbarasaNessuna valutazione finora

- Flange Bolt Tightening ProcedureDocumento5 pagineFlange Bolt Tightening ProcedureArya100% (1)

- Installation Instructions For PSI and Pikotek® Gaskets: Sleeves Through The Bolt HolesDocumento4 pagineInstallation Instructions For PSI and Pikotek® Gaskets: Sleeves Through The Bolt Holesquiron2010Nessuna valutazione finora

- FP196BDocumento8 pagineFP196BArnold GonzalesNessuna valutazione finora

- Definition and Details of Flanges Torque TighteningDocumento4 pagineDefinition and Details of Flanges Torque TighteningFsNessuna valutazione finora

- Lot 1.14 - Running ProceduresDocumento49 pagineLot 1.14 - Running ProcedureslfbenahmedNessuna valutazione finora

- GF - Installation Instructions For FlangesDocumento6 pagineGF - Installation Instructions For FlangesHafiz KamalNessuna valutazione finora

- Method Statement of Gasket, Flange, Fittings and Valves Tightening SequenceDocumento6 pagineMethod Statement of Gasket, Flange, Fittings and Valves Tightening SequenceRuel CabonceNessuna valutazione finora

- BOLTRIGHT Tightening Procedure 6 - 2500Documento2 pagineBOLTRIGHT Tightening Procedure 6 - 2500Saad Abou-ZeidNessuna valutazione finora

- BOLTRIGHT Tightening Procedure 6 - 2500Documento2 pagineBOLTRIGHT Tightening Procedure 6 - 2500Saad Abou-ZeidNessuna valutazione finora

- BOLTRIGHT Tightening Procedure 6 - 2500Documento2 pagineBOLTRIGHT Tightening Procedure 6 - 2500Saad Abou-ZeidNessuna valutazione finora

- BOLTRIGHT Tightening Procedure 6 - 2500Documento2 pagineBOLTRIGHT Tightening Procedure 6 - 2500Saad Abou-ZeidNessuna valutazione finora

- Flange Tightening ReportDocumento1 paginaFlange Tightening ReportSaad Abou-ZeidNessuna valutazione finora

- TB400 Painting and Corrosion ProtectionDocumento21 pagineTB400 Painting and Corrosion ProtectionAliZenatiNessuna valutazione finora

- Buku Miller's Anesthesia BAB 20 Dan 21Documento88 pagineBuku Miller's Anesthesia BAB 20 Dan 21Rahma TomuNessuna valutazione finora

- Competition & Luxury Vehicle Club of Darlington SuitDocumento31 pagineCompetition & Luxury Vehicle Club of Darlington SuitBenjamin DuerNessuna valutazione finora

- Vermicomposting GuideDocumento34 pagineVermicomposting GuideRobin RheaumeNessuna valutazione finora

- Chapter 13 Oil Based MudsDocumento65 pagineChapter 13 Oil Based Mudsمحمد أحمد عبداللطيفNessuna valutazione finora

- Nadcap 2020Documento4 pagineNadcap 2020amirkhakzad498Nessuna valutazione finora

- Electro Chemical GrindingDocumento2 pagineElectro Chemical GrindingKingsly JasperNessuna valutazione finora

- Algal Oil Production: Modeling and Evaluation Using Superpro DesignerDocumento26 pagineAlgal Oil Production: Modeling and Evaluation Using Superpro DesignerMira FazziraNessuna valutazione finora

- Current Trends in Explosive Detection Techniques PDFDocumento16 pagineCurrent Trends in Explosive Detection Techniques PDFSandra LuizNessuna valutazione finora

- A Modified UNIFAC ModelDocumento16 pagineA Modified UNIFAC Modelmappemaq100% (1)

- Reactor DesignDocumento27 pagineReactor Designcheckmeout803100% (3)

- Iso AnnealingDocumento2 pagineIso AnnealingPurushottam Sutar100% (1)

- Section 16 - Drilling Fluid Products Reference PDFDocumento34 pagineSection 16 - Drilling Fluid Products Reference PDFEjaz ul Haq kakarNessuna valutazione finora

- Steam TurbinesDocumento38 pagineSteam Turbinesmanoj100% (1)

- CFD in Chemical ReactorsDocumento15 pagineCFD in Chemical Reactorswitker2008Nessuna valutazione finora

- OAP ExamDocumento13 pagineOAP ExamCarmelita F. Cadapan100% (1)

- Arthrex Starfish ™ Scope Rotation Attachment Insert Manual: 950-0036-01 Revision 0 08/2020Documento36 pagineArthrex Starfish ™ Scope Rotation Attachment Insert Manual: 950-0036-01 Revision 0 08/2020eliaNessuna valutazione finora

- Articol Excelent ZerDocumento20 pagineArticol Excelent Zerlylya_bejenaruNessuna valutazione finora

- CCWDocumento2 pagineCCWspearboraNessuna valutazione finora

- HKR - Expansion Joints CatalogueDocumento80 pagineHKR - Expansion Joints Cataloguemksingh_22Nessuna valutazione finora

- Vacuum Testing of Fixed Roof Welded Storage Tanks As Per API 650,620Documento7 pagineVacuum Testing of Fixed Roof Welded Storage Tanks As Per API 650,620Rakesh RanjanNessuna valutazione finora

- B31.3 Course Handout IntroDocumento0 pagineB31.3 Course Handout IntroNeily LiuNessuna valutazione finora

- The Calorific Value of A Fuel Is TheDocumento4 pagineThe Calorific Value of A Fuel Is TheRana PrathapNessuna valutazione finora

- Food Chemistry: M.S. Altaki, F.J. Santos, M.T. GalceranDocumento6 pagineFood Chemistry: M.S. Altaki, F.J. Santos, M.T. GalceranAberuNessuna valutazione finora

- En 50216-10Documento16 pagineEn 50216-10Mahmoud ShaheenNessuna valutazione finora

- Division9 FinishesDocumento159 pagineDivision9 FinishesJosh HabanNessuna valutazione finora

- Air CompressorsDocumento14 pagineAir CompressorsEduardo Belvis Jr.Nessuna valutazione finora

- Group #4: September 25, 2019Documento5 pagineGroup #4: September 25, 2019MIKAYLA ELAINE P. DELA CRUZNessuna valutazione finora

- Khairat Al-Emar Co. For Oil Services: Material Safety Data SheetDocumento6 pagineKhairat Al-Emar Co. For Oil Services: Material Safety Data SheetqwaszxcdeNessuna valutazione finora

- From Cellulosomes To Cellulosomics: THE Chemical RecordDocumento14 pagineFrom Cellulosomes To Cellulosomics: THE Chemical RecordsajjalNessuna valutazione finora