Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

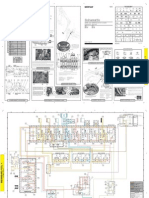

950H, 962H and IT62H Wheel Loader Hydraulic System: Command Control Steering

Caricato da

Rodrigo ChaccaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

950H, 962H and IT62H Wheel Loader Hydraulic System: Command Control Steering

Caricato da

Rodrigo ChaccaCopyright:

Formati disponibili

RENR8879-03 September 2009

FLUID POWER SYMBOLS

BASIC COMPONENT SYMBOLS

MAIN AUX.

10 K

MM

SOS

C D E

31

28

PUMP or MOTOR FLUID CONDITIONER SPRING CONTROL VALVES RESTRICTION LINE RESTRICTION (FIXED) VARIABILITY SPRING (ADJUSTABLE) LINE RESTRICTION (VARIABLE) PRESSURE COMPENSATION HYDRAULIC PNEUMATIC ENERGY TRIANGLES

2-SECTION PUMP

PUMP: VARIABLE and PRESSURE COMPENSATED

LINE RESTRICTION

VARIABLE and PRESSURE COMPENSATED

ATTACHMENT

J F G H 49 A

B C

ONE POSITION

VALVES

VALVE ENVELOPES VALVE PORTS

TWO POSITION

THREE POSITION

TWO-WAY

THREE-WAY

FOUR-WAY

CONTROL VALVES

AB AB

CHECK VALVES

NN GG

24

The service center is located on the right side of the machine below the cab. The Following components are located in the service center: - Case drain filter (31) - Hydraulic oil fluid sampling valve (SOS) - Hydraulic systems kidney loop filter (28) - Brake system accumulators (49) The Following components are not referenced on the Hydraulic System Schematic: - Power train oil fluid sampling valve (A) - Power train oil filter (B) - Ecology drain for the hydraulic tank (C)

P T NORMAL POSITION

P T SHIFTED POSITION

INFINITE POSITION

BASIC SYMBOL

SPRING LOADED

SHUTTLE

PILOT CONTROLLED

MEASUREMENT

ROTATING SHAFTS

BOTTOM VIEW

This photo shows a front view of the implement control valve (36) in the loader frame. The following components can be seen in this view: - Pilot accumulator (24) - Pilot supply pressure tap (GG)

PRESSURE

TEMPERATURE

FLOW

UNIDIRECTIONAL

BIDIRECTIONAL

The Following components are not referenced on the Hydraulic System Schematic: - Pressure differential relief valve (A) - Head end solenoid valve (ride control) (B) - Signal relief valve (C) - Tilt anti-drift valve (D) - Rod end solenoid valve (ride control) (E) - Ride control balance solenoid valve (F) - Pilot pressure reducing valve (G) - Lift cylinder head end pressure tap (H) - Lift cylinder head end pressure sensor for Payload Control System and Autodig (J) - Hydraulic lockout solenoid valve (K)

950H, 962H and IT62H Wheel Loader Hydraulic System

950H: N1A1-UP M1G1-UP K5K1-UP J5J1-UP JAD1-UP 962H: N4A1-UP M3G1-UP K6K1-UP J6J1-UP MAL1-UP IT62H: M5G1-UP

FLUID STORAGE RESERVOIRS

VENTED

PRESSURIZED

RETURN ABOVE FLUID LEVEL

RETURN BELOW FLUID LEVEL

COMBINATION CONTROLS

SOLENOID

SOLENOID or MANUAL

SOLENOID and PILOT

SOLENOID and PILOT or MANUAL

SERVO

THERMAL

DETENT

MANUAL CONTROL SYMBOLS

PUSH-PULL LEVER

MANUAL SHUTOFF

GENERAL MANUAL

PUSH BUTTON

PEDAL

SPRING

PILOT CONTROL SYMBOLS

RELEASED PRESSURE REMOTE SUPPLY PRESSURE

A N

KK

EE

PP

EXTERNAL RETURN INTERNAL RETURN SIMPLIFIED COMPLETE INTERNAL SUPPLY PRESSURE

F A B C D

ACCUMULATORS

CROSSING AND JOINING LINES

HYDRAULIC AND PNEUMATIC CYLINDERS

M

SPRING LOADED GAS CHARGED

LINES CROSSING

LINES JOINING

SINGLE ACTING

DOUBLE ACTING

L E

CC

LL

12

M L K J H G F D C H J K

HYDRAULIC PUMPS

FIXED DISPLACEMENT VARIABLE DISPLACEMENT NON-COMPENSATED

HYDRAULIC MOTORS

FIXED DISPLACEMENT VARIABLE DISPLACEMENT NON-COMPENSATED

INTERNAL PASSAGEWAYS

INFINITE POSITIONING THREE POSITION TWO POSITION

RIGHT SIDE MACHINE VIEW

UNIDIRECTIONAL

UNIDIRECTIONAL

CROSS FLOW

BIDIRECTIONAL

BIDIRECTIONAL

FLOW IN ONE DIRECTION

PARALLEL FLOW

FLOW ALLOWED IN EITHER DIRECTION

COMMAND CONTROL STEERING

E

The following remote pressure taps are located inside the panel on the frontside of the service center: - Steering pump outlet pressure (EE) - Brake system accumulator pressure (PP)

2009 Caterpillar All Rights Reserved

Printed in U.S.A.

Component Locations

Item Number

1 2 3 4 5 6 7 8 9 10 11 12 13 14

Description

HMU STEERING CIRCUIT Hand Metering Unit Connector - Orifice Cylinder Gp - Steer Valve Gp - Neutralizer Valve Gp - Steer Valve Gp - Neutralizer Valve Gp - Steer Cylinder Gp - Steer Valve Gp - Check Valve Gp - Pilot Valve Gp - Shuttle Screen Gp MAIN SCHEMATIC Pump Gp - Steering Pump Gp - Implement Cylinder - Tilt Cylinder - Tilt (Mid Lift) Cylinder - Tilt (High Lift) Cylinder - Tilt (Logger) Cylinder - Lift (LH) Cylinder - Lift (RH) Valve - Choke Check Valve Gp - Manual Lowering Accumulator - Pilot Oil Pump Gp - Fan Motor Gp - Fan Valve Gp - Cooler Bypass Filter Gp - Return Oil Manifold Gp - Fan & Brake Charge Filter Gp - Case Drain Valve Gp - Breaker Relief Tank Gp - Hydraulic Oil Valve Gp - Secondary Steer Diverter Pump Gp - Secondary Steer Valve Gp - Control (2 Function Standard) Valve Gp - Control (2 Function W/RC)

Part Number

230-4176 122-2340 163-0324 146-7571 142-4000 8J-1553 124-8635 163-0324 111-7775 147-1790 8J-6875 154-2883 241-9299 254-4108 242-4220 247-0497 245-7491 245-7487 242-4272 242-4271 276-9072 112-1817 245-2975 254-5146 246-6152 244-1426 244-1031 242-1307 249-2334 220-0814 237-2742 141-2597 275-8544 261-4171 261-3682 261-4172 261-3683 274-8055 245-2973 263-5832 228-8527 180-8585 237-0946 112-1817 254-5146 242-1307 193-1448 105-6117 214-4863 215-3687 213-8773 129-8090 106-1774 174-4312 175-3244

Schematic Location

A-4 B-3 , B-4 B-1 B-3 , B-4 B-2 D-3 D-1 E-1 D-3 D-4 C-3 E-2 A-6 A-7 F-8 F-8 F-8 F-8 F-7 F-7 D-9 E-9 F-5 B-8 D-6 B-9 B-9 C-8 A-8 A-8 A-8 B-6 A-6 D-9 D-9 D-9 D-9 D-9 F-6 C-7 C-6 C-9 C-9 C-9 F-2 F-2 F-3 F-3 F-3 F-3 F-2 F-1 F-2 F-1 F-3

This photo shows a left rear view of the implement control valve (36). The following components can be seen in this view: - Implement control valve supply pressure tap (GG) The Following components are not referenced on the Hydraulic System Schematic: - Tilt anti-drift valve (A) - Signal relief valve (B) - Signal duplication valve (C) - Return to tank port (D) - Supply port from pump (E) - Signal line to pump (F) - Tank line (G) - Screen (H) - Tilt back pilot solenoid valve (J) - Tilt back pilot (K) - Tilt cylinder rod end line relief (L) - Ride control balance solenoid valve (M) - Rod end solenoid valve (ride control) (N)

The Following components are not referenced on the Hydraulic System Schematic: - Transmission reverse clutch (A) - Transmission forward clutch (B) - Transmission fourth speed clutch (C) - Transmission third speed clutch (D) - Transmission second speed clutch (E) - Transmission first speed clutch (F) - Torque converter inlet pressure (G) - Transmission lubrication pressure (H) - Transmission pump outlet pressure (J) - Torque converter outlet pressure (K) - Steering cylinder rod end grease fittings (L) - Rear axle oscillation bearing grease fittings (M)

XX

YY

Electrical Symbols Table

15

Hydraulic Symbols (Electrical)

COMMAND CONTROL STEERING

G

Transducer (Fluid) Transducer (Gas / Air) Generator

M

Electric Motor

15

Pressure Switch

Pressure Switch (Adjustable)

Temperature Switch

Electrical Wire

20 21 22 23 24 25 26 27 28 30 31 32 33 34 35

Electrical Symbols (Electrical)

CC DD

48

RR FF

T

RENR8879-03

SERVICE CENTER

RIGHT SIDE VIEW

Pressure Symbol

Temperature Symbol

Level Symbol

Flow Symbol

Wire Number Identification Codes

Electrical Schematic Example

XX YY

Hydraulic Schematic Example

Current Standard

Current Standard

Harness identification code This example indicates wire 135 in harness "AG". Wire Circuit Number Identification

36

Valve Gp - Control (3 Function) Valve Gp - Control (2 Function W/RC) Valve Gp - Control (Snow Removal) (3 Function W/RC)

15

The following components are located under the front of the cab. This drawing shows a right side view of the wheel loader. The following components can be seen in this view: - Implement pump pressure tap (CC) - Implement pump load Sense pressure tap (DD) - Hand metering unit (1) - Foot service brake valve (48) - Steer pump load sense test port (FF) - Front sercive brake test port (QQ) - Rear service brake test port (RR)

Circuit Identification Number

Wire Color

325-AG135 PK-14 325-PK

Wire Color Wire Gauge

41 42 43 54 55 56 25 30 45 46 47 48 49 50 51 52 53

Accumulator - Ride Control (RC) Valve Gp - Control & Relief Motor Gp - Reversing Fan Valve Gp - Quick Coupler Cylinder Gp - Quick Coupler Valve Gp - Manual BRAKE SYSTEM Pump Gp - Fan Manifold Gp - Fan & Brake Charge Control Gp - Foot Brake Switch As - Foot Brake Limit Sensor Gp - Foot Brake Valve Gp - Foot Brake Accumulator - Service Brake Actuator As - Parking Brake Valve Gp - Parking Brake Switch As - Parking Brake Pressure Switch As - Brake Pressure

Previous Standard

Wire Wire Color

IMPLEMENT CONTROL VALVE

HMU & SERVICE BRAKES

325-PK-14

VIEW A - A

Circuit Number Identification Wire Gauge

(EXAMPLE VALVE)

TILT CYLINDER LINES GROUP

33 32 32 33 45 46 1 47 48 20 21 15 1 21 45 46 47 48 20 15

Tap Locations Pressure, Sampling, and Sensor

Tap Number

AA CC DD EE FF GG HH KK LL MM NN PP QQ RR XX YY SOS

27 28

Schematic Location

B-8 E-9 B-7 B-7 A-4 or C-4 E-5 B-8 D-2 D-2 D-3 D-3 F-3 F-4 F-4 F-8 F-8 B-9

27 26 43

26 43

31 49

25

FAN AND BRAKE HYDRAULIC SYSTEM

AA

The fan and brake pump (25) is located on the front gear train of the engine, on the right side of the machine. The fan and brake pump provides oil flow for the electronic demand fan systemand the brake hydraulic system. The outlet pressure tap (AA) is located on the fan and brake pump.

Description

Fan Pump Discharge Pressure Implement Pump Charge Pressure Implement Pump Load Sense Pressure Steer Pump Pressure Steer Pump Load Sense Pressure Pilot Supply Pressure Fan Pump Load Sense Pressure Command Control Right Steer Pilot Pressure Command Control Left Steer Pilot Pressure Command Control Steering Neutral Pilot Press Command Control Steering Supply Pressure Service Brake Pressure Front Service Brake Pressure Rear Service Brake Pressure Tilt Cylinder Rod End Pressure Tilt Cylinder Head End Pressure Hydraulic Oil Sampling Port

42 3 8 23 34 35 25 30 53 13 14 50 51 52 34 35 42 25 30 53 13 14 3 8 50 51 5 7 12 23 28 31 2 4 6 9 10 11 22 24 36 41 2 4 6 5 7 10 11 12 22 24 36 41 9 2 4 6 3 8

HH

Also located on the engine on the right side of the machine is the fan control and brake accumulator charging valve (30). The fan pump load sense pressure tap (HH) is located above the brake charging valve.

REAR VIEW

49 52

30

FRONT VIEW

Machine Component Locations

FAN & BRAKE PUMP

30 Page

41 15 23

F

FRONT AXLE

49 51

RELEASE APPLY

TILT

XX

20

LIFT

21

Port B Lever Rearward Right Hand Line on Boom (When Viewed From Cab)

50

52

3RD FUNCTION

YY

R H

(ATTACHMENT)

Port A Lever Forward Left Hand Line on Boom (When Viewed From Cab)

47 24

QQ

C C

46

TO BRAKE LIGHTS

53 45

PS

A2

A1

30

HITCH

TO TRANSMISSION CONTROL

NO

NC

RR

RACK BACK RAISE HEAD END

PP

25

48

F To Fan Motor LS P T

REAR AXLE

RACK

To Case Drain Manifold

HYDRAULIC TANK

CC

BACK

RAISE

PORT A HOLD

HOLD DUMP

HOLD

GG

BRAKE SYSTEM

12 8 10

LL KK

CROSSOVER RELIEF CYL PORT "B" CYL PORT "A" SHUTTLE VLV

LOWER FLOAT

PORT B

8 7

a1

LOWER/ DUMP FLOAT

ROD END PILOT PORT"A"

LOAD SENSING PUMP PORT DIRECTIONAL SPOOL MAKE UP CHECK

LS

D

DR

36 6

QUICK COUPLER (ATTACHMENT)

55 55 30

TO FRONT BRAKES

LINE PATTERNS

Pressure Line Pilot / Load Sensing Pressure Drain / Return Lines

A1

TO REAR BRAKES

PILOT PORT"B"

TANK PORT

b1

NN MM

PRESSURE REDUCING VALVE

BACK UP RELIEF

A2

Component Group Attachment Air Line

a1 e1 c1 d1

PS

11

REGULATED PRESS. PORT TO PILOT VALVE

CALLOUTS

YY

RENR8879-03

Taps (Pressure, Sampling,Sensor) by letter Components by number

52

FF

30 Page, Color 2

56 54

56

HYDRAULIC CIRCUIT COLOR DESCRIPTIONS

IMPLEMENT PUMP OUTPUT IMPLEMENT PILOT SUPPLY OIL PRIMARY STEERING PUMP CIRCUIT STEERING CIRCUIT SECONDARY STEERING CIRCUIT IMPLEMENT PUMP LOAD SENSING CIRCUIT

COMMAND CONTROL STEERING ATTACHMENT

PILOT CONTROL SPOOL PILOT PORT "B"

5

CYL PORT "B"

56

MAIN RELIEF VALVE LOAD SENSING CIRCUIT SUPPLY LINE DRAIN / RETURN LINE LIFT CYLINDER CIRCUIT TILT CYLINDER CIRCUIT AUXILIARY CIRCUIT

4 4

LS

BRAKE CHARGE VALVE AND FAN CONTROL CIRCUIT BRAKE CONTROL CIRCUIT

26

B

HH

25

Connection b1 only for Command Control Steering

b1

2

PILOT PORT "A"

B

CROSSOVER RELIEF CYL PORT "A"

EE

27

AA

SOS

14

34

e1

DD

e1 d1

DIRECTIONAL SPOOL PUMP PORT

28

35 32

A

1

BACK-UP RELIEF

MAKE-UP CHECKS

31

c1

c1

FF

HMU SUPPLY PORT

HMU STEER AND 3PC IMPLEMENT

33 13

THIS SCHEMATIC IS FOR THE 950H AND 962H WHEEL LOADER

PART #: 241-0475 CHG 09 and BRAKE SYSTEM PART # 244-1398 CHG 00

d1

9 8 7 6 5 4 3 2

Components are shown installed on a fully operable machine with the key and engine off and transmission shifter in neutral. Refer to the appropriate Service Manual for Troubleshooting, Specifications and Systems Operations

Potrebbero piacerti anche

- 950H Wheel Loader Hydraulic SystemDocumento2 pagine950H Wheel Loader Hydraulic Systemwtn2013100% (16)

- Material Schematic Caterpillar 950h 962h It62h Wheel Loader Hydraulic SystemDocumento2 pagineMaterial Schematic Caterpillar 950h 962h It62h Wheel Loader Hydraulic SystemGanapati Hegde100% (1)

- Manual 950GDocumento4 pagineManual 950Gabumagico85% (13)

- 950H Elictrical Circuit DiagramDocumento15 pagine950H Elictrical Circuit Diagramविशाल पुडासैनी100% (8)

- CAT 950H Wheel LoaderDocumento28 pagineCAT 950H Wheel Loaderojhawk1380% (5)

- 966h Main Control System OperationDocumento17 pagine966h Main Control System Operationesternocleido24100% (3)

- 950H 4762022Documento4 pagine950H 4762022Pizarro Andres100% (3)

- Cf.966h Sist - Elect.Documento25 pagineCf.966h Sist - Elect.rmatico1234100% (5)

- CAT - 950G - SchematicDocumento2 pagineCAT - 950G - Schematicssinokrot95% (20)

- CAT 385CLRE ElectricalDocumento17 pagineCAT 385CLRE ElectricalGeorge Zormpas100% (1)

- Diagnostic Code List: TroubleshootingDocumento7 pagineDiagnostic Code List: Troubleshootingmiguelfpinto100% (1)

- Esquema Electrico d6r Serie FDTDocumento10 pagineEsquema Electrico d6r Serie FDTmekanicobucaroNessuna valutazione finora

- Serv1824 950H 962H PDFDocumento248 pagineServ1824 950H 962H PDFWALTHERSITO97% (33)

- 325D Excavator Hydraulic System: Fluid Power SymbolsDocumento2 pagine325D Excavator Hydraulic System: Fluid Power SymbolsDennis Olaya100% (3)

- CAT 950G 962G II Manual Service Maintenance PDFDocumento61 pagineCAT 950G 962G II Manual Service Maintenance PDFJulian Aleman81% (21)

- Electrohydraulic System Operation GuideDocumento8 pagineElectrohydraulic System Operation GuideSele CasMa ヅ100% (4)

- 966F Wheel Loader Electrical SystemDocumento2 pagine966F Wheel Loader Electrical SystemAhmed Nahrawy82% (11)

- 140h Sist. Electrico - SisDocumento2 pagine140h Sist. Electrico - SisRodrigo Chacca100% (4)

- 966F & 966F Series II Wheel Loaders Hydraulic SystemDocumento2 pagine966F & 966F Series II Wheel Loaders Hydraulic SystemAhmed Nahrawy100% (7)

- Techdoc Print Page-140h-5 PDFDocumento8 pagineTechdoc Print Page-140h-5 PDFFranciscoOliveira100% (1)

- CP-563 & CS-563 VIBRATORY COMPACT ELECTRICAL SCHEMATIC - CAT Machines Electrical SchematicDocumento6 pagineCP-563 & CS-563 VIBRATORY COMPACT ELECTRICAL SCHEMATIC - CAT Machines Electrical Schematicanggie100% (2)

- Caterpillar D6R Tractor (Electronic Clutch Brake) Electrical System PDFDocumento2 pagineCaterpillar D6R Tractor (Electronic Clutch Brake) Electrical System PDFdothao78% (9)

- Implement Hydraulic System WL 950h 962h 966h 972hDocumento51 pagineImplement Hydraulic System WL 950h 962h 966h 972hElvis Gonzalez Huerta100% (1)

- Curso Cat 950-962G Steering Syst STMGDocumento24 pagineCurso Cat 950-962G Steering Syst STMGSilas F Pimenta100% (18)

- Troubleshooting 966H WL POWERTRAINDocumento12 pagineTroubleshooting 966H WL POWERTRAINAhmet100% (1)

- Serv1852 02 TXT8Documento52 pagineServ1852 02 TXT8ابو احمد100% (8)

- Sistema Control Trans 140hDocumento7 pagineSistema Control Trans 140hFernando Ortiz86% (7)

- CS533E Hydraulic Schematic KENR3668Documento2 pagineCS533E Hydraulic Schematic KENR3668Luis Florentino Grajeda100% (5)

- 966HDocumento4 pagine966Hwords2zhigang_61254588% (8)

- 950H JLX PDFDocumento12 pagine950H JLX PDFJeiner Mostacero Espinoza100% (1)

- Cargador 938h Jkmrenr9764renr9764-06 - SisDocumento20 pagineCargador 938h Jkmrenr9764renr9764-06 - SisJose Tito100% (2)

- Renr8879renr8879-04 Sis PDFDocumento2 pagineRenr8879renr8879-04 Sis PDFMAQUINARIAPESADA100% (1)

- 950H, 962H, and IT62H Wheel Loader Hydraulic System: Command Control SteeringDocumento2 pagine950H, 962H, and IT62H Wheel Loader Hydraulic System: Command Control SteeringPacoNessuna valutazione finora

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Documento17 pagineInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768lull434100% (2)

- Diagrama Hidraulico 420E CATERPILLARDocumento4 pagineDiagrama Hidraulico 420E CATERPILLARjulio cesar100% (6)

- Component Locations: 966G and 972G Wheel Loader Hydraulic SystemDocumento4 pagineComponent Locations: 966G and 972G Wheel Loader Hydraulic SystemAndrei Bleoju100% (3)

- D PWT D6riii PDFDocumento2 pagineD PWT D6riii PDFDennis Olaya100% (1)

- RENR8305RENR8305-04 - SIS 777f 1Documento4 pagineRENR8305RENR8305-04 - SIS 777f 1gadolineo100% (1)

- 444EDocumento2 pagine444EHelar W. Cutipa MachacaNessuna valutazione finora

- Plano Hidraulico TelehandlerDocumento16 paginePlano Hidraulico TelehandlerEVCY100% (4)

- Plano Hidraulico 16m CatDocumento2 paginePlano Hidraulico 16m CatLuis Ramos100% (2)

- Plano Hidrulico de 272cDocumento4 paginePlano Hidrulico de 272cMaría Felisa López QuintoNessuna valutazione finora

- 16m Hydraulic r9hDocumento11 pagine16m Hydraulic r9hqwureyquweryNessuna valutazione finora

- Hydraulic System 950H, 962H, and IT62H Wheel Loader: Front of Frame Hand Metering UnitDocumento2 pagineHydraulic System 950H, 962H, and IT62H Wheel Loader: Front of Frame Hand Metering UnitMarcelino Huamani100% (1)

- 994F HydrDocumento4 pagine994F HydrF Diaz BarreraNessuna valutazione finora

- Plano Hidraulico D10T PDFDocumento2 paginePlano Hidraulico D10T PDFJHOSMAR_22Nessuna valutazione finora

- Uenr5986uenr5986-00 SisDocumento2 pagineUenr5986uenr5986-00 SisHelar W. Cutipa MachacaNessuna valutazione finora

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Documento18 pagineInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Alexander CaluaNessuna valutazione finora

- 784C Tractor and 785C Off-Highway Truck Hydraulic System: 784C: 2PZ1-105 785C: 1HW1-Up APX1-450 785C (HAA) : 5AZ1-399Documento2 pagine784C Tractor and 785C Off-Highway Truck Hydraulic System: 784C: 2PZ1-105 785C: 1HW1-Up APX1-450 785C (HAA) : 5AZ1-399Jorge SolisNessuna valutazione finora

- 785d HydraulicDocumento2 pagine785d HydraulicSainbayr SainaaNessuna valutazione finora

- Diagrama Hidraulico 777FDocumento4 pagineDiagrama Hidraulico 777Ffabioalbor100% (1)

- 14M Hydraulic SchematicDocumento2 pagine14M Hydraulic SchematicKhaled Kamel67% (3)

- 966g - II Renr4398-02 Hyd SchemDocumento2 pagine966g - II Renr4398-02 Hyd SchemEnergy Sun Biocar100% (4)

- 938h Hyd SchematicDocumento13 pagine938h Hyd SchematicMahmud Maher80% (10)

- Uenr0213uenr0213-01 Sis PDFDocumento2 pagineUenr0213uenr0213-01 Sis PDFRaphael Ruiz Ramos100% (2)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Documento11 pagineInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Roberto Antonio Chihuaihuan Araya100% (1)

- Pump GP - Main Hydraulic Main Control Valve: 320E RR Excavator Hydraulic System - AttachmentDocumento2 paginePump GP - Main Hydraulic Main Control Valve: 320E RR Excavator Hydraulic System - AttachmentYvan Vidal Calapuja MachacaNessuna valutazione finora

- Motorcycle, Solo (Harley-Davidson Model WLA)Da EverandMotorcycle, Solo (Harley-Davidson Model WLA)Nessuna valutazione finora

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDa EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNessuna valutazione finora

- Tractores d9r D10r-HeuiDocumento49 pagineTractores d9r D10r-HeuiRodrigo Chacca100% (1)

- Cs533d Plano HidraulicoDocumento2 pagineCs533d Plano HidraulicoRodrigo ChaccaNessuna valutazione finora

- Bomba Feluma RelaveDocumento6 pagineBomba Feluma RelaveRodrigo ChaccaNessuna valutazione finora

- Cursor 13 Iveco CalibracionDocumento59 pagineCursor 13 Iveco CalibracionWaliixiitoo Landerxito Thv Xikito AL93% (28)

- Machine Component Location: 330D and 336D Excavator Hydraulic System - AttachmentDocumento2 pagineMachine Component Location: 330D and 336D Excavator Hydraulic System - AttachmentRodrigo ChaccaNessuna valutazione finora

- 140h Sist. Electrico - SisDocumento2 pagine140h Sist. Electrico - SisRodrigo Chacca100% (4)

- Schroeter R - 91 Smoker's BookletDocumento21 pagineSchroeter R - 91 Smoker's BookletFrankPapa100% (2)

- Essential P&ID guide with symbols and usesDocumento5 pagineEssential P&ID guide with symbols and useslochoadauk53Nessuna valutazione finora

- Dale Gulley's Heat Exchanger Tips WorkbookDocumento156 pagineDale Gulley's Heat Exchanger Tips WorkbookbadelitamariusNessuna valutazione finora

- Basic Pneumatic ControlsDocumento45 pagineBasic Pneumatic ControlsMartin BourgonNessuna valutazione finora

- Air Handling Unit Construction ChecklistDocumento7 pagineAir Handling Unit Construction Checklistameeri143Nessuna valutazione finora

- INSTALLED POWER LISTINGDocumento2 pagineINSTALLED POWER LISTINGade_rusdi100% (1)

- HVAC Master Validation PlanDocumento51 pagineHVAC Master Validation Plannavas197293% (30)

- PC-Bedienungsanleitung Heater enDocumento33 paginePC-Bedienungsanleitung Heater enZoran Tanja JarakovićNessuna valutazione finora

- Modbus Communication Guide 3 - 1Documento17 pagineModbus Communication Guide 3 - 1Socaciu VioricaNessuna valutazione finora

- Basic Understanding of Machinery VibrationDocumento47 pagineBasic Understanding of Machinery Vibrationramnadh803181Nessuna valutazione finora

- Hydrovane Refrig Dryer-HV04-05-07 PDFDocumento13 pagineHydrovane Refrig Dryer-HV04-05-07 PDFMark CarterNessuna valutazione finora

- Vrviii - Brochure - Pcvuse11-02b - Daikin AcDocumento28 pagineVrviii - Brochure - Pcvuse11-02b - Daikin AcDarko JuricNessuna valutazione finora

- Manual de Condensadoras Modelo Yc. Mca YorkDocumento128 pagineManual de Condensadoras Modelo Yc. Mca YorkMichel Cp100% (1)

- Ge DC MotorlarDocumento24 pagineGe DC MotorlarjalilemadiNessuna valutazione finora

- Samsung Sh09apgDocumento26 pagineSamsung Sh09apgKristopher Hendrix100% (1)

- SH 09 12 BWH Service ManualDocumento54 pagineSH 09 12 BWH Service ManualAndrew BienNessuna valutazione finora

- Best Practice Guide RefrigerationDocumento36 pagineBest Practice Guide Refrigerationbarelihb100% (1)

- PCA, GPU - CavotecDocumento14 paginePCA, GPU - CavotecVijay Barrey100% (1)

- Term Paper: Ele102 Topic:: Cooling Methods of TransformersDocumento7 pagineTerm Paper: Ele102 Topic:: Cooling Methods of Transformersshailesh singhNessuna valutazione finora

- Centrifugal Fan Bearing FailureDocumento8 pagineCentrifugal Fan Bearing FailureMuhd Fadzlee ZNessuna valutazione finora

- Energy 400Documento58 pagineEnergy 400fv740% (1)

- Gas Turbine - Traning Report Bhel - 14 PageDocumento14 pagineGas Turbine - Traning Report Bhel - 14 PageVivek PatelNessuna valutazione finora

- LSWTDocumento23 pagineLSWTprashasscribdNessuna valutazione finora

- Ahu SpecDocumento40 pagineAhu SpecVuTranNessuna valutazione finora

- York Cat LC 2012 enDocumento148 pagineYork Cat LC 2012 enMary Andrews100% (1)

- NFPA 96 Minnesota4Documento93 pagineNFPA 96 Minnesota4poetoetNessuna valutazione finora

- Bow tie method coal mine explosionDocumento6 pagineBow tie method coal mine explosionhazopmanNessuna valutazione finora

- GE Aviation Inventory Management ToolDocumento58 pagineGE Aviation Inventory Management ToolArunNessuna valutazione finora

- PA3500Documento15 paginePA3500plaki_7Nessuna valutazione finora

- 50LC Product Data 12.5-23 TonDocumento90 pagine50LC Product Data 12.5-23 TonAcerz VillagraciaNessuna valutazione finora