Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

6 Sigma Lean

Caricato da

Rheneir MoraDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

6 Sigma Lean

Caricato da

Rheneir MoraCopyright:

Formati disponibili

6-Sigma & Lean 101 A Lean-SS Overview

6-Sigma Other Process Improvement Tools

Introduction of 6-Sigma Tools

DMAIC process & tools discussion

Introduction of Lean Concepts

Lean

Identification of Waste Workplace Lean Improvements Sustainability Business Score Card

A Business Case Example

please contact mrdrking@gmail.com for an animated PowerPoint presentation 1

ISandR@usa.com

Copyright - ISandR Services and Accelper

6-Sigma & Lean 101

ISandR Services Presents -

A Lean-SS overview, not detailed presentation Introduction of Six-Sigma Tools without stats

DMAIC process & tools associated with each phase

Introduction of Lean Concepts

Identification of Waste Lean Improvements in Gemba (Workplace)

Sustainability

Business Score Card

ISandR@usa.com

Copyright - ISandR Services and Accelper

6-Sigma & Lean 101

Process Improvement Describe & Measure

When you can measure what you are speaking about, and express it in numbers, you know something about it; but when you cannot measure it, when you cannot express it in numbers, your knowledge is of a meager and unsatisfactory kind.

William Thompson (Lord Kelvin), 1824-1907

If you can't describe what you are doing as a process, you don't know what you're doing.

W. Edwards Deming, 1900-1993

ISandR@usa.com

Copyright - ISandR Services and Accelper

6-Sigma & Lean 101

The Average and the Standard Deviation are Most Important

X

S

xi ) / n

( xi X ) n 1

2

AVERAGE

STANDARD DEVIATION

These metrics are important, but we will keep this simple

ISandR@usa.com

Copyright - ISandR Services and Accelper

6-Sigma & Lean 101

Process Improvement The Family Vacation Example

Start with the end in mind THE GOAL Analogy of the family vacation

Would you start with how to pack better? Where, What, Who - Destination, Activities, You & Route - how far/long, transport vehicle MEASURE Cost of alternatives ANALYZE What to take - backpacks or suitcase ANALYZE What can be done better from last time IMPROVE Stick to budget & plan CONTROL

ISandR@usa.com

DEFINE

Activities, Accommodations, Alt Options, Where is Start

Copyright - ISandR Services and Accelper

6-Sigma & Lean 101

What is 6-Sigma? A Short History

Improvement tools known for a LONG time Popularized by GE, Motorola, et al Collection of tools with standardize usage! About BEST in class About dramatic improvement not stats ASQ 80% of tools are not statistical Process based on D M A I C

- Define - Measure - Analyze - Improve - Control

Presentation parallels book Stat Free Six Sigma P. Gupta (Accelper)

Copyright - ISandR Services and Accelper

ISandR@usa.com

6-Sigma & Lean 101

What is the Significance of the Words 6-Sigma?

What does 6-Sigma imply?

Process of 3 defective parts per million (3ppm) Depends on

Customers specified limits (Upper & Lower Bound) Average in the process (Average or Mean) Variability in the process (Standard Deviation)

Not all processes need to be 6-Sigma Capable

A process that meets customer specifications by providing consistent accurate results with no variation - near zero defects

ISandR@usa.com

Copyright - ISandR Services and Accelper

6-Sigma & Lean 101

What is 6-Sigma? Statistics Concepts, Without Statistics

Customer specifies LL and UL Distribution:

Gaussian Random Normal

Low Limit

Mean = X

Examples

Hi Limit

Production size & location of hole in a part Service preparation of tabloid content & distribution, early vs late

Variation = 2

Error

1 sigma ( )

width at height

Characterizing The Process The Process

6 Good Mean Good Variability Good Capability

Process Capability

CpK = [ Closest Limit X ] 3 Higher sigma is better to avoid quality escapes!

Copyright - ISandR Services and Accelper

ISandR@usa.com

6-Sigma & Lean 101

What Process Capability?

mean LL HL

variation This is previous slide

Good Mean Good Variability Good Capability

ISandR@usa.com

Poor Mean Good Variability Poor Capability

Copyright - ISandR Services and Accelper

Poor Mean Poor Variability Poor Capability

9

6-Sigma & Lean 101

What Makes 6-Sigma Work?

When everyone understands the Cost of Poor Quality

In / ext failures, inspection, testing, rework (calc $$s)

Align VOC and biz needs for big improvements S M A R T goals

Specific why, what, when, who, where, finally how Measurable which metrics: how much / many, B4 & after Attainable have resources: attitudes, abilities, finances Realistic challenging believable & achievable Timely* reasonable duration to complete with urgency

Visible with Executive Management Support Employees encouraged to take risks (Deming, Drive out fear)

* Could be Tangible can experience with senses makes it more realistic and measurable

ISandR@usa.com

Copyright - ISandR Services and Accelper

10

6-Sigma & Lean 101

What makes 6-Sigma Work? Culture Change Response Curve

The energy to overcome an existing culture, make improvements and sustain change takes effort, time and money The paths are different for each organization.

Effort/Cost/Resistance

A M D

I C

Organization B

Organization A

Present

Time

Copyright - ISandR Services and Accelper

Future

ISandR@usa.com

11

6-Sigma & Lean 101

Customer Surveys Voice Of the Customer (VOC)

Research on customer satisfaction:

Determine what is quality [Q is what the customer says it is] Find out what competitors are doing [better] Define quality performance measures to identify defects [Pareto] Identify factors to give a competitive edge [SWOT] Identify urgent problems [low hanging fruit 1st with best ROI]

Use multiple instruments to ID customer satisfaction. The opportunity to collect misleading or useless information is possible with just one instrument.

Surveys, Focus Group, Face-to-face, (Dis)satisfaction cards, Competitive Shopping

- to gain information on Stated Needs, Real Needs, Perceived Needs, Cultural/Unstated Needs, Unintended Needs (Distinguish: Wants, Needs, Dissatisfiers)

ISandR@usa.com

Copyright - ISandR Services and Accelper

12

6-Sigma & Lean 101

Customer Surveys - VOC

Customer Response to Survey

HI MUST Improve

Feature Importance

Opportunity Being Lost

Maintain Good Work & Performance

Maintain Current Status

Over-effort for little value

LO

Feature/Process Satisfaction

HI

What was expected and experienced, what was the level of satisfaction and importance

13

ISandR@usa.com

Copyright - ISandR Services and Accelper

6-Sigma & Lean 101

How to look for and improve the PROBLEMS

ISandR@usa.com

Copyright - ISandR Services and Accelper

14

6-Sigma & Lean 101

What is DMAIC?

Define the charter: why do this (ROI / VOC), which process (Pareto), achieve what, measure what (errors, FTT), which resources, whos involved, how to accomplish (brainstorm / fishbone), what is goal, when complete, whats not included, Measure specify info sources to measure, precision, frequency of measurement, instruments used to measure, Analyze examine patterns, correlate dependent & independent variables (SIPOC / histograms / scatter-plots), root-cause, failure influence (FMEA-SOD), Improve development of alternatives to reduce cost, variation, & waste or for faster delivery, Control sustaining gains from project and maintaining process control

ISandR@usa.com

Copyright - ISandR Services and Accelper

15

6-Sigma & Lean 101

What are Tools Used with DMAIC?

Define Measure

Phase D Tools Project Priority Index Brief Description PPI = (Benefit/Cost) X (Probability of Success/Time to complete in years) Time < .5 Estimated Savings/Cost > 2.0 Recommended PPI > 4.0 A graphical tool to prioritize various defects to identify the most important one A graphical description of activities and decision points A graphical tool to identify customer critical requirements, including customers' `love to have' requirements An excellent tabular capture of most of the process constraints Operational critical-to-quality characteristics related to the customer expectation Project plan with clearly-defined goals and milestones Breakdown of product or service cost related to appraisal, failures and prevention A product measurement, which is a ratio of the number of defects observed per unit verified The percent of process output with no error or defect. A process measurement, which is the DPU normalized to the product or process complexity A business measurement, estimated from DPMO, commonly used for benchmarking Typical performance Range of performance (maximum minimum)

Analyze Improve

D D D D D D M M M A A A I

Pareto Process Map Kano's Analysis SIPOC CTQ Project Charter Cost of Quality DPU Yield DPMO Sigma Level Average Range

Stat Free Six Sigma, Gupta

ISandR@usa.com

Copyright - ISandR Services and Accelper

16

6-Sigma & Lean 101

What are Tools Used with DMAIC?

Improve Control

Phase I I I I I I I I I I C C C C Tools Standard Deviation Statistical Thinking Root Cause Analysis FMEA Scatter Plot Visual Regression Analysis Component Search Comparative Tests - Improving Means Comparative Tests - Improving Variance Full Factorial Experiment Process Thinking (4P Model) Management Review Control Chart Scorecard Brief Description More accurate estimate of performance range Ability to distinguish assignable causes from random causes of variation Fishbone diagram consisting causes that produce effects - materials, machines, methods, man, nature, measurements Failure Mode and Effects Analysis for anticipating problems Graphical display of relationship between output (dependent) and input (independent) variables Estimate of relationship between input and output variables To identify the defective part in an assembly by exchanging the questionable part between 'good' and 'bad' units Evaluating significance of shift or change in the process means Ratio of variances between the current and reduced variances Evaluating various combinations of multiple variables to determine the right combination for best performance. Total combinations = level to the power variables (Lv, e.g., 23 = 8) A logical building block of the process management for achieving excellence. 4P => Prepare 4Ms, Perform Well, Perfect on target, Progress by reducing inconsistencies A review meeting led by the leader to ensure targeted performance is achieved and to identify necessary actions to sustain improved performance Graphical tool to sustain normal (without known problems) behavior of the process Measure of business performance for identifying new opportunities

Stat Free Six Sigma, Gupta

ISandR@usa.com

Copyright - ISandR Services and Accelper

17

6-Sigma & Lean 101

Good Charter Components?

Business need - cost reduction, margin increase, government compliance or increased customer satisfaction. Business advantage ROI? - case should show the business need as dollars ($$s) to substantiate which projects selection. High-level project scope sponsors vision of the project. Critical to success factors ID project, team, deliverables, schedule, what is needed for project success: scope, schedule, Constitution cost, or quality. Project constraints, risks and assumptions document these conjectures; revisit during project to see if these remain true. Bill of Rights Authority of the project manager what is the responsibility of Plans Change the project manager, to clarify their role assists with future decisions (controversial?) dealing with the stakeholders and organization. Signatures demonstrates management importance & support

Example of form to assist in addressing items to consider

ISandR@usa.com

Copyright - ISandR Services and Accelper

18

6-Sigma & Lean 101

DMAIC Tools PARETO Ranking of Issues

Customer's Order Complaints Late Defective Rude CS No call back Wrong Item Incomplete Refund late Wrong Price No Gift Card Missing item Not New - Used Never Received * 192 44 37 23 72 101 17 15 3 2 12 7

Minitab

Figure out cost/benefit

Excel

ISandR@usa.com

Copyright - ISandR Services and Accelper

19

6-Sigma & Lean 101

Process Map (This is the as is also need the proposed)

ORDER FULFILLMENT SWIM LANE FLOWCHART

CUSTOMER SERVICE ACCOUNTING WAREHOUSE

Possibilities for improvement?

ENGINEERING & RECEIVING

20

Loops and Many Crossings SHIPPING

Created with Visio

ISandR@usa.com

Copyright - ISandR Services and Accelper

6-Sigma & Lean 101

What is SIPOC?

Look for relationships so Input improves stability in Output

Suppliers individuals providing resources Inputs info, materials & Services Process value added transformation steps Outputs final product or service Customers entity finding value in output

Suppliers

Paper Graphics Electronics Binders Authors

Inputs

Figs & Photos Electronic Docs

Process

Outputs

Cliffnotes DVDs & CDs Abstracts Album of Related work

Customers

Bookclubs Audio books Web Whit Papers Libraries Consultants Educators & Trainers Magazines

Original Written Manuscript Scholarly References Suggested Adds & Deletes Reference Docs

Exercises Training Instructional Info

Researchers

Editors Library

Process for Publishing and Distribution of Scholarly Research an d Textbook Materials

Authors submit content Graphics submits figures and photos Editor checks content Publisher Approval & Printing Schedule First Printing Promotio n Process Distributo r Orders Shipment of Orders

>

>

>

>

>

>

ISandR@usa.com

Copyright - ISandR Services and Accelper

21

6-Sigma & Lean 101

What is SWOT?

Internal Characteristics to Business

STRENGTH list and find how to improve these WEAKNESSES list and find how to minimize these

External Characteristics to Business (in Industry or with the Competition)

OPPORTUNITIES what can you take advantage of THREATS what should you avoid

ISandR@usa.com

Copyright - ISandR Services and Accelper

22

6-Sigma & Lean 101

Cost of Quality

The cost of quality isnt the price of creating a quality product or service. Its the cost of NOT creating a quality product or service.

Prevention Costs - New product review, Quality planning, Supplier capability

surveys, Process capability evaluations, Quality improvement team meetings, Quality improvement projects, Quality education and training, Appraisal Costs

Inspection Costs - measuring, evaluating or auditing products or services to

assure conformance to quality standards and performance requirements; Incoming and source inspection/test of purchased material; In-process and final inspection/test; Product, process or service audits; Calibration of measuring and test equipment; Associated supplies and materials; Failure Costs

Internal Failure Costs - Failure costs occurring prior to delivery or shipment of the

product, or the furnishing of a service, to the customer. Scrap, Rework, Reinspection, Re-testing, Material review, Downgrading

External Failure Costs - Failure costs occurring after delivery or shipment of the

product -- and during or after furnishing of a service -- to the customer. Processing customer complaints, Customer returns, Warranty claims, Product recalls

ISandR@usa.com

Copyright - ISandR Services and Accelper

23

6-Sigma & Lean 101

Brainstorming Fishbone / Cause-Effect / Ishikawa

This is a way of analyzing problem and get to the root cause The effect is usually negative - a problem The problem should be specific and clearly stated The ideas are generated by using brainstorming (vocal or silent) Keep the group to asking themselves what would cause the problem? Keep attention on the effect of the problem not criticism or how to fix The goal is to find as many sources for variation as possible that cause the problem

Measurements Machine Man PM vs AM Shift Temp Effect RMAs Season Methods Mother Nature Storage Preparation Materials

ISandR@usa.com

Copyright - ISandR Services and Accelper

24

6-Sigma & Lean 101

FMEA Failure Mode Effects Analysis

Determine what can go wrong, the severity, and how to avoid it FMEA Number: This Risk Assessment should be a log controlled number for tracking the document The part number, name, or other description Probabilitydesign responsibility: Which department or group is responsible for The of Effect of Failure Occurrence this design? for FMEA preparation The person responsible was prepared Severity The date the FMEAcomponent partand any necessary revision level Part Number & Function The subsystem or number getting detailed analysis Ability toThe component function Detect mode The potential failure Potential Failure The potential effect of failure Risk Priority Number The potential cause of failure Cause of Failure What are the current controls in place to prevent the cause from Actions & Re-evaluation Control for Failure OCorrectivefailure mode will occur. This index is from 1 to 10 occurring? is the probability this

with 1 being virtually no chance and 10 being near certainty of occurrence. S is the severity of the effect of the failure on the rest of the system if the failure occurs. Values are from 1 to 10. A value of 1 means the user will be unlikely to notice with a 10 meaning that the safety of the user is in jeopardy. D is a measure of the effectiveness of the current controls to identify the potential weakness or failure prior to release to production. This index ranges from 1 to 10. A value of 1 means this will certainly be caught whereas a value of 10 indicates the design weakness would most certainly make it to final production without detection. RPN The Risk Priority Number is the product of the indices from the previous three columns. RPN = OSD The actions then are based upon what items either have the highest RPN and/or where the major safety issues are. There is a column for actions to be taken to reduce the risk, a column for the responsibility and finally a column for the revised RPN once corrective action is implemented. FMECA provides a disciplined approach for the engineering team to evaluate designs to ensure that all the possible failure modes have been taken into consideration.

QCI Indiana Quality Council

ISandR@usa.com

Copyright - ISandR Services and Accelper

25

6-Sigma & Lean 101

Average, Standard Deviation, Max Value, Min Value in Data Sets

Average

Standard Deviation

Active Cell

Maximum

Minimum

ISandR@usa.com

Copyright - ISandR Services and Accelper

26

6-Sigma & Lean 101

Evaluating Data

Quantify what you want to improve and make decisions based on the data.

ISandR@usa.com

Copyright - ISandR Services and Accelper

27

6-Sigma & Lean 101

Comparative Tests - Improving Means & Variance - Visualization

T-test to Visualize the Data to difference in Means Use Methodsfor determining significant Make decisions Easier

Middle F-test for determining significant difference in Variance 50% of Mean Data Range Data

6 Samples - Comparison of Means and Variation

2. 0 2. 0

6 Samples - Comparison of Means and Variation

1. 8

1. 8

1.68022

1.78123

Dat a

Dat a

1. 6

1. 6

1.52912 1.45738 1.47119 1.47366

1. 4

1. 4

1. 2

1. 2

1. 0 sample1 sample2 sample3 sample4 sample5 sample6

1. 0 sample1 sample2 sample3 sample4 sample5 sample6

Same Mean Diff Mean Same Mean Same Vari(1) Same Vari(2) Diff Vari(3)

Same Mean Same Vari

Diff Mean Same Mean Diff Vari Same Vari

ISandR@usa.com

Copyright - ISandR Services and Accelper

28

6-Sigma & Lean 101

Yield - Efficiency of the Process

%Yield

%Yield

%Yield

most familiar for defect eval

TheseTotalDefecformulas are tsObserved DPU Units Pr oduced with examples from 53 DPU .106 500 this table. Please Defect per Million Opportunities (DPMO) - the number of ways a defect can occur. If each item could at theseto fail (label, scratch, color, wrong info, performance, ) then look have 8 ways offline.

DPU

DefectsPerUnit

Units Pr oduced DefectiveUnits *100 Units Pr oduced 500 26 *100 94.8% 500

DPMO

DPU *1,000,000 # ofWayUnitCanBeDefective

0.106 * 1,000,000 8

106,000 8

13,250

Rolled Throughput Yield (RTY) What is overall Y1 x Y2 chainx Y4 yield in x Y3 of processes?

Yield Y1=0.90 Process 1 = .9 Yield Y2=0.90 Process 2 = .9 Yield Y3=0.90 Process 3 = .9 Yield Y4=0.90 Process 4 = .9

(.90)x(.90)x(.90)x(.90)= .656 Guess

65.6%

ISandR@usa.com

Copyright - ISandR Services and Accelper

29

6-Sigma & Lean 101

Scatter Plot Visualize Process Data & Look for Trends

Y has equivalent response to X and similar variation along response curve

25

Y has varying response to X and different variation along response curve

20

Dependent Variable Y

15

y=f(x) x

0 5 10 15 20 25

10

Independent Variable X

What is different about processes?

30

ISandR@usa.com

Copyright - ISandR Services and Accelper

6-Sigma & Lean 101

Control/Run Chart - Variable & Attribute - Track/React to Trends

Average & Range SPC Chart

31

UCL (3 )

29 27

Continuous

Variable

Median & Range

Average

25 23 21 19 17

6 4 2 0 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29

Diameter of Hole Average & Range

Average & Std Deviation

You would look into why these extremes happened

Short Run Charts

LCL (3 )

Discrete

Attribute

Fraction Defective

UCL

Ra nge

Number Defective P.O. with Errors Number of Defects Percent Defective

ISandR@usa.com

Copyright - ISandR Services and Accelper

31

6-Sigma & Lean 101

Objectives of Design of Experiments (DOE)

DOE is a systematic approach to determine & optimize the response between process inputs & outputs (independent and dependent variables). S & H and Part Size Delivery Time

PROCESS

The objective - optimize S&H of different part sizes for best delivery time. DOE experiments do not change only one variable - variables can interact Consider the interaction of temperature and wind velocity in the wind chill factor; more wind makes it feel colder and an engine requires the right amount of both gasoline and air to get the maximum performance. The experiment that changes variables one-at-a-time (OAAT) requires more experiments and cannot evaluate interactions; it is inefficient at best.

ISandR@usa.com

Copyright - ISandR Services and Accelper

32

6-Sigma & Lean 101

Two Factor DOE Variable Influence

If you want to know the affects from two factors (i.e. temperature and pressure), then vary both T and P then record the results of the dependent variable (i.e. yield).

P P1 P1 P2 P2 INPUT T T1 T2 T1 T2 RESULT Yield Y1 Y2 Y3 Y4

Dont just change one factor at a time.

Introduce terms, select levels, run experiment. Change the pressure between 50 and 100 psi and the temperature between 25 and 75 degrees F; record the yield results. Calculate the mean yield for each factor level Y@P1 = 93 Y@P2 = 92 Y@T1 = 95 Y@T2 = 90

P 50 50 100 100

INPUT T 25 75 25 75

RESULT Yield 94 92 96 88

This experiment is with 2 levels of P & T with a yield result It could be Internal vs External S&H with big vs small parts and delivery time result

Plot the response. From the main effects pressure has lower influence on the yield, while temperature has a larger effect on the yield (more slope, more effect).

96 94 92 90 88 86

P1

ISandR@usa.com

P2

T1

T2 33

Copyright - ISandR Services and Accelper

6-Sigma & Lean 101

Two Factor DOE Hi vs Lo Importance

OK. Some of you are saying Wait a second! When P is changing so is T!? WHAT??????? EXAMPLE - Calculate the effect of P change. Yield at P1 = (Result Y1) + (Result Y2) Yield at P2 = (Result Y3) + (Result Y4)

SUBSTITUTING VARIABLES PRODUCING THOSE YIELDS

INPUT P P1 P1 P2 P2 T T1 T2 T1 T2

RESULT Yield Y1 Y2 Y3 Y4

INPUT P 50 50 100 100 T 25 75 25 75

Yield at P1 = (P1 + T1) + (P1 + T2) Yield at P2 = (P2 + T1) + (P2 + T2)

REARRANGING & REASSOCIATING

Yield at P1 = (P1 + P1 ) + (T1 + T2) Yield at P2 = (P2 + P2 ) + (T2 + T2)

SIMPLIFYING

RESULT Yield 94 92 96 88

Yield at P1 = 2P1 + (T1 + T2) Yield at P2 = 2P2 + (T1 + T2)

GRAPHICAL DEPICTION

T1 & T2 contribute the This is what is important!!!! same amount to P1 or P2 2P1

2P2 T1+T2 Y@P1 T1+T2 Y@P2

or consider, the difference removes T effect (Yield at P1) - (Yield at P2) = 2P1 - 2P2

ISandR@usa.com

Copyright - ISandR Services and Accelper

34

6-Sigma & Lean 101

More Factorial Experiment Designs 3 & 4 Variables

INPUT A A1 A1 A1 A1 A1 A1 A1 A1 A2 A2 A2 A2 A2 A2 A2 A2

ISandR@usa.com

OUTPUT D D1 D2 D1 D2 D1 D2 D1 D2 D1 D2 D1 D2 D1 D2 D1 D2 Result1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 R1 Result2 R2 R2 R2 R2 R2 R2 R2 R2 R2 R2 R2 R2 R2 R2 R2 R2 A A1 A1 A1 A1 A2 A2 A2 A2

INPUT B B1 B1 B2 B2 B1 B1 B2 B2 C C1 C2 C1 C2 C1 C2 C1 C2

OUTPUT Result1 R1 R1 R1 R1 R1 R1 R1 R1 Result2 R2 R2 R2 R2 R2 R2 R2 R2

B B1 B1 B1 B1 B2 B2 B2 B2 B1 B1 B1 B1 B2 B2 B2 B2

C C1 C1 C2 C2 C1 C1 C2 C2 C1 C1 C2 C2 C1 C1 C2 C2

Exercise for later these are balanced experiments equal number of each variable (A1, A2, B1, B2, C1, C2), within all experiments that are also unique with respect to the arrangement of these variables note: check out the colors.

35

Copyright - ISandR Services and Accelper

6-Sigma & Lean 101

Lean

Document the process Find the waste Make a plan to eliminate the waste

ISandR@usa.com

Copyright - ISandR Services and Accelper

36

6-Sigma & Lean 101

What Are Key Concepts of Lean?

Give customers

what they want, when they want it, for what they want to pay, and without more inve$tment by your company

Get the big picture of the process to

Improve Quality Eliminate Waste - ID Value Added vs. Non-Value Added Activities Reduce Lead Time Reduce Total Costs

ISandR@usa.com

Copyright - ISandR Services and Accelper

37

6-Sigma & Lean 101

Create a Value Stream Map Present (Need Future State) This is the value stream Description ID Customer, Supplier, entire process for theand Production Customer Requirements per Time plant. You can also Interval Production & Containment Requirements make a value stream Shipping mapDelivery a sub-process. for Sequence of you EventuallyProcesses need to lookData specific toentire at the each Sequence Communication Methods processAttributes: times, Efficiency 6 to make sure Process Operator did number changesSymbol - not shift 7 Inventory Work in Process (WIP) waste or &problems to "Push" vs "Pull" Operations another process and Other Info onlyWorking Hours Availability created a local Cycle & Lead optimum.Times

item 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 ISandR@usa.com

14 8 1 1 15 4 2 5 3 1

11 12 10 14 15

You will probably do this with pencil & paper

Example from - www.strategosinc.com

Copyright - ISandR Services and Accelper

38

6-Sigma & Lean 101

How to Identify Waste TIMWOOD or DOWNTIME Look for these forms of waste in the Value Stream Map

TIMWOOD

Transportation Inventory Motion Waiting Over-processing Over-production Defects

DOWNTIME

Defects Over-production Waiting Not Utilizing Employees* Transportation Inventory Motion Excess processing

*skills, ideas, creativity

ISandR@usa.com

Copyright - ISandR Services and Accelper

39

6-Sigma & Lean 101

How does 5S Help Eliminate Waste? Makes Waste Visible.

5 S - seiri, seiton, seiso, seiketsu and shitsuke

Sort, separate needed from unneeded items & remove the latter Set-in-Order*/Straighten, arrange items for ease of use Shine/Scrub, means to cleanup Standardize/Systemize, disciplined structured routines Sustain/Self-Discipline, create a new habit

* 6 S adds Safety (part of Set-in-Order) make safety equipment easy to use

ISandR@usa.com

Copyright - ISandR Services and Accelper

40

6-Sigma & Lean 101

Relation of What We Learned wrt Process Improvement

6-Sigma

Other PI Tools

There is more Lean

ISandR@usa.com

Copyright - ISandR Services and Accelper

41

6-Sigma & Lean 101

Other Process Improvement Concepts/Tools

ISandR@usa.com

Copyright - ISandR Services and Accelper

42

6-Sigma & Lean 101

What is 6-Sigma? Components of Sustained Profitable Growth

Good Management Systems

Innovation

Business Scorecard

6-Sigma Lean

Creating a culture to sustain & create new improvements

ISandR@usa.com

Copyright - ISandR Services and Accelper

43

6-Sigma & Lean 101

How to Sustain Progress with Lean & 6-Sigma

Keep employees motivated, customers happy, processes running smoothly, and the company making money

LEAN is NOT MEAN

ISandR@usa.com

Copyright - ISandR Services and Accelper

44

6-Sigma & Lean 101

What are Components of Sustained Profitable Growth

Business Scorecard

Customer

Financials

Vision & Strategy

Employees

Processes

Management Provides Vision & Strategy so the Business Can: #1 Take Care of Customers (VOC), #2 Take Care of Employees (Training, Resources, Rewards) Employees Take Care of Processes (Process Control & Improvement) Processes Take Care of Finances (Efficient Value Added Processes = $$s) Finances Take Care of Stakeholders and Provide $$s for Growth and Improvements that add value for the customer

ISandR@usa.com

Copyright - ISandR Services and Accelper

45

6-Sigma & Lean 101

Six Sigma: Objective Quality Measures All Matter But Some Measurements Tend to Matter More than Others

Sturdy averages seem impressive from inside the organization (the inside-out perspective)

But it is variability that the customer feels and fears (the outside-in perspective)

Copyright - ISandR Services and Accelper

ISandR@usa.com

46

6-Sigma & Lean 101

Challenges with Six Sigma for Transactional Functions like Purchasing/Procurement, SRM

Projects tend to lack objective data. What data there is tends to be attribute (pass fail/ no. of shortcomings) and categorical

Solution: work with continuous data when possible to mimic previously shown production charts. There are more options for stat. tool use; yield more guidance information. ROThumb: consider converting if at least 10 different values occur and no more than 20% of the data set are repeat values

You may have a defined process and goal, but no tangible spec limits. Arbitrary metric or soft target setting can mislead, distort. Example: 1-5 supplier rating.

*SRM = Supplier Relationship Mgmt

ISandR@usa.com

Copyright - ISandR Services and Accelper

47

6-Sigma & Lean 101

Challenges with Six Sigma for Transactional Functions like Purchasing/Procurement, SRM

-Data integrity problems of attribute data. MSA may be needed -Meaningful metrics may take more doing and trial and error early on -Regression, DOE and ANOVA can be applied to multivariable situations with lots of moving and interacting parts DCs, office locations, site specific paperwork procedures, carrier selection, suppliers with different lead time averages and extremes, etc.

ISandR@usa.com

Copyright - ISandR Services and Accelper

48

6-Sigma & Lean 101

Lean Ramifications for SRM and Logistics Some procurement and purchasing metrics tied to traditional financials may be detrimental:

PPV - Keeps the raw expenditures down, but at the expense of excess inventory, idle assets and not harvesting cash from inventory. Variance reporting in general more conducive to traditional mass production, not lean. Leads to a wait time-order size spiral. True lean operations are real time, rapid response, small run oriented. Some of the blame goes to standard costing a discussion for another time!! PO reconciliations/matchups with receivers, invoices, etc. Instead expand use of blanket POs, invoiceless daily or frequent deliveries Bucketed point-of-use deliveries; backflush usage on low value components

ISandR@usa.com

Copyright - ISandR Services and Accelper

49

6-Sigma & Lean 101

Lean Ramifications for SRM and Logistics

Some procurement and purchasing metrics tied to traditional financials may be detrimental:

On Time Delivery May encourage storing JIC inventory, padding lead times: a supply chains lump under the carpet. Instead redirect efforts to lead time reduction at many points Other old EOQ policies (assumes steady and independent demand for all skus, not custom or responsive), batching and queuing of orders and paperwork, etc.

ISandR@usa.com

Copyright - ISandR Services and Accelper

50

6-Sigma & Lean 101

Pareto Diagram: Example

PO Cycle Time - Unapproved Vendors

Days Delayed

Total Count = 895 900 810 720 630 540

COUNT

100 (80%) (65%) (36%) 324 255 135 92 89 (90%) 90 80 70 60 50 40 30 20 10 0

450 360 270 180 90 0

PERCENT

Raw Material

Equipment

Engr. Matl.

OTHER

Admin

ISandR@usa.com

Copyright - ISandR Services and Accelper

51

6-Sigma & Lean 101

Poor Customer Response Time

Cause and Effect Diagram Man

Disorganized Untrained Too few No established methods No step by step documentation Improper use of e-mail

Materials

Always running out of materials Materials outdated Proper materials never ordered System errors in reporting Wait time not comprehensive

Poor Customer Response Time

Methods

Measurement

ISandR@usa.com

Copyright - ISandR Services and Accelper

52

6-Sigma & Lean 101

Box Plots of Supplier Bids

70 60

50

40

Hi for Mo Q3 for Mo Q1 for Mo Lo for Mo

30

20

10

0 Suppl 1 Bids Suppl 2 Bids Suppl 3 Bids Suppl 4 Bids Suppl 5 Bids

Similar Items Over Course of 1 Month (These patterns may be congruent with other Supplier Behaviors such as RFQ Cycle Times, etc.)

ISandR@usa.com

Copyright - ISandR Services and Accelper

53

6-Sigma & Lean 101

Supply Chain Basic Flow Chart for Component Assembly Value Stream

New/ECO Product Devlpt ! Supplier In House Plant Conveyance, Freight Carrier ! Customer Customer Service Dept Sales Personnel

Marketing

Supplier Issue Resolution

Waste, Rework Unused Inv.

Customer Issue Resolution

ISandR@usa.com

Copyright - ISandR Services and Accelper

54

6-Sigma & Lean 101

Variation in RFQ Cycle Times for Critical Part

Days

ISandR@usa.com

Copyright - ISandR Services and Accelper

55

6-Sigma & Lean 101

Component RFQ Process Time-Value Diagram

Collect Information From Customer 3 hours 1 day Collect Cost Info From Outsourced Mfg 0.25 hours 5 days Generate Quote 0.5 hours 2 hours

Start

Province of Lean Sigma SRM

Negotiate Price 1 day 3 days

Enter Order 0.25 hours 1 day

Assemble & Delivery d 1 week 10 weeks

End E

Province of Lean Sigma Manufacturing

ISandR@usa.com

Copyright - ISandR Services and Accelper

56

6-Sigma & Lean 101

As Is Process Lane Map For Component RFQ

Component Company

Start

Compile, Send RFQ

Assemble Quote

Submit

Outsourced Supplier

Send to Support Office

Compile Information

Outsourced Supplier Support Office

Process request

Return to Own Plant

ISandR@usa.com

Copyright - ISandR Services and Accelper

57

6-Sigma & Lean 101

Future State Process Map For Component RFQ

Apply Costing Table

Component Company

Start SSt

Compile Request

Assemble Quote

Send SE

Outsourced Supplier

Maintain Costing Tables

ISandR@usa.com

Copyright - ISandR Services and Accelper

58

6-Sigma & Lean 101

Variation in RFQ Cycle Times for Key Part

AFTER CHANGES

Process Shift, New Avg, New CLs

ISandR@usa.com

Copyright - ISandR Services and Accelper

59

6-Sigma & Lean 101

Supplier Quote Time, Before and After Change

Before Changes After Changes

Cycle Time, Days

ISandR@usa.com

Copyright - ISandR Services and Accelper

60

6-Sigma & Lean 101

Normal Probability Plot for RFQ Time

New Quote Time, Days

ISandR@usa.com

Copyright - ISandR Services and Accelper

61

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Sop 4590Documento230 pagineSop 4590Mike WilliamNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Shear Key PDFDocumento3 pagineShear Key PDFBijaya RaulaNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

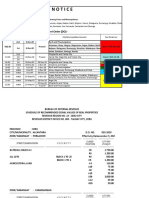

- Tax Alert (December 2020)Documento10 pagineTax Alert (December 2020)Rheneir MoraNessuna valutazione finora

- Hydrogen Safety NFPADocumento22 pagineHydrogen Safety NFPArome_n21100% (1)

- Ihs Kingdom Hot Keys ReferenceDocumento1 paginaIhs Kingdom Hot Keys ReferenceMuhammad Jahangir100% (1)

- WPCE Pump-In Sub by NOV ELMARDocumento1 paginaWPCE Pump-In Sub by NOV ELMARvipequi50Nessuna valutazione finora

- Epanet Vs Watergems (083011)Documento9 pagineEpanet Vs Watergems (083011)MABA02100% (1)

- RDO No. 90 - Maasin City, Southern Leyte 2Documento465 pagineRDO No. 90 - Maasin City, Southern Leyte 2Ramonbeulaneo Rances100% (1)

- 49 Insights June 2022V2Documento24 pagine49 Insights June 2022V2Rheneir MoraNessuna valutazione finora

- O&M TransformerDocumento47 pagineO&M TransformerAshish PatelNessuna valutazione finora

- Collaborative and RevenueDocumento7 pagineCollaborative and RevenueRheneir MoraNessuna valutazione finora

- RDO No. 80 - Mandaue City, CebuDocumento798 pagineRDO No. 80 - Mandaue City, CebuCecil GubaNessuna valutazione finora

- Form45 1Documento1 paginaForm45 1Rheneir MoraNessuna valutazione finora

- Form45 3Documento2 pagineForm45 3Rheneir MoraNessuna valutazione finora

- Form45 3Documento2 pagineForm45 3Rheneir MoraNessuna valutazione finora

- Form 45 TemplateDocumento3 pagineForm 45 TemplateELNessuna valutazione finora

- RDO No. 47 - East MakatiDocumento83 pagineRDO No. 47 - East MakatiRheneir MoraNessuna valutazione finora

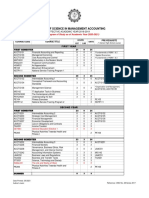

- Cit U Bsma ProspectusDocumento4 pagineCit U Bsma ProspectusRheneir MoraNessuna valutazione finora

- Cit U Bsais ProspectusDocumento5 pagineCit U Bsais ProspectusAtty. Rheneir MoraNessuna valutazione finora

- RDO No. 83 - Talisay City, CebuDocumento619 pagineRDO No. 83 - Talisay City, CebuNiki Daymiel MalazarteNessuna valutazione finora

- Attendance SheetDocumento4 pagineAttendance SheetRheneir MoraNessuna valutazione finora

- Creative Solutions + Sound Business Judgment: Success ManagementDocumento4 pagineCreative Solutions + Sound Business Judgment: Success ManagementRheneir MoraNessuna valutazione finora

- Tax Alert Jan 16 To Feb 15, 2020 FinalDocumento11 pagineTax Alert Jan 16 To Feb 15, 2020 FinalRheneir MoraNessuna valutazione finora

- Sci PoDocumento1 paginaSci PoRheneir MoraNessuna valutazione finora

- Cit U Bsa ProspectusDocumento4 pagineCit U Bsa ProspectusRheneir MoraNessuna valutazione finora

- Tax Alert Special Issue March 31, 2020 (Final)Documento15 pagineTax Alert Special Issue March 31, 2020 (Final)Rheneir MoraNessuna valutazione finora

- Tax Alert September 2020 Final v2Documento6 pagineTax Alert September 2020 Final v2Rheneir MoraNessuna valutazione finora

- October 2020 Tax AlertDocumento5 pagineOctober 2020 Tax AlertRheneir MoraNessuna valutazione finora

- Tax Alert For November 2020Documento4 pagineTax Alert For November 2020Rheneir MoraNessuna valutazione finora

- Tax Alert July 2020 (Final)Documento4 pagineTax Alert July 2020 (Final)Rheneir MoraNessuna valutazione finora

- Tax Alert Aug 2020Documento2 pagineTax Alert Aug 2020Rheneir MoraNessuna valutazione finora

- Tax Alert (April 2020) FinalDocumento30 pagineTax Alert (April 2020) FinalRheneir MoraNessuna valutazione finora

- Tax Alert (June 2020)Documento7 pagineTax Alert (June 2020)Rheneir MoraNessuna valutazione finora

- 2020soar 2019 Ifiar Survey ReportDocumento28 pagine2020soar 2019 Ifiar Survey ReportRheneir MoraNessuna valutazione finora

- SECMCNo18 1 PDFDocumento4 pagineSECMCNo18 1 PDFzelayneNessuna valutazione finora

- IOSCO Report On Good Practices For Audit Committees in Supporting Audit QualityDocumento33 pagineIOSCO Report On Good Practices For Audit Committees in Supporting Audit QualityRheneir MoraNessuna valutazione finora

- Tax Alert Regular Issue (March 2020)Documento19 pagineTax Alert Regular Issue (March 2020)Rheneir MoraNessuna valutazione finora

- CS193a Android ProgrammingDocumento4 pagineCS193a Android Programmingrosy01710Nessuna valutazione finora

- Ahu-Ok CatalogueDocumento6 pagineAhu-Ok Catalogue-Tokusatsu Man-Nessuna valutazione finora

- Wind Loads - IS 875 - Where Does Our Code of Practice StandDocumento11 pagineWind Loads - IS 875 - Where Does Our Code of Practice StandRavi Kiran NandyalaNessuna valutazione finora

- Greenstar Cdi Installation ManualDocumento60 pagineGreenstar Cdi Installation Manualkb1856Nessuna valutazione finora

- Binary Search of Unsorted ArrayDocumento3 pagineBinary Search of Unsorted ArrayGobardhan BaralNessuna valutazione finora

- Transportation ChecklistDocumento1 paginaTransportation ChecklistHolly Smith100% (1)

- Astm A182 f22 Class 3Documento3 pagineAstm A182 f22 Class 3VõTạNessuna valutazione finora

- TTO-ST-0-SPC-05100 - Structural Steel SpecificationDocumento18 pagineTTO-ST-0-SPC-05100 - Structural Steel Specificationsara saravananNessuna valutazione finora

- Overview of Ultrasound Detection Technologies For Photoacoustic ImagingDocumento24 pagineOverview of Ultrasound Detection Technologies For Photoacoustic ImagingShuvam5 GuptaNessuna valutazione finora

- Interfaces KelloggDocumento16 pagineInterfaces KelloggUrrNessuna valutazione finora

- Work at Height Questions For Height PassDocumento3 pagineWork at Height Questions For Height PassPravash Mohanty100% (1)

- February 2016Documento104 pagineFebruary 2016Cleaner MagazineNessuna valutazione finora

- Zaštita Transformatora Osiguračima - Nadstrujna - Zaštita PDFDocumento4 pagineZaštita Transformatora Osiguračima - Nadstrujna - Zaštita PDFKristian MevželjNessuna valutazione finora

- Pic Attack1Documento13 paginePic Attack1celiaescaNessuna valutazione finora

- New Premium ListDocumento10 pagineNew Premium ListAshwani SainiNessuna valutazione finora

- Current Electricity All DerivationsDocumento11 pagineCurrent Electricity All DerivationsRonit VaskarNessuna valutazione finora

- Project 3 FinalDocumento15 pagineProject 3 Finalapi-285419046Nessuna valutazione finora

- Critical Care Systems Test Equipment For Repairs and PMS in The USA and CanadaDocumento6 pagineCritical Care Systems Test Equipment For Repairs and PMS in The USA and CanadaMedsystem atNessuna valutazione finora

- Rotarex Certificate - UL EX15624-20131227 FM 200 - 0214Documento2 pagineRotarex Certificate - UL EX15624-20131227 FM 200 - 0214Mehmet AltanNessuna valutazione finora

- Metrolla Steels Industrial Visit ReportDocumento39 pagineMetrolla Steels Industrial Visit ReportSanjay R Nair100% (1)

- 24 - Article - $mbps Vs $MHZ Why Is This ImportantDocumento2 pagine24 - Article - $mbps Vs $MHZ Why Is This ImportantShiraz SiddiqNessuna valutazione finora

- Day 1 Borehole Geophysics WDocumento21 pagineDay 1 Borehole Geophysics Waliy2k4uNessuna valutazione finora

- Drive Test AnalysisDocumento47 pagineDrive Test Analysis3a9aNessuna valutazione finora