Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Work at Inspection Dept.

Caricato da

bukboyDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Work at Inspection Dept.

Caricato da

bukboyCopyright:

Formati disponibili

20

2.5.1 Inspection at the Incoming Material Inspection Dept. : The task given to me was to inspect the SION components, manufactured by Indian vendors, to be used for the assembly of SION prototype in India. I was posted at this department for around two months. The inspection procedure is carried out in following three stages: Study of part drawings & visual inspection: First stage in inspecting a given part is a proper understanding of part drawing. The drawing must be read carefully & deeply studied before starting the inspection. Following thing should be deciphered properly: Name Item number & version (if many types are available) Method of projection used in design Standards to be followed Dimensions, tolerances & specifications Special instructions (if any) Bill of Materials (BoM) for assembly drawings

Secondly, visual inspection is done so that any flaws in surface finish or plating or presence of burrs or oxides can be detected. The sense of touch can also be used. If any component is damaged then the reasons are to found out such as poor quality of material or faulty manufacturing process or mishandling by vendor or during transportation & remarks are written in the inspection report. Visual inspection also helps to detect anomalies in a part such as absence of taper or misalignment of holes & the part can be rejected without wasting any time on actual inspection. Inspection for dimensional accuracy: Second stage involves inspection for accuracy of dimensions as per design specifications. This is a very important stage as each and every possible dimension is to be checked for accuracy & precision & the possibility of

V.J.T.I.

Nishikant. V. Kulkarni

074010032

21

rejection or acceptance depends on the results obtained. For checking dimensions one should have studied the drawing carefully & must have sufficient knowledge of standards & metrological concepts. Following instruments were used to measure various dimensional parameters: Surface plate: It is a rectangular flat surface usually made of granite or cast iron. It is used as a datum. All the linear dimensions representing height or depth are measured considering the surface plate as reference. Digital height gauge & calipers: Height gauge is used to measure height, centre to centre distances elevation etc. It consists of sliding mechanism which houses the sensitive scriber and digital readout. Calipers are used to measure all shorter linear dimensions Thread & ring gauges: A thread gauge is used to check external threads of a bolt or screw. A ring gauge is used to check internal threads of a nut or tapped hole. Gauges are available for both British & ISO threads.

V.J.T.I.

Nishikant. V. Kulkarni

074010032

22

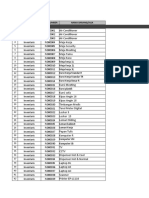

Pin gauge: It is a type of plug gauge. These are inserted into the holes to check their diameter. Pin gauges are available in steps of 0.01mm to 0.1mm depending on the accuracy required. Radius gauge: It used to check the radius of a curve. There is provision for checking both internal & external radii in single gauge itself. The standards used for SION components are DIN (German) or EN (European) standards. The tolerances which are not given in the design, are taken from standard tolerance charts. Preparation of inspection reports: An inspection report is prepared finally. These report is prepared using a standard format made in Microsoft Excel. The report may be hand-written or prepared on computer. First the following details are filled before writing down the measurements: Name of the part Item number (version, if any) Name of the vendor Raw material of the part Quantity checked Date of inspection Received quantity Order number

V.J.T.I.

Nishikant. V. Kulkarni

074010032

23

Those dimensions which are not within tolerances are highlighted. The remarks regarding visual inspection are written below the measured readings. Finally the report is signed by the inspector. The complete report is then reviewed by senior members of SION localization project.

V.J.T.I.

Nishikant. V. Kulkarni

074010032

Potrebbero piacerti anche

- Data Driven System Engineering: Automotive ECU DevelopmentDa EverandData Driven System Engineering: Automotive ECU DevelopmentNessuna valutazione finora

- IQC - 6TH ME E NotesDocumento27 pagineIQC - 6TH ME E NotesShobhit SinghNessuna valutazione finora

- Automated Inspection: Unit ViDocumento45 pagineAutomated Inspection: Unit ViAnonymous surAitMpaNessuna valutazione finora

- OJTDocumento19 pagineOJTKiran PadalaNessuna valutazione finora

- Inspection Gauges TypesDocumento12 pagineInspection Gauges Typesahsan aliNessuna valutazione finora

- 35232chapter 3 Linear MeasurementDocumento14 pagine35232chapter 3 Linear Measurementk.ghanemNessuna valutazione finora

- ScopeDocumento7 pagineScopeNICKNessuna valutazione finora

- Assignment # 1Documento12 pagineAssignment # 1ahsan aliNessuna valutazione finora

- Weld GaugesDocumento15 pagineWeld GaugesHaleemUrRashidBangashNessuna valutazione finora

- Chapter 2 - METROLOGY-Main NotesDocumento25 pagineChapter 2 - METROLOGY-Main NotesyamadaNessuna valutazione finora

- Unit-Ii 3Documento30 pagineUnit-Ii 3k.ghanemNessuna valutazione finora

- NDI EquipmentDocumento20 pagineNDI EquipmentswenthomasNessuna valutazione finora

- Unit Ii: Paavai Institutions Department of MechDocumento37 pagineUnit Ii: Paavai Institutions Department of Mechanon_319307852Nessuna valutazione finora

- Metrology Uniit IIDocumento53 pagineMetrology Uniit IIrramesh2k8712Nessuna valutazione finora

- Quality Control and Quality AssuranceDocumento4 pagineQuality Control and Quality AssurancerampdwnNessuna valutazione finora

- Unit 3 Linear and Angular MeasurementsDocumento22 pagineUnit 3 Linear and Angular Measurementsbhuyanuttam7Nessuna valutazione finora

- Sun Industries Procedure For Design Activity Doc No: SI/QSP/012 Page: 1 of 3 1.0 PurposeDocumento3 pagineSun Industries Procedure For Design Activity Doc No: SI/QSP/012 Page: 1 of 3 1.0 PurposeJamil VoraNessuna valutazione finora

- Metrology Lab w2014Documento15 pagineMetrology Lab w2014ObaidNessuna valutazione finora

- System of Fuel SupplyDocumento28 pagineSystem of Fuel SupplyJM PraveenNessuna valutazione finora

- Lab MetrologyDocumento5 pagineLab MetrologyMuhammad AfnanNessuna valutazione finora

- Inspection of Press Tools and MouldsDocumento35 pagineInspection of Press Tools and MouldsPra VeeNessuna valutazione finora

- Engineering Metrology & InstrumentsDocumento28 pagineEngineering Metrology & InstrumentsJobanjit SinghNessuna valutazione finora

- VT 4Documento18 pagineVT 4demoknight tf2Nessuna valutazione finora

- QC System Manual PDFDocumento41 pagineQC System Manual PDFwhitebros100% (1)

- MQC Lab Manual 2021-2022-AutonomyDocumento39 pagineMQC Lab Manual 2021-2022-AutonomyAniket YadavNessuna valutazione finora

- Metrology 1CDocumento44 pagineMetrology 1CRadhaMadhavNessuna valutazione finora

- ME2308 Metrology and Measurements Lab ManualDocumento48 pagineME2308 Metrology and Measurements Lab ManualratchagarajaNessuna valutazione finora

- CAD-CAM Unit-5aDocumento14 pagineCAD-CAM Unit-5aSHYAM NANINessuna valutazione finora

- Quality Control ShopDocumento20 pagineQuality Control ShopAshu ThakurNessuna valutazione finora

- Eb4069135 F enDocumento13 pagineEb4069135 F enkalvino314Nessuna valutazione finora

- Lect - Linear and Angular Measurements PDFDocumento118 pagineLect - Linear and Angular Measurements PDFEmmanuel Thomas100% (1)

- 3 Exercises Product Quatity Control Measurement ProceduresDocumento29 pagine3 Exercises Product Quatity Control Measurement ProceduresHasan Can MuratNessuna valutazione finora

- AP Ipr FR r03 71 enDocumento10 pagineAP Ipr FR r03 71 enChany MaiaaNessuna valutazione finora

- Visual Weld InspectionDocumento7 pagineVisual Weld InspectioninsiderrNessuna valutazione finora

- Construction Methodology: AECOM India Private LimitedDocumento5 pagineConstruction Methodology: AECOM India Private LimitedJ. Kumar Infraprojects LtdNessuna valutazione finora

- Mechanical Design Engineer Interview QuestionsDocumento13 pagineMechanical Design Engineer Interview QuestionspravagaNessuna valutazione finora

- Assignment # 1: Submitted ToDocumento12 pagineAssignment # 1: Submitted Toahsan aliNessuna valutazione finora

- Automobile Manufacturing Technology 05 04 2020Documento2 pagineAutomobile Manufacturing Technology 05 04 202031 Sameer SinhaNessuna valutazione finora

- R2019 - MESBL601 - MA Lab ManualDocumento30 pagineR2019 - MESBL601 - MA Lab Manualsealrohan0Nessuna valutazione finora

- Measurement and InspectionDocumento33 pagineMeasurement and InspectionSri RNessuna valutazione finora

- MQA Lab ReportDocumento15 pagineMQA Lab ReportMuhammad Waleed TariqNessuna valutazione finora

- 18 Inch 9 5 MM Combo (MFL+CLP+IMU) (Ver Data Sheet Pàg. 8) PDFDocumento19 pagine18 Inch 9 5 MM Combo (MFL+CLP+IMU) (Ver Data Sheet Pàg. 8) PDFOscar Miguel Fuquen SanabriaNessuna valutazione finora

- 24 Practical Visual InspectionDocumento5 pagine24 Practical Visual InspectionMai Anh TaiNessuna valutazione finora

- Quality InspectionDocumento17 pagineQuality InspectionDeepakPandeyNessuna valutazione finora

- Method Statement FOR Station Survey Work 1. Purpose: 3.1 Project ManagerDocumento5 pagineMethod Statement FOR Station Survey Work 1. Purpose: 3.1 Project ManagerJ. Kumar Infraprojects LtdNessuna valutazione finora

- Division 1 General Requirements Section 01000 - Field EngineeringDocumento10 pagineDivision 1 General Requirements Section 01000 - Field EngineeringLuis Gabriel BautistaNessuna valutazione finora

- MEP Design Verification Report-Report No. 1-Underground Services-Final - Rev 1Documento292 pagineMEP Design Verification Report-Report No. 1-Underground Services-Final - Rev 1uddinnadeem100% (4)

- MCL 231 Metrology Part 1Documento26 pagineMCL 231 Metrology Part 1rakesh kumarNessuna valutazione finora

- Research and DevelopmentDocumento5 pagineResearch and DevelopmentAnand VasudevanNessuna valutazione finora

- PVC Coated Conduit ProcedureDocumento7 paginePVC Coated Conduit ProcedureAlexey LeonichevNessuna valutazione finora

- MEC 212 Engineering MeasurementDocumento4 pagineMEC 212 Engineering Measurementysuleman1994Nessuna valutazione finora

- Engineering MetrologyDocumento84 pagineEngineering MetrologyLalit MohanNessuna valutazione finora

- Metrology Lab ManualDocumento39 pagineMetrology Lab ManualNivedh Vijayakrishnan0% (1)

- Quality Assurance and Quality ControlDocumento4 pagineQuality Assurance and Quality ControlRuli DarmawanNessuna valutazione finora

- Calibration of Dial GaugeDocumento21 pagineCalibration of Dial GaugeAnthony Burns82% (11)

- Nazim Lab Session 1-15Documento48 pagineNazim Lab Session 1-15Hammad SaeedNessuna valutazione finora

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisDa EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisValutazione: 4 su 5 stelle4/5 (2)

- Introduction to N.C.M., a Non Contact Measurement ToolDa EverandIntroduction to N.C.M., a Non Contact Measurement ToolNessuna valutazione finora

- Handbook of Mechanical and Materials EngineeringDa EverandHandbook of Mechanical and Materials EngineeringValutazione: 5 su 5 stelle5/5 (4)

- OpenSAP Ml2 Week 1 InstallationGuide AnacondaDocumento6 pagineOpenSAP Ml2 Week 1 InstallationGuide AnacondaVivek ThotaNessuna valutazione finora

- UsrGuide 9650SE 9690SA 9 5 2Documento361 pagineUsrGuide 9650SE 9690SA 9 5 2za1725262Nessuna valutazione finora

- Win StepsDocumento463 pagineWin StepsAnonymous 105zV1Nessuna valutazione finora

- IkegamiDocumento4 pagineIkegamialelendoNessuna valutazione finora

- Daftar Spare Part PDFDocumento80 pagineDaftar Spare Part PDFManiso MnsNessuna valutazione finora

- Name Date Drawn Checked Eng Appr MGR ApprDocumento1 paginaName Date Drawn Checked Eng Appr MGR ApprLamHotNessuna valutazione finora

- IAM - 0004 - EN - SINUMERIK 840D810D MMCHMI Installation and Start-Up Guide (IAM) - 04.00 EditionDocumento34 pagineIAM - 0004 - EN - SINUMERIK 840D810D MMCHMI Installation and Start-Up Guide (IAM) - 04.00 EditionJackam kamNessuna valutazione finora

- PMU Control Over CAN BUS Rev1Documento6 paginePMU Control Over CAN BUS Rev1Adrián HerzogNessuna valutazione finora

- DR ZXDocumento192 pagineDR ZXcherif100% (7)

- CNMS Quick StartDocumento24 pagineCNMS Quick StartMr. XNessuna valutazione finora

- Explain Tables - LawsonDocumento23 pagineExplain Tables - LawsonVibhaw Prakash RajanNessuna valutazione finora

- SAS Slides 2: Basics of SAS Programming LanguageDocumento25 pagineSAS Slides 2: Basics of SAS Programming LanguageSASTechies100% (1)

- Datalink Control Protocol 2Documento24 pagineDatalink Control Protocol 2Albert Kenneth Lupase UcangNessuna valutazione finora

- HAL 102 - LabDocumento43 pagineHAL 102 - LabSyrd MdeNessuna valutazione finora

- SetupDocumento16 pagineSetupDeisy M SNessuna valutazione finora

- Hardware Design of Data Controller For Nand Flash MemoryDocumento33 pagineHardware Design of Data Controller For Nand Flash MemoryDevasish BhagawatiNessuna valutazione finora

- Esc Manualhw 01 v4Documento2 pagineEsc Manualhw 01 v4Neil100% (1)

- MKF Tool HelpDocumento6 pagineMKF Tool HelpRob GoetzNessuna valutazione finora

- NO Klasifikasi Code Number Nama Barang/Jasa: InventarisDocumento28 pagineNO Klasifikasi Code Number Nama Barang/Jasa: InventarisRavita TrivegaNessuna valutazione finora

- Gimp TutorialDocumento519 pagineGimp TutorialBth BkaNessuna valutazione finora

- ReadmeDocumento3 pagineReadmeoctavio RamosNessuna valutazione finora

- Cavendish ManualDocumento6 pagineCavendish ManualbertosamNessuna valutazione finora

- MACCOY - PINZA - DE POTENCIA - HIDRAULICA - KT20-50K Tech ManualDocumento198 pagineMACCOY - PINZA - DE POTENCIA - HIDRAULICA - KT20-50K Tech ManualJavier Ramirez100% (1)

- VSP 516 SeriesDocumento20 pagineVSP 516 Seriesimaginariasur.sasNessuna valutazione finora

- A320 AutothrustDocumento14 pagineA320 AutothrusthhgaffadfNessuna valutazione finora

- RV-4A, 5AJ, 3AL, 4AJL - Instruction Manual (Arm Setup, Maintenance CR2A-572 Controller) BFP-A8229-A (02.02)Documento82 pagineRV-4A, 5AJ, 3AL, 4AJL - Instruction Manual (Arm Setup, Maintenance CR2A-572 Controller) BFP-A8229-A (02.02)ibraheemNessuna valutazione finora

- Simrad AP70 and AP80 Autopilot Systems: Pending ApprovalDocumento21 pagineSimrad AP70 and AP80 Autopilot Systems: Pending ApprovalAhmedNessuna valutazione finora

- B&R Industrial Automation - 4SIM.10-01Documento18 pagineB&R Industrial Automation - 4SIM.10-01zakaria rizaNessuna valutazione finora

- FFT Dif R2Documento1 paginaFFT Dif R2Delia InesNessuna valutazione finora

- ADE7880 Medidor de EnergiaDocumento104 pagineADE7880 Medidor de EnergiaJeziel Vazquez NavaNessuna valutazione finora