Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Asme A-2 Reverse Flange Calculation

Caricato da

pastylDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Asme A-2 Reverse Flange Calculation

Caricato da

pastylCopyright:

Formati disponibili

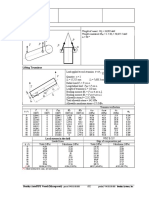

ASME VIII Div.

1 A-2

BOLTED FLANGE CONNECTIONS

LOOSE REVERSE FLANGE

P= T=

17.24 bar o 150.00 C SA-350 LF2 SA-193 B7 0.00 mm

REVERSE LOOSE FLANGE DESIGN CONDITIONS Allowable Stress Flange Bolting Sfo (Oper.) 1379.00 barSbo (Oper.) 1720.00 bar Sfa (G. Seat.) 1379.00 barSba (G. Seat.) 1720.00 bar E

Attached Nozzle Sno (Oper.) 1379.00 bar Sna (G. Seat.) 1379.00 bar

202.00 GPa GASKET AND FACING DETAILS Facing TABLES 2.5.1 and 2.5.2 4 LOADS AND BOLT CALCULATION 2 Total hydrostatic force = 0.785G P H= Gasket O.D.= 450.00 mm ' Gasket I.D.= Total joint-contact surface compression load = 2bx3.14GmP +2Pm blrl HP= 406.40 mm Minimum required bolt load for the operating conditions = H+HP Wm1= N= 21.80 mm b0= Minimum required bolt load for gasket seating = 3.14GbY+blrlY' Wm2= 10.90 mm b= G= m= y= m'= y'= N of pass partition br= rl= Nmin= Load HG=W-H 96821.30 N HD =0.785B 422492.44 N HT=H-HD -168237.63 N 8.25 mm 433.49 mm 2.50 69.00 Mpa 0.00 0.00 0.00 0.00 0.00 8.89 Mpa mm mm mm mm x for the operating =Wm1/Sbo Am1= , for gasket seating conditions=Wm2/Sba Am2= total area the of bolts, greater of Am1 and Am2 Am= Required area of bolts ( least unth.diameter) Ab=

c=

254254.81 96821.30 351076.11 775199.55 20.41 45.07 45.07 95.90

5 N N N N cm2 2 cm 2 cm 2 cm

FLANGE DESIGN (A-2,Fig.2-13.1) Thickness g0 6.35 mm Thickness g1 6.35 mm In. diameter B' 406.40 mm Cor.thickness g0 Cor.thickness g1 Fl. thickness t Hube length h Out. diameter A Cor.inside B' Bolt circle C Inside diam B Corr.insi.diam. B R=(C-B)/2-g1 6.35 6.35 68.45 0.00 571.50 406.40 mm mm mm mm mm mm

490.00 mm 558.80 mm 558.80 mm 35.45 mm

Flange design bolt load GS K=(Ab+Am)Sba/2 W=

Flange design bolt load OP C=Wm1 W=

1212339.77 N 351076.11 N

MOMENT CALCULATION Lever Arm = Moment Operating MH hG=(C-G)/2 Comp. moment due to G= 28.25 mm 2735.57 Nm MH hD=(C-B)/2 Comp. moment due to D= -34.40 mm -14533.74 Nm MH hT=(1/2)[C-(B+G)/2] Comp. moment due to T= -3.07 mm 517.01 Nm Total moment acting upon the flange for operating conditions Mo=M 11281.16 Nm 34253.19 Nm 34253.19 Nm

HG=W-H

Gasket Seating MH Comp. moment due to G= 1212339.77 from gasket load reac. to the bolt circle hG Dist. N 28.25 mm Total moment acting upon the flange for gasket seating conditions Mo=M K AND HUB FACTORS g1/g ho= h/h f= F= V= 1.00 60.24 mm 0.00 1.0000 0.9089 0.5501

factor g1/g0 factor ho =(Ag0) 3 factor h/h0 d= 18324.26 mm -1 e= hub stress correction mm as a function of g1/g0 and h/h0 0.0151 factor ar =[1+0.668(K+1)/Y]/K Factor F as a function of g1/g0 and h/h0 0.644 Factor V as Tr,Zr,Yr,Ur T,Z,Y,U a function of g1/g0 and h/h0 Tr=(Z+0.3)/(Z-0.3)a 1.375 1.752 Zr=Z 3.046 3.046 Yr=arY 3.776 5.860 Ur=arU 4.150 6.440 K= 1.41 L= 18.980 STRESS CALCULATION Operating Sallowable

Sallowable

S=YMo/t W/Ab

347.20 bar 366.09 bar

1379.00 OK 1720.00 OK Gasket Seating Sallowable Sallowable Maximum Rigidity Factor, K1=0.3

ST=YMo/t W/Ab

1054.22 bar 808.34 bar

1379.00 OK 1720.00 OK barg barg

J=

109.4Mo/ Et3KL(lnk)

0.848

OK

M.A.W.P. (Operating): M.A.W.P. (Gasket seating):

PStylianopoulos

Pressure Vessel Engineer

1 of 1 LOOSE REVERSE FLANGE

Potrebbero piacerti anche

- 17 Asmeviii A-2 Reverse Integral FlangeDocumento1 pagina17 Asmeviii A-2 Reverse Integral FlangepastylNessuna valutazione finora

- Solution: WE1 12 Nov 2008Documento9 pagineSolution: WE1 12 Nov 2008aauppalNessuna valutazione finora

- PV Elite Webinar 001Documento23 paginePV Elite Webinar 001MEC_GuiNessuna valutazione finora

- PTB E4.18.5 Fixed TubesheetDocumento83 paginePTB E4.18.5 Fixed TubesheetNicolaSaviliNessuna valutazione finora

- News Letter For Expansion Bellow PDFDocumento4 pagineNews Letter For Expansion Bellow PDFAsma Khan100% (1)

- PD5500 - 133 - RectangularFlange CalculationDocumento9 paginePD5500 - 133 - RectangularFlange CalculationDarshan PanchalNessuna valutazione finora

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Documento32 paginePV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoNessuna valutazione finora

- Bolt TorqueDocumento3 pagineBolt TorqueHeri KurniawanNessuna valutazione finora

- Stresses in Large Horizontal Cylindrical Pressure Vessels On Two Saddle SupportsDocumento12 pagineStresses in Large Horizontal Cylindrical Pressure Vessels On Two Saddle SupportsAlexander BlackNessuna valutazione finora

- FatigueLife FEA PDFDocumento43 pagineFatigueLife FEA PDFAbigail SommersetNessuna valutazione finora

- Ref: Procedure No. 2-10 Pg. No. 59, Pressure Vessel Design Manual by Dennis Moss, 3rd EditionDocumento5 pagineRef: Procedure No. 2-10 Pg. No. 59, Pressure Vessel Design Manual by Dennis Moss, 3rd EditionSivi NallamothuNessuna valutazione finora

- PV Elite WebinarDocumento24 paginePV Elite WebinarAndrea Hank LattanzioNessuna valutazione finora

- Project of Pressure VesselDocumento25 pagineProject of Pressure VesselKalkidan DanielNessuna valutazione finora

- CAL-ST-070!17!01 Rev01 Shipping Saddles CalculationDocumento11 pagineCAL-ST-070!17!01 Rev01 Shipping Saddles CalculationgiubelloNessuna valutazione finora

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDocumento5 pagineASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaNessuna valutazione finora

- Design of Tooth Locked Quick Open Die Pressure VesselDocumento4 pagineDesign of Tooth Locked Quick Open Die Pressure VesselSEP-PublisherNessuna valutazione finora

- U-V-673 - Manual Flange and GussetDocumento8 pagineU-V-673 - Manual Flange and GussetDarshan PanchalNessuna valutazione finora

- STHE Design (Training Material)Documento37 pagineSTHE Design (Training Material)Herman_ms2000100% (2)

- External PressureDocumento22 pagineExternal PressureAbhijeet SahuNessuna valutazione finora

- Design of Pressure VesselsDocumento8 pagineDesign of Pressure Vesselsanswer1Nessuna valutazione finora

- Code Case 2901 - Consideration of External Loads On ASME B16.5 Standard Flanges Under ASME Code Section VIII, Division 1 & 2Documento2 pagineCode Case 2901 - Consideration of External Loads On ASME B16.5 Standard Flanges Under ASME Code Section VIII, Division 1 & 2msn1981Nessuna valutazione finora

- Diaphragm Elimination Using Taper-Lok - NPRADocumento11 pagineDiaphragm Elimination Using Taper-Lok - NPRAN. S. PanditNessuna valutazione finora

- Demo Vessel Calc SecviiiDocumento51 pagineDemo Vessel Calc SecviiihrabiecNessuna valutazione finora

- Comparison ASME KTADocumento7 pagineComparison ASME KTAAndres_Pastor1987Nessuna valutazione finora

- SEISMIC ANALYSIS KazzincDocumento14 pagineSEISMIC ANALYSIS KazzincArees KhambattaNessuna valutazione finora

- Wind Seismic Calculation DataDocumento8 pagineWind Seismic Calculation Dataaknauriyal2013Nessuna valutazione finora

- Girth Flange Load Calculation Using by FEA TechniquesDocumento12 pagineGirth Flange Load Calculation Using by FEA TechniqueskingstonNessuna valutazione finora

- Hemispherical Head Design Tool: Pressure Vessel Engineering LTDDocumento1 paginaHemispherical Head Design Tool: Pressure Vessel Engineering LTDExsan OthmanNessuna valutazione finora

- Auto PipeDocumento18 pagineAuto PipeAdi Sutardi100% (1)

- Analysis of Vertical Vessels Supported On Legs By: Ray DelaforceDocumento6 pagineAnalysis of Vertical Vessels Supported On Legs By: Ray Delaforcesonali panditNessuna valutazione finora

- Saddle AnalysisDocumento17 pagineSaddle AnalysisAntonio Perez Zornoza100% (1)

- Calcu Nozzle NeckDocumento15 pagineCalcu Nozzle Necksachmaya0% (1)

- Lug SupportDocumento2 pagineLug SupportSachin5586Nessuna valutazione finora

- NozzleDocumento11 pagineNozzleharyfadlyNessuna valutazione finora

- Pveng: Pressure Vessel Engineering LTDDocumento11 paginePveng: Pressure Vessel Engineering LTDSivateja NallamothuNessuna valutazione finora

- ASME DIV 2 Class 1 Vs Class 2Documento3 pagineASME DIV 2 Class 1 Vs Class 2Idris SiddiquiNessuna valutazione finora

- Calculations For: Calculations No. Asme Viii Div 1 Ed 2019Documento21 pagineCalculations For: Calculations No. Asme Viii Div 1 Ed 2019David Vanegas100% (1)

- Platform - Bracing SupportDocumento12 paginePlatform - Bracing Supportpandiangv100% (1)

- Shell Thickness CalcDocumento1 paginaShell Thickness CalcDidi KurniadiNessuna valutazione finora

- Method For Finding Stress in Cylinders With Radial NozzlesDocumento10 pagineMethod For Finding Stress in Cylinders With Radial NozzlesmatodelanusNessuna valutazione finora

- How To Use Code Case in PV EliteDocumento2 pagineHow To Use Code Case in PV EliteMukeshChopraNessuna valutazione finora

- Pressure Vessel Design and AnalysisDocumento30 paginePressure Vessel Design and AnalysisAlok SaxenaNessuna valutazione finora

- PVP2016 Final ProgramDocumento76 paginePVP2016 Final Programthaivinhtuy100% (1)

- Saddle Support Design of Horizontal Vessels As Per Asme Section Viii, Div.2Documento6 pagineSaddle Support Design of Horizontal Vessels As Per Asme Section Viii, Div.2SISIR KR BARMAN0% (1)

- Nozzle TempDocumento2 pagineNozzle TempRakeshNessuna valutazione finora

- Blind Flange (10 Bar)Documento7 pagineBlind Flange (10 Bar)SyedZainAliNessuna valutazione finora

- Calculo de Brida Segun ASMEDocumento29 pagineCalculo de Brida Segun ASMEakarcz6731Nessuna valutazione finora

- 5.7 Asmeviii A-2 & Tema Split Backing RingDocumento1 pagina5.7 Asmeviii A-2 & Tema Split Backing RingpastylNessuna valutazione finora

- BlindDocumento3 pagineBlindSajal KulshresthaNessuna valutazione finora

- Modification Thickness of A FlangeDocumento3 pagineModification Thickness of A FlangePeter PerezNessuna valutazione finora

- Blind Flange Calculation11Documento3 pagineBlind Flange Calculation11jaymuscatNessuna valutazione finora

- Sample FLG CalcDocumento6 pagineSample FLG CalcameyyammaiNessuna valutazione finora

- Calculo Brida Ejemplo PV - EliteDocumento8 pagineCalculo Brida Ejemplo PV - ElitePedro Montes MarinNessuna valutazione finora

- Flange Input Data Values Description: FLGDocumento4 pagineFlange Input Data Values Description: FLGAnonymous AyDvqgNessuna valutazione finora

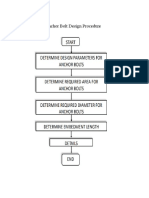

- Towerwind Analysis - Anchoragebolt - Base PlateDocumento14 pagineTowerwind Analysis - Anchoragebolt - Base PlateJoy lauriaNessuna valutazione finora

- Flange Input CalcDocumento12 pagineFlange Input CalcdharwinNessuna valutazione finora

- Calculation For Sight Glass FlangeDocumento4 pagineCalculation For Sight Glass FlangeOmil Rastogi0% (2)

- ASME BPVC 2008a Section VIII - Division 1 General Requirement UG-34Documento12 pagineASME BPVC 2008a Section VIII - Division 1 General Requirement UG-34akarczNessuna valutazione finora

- Wind Calculation SheetDocumento32 pagineWind Calculation SheetaauppalNessuna valutazione finora

- Asme A-2 Reverse Flange CalculationDocumento1 paginaAsme A-2 Reverse Flange CalculationpastylNessuna valutazione finora

- 15.1 Isa20 50 Control ValveDocumento2 pagine15.1 Isa20 50 Control Valvepastyl100% (1)

- 5.7 Asmeviii A-2 & Tema Split Backing RingDocumento1 pagina5.7 Asmeviii A-2 & Tema Split Backing RingpastylNessuna valutazione finora

- 10.1 Asme Viii A-13 Rectangular VesselDocumento2 pagine10.1 Asme Viii A-13 Rectangular Vesselpastyl100% (1)

- 5 Asme Viii A-24 Clamp ConnectionDocumento6 pagine5 Asme Viii A-24 Clamp ConnectionpastylNessuna valutazione finora

- 5 Asmeviii A-24 Clamp ConnectionDocumento6 pagine5 Asmeviii A-24 Clamp ConnectionpastylNessuna valutazione finora

- Asme Viii Uhx Tubesheet CalcsDocumento3 pagineAsme Viii Uhx Tubesheet CalcsjdfdfererNessuna valutazione finora

- Revision - Summary - 7T04 MP 00 TS 004 - Rev10Documento10 pagineRevision - Summary - 7T04 MP 00 TS 004 - Rev10Cristi DemNessuna valutazione finora

- 3-Way ValveDocumento4 pagine3-Way ValveAhrian BenaNessuna valutazione finora

- S 000 1378 001 - 1 - 0001Documento53 pagineS 000 1378 001 - 1 - 0001sifoouNessuna valutazione finora

- 5X2X3 - JapfaMedanDocumento1 pagina5X2X3 - JapfaMedanGrab StrongNessuna valutazione finora

- PricelistDocumento80 paginePricelistCrisanto CajulisNessuna valutazione finora

- Pre Start Up Safety ReviewDocumento8 paginePre Start Up Safety ReviewAhmed MorsyNessuna valutazione finora

- G3 Gland Sealed Stop Valve-Installation Maintenance Manual PDFDocumento2 pagineG3 Gland Sealed Stop Valve-Installation Maintenance Manual PDFchanNessuna valutazione finora

- Saes A 004Documento22 pagineSaes A 004Branko_62100% (1)

- ASME B 31.3 QuestionsDocumento12 pagineASME B 31.3 Questionsemaanazeem91% (11)

- Ep 61450Documento9 pagineEp 61450Maura ApostolacheNessuna valutazione finora

- Piping Material Take Off-MTO, BOM, BOQ & MTO Stages (With PDFDocumento5 paginePiping Material Take Off-MTO, BOM, BOQ & MTO Stages (With PDFDhiren PatelNessuna valutazione finora

- KSVB - Manual Installation Operation Maintenance Repair Manual - Oil Lubricated, Rotary Vane Vacuum PumpDocumento24 pagineKSVB - Manual Installation Operation Maintenance Repair Manual - Oil Lubricated, Rotary Vane Vacuum PumpahmedNessuna valutazione finora

- Bolt Tightening e PDFDocumento15 pagineBolt Tightening e PDFdromaki0% (1)

- SP PI PP 001 (General Piping System)Documento49 pagineSP PI PP 001 (General Piping System)Ari IndrajayaNessuna valutazione finora

- API RTJ Ring Gasket Profiles (Shapes) of API 6A, 16A, 17D, R, RX, BX, SRX, SBX Ring Gaskets, Ring Gasket TypesDocumento2 pagineAPI RTJ Ring Gasket Profiles (Shapes) of API 6A, 16A, 17D, R, RX, BX, SRX, SBX Ring Gaskets, Ring Gasket TypesKaleem UllahNessuna valutazione finora

- Specification For A Land 2000 HP DrillinDocumento33 pagineSpecification For A Land 2000 HP Drillinanthonmirandas100% (1)

- Mov Specification PDFDocumento27 pagineMov Specification PDFpl_arunachalam79Nessuna valutazione finora

- Fisher EWN Series and EW 1 Series Valves: Scope of ManualDocumento24 pagineFisher EWN Series and EW 1 Series Valves: Scope of ManualMOUWAKILNessuna valutazione finora

- Tabla de Bridas y Esparragos PDFDocumento1 paginaTabla de Bridas y Esparragos PDFjairo ardila100% (1)

- IMBIL Slurry Pumps General Technical CatalogueDocumento39 pagineIMBIL Slurry Pumps General Technical CatalogueCardoso MalacaoNessuna valutazione finora

- Domestic Water Filtration EquipmentDocumento10 pagineDomestic Water Filtration EquipmentElie HajjNessuna valutazione finora

- Butterfly ValveDocumento30 pagineButterfly ValvesaifulNessuna valutazione finora

- Ralph C. Whitley SR.: From: Sent: To: CCDocumento7 pagineRalph C. Whitley SR.: From: Sent: To: CCRalph Charles Whitley, Sr.Nessuna valutazione finora

- Quotation: Los Buenos Amigos 9016, Culiacan, Sinaloa, Mexico, 80135 Phone: +52 667 759 0470Documento18 pagineQuotation: Los Buenos Amigos 9016, Culiacan, Sinaloa, Mexico, 80135 Phone: +52 667 759 0470Leonardo Zermeño SanchezNessuna valutazione finora

- Vehicules & EquipimentsDocumento29 pagineVehicules & EquipimentsMohamed OukassiNessuna valutazione finora

- CLASS 153086: DEP 31.38.01.12-Gen Class 153086, Rev. G Page 1 of 10Documento10 pagineCLASS 153086: DEP 31.38.01.12-Gen Class 153086, Rev. G Page 1 of 10SaguesoNessuna valutazione finora

- Piping Stress-Interview QuestionsDocumento17 paginePiping Stress-Interview QuestionsAnkush Varshney100% (2)

- Appendix B Approved List of MaterialsDocumento33 pagineAppendix B Approved List of MaterialsAshok Suresh0% (1)

- Data Sheet Lungo - 1000042831 - 02 - 1 PDFDocumento2 pagineData Sheet Lungo - 1000042831 - 02 - 1 PDFMilan GrujićNessuna valutazione finora

- FK 30.70 (3) GB NAF-Check Tilting Disc Check Valves: CharacteristicsDocumento6 pagineFK 30.70 (3) GB NAF-Check Tilting Disc Check Valves: CharacteristicsNguyen KhaNessuna valutazione finora