Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Detection

Caricato da

Ahmed SaadDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Detection

Caricato da

Ahmed SaadCopyright:

Formati disponibili

Company profile

Detection is a Full service inspection company providing both field and laboratory inspection services. Our services include a full range of NDT methods, Quality Control and Quality Assurance functions, and physical testing. Our company experience as an independent contractor of inspection in the Oil, Gas, Chemicals, Industrial and petrochemicals industries is very well distinguished in the Egyptian and the Middle East. Experience includes planning, organizing and implementing all inspection related activities for both domestic and foreign purchased project material, vendor fabricated and manufactured equipment and site erection/installation, supervising quality control; training, qualifying and evaluating company inspector expertise in the areas of welding, fabrication, non-destructive testing and quality control.

Contact us : # 31 Hadayek El Obour Buildings,Salah Salem Street, Cairo, Egypt. E-mail: detection_ndt@yahoo.com info@detection-ndt.com Tel: (202) 2 4023004, Fax: 0222634899 Mobile: 010-344 9707 www.detection-ndt.com www.facebook.com/Detection.ndt

COMPANY PROFILE

INDEX

Quality policy Company profile. Services that can be provided

INSPECTION AND QUALITY CONTROL TRAINING COURSES

RECRUITNG SERVICES Advanced NDT Services.

# 31 Hadayek El Obour Buildings,Salah Salem Street, Cairo, Egypt. E-mail: detection_ndt@yahoo.com info@detection-ndt.com Tel: (202) 2 4023004, Fax: 02- 22634899 Mobile: 010-344 9707 www.detection-ndt.com www.facebook.com/detection.ndt

Rev.: 01, Page 2 of 13

COMPANY PROFILE

DETECTION Quality Policy

The quality of our services is of decisive significance for the competitiveness of our company, as well as for that of our clients each employee bears a part of the responsibility for control and improvement of the quality. Only a permanent striving for improvement ensures the success and continuance of the company. The Quality Management System (QMS) of DETECTION ensures that organizational, commercial and technical activities are planned, managed and supervised to fulfill contractual requirements. Our Company recognizes that it is essential for the Companys long-term success and prosperity that we maintain an excellent name for quality. Our Top Management ensures that this Policy Statement is understood, implemented and maintained at all levels within the organization. As one of the measurements of the performance of the quality management system DETECTION monitors information relating to customer perception as to whether the organization has fulfilled customer requirements.

DETECTION conducts internal audits at planned intervals to determine whether the quality management system conforms to the planned arrangements to the requirements of ISO 9001:2000 Standard and to the quality management system requirements established by the organization, and is effectively implemented and maintained. DETECTION applies suitable methods for monitoring and, where applicable, measurement of the quality management system processes. These methods demonstrate the ability of the processes to achieve planned results. When planned results are not achieved, correction and corrective action are taken, as appropriate, to ensure conformity of the product. DETECTION determines, collects and analyzes appropriate data to demonstrate the

suitability and effectiveness of the quality management system and evaluates where continual improvement of the quality management system can be made. This includes data generated as a result of monitoring and measurement and from other relevant sources. The analysis of data provides information (at a minimum) relating to customer satisfaction, conformance to service requirements, characteristics and trends of processes and products including opportunities for preventive action, and suppliers.

DETECTION continually improves the effectiveness of the quality management system through the use of the quality policy, quality objectives, audit results, analysis of data, corrective and preventive actions and management review.

# 31 Hadayek El Obour Buildings,Salah Salem Street, Cairo, Egypt. E-mail: detection_ndt@yahoo.com info@detection-ndt.com Tel: (202) 2 4023004, Fax: 02- 22634899 Mobile: 010-344 9707 www.detection-ndt.com www.facebook.com/detection.ndt

Rev.: 01, Page 3 of 13

COMPANY PROFILE

Services provided by Detection

1. INSPECTION AND QUALITY CONTROL 1.1. Welding:

Welding inspection and quality control. Welders And Welding Procedure Qualification Training & qualifying of welders and certification to ASME, AWS & API requirements . Developing welding procedure & specification and witness their Qualifications. Consulting activities in welding and NDT. Prepare/Renew WPSs/PQRs for all types of materials according to the client's specifications, ASME sec IX, API 1104 and AWS D 1.1.

1.2 Non-destructive Testing Level III Services

Training, Qualification and Certification for Level I & II NDT Inspectors and/or Tubular

Inspection personnel.

Performing NDT (RT, UT, MP, PT, ET, and VT) & Third Party Services. Developing Inspectoion Techniques and Procedures in Different Applications:

Aircraft Maintenance, Repair, and Overhaul. Shipbuilding Industries. Oilfield Maintenance and Construction. Steel Constructions. Tubular and Drilling Tools.

Assist Companies and Manufacturers in Developing Their Own Specifications and Quality manuals for Inspection and Testing Of Ferrous, Nonferrous and Composite Materials and Products. Consulting Services In Selection Of Inspection Equipment And Test Material . Training, qualification and certification of Companys NDT Establishing Companys written practice in accordance with SNT-TC-1A and/or API RP 5A5. Establishing NDT procedures (RT, UT, MT, PT, ET, and VT) in accordance with ASME Code / AWS D1.1 and /or Tubular Inspection Standard Operating Procedures Reviewing / preparing of Company Quality Manuals. Reviewing of NDT Equipment Calibration procedures.

# 31 Hadayek El Obour Buildings,Salah Salem Street, Cairo, Egypt. E-mail: detection_ndt@yahoo.com info@detection-ndt.com Tel: (202) 2 4023004, Fax: 02- 22634899 Mobile: 010-344 9707 www.detection-ndt.com www.facebook.com/detection.ndt

Rev.: 01, Page 4 of 13

COMPANY PROFILE

1.3 Provide the clients with the following NDT operations and welding Inspection services :

Tank floor inspection using magnetic flux leakage technique. Heat exchanger tube inspection using eddy current techniques. Pipe line inspection using RT, MT, UT, PT, VT Tank inspection using RT, MT, UT, PT, V Pressure vessel inspection using RT, MT, UT, PT, VT Welding inspection using RT, MT, UT, PT, VT Post weld heat treatment Hardness testing Wall thickness measurements above coating. Vacuum box systems for Bubble Leak Testing of both lap welds and shell to annular wel areas. Painting inspection Quality control on all fabrication and repair works

# 31 Hadayek El Obour Buildings,Salah Salem Street, Cairo, Egypt. E-mail: detection_ndt@yahoo.com info@detection-ndt.com Tel: (202) 2 4023004, Fax: 02- 22634899 Mobile: 010-344 9707 www.detection-ndt.com www.facebook.com/detection.ndt

Rev.: 01, Page 5 of 13

COMPANY PROFILE

1.4. Provide the clients with the following High Technology NDT operations and welding Inspection services:

Integral to our range of services, Detection offers Specialized Non-Destructive Testing (NDT) and inspection to complement our other traditional Quality Assurance and Quality Control Services. These services help our clients to improve plant reliability,Reduce Operational and maintenance costs, enhance safety,extend plant life and meet regulatory requirements. We believe our personnel are our greatest assets. Besides state of the art equipment for best results, we have highly trained and certified inspectors to perform your inspection. Our inspectors are experienced and have technical expertise to conduct the inspection surveys to international standard. Our reputation within all industries is not only known for our quality of personnel and equipment but equally our professionalism and knowledge. Detection 's comprehensive range of inspection techniques ensures that we remain at the forefront of Specialized Non-Destructive Testing. Our services include;

Robe Access Inspection using all methods of NDT. Inspections on tank floors through protective coating using Magnetic flux leakage. (MFL) Visual inspection of pipelines and firewater pipes using video fiber scopes. RIPLECA tests for surface roughness and microstructure. Eddy current and remote field Inspection of ferrous and nonferrous Heat Exchangers tubes. Fully automated Corrosion mapping system using ToFD and multi probe. Manual UT system complete with R-Scan Lite, Theta-Scan Lite and ToFD Lite accessories PipeScan system complete with PS100B, PS200, PS 500 PS 1200 and PS 400 accessories. Omniscan MX Phased array unit with a wide selection of probes. GUL Wavemaker 3 guided wave system with EFC and accessories to cover a range of pipe sizes.

# 31 Hadayek El Obour Buildings,Salah Salem Street, Cairo, Egypt. E-mail: detection_ndt@yahoo.com info@detection-ndt.com Tel: (202) 2 4023004, Fax: 02- 22634899 Mobile: 010-344 9707 www.detection-ndt.com www.facebook.com/detection.ndt

Rev.: 01, Page 6 of 13

COMPANY PROFILE

2. TRAINING COURSES

Detection is one of the most reliable professional training centers accredited from well known Oil/Gas and Industrial Organizations in Egypt and Middle East.

2.1 Organize Training Courses On The Following Non-destructive Testing Methods For Qualifying And Certifying NDT Level I & II Inspection: Radiographic Testing (RT) Ultrasonic Testing (UT) Eddy Current Testing (ET) Magnetic Particle Testing (MT) Penetrant Testing (PT) Visual Testing (VT)

The Training Courses And The Certification Procedures Are In Accordance With The Requirements Of The American Society For Non-destructive Testing (ASNT). Recommended Practice No. SNT TC 1A,Latest Edition and ANSI/ASNT-CP-105,ANSI/ASNT-189 Latest Edition. 2.2 Organize NDT Level III Refresher Courses (Basic, RT, UT, MT, and PT) for NDT Personnel seeking ASNT NDT Level III certification by Examination. 2.3 .Organize Tailor-Made Training Courses in different fields such as: Heat treatment, Tubular Inspection ,Welding Fundamentals, Material Selection and testing and etc... 2.4 Training & qualifying of welders and certification to ASME, AWS & API requirements. 2.5 All certificates are approved by Detection level III Consultant Eng.Abdallah Hassanein

o o o o o PED NDT Level 3 (04 502 1132) RT, UT, MT, PT (Welding) in accordance with EN 473, ISO 9712 ACCP Professional Level III (74268) RT, UT, MT, PT, VT Sectors GI & PE ASNT NDT Level III (74268) in RT, UT, MT, PT, ET, VT. APPROVED ARAMCO INSPECT0R FOR PRESSURE VESSELS, PIPING, PIPELINES Since 2006 Consulting Engineer (92/5) in QA/QC of material manufacturing technology, NDT, Mechanical Testing, Surface and Heat Treatments.

# 31 Hadayek El Obour Buildings,Salah Salem Street, Cairo, Egypt. E-mail: detection_ndt@yahoo.com info@detection-ndt.com Tel: (202) 2 4023004, Fax: 02- 22634899 Mobile: 010-344 9707 www.detection-ndt.com www.facebook.com/detection.ndt

Rev.: 01, Page 7 of 13

COMPANY PROFILE

3.RECRUITNG SERVICES

DETECTION offers Inspection Recruiting Services to help firm connect qualified NDT candidates with the most demanding occupational needs. Our clients trust us providing them with the most highly qualified labour in all fields. We offer reasonable rates and the quality services needed in todays competitive environment. 1. We Provide contractors with the following highly qualified labour: Quality control managers and Engineers QC & Welding inspectors NDT Engineers & Technicians for RT, MT, UT, PT, VT Welders, Foreman, Supervisors Pipe fitters & Platers API 570,653,Inspectors. CWI/CSWIP Engineers. 2. Provide petroleum companies with highly qualified plant inspectors. 3. Provide clients with third party surveyors . Contact Detection recruiting team today to get personalized staffing services from veterans in the Inspection Industry.

# 31 Hadayek El Obour Buildings,Salah Salem Street, Cairo, Egypt. E-mail: detection_ndt@yahoo.com info@detection-ndt.com Tel: (202) 2 4023004, Fax: 02- 22634899 Mobile: 010-344 9707 www.detection-ndt.com www.facebook.com/detection.ndt

Rev.: 01, Page 8 of 13

COMPANY PROFILE

DETECTION ADVANCED NDT SERVICES

DETECTION offers conventional radiographic, ultrasonic, magnetic particle, dye penetrant testing services along with a wide array of advanced technology solutions to our clients. DETECTION experts are able to customize our technologically advanced inspection services to provide superior inspection results while helping to reduce overall integrity management costs. DETECTION distinguishes itself by providing the widest range of advanced inspection technologies available. Our extensive resources enable us to offer inspection solutions for virtually any requirement. DETECTION works with industry organizations, research and development facilities, and clients to develop new inspection equipment, applications and procedures. Using the most up to date technologies helps DETECTION minimize our client's down time and ensure they get the most comprehensive information possible on the condition of their equipment. Our highly trained NDE professionals go through rigorous training and meet or exceed all industry requirements. In addition, DETECTION provides extensive in-house training and ensures all of our NDE professionals are current on all relevant industry codes and regulations. DETECTION has an ongoing commitment to continually bring new inspection solutions to our clients that will help provide them with better information to make decisions as well as help save them money with their integrity management programs. With our Professional NDE technicians, our size and expertise make DETECTION the logical choice to meet your inspection requirements. Whether it is for daily inspection activities or large turn around projects, DETECTION provides clients with the industry's best integrity management solutions. Our focus is on safety, improving efficiencies, raising the standard of quality. We are committed to delivering the highest performance standards any time where we are needed.

# 31 Hadayek El Obour Buildings,Salah Salem Street, Cairo, Egypt. E-mail: detection_ndt@yahoo.com info@detection-ndt.com Tel: (202) 2 4023004, Fax: 02- 22634899 Mobile: 010-344 9707 www.detection-ndt.com www.facebook.com/detection.ndt

Rev.: 01, Page 9 of 13

COMPANY PROFILE

Eddy Current Testing Eddy Current Testing is the most commonly used method, but is limited to non-ferromagnetic and slightly magnetic alloys. The Eddy Current technique is based on the induction of an electromagnetic field in the component being examined and can detect various forms of internal and external damage. The inspection consists of a full-length examination performed on the inside of the tube with equal inner and outer surface discontinuity detection and sizing. The purpose of this application is to detect I.D. and O.D. degradation such as cracking, corrosion, erosion, pitting, fretting and gradual wall loss generally found in non-ferromagnetic tubing. At DETECTION we believe in diversity and advanced technologies. Therefore we utilize the most advanced Eddy Current technologies for heat exchanger inspection.We currently use the Zetec MIZ 17, and THE ect MAD 8D EDDY CURRENT SYSTEM for our tube testing instruments.

Applications

Inspection of Non-Ferromagnetic Tubing Can detect and size wear (wall loss) at baffle locations. Can detect and size isolated pitting, corrosion, cracking, and gradual wall loss. Can inspect tubes from 3/8 to 2-1/2 diameter. (Larger with special probe designs i.e. Array). Can distinguish between ID and OD Orientations. Can inspect tubing that has been coated with non-conductive coating

Production

Two-man crew can inspect roughly 500 tubes (20 in length) in an 8 hour shift.

Site Preparation

Tubes require cleaning sufficiently enough to remove scale, debris, and most importantly magnetic deposits. (10,000-20,000 psi hydro-blasting is recommended). 110 VAC Power Source.

# 31 Hadayek El Obour Buildings,Salah Salem Street, Cairo, Egypt. E-mail: detection_ndt@yahoo.com info@detection-ndt.com Tel: (202) 2 4023004, Fax: 02- 22634899 Mobile: 010-344 9707 www.detection-ndt.com www.facebook.com/detection.ndt

Rev.: 01, Page 10 of 13

COMPANY PROFILE

Scaffolding and/or cover for equipment.

Pre Job Information

Equipment Number Service Name Total Number of Tubes Percentage of Tubes for Inspection Tube Material Tube OD Tube Wall Thickness or Gauge Tube Length Access Requirements to Exchanger Special Safety Requirements Suspected or Predicted Damage Tube Side Service Shell Side Service All the above mentioned data must be available prior to the start of the job by at least 2 month in order to prepare the suitable probes and test samples

Detection team inspecting Heat Exchangers

# 31 Hadayek El Obour Buildings,Salah Salem Street, Cairo, Egypt. E-mail: detection_ndt@yahoo.com info@detection-ndt.com Tel: (202) 2 4023004, Fax: 02- 22634899 Mobile: 010-344 9707 www.detection-ndt.com www.facebook.com/detection.ndt

Rev.: 01, Page 11 of 13

COMPANY PROFILE

Surface Eddy Current Testing At DETECTION we believe in diversity and advanced technologies. Therefore we utilize the most advanced Eddy Current technologies for Surface We currently use the HALEC Eddy current crack detector which is capable of detecting surface breaking cracks in ALL METALS ,it can operate through paint or insulation coating and on samples which are oil or grease covered without any pre-cleaning. It is a HIGH FREQUENCY equipment, operating at a frequency of 3MHz. It is a modern design incorporating up-to-date components, and it has been designed to be particularly EASY TOUSE. The design also incorporates a novel feature Which eliminates the conventional EDGE-EFFECT on the majority of common metals. In the HALEC the zero level shifts in a negative direction as the edge is approached and passed over. False indications of defects at edges are thus not given by the HALEC. The HALEC has a wide range of PROBES available for use with it.Standard types include PENCIL, KNIFE, BOLT HOLE, METAL SORTING, and numerous SPECIAL PROBES which have been developed for non-standard applications. The HALEC has an excellent AUDIO facility. This delivers information to the operator that allows him to set-up the HALEC and discover defects without looking at the instrument. This is a most useful facility in many applications and frees the user to concentrate on the probe and the workpiece. The HALEC gives an output signal to drive a CHART RECORDER,and a power output to supply the AUDIO/THRESHOLD Unit. This unit, the AU2, is a combination of an AUDIO AMPLIFIER and a TRIGGER unit with a variable threshold level. The use of this unit simplifies even more the use of the HALEC in many situations, particularly where certain repetitive checks are required. The METAL SORTING PROBE extends the use of the HALEC beyond the simple crack detection role. It enables the user to distinguish, quickly and easily, between metals with different characteristics or analysis. In simple cases it is possible to distinguish between similar metals whose analyses differ by only 0.5% -1%chromium for example. In addition to the obvious uses to identify material in stores or in production, it can also detect unhardened components in batches of hardened components or for example high tensile bolts or nuts from their mild-steel counterparts. In this role again the instrument is both easy to set, and easy to use. These reasons contribute to the excellent results that can be obtained with it.

# 31 Hadayek El Obour Buildings,Salah Salem Street, Cairo, Egypt. E-mail: detection_ndt@yahoo.com info@detection-ndt.com Tel: (202) 2 4023004, Fax: 02- 22634899 Mobile: 010-344 9707 www.detection-ndt.com www.facebook.com/detection.ndt

Rev.: 01, Page 12 of 13

COMPANY PROFILE

Tank bottom Inspection by Magnetic Flux Leakage Inspection (MFL) Service

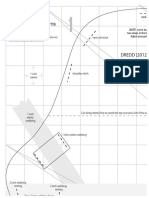

DETECTION in co-operation with Silverwing (UK) provides Magnetic Flux Leakage Inspection for the oil & gas, petrochemical and power industries. The FloormapVS2i system is a next generation of the magnetic flux leakage detection technique. The FloormapVS2i is latest version of the best selling MFL floor scanner and now comes with upgraded magnets to improve defect detectability and sizing on thicker materials, faster data capture with a custom designed micro controller and all new software. The VS2i contains significant improvements in terms of defect positioning,electronic data processing and software manipulation. A new High Specification encoder system has been developed which is electronically calibrated to each individual scanner eliminating errors caused by component tolerances. The new encoder now gives accuracy to within 3 mm on an 8 meter track length and providing it is calibrated on an annual basis will not be effected by normal wear and tear. The ruggedised on-board computer uses touch screen technology for ease of use within the hostile storage tank environment. The custom designed data acquisition software not only captures all the MFL signals but analyses and displays the location and severity of the corrosion in real time. The off-line reporting software automatically produces a CAD drawing of the tank floor with the defects being positioned to within 30mm accuracy. All captured data, over 20% loss of the nominal plate thickness, is re-analyzed to identify the defect profile and separate the corrosion into 1 of 3 classes. Different sizing algorithms are applied to each class of corrosion ensuring enhanced defect sizing even on badly corroded floors where small diameter deep pits may otherwise have been undersized. Additional data from visual, ultrasonic, vacuum box and magnetic particle inspection can be added to the report generating a full fingerprint of the tank floor including the annular plates. An innovative feature of the software allows subsequent inspection data to be overlaid and corrosion growth identified. These features coupled together with a patch plate design function and full statistics package give the tankage engineer a powerful, cost effective tool with which to carry out trending and asset life projections.

Reporting

# 31 Hadayek El Obour Buildings,Salah Salem Street, Cairo, Egypt. E-mail: detection_ndt@yahoo.com info@detection-ndt.com Tel: (202) 2 4023004, Fax: 02- 22634899 Mobile: 010-344 9707 www.detection-ndt.com www.facebook.com/detection.ndt

Rev.: 01, Page 13 of 13

Potrebbero piacerti anche

- Company Profile 9Documento15 pagineCompany Profile 9ทิวากร กฤษณามระNessuna valutazione finora

- Tuvpak Certification & Technical Inspection ServicesDocumento18 pagineTuvpak Certification & Technical Inspection ServicesDilshad aliNessuna valutazione finora

- PED HelpDocumento77 paginePED HelpShane Hancock100% (1)

- Lesson 1 Inspection Work Done-SMAWDocumento32 pagineLesson 1 Inspection Work Done-SMAWAlexander OrsenoNessuna valutazione finora

- i-NEEMA Oil & Gas Services Company ProfileDocumento10 paginei-NEEMA Oil & Gas Services Company ProfileIfeanyiAguNessuna valutazione finora

- ADMET Calibration Brochure 2017Documento4 pagineADMET Calibration Brochure 2017Salvador MazzaNessuna valutazione finora

- Attachment 1 Company ProfileDocumento45 pagineAttachment 1 Company Profilelemuel bacsaNessuna valutazione finora

- Quality Control & Assurance SystemsDocumento42 pagineQuality Control & Assurance Systemssurender20111991Nessuna valutazione finora

- Company Profile Bureau Veritas ThailandDocumento13 pagineCompany Profile Bureau Veritas ThailandPitichai PakornrersiriNessuna valutazione finora

- Integrity v6Documento16 pagineIntegrity v6khanz88_rulz1039Nessuna valutazione finora

- Medical Device Turnkey Project Consultant Presented by Operon Startegist, PuneDocumento10 pagineMedical Device Turnkey Project Consultant Presented by Operon Startegist, PuneLili SopiandiNessuna valutazione finora

- Mechanical QA QC Course in Kerala - 100% PlacementDocumento9 pagineMechanical QA QC Course in Kerala - 100% Placementmohammadbinshad332Nessuna valutazione finora

- Assurance Brochure Assurance Services 01 2011Documento4 pagineAssurance Brochure Assurance Services 01 2011Poonam ChhabriaNessuna valutazione finora

- TIC BrochureDocumento28 pagineTIC BrochureSGS - Head of OperationsNessuna valutazione finora

- Salem CVDocumento6 pagineSalem CVburgeees kamranNessuna valutazione finora

- TOTAL QUALITY MANAGMENT IN OIL AND GAS SECTOR (A Research)Documento20 pagineTOTAL QUALITY MANAGMENT IN OIL AND GAS SECTOR (A Research)Shaaf Amjad100% (2)

- PetroMaster Company Profile1 Last VesrionDocumento37 paginePetroMaster Company Profile1 Last VesrionOwais MalikNessuna valutazione finora

- Syed Shiraz Ali Resume SummaryDocumento4 pagineSyed Shiraz Ali Resume SummarySyed Shiraz Ali100% (1)

- Project Quality Plan (8.7.2012)Documento27 pagineProject Quality Plan (8.7.2012)Vinodh Palanichamy75% (4)

- Fire Protection Testing InspectionDocumento5 pagineFire Protection Testing InspectionAhmed ElsayedNessuna valutazione finora

- NonDocumento14 pagineNonShahbaz KhanNessuna valutazione finora

- Integrated Inspection ServicesDocumento10 pagineIntegrated Inspection ServicesKhurram S. MuzammilNessuna valutazione finora

- Non-Destructive Testing - NDT - TWIDocumento2 pagineNon-Destructive Testing - NDT - TWIRodolfoMarínNessuna valutazione finora

- Servicios de ApplusDocumento13 pagineServicios de ApplusDERLY ROBINSON TORRES BARRERONessuna valutazione finora

- Inspection, Expediting, Training, Aws Cwi, NDT, Isondt, API, Profile, DashinspectorateDocumento22 pagineInspection, Expediting, Training, Aws Cwi, NDT, Isondt, API, Profile, DashinspectoratedashNessuna valutazione finora

- Company ProfileDocumento16 pagineCompany ProfileDendukuri varmaNessuna valutazione finora

- Trimurtulu. Pedasingu: Assurance & Control With An Organisation of High Repute in Oil & Gas IndustryDocumento4 pagineTrimurtulu. Pedasingu: Assurance & Control With An Organisation of High Repute in Oil & Gas IndustrySài TejaNessuna valutazione finora

- Brochure AftermarketDocumento4 pagineBrochure AftermarketlatasharmaNessuna valutazione finora

- Asif Muhammad (QC Lead Engineer)Documento5 pagineAsif Muhammad (QC Lead Engineer)Hello GuysNessuna valutazione finora

- NDTDocumento9 pagineNDTrajbubl23Nessuna valutazione finora

- Job Descriptions QDocumento18 pagineJob Descriptions QyespepeNessuna valutazione finora

- Fundamental of Quality Assurance (Upload)Documento15 pagineFundamental of Quality Assurance (Upload)Shafiq IbrahimNessuna valutazione finora

- Third-Party Quality Inspections: How Onsite Agency Support Helps Companies Meet StandardsDocumento3 pagineThird-Party Quality Inspections: How Onsite Agency Support Helps Companies Meet Standardszayarmyint_uNessuna valutazione finora

- Trimax Company ProfileDocumento8 pagineTrimax Company Profilerajeshjoel26Nessuna valutazione finora

- Pipeline BrochureDocumento8 paginePipeline BrochureThana_MNessuna valutazione finora

- FDA-compliant Validation of Medtech Implants and Devices: Installation Qualification (Iq)Documento2 pagineFDA-compliant Validation of Medtech Implants and Devices: Installation Qualification (Iq)Junaid AkhtarNessuna valutazione finora

- TO: Saudi Embassy Islamabad, PakistanDocumento3 pagineTO: Saudi Embassy Islamabad, PakistanVIVEKNessuna valutazione finora

- PAK INSPEC TPI Leading NDT and Inspection ServicesDocumento5 paginePAK INSPEC TPI Leading NDT and Inspection ServicesMuzamal HussainNessuna valutazione finora

- Alhoty Pre QualificationDocumento91 pagineAlhoty Pre QualificationSridhar ShankarNessuna valutazione finora

- Oil Gas Services TUV RheinlandDocumento2 pagineOil Gas Services TUV RheinlandUppiliappan GopalanNessuna valutazione finora

- FIRST Inspection ProfileDocumento1 paginaFIRST Inspection ProfileAhmed ElsayedNessuna valutazione finora

- Testing BrochureDocumento7 pagineTesting BrochurejenadebisankarNessuna valutazione finora

- Technical Services Brochure - 2010Documento54 pagineTechnical Services Brochure - 2010Ahmed El-ShafeiNessuna valutazione finora

- SurveyDocumento4 pagineSurveyInas BawareshNessuna valutazione finora

- Pas43 Safe Working of Vehicle Breakdown Recovery and Removal Operations - FactsheetDocumento2 paginePas43 Safe Working of Vehicle Breakdown Recovery and Removal Operations - Factsheetguest99Nessuna valutazione finora

- Emil VELCEAMobile: +40 745 518 933E-mail: emil.velcea@bsoc.euBlack Sea Offshore Centre SRLStr. Iuliu Maniu Nr. 6 Constanta 900740, Romaniawww.bsoc.euDocumento14 pagineEmil VELCEAMobile: +40 745 518 933E-mail: emil.velcea@bsoc.euBlack Sea Offshore Centre SRLStr. Iuliu Maniu Nr. 6 Constanta 900740, Romaniawww.bsoc.euDragos NeaguNessuna valutazione finora

- Curriculum Vitae Of: Correspondence/Permanent Address: EmailDocumento19 pagineCurriculum Vitae Of: Correspondence/Permanent Address: EmailsojeckNessuna valutazione finora

- QC Systems PDFDocumento48 pagineQC Systems PDFSidi100% (1)

- JD - 3201 Quality Assurance System Maintenance EngineerDocumento1 paginaJD - 3201 Quality Assurance System Maintenance EngineerSai AshzwathNessuna valutazione finora

- BV Inspection+GuideDocumento16 pagineBV Inspection+GuidesuhailpmNessuna valutazione finora

- Quality Assurance and Auditing in Shipbuilding: European, Japanese and Indian Welding ProcessesDocumento13 pagineQuality Assurance and Auditing in Shipbuilding: European, Japanese and Indian Welding ProcessesDarshanNessuna valutazione finora

- GazNeft Morgan FZE PDFDocumento15 pagineGazNeft Morgan FZE PDFKashif AslamNessuna valutazione finora

- Value Plastics Quality Policy ManualDocumento39 pagineValue Plastics Quality Policy ManualLoveNessuna valutazione finora

- Asphalt Testing EquipmentDocumento104 pagineAsphalt Testing EquipmentCooper TechnologyNessuna valutazione finora

- Api, Qa, QC, Welding, Painting, NDT InspectorDocumento7 pagineApi, Qa, QC, Welding, Painting, NDT InspectorBalaji ViswanathanNessuna valutazione finora

- Company Profile (QNDE)Documento9 pagineCompany Profile (QNDE)Muhammad UmairNessuna valutazione finora

- A Study of the Supply Chain and Financial Parameters of a Small BusinessDa EverandA Study of the Supply Chain and Financial Parameters of a Small BusinessNessuna valutazione finora

- Post Weld Heat TreatmentDocumento2 paginePost Weld Heat TreatmentgullenariNessuna valutazione finora

- Translation Basic English Grammar Book 1Documento13 pagineTranslation Basic English Grammar Book 1Sami MegherbiNessuna valutazione finora

- Forklift Inspection Check SheetDocumento2 pagineForklift Inspection Check SheetAhmed SaadNessuna valutazione finora

- Epoxy Coating System for Damp Steel SurfacesDocumento1 paginaEpoxy Coating System for Damp Steel SurfacesAhmed SaadNessuna valutazione finora

- MantisDocumento2 pagineMantisMuhammad AkramNessuna valutazione finora

- FINAL 235803 Veo Brochure Issue3 April2018 V6 Sep Pages 1Documento6 pagineFINAL 235803 Veo Brochure Issue3 April2018 V6 Sep Pages 1Ahmed SaadNessuna valutazione finora

- CH11Documento3 pagineCH11Ahmed SaadNessuna valutazione finora

- FINAL 236146 Prisma Brochure - 8pp A4 V3 1Documento8 pagineFINAL 236146 Prisma Brochure - 8pp A4 V3 1Ahmed SaadNessuna valutazione finora

- 1490Documento8 pagine1490Ahmed SaadNessuna valutazione finora

- CH23Documento30 pagineCH23Ahmed SaadNessuna valutazione finora

- CH33Documento38 pagineCH33Ahmed SaadNessuna valutazione finora

- 19680NASAUTDocumento260 pagine19680NASAUTAhmed SaadNessuna valutazione finora

- Sigma Marine CoatingsDocumento417 pagineSigma Marine CoatingsAhmed Saad80% (5)

- Material ConversionDocumento12 pagineMaterial ConversionAhmed SaadNessuna valutazione finora

- DIN 17175-79 Seamless Steel Tubes Chemical CompositionsDocumento0 pagineDIN 17175-79 Seamless Steel Tubes Chemical CompositionsAhmed SaadNessuna valutazione finora

- 0100 Sigmazam ReducerDocumento2 pagine0100 Sigmazam ReducerAhmed SaadNessuna valutazione finora

- LOLERDocumento71 pagineLOLERErcan AkkayaNessuna valutazione finora

- Intro To Basic UTDocumento41 pagineIntro To Basic UTgirish310100% (1)

- Aws 2008Documento38 pagineAws 2008Nani Nani's75% (4)

- Coating ThicknessDocumento5 pagineCoating ThicknessAhmed SaadNessuna valutazione finora

- L 22Documento87 pagineL 22Ahmed SaadNessuna valutazione finora

- USFD ManualDocumento120 pagineUSFD Manualsuneelvaram100% (3)

- Equivalent ASTM MaterialDocumento34 pagineEquivalent ASTM Materialgolf0910251891% (45)

- Buk2014 Full Web 178Documento1 paginaBuk2014 Full Web 178Ahmed SaadNessuna valutazione finora

- Lubeoil ManualDocumento255 pagineLubeoil ManualArumugam Ramalingam100% (1)

- Master Scan Series350Documento4 pagineMaster Scan Series350Ahmed SaadNessuna valutazione finora

- Inspections Using NA CodesDocumento7 pagineInspections Using NA Codeslguevara54Nessuna valutazione finora

- Install Acrobat Reader to View DocumentsDocumento1 paginaInstall Acrobat Reader to View DocumentsAhmed SaadNessuna valutazione finora

- Inspections Using NA CodesDocumento7 pagineInspections Using NA Codeslguevara54Nessuna valutazione finora

- Basic Five Creative ArtsDocumento4 pagineBasic Five Creative Artsprincedonkor177Nessuna valutazione finora

- Quiz-Travel - Beginner (A1)Documento4 pagineQuiz-Travel - Beginner (A1)Carlos Alberto Rodriguez LazoNessuna valutazione finora

- Vidura College Marketing AnalysisDocumento24 pagineVidura College Marketing Analysiskingcoconut kingcoconutNessuna valutazione finora

- Huawei WCDMA Primary Scrambling Code PlanningDocumento22 pagineHuawei WCDMA Primary Scrambling Code PlanningZeljko Vrankovic90% (31)

- Environmental Technology Syllabus-2019Documento2 pagineEnvironmental Technology Syllabus-2019Kxsns sjidNessuna valutazione finora

- Finance at Iim Kashipur: Group 9Documento8 pagineFinance at Iim Kashipur: Group 9Rajat SinghNessuna valutazione finora

- Cells in The Urine SedimentDocumento3 pagineCells in The Urine SedimentTaufan LutfiNessuna valutazione finora

- EE290 Practice 3Documento4 pagineEE290 Practice 3olgaNessuna valutazione finora

- sl2018 667 PDFDocumento8 paginesl2018 667 PDFGaurav MaithilNessuna valutazione finora

- Sekolah Menengah Kebangsaan Ss17 JALAN SS17/1, Subang Jaya English Scheme of Work Form 3Documento11 pagineSekolah Menengah Kebangsaan Ss17 JALAN SS17/1, Subang Jaya English Scheme of Work Form 3Rohana YahyaNessuna valutazione finora

- Trading Course DetailsDocumento9 pagineTrading Course DetailsAnonymous O6q0dCOW6Nessuna valutazione finora

- Capacity PlanningDocumento19 pagineCapacity PlanningfarjadarshadNessuna valutazione finora

- Arduino Guide using MPU-6050 and nRF24L01Documento29 pagineArduino Guide using MPU-6050 and nRF24L01usmanNessuna valutazione finora

- SWOT Analysis of Solar Energy in India: Abdul Khader.J Mohamed Idris.PDocumento4 pagineSWOT Analysis of Solar Energy in India: Abdul Khader.J Mohamed Idris.PSuhas VaishnavNessuna valutazione finora

- Mythi From AndromedaDocumento383 pagineMythi From AndromedaRico MinnerNessuna valutazione finora

- THE PEOPLE OF FARSCAPEDocumento29 pagineTHE PEOPLE OF FARSCAPEedemaitreNessuna valutazione finora

- Chicago Electric Inverter Plasma Cutter - 35A Model 45949Documento12 pagineChicago Electric Inverter Plasma Cutter - 35A Model 45949trollforgeNessuna valutazione finora

- Sieve Shaker: Instruction ManualDocumento4 pagineSieve Shaker: Instruction ManualinstrutechNessuna valutazione finora

- Urodynamics Griffiths ICS 2014Documento198 pagineUrodynamics Griffiths ICS 2014nadalNessuna valutazione finora

- Modern Indian HistoryDocumento146 pagineModern Indian HistoryJohn BoscoNessuna valutazione finora

- Variable Speed Pump Efficiency Calculation For Fluid Flow Systems With and Without Static HeadDocumento10 pagineVariable Speed Pump Efficiency Calculation For Fluid Flow Systems With and Without Static HeadVũ Tuệ MinhNessuna valutazione finora

- Furnace ITV Color Camera: Series FK-CF-3712Documento2 pagineFurnace ITV Color Camera: Series FK-CF-3712Italo Rodrigues100% (1)

- Gi 007 Gerund InfinitiveDocumento2 pagineGi 007 Gerund Infinitiveprince husainNessuna valutazione finora

- Supplier GPO Q TM 0001 02 SPDCR TemplateDocumento6 pagineSupplier GPO Q TM 0001 02 SPDCR TemplateMahe RonaldoNessuna valutazione finora

- Judge Vest Printable PatternDocumento24 pagineJudge Vest Printable PatternMomNessuna valutazione finora

- Biomotor Development For Speed-Power Athletes: Mike Young, PHD Whitecaps FC - Vancouver, BC Athletic Lab - Cary, NCDocumento125 pagineBiomotor Development For Speed-Power Athletes: Mike Young, PHD Whitecaps FC - Vancouver, BC Athletic Lab - Cary, NCAlpesh Jadhav100% (1)

- SYNOPSIS - Impact of GST On Small Traders!Documento21 pagineSYNOPSIS - Impact of GST On Small Traders!Laxmi PriyaNessuna valutazione finora

- CGV 18cs67 Lab ManualDocumento45 pagineCGV 18cs67 Lab ManualNagamani DNessuna valutazione finora

- Weekly Choice - Section B - February 16, 2012Documento10 pagineWeekly Choice - Section B - February 16, 2012Baragrey DaveNessuna valutazione finora

- Diemberger CV 2015Documento6 pagineDiemberger CV 2015TimNessuna valutazione finora