Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Smart Dust

Caricato da

archanadevivemulaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Smart Dust

Caricato da

archanadevivemulaCopyright:

Formati disponibili

SMART DUST A SEMINAR REPORT Submitted by ROHIT KUMAR in partial fulfillment of the award of the degree of BACHELOR OF TECHNOLOGY

in COMPUTER SCIENCE AND ENGINEERING SCHOOL OF ENGINEERING COCHIN UNIVERSITY OF SCIENCE & TECHNOLOGY, KOCHI-682022 AUGUST 2008

DIVISION OF COMPUTER SCIENCE & ENGINEERING SCHOOL OF ENGINEERING COCHIN UNIVERSITY OF SCIENCE & TECHNOLOGY KOCHI-682022 C e r t i f i c a t e Cerified that this is a bonafide record of seminar entitled SMART DUST done by the following student ROHIT KUMAR of the viith semester,Computer Science and Eengineering in the year 2008 in partial fulfillment of the requirements to the award of Degree of Bachelor of Technology in Computer Science and Engineering of Cochin University of Science and Technology. Mrs. Laya Simpson Dr. David Peter S SEMINAR GUIDE Head of the Department Date:

ACKNOWLEDGEMENT I thank my seminar guide Mrs. Laya Simpson, Lecturer, CUSAT, for her proper guidance, and valuable suggestions. I am indebted to Mr. David Peter, the HOD, Computer Science division & other faculty members for giving me an opportunity to learn and present the seminar. If not for the above mentioned peo ple my seminar would never have been completed successfully. I once again extend my sincere thanks to all of them. Rohit kumar

ABSTRACT Advances in hardware technology have enabled very compact, autonomous and mobile nodes each having one or more sensors, computation and communication capabilities, and a power supply. The Smart Dust project is exploring whether an autonomous sensing, computing, and communication system can be packed into a cubic millimeter mote to form the basis of integrated massively distributed sens or networks. It focuses on reduction of power consumption, size and cost. To build these small sensors, processors, communication devices, and power supply, designers have used the MEMS (Micro electro mechanical Systems) technology. Smart Dust nodes otherwise known as sand and each mote consists of: motes are usually of the Size of a grain of

1. Sensors 2. Transmitter &receiver enabling bidirectional wireless communication. 3. Processor sand control circuitry 4. Power supply unit Using smart dust nodes, the energy to acquire and process a sample and then transmit some data about it could be as small as a few nano Joules. These dust motes enable a lot of applications, because at these small dimensions, these can be scattered from aircraft for battle field monitoring or can be stirred int o house paint to create the ultimate home sensor network.

TABLE OF CONTENTS CHAPTER NO. TITLE PAGE NO 1 2 3 4 ABSTRACT iii LIST OF FIGURES v LIST OF SYMBOLS vi INTRODUCTION 1

5. THE MEMS TECHNOLOGY IN SMART DUST 2 6. SMART DUST TECHNOLOGY 5 7. OPERATION OF THE MOTE 6 8. COMMUNICATING WITH SMART DUST 8 9. OPTICAL COMMUNICATION 10 10. ACTIVE OPTICAL TRANSMITTERS 14 11. LISTENING TO A DUST FIELD 15 12. CORE FUNCTIONALITY SPECIFICATION 17 13. MAJOR CHALLENGES 22 14. APPLICATIONS 23 15. HOW GAR THEY HAVE BEEN IMPLEMENTED 24 16. SUMMARY 25 17. REFRENCE 26

LIST OF FIGURES SI NO IMAGES PAGE NO 2 STRUCTURAL COMPONENTS OF THE SMART DUST MOTE 4 6 ACTIVE STERED LASER 12 7 FREE SPACE OPTICAL NETWORK 13 9 IMAGING RECEIVER 16 10 TOP LEVEL DIAGRAM OF THE MOTE AND ARCITECTURE 18 10 TIMER AND ASSOCIATED MEMORIES 19 10 FUNCTIONAL BLOCKS 20

List of Symbols, Abbreviations and Nomenclature SI. NO. ITEM DEFINITION 1 MEMS Micro-Electo-Mechanical Systems 2 IC Integrated Circuit 3 SRAM Static Random Acess Memory 4 CCR Corner Cube Retroreflector 5 SDMA Space Division Multiple Acess 6 CDMA Code division Multiple Acess

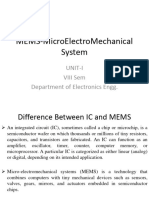

Smart Dust INTRODUCTION The current ultramodern technologies are focusing on automation and miniaturization. The decreasing computing device size, increased connectivity an d enhanced interaction with the physical world have characterized computing's hist ory. Recently, the popularity of small computing devices, such as hand held computers and cell phones; rapidly flourishing internet group and the diminishing size and cos t of sensors and especially transistors have accelerated these strengths. The emergen ce of small computing elements, with sporadic connectivity and increased interaction w ith the environment, provides enriched opportunities to reshape interactions between peo ple and computers and spur ubiquitous computing researches. Smart dust is a tiny dust size device with extra-ordinary capabilities. Smart d ust combines sensing, computing, wireless communication capabilities and autonomous power supply within volume of only few millimeters and that too at low cost. The se devices are proposed to be so small and light in weight that they can remain sus pended in the environment like an ordinary dust particle. These properties of Smart Dust w ill render it useful in monitoring real world phenomenon without disturbing the original pr ocess to an observable extends. Presently the achievable size of Smart Dust is about 5mm cube, but we hope that it will eventually be as small as a speck of dust. Individual s ensors of smart dust are often referred to as motes because of their small size. These dev ices are also known as MEMS, which stands for micro electro-mechanical sensors. Division of Computer Engineering

Smart Dust THE MEMS TECHNOLOGY IN SMART DUST Smart dust requires mainly revolutionary advances in miniaturization, integratio n and energy management. Hence designers haves used MEMS technology to build small sensors, optical communication components and power supplies. Micro electromecha nical systems consist of extremely tiny mechanical elements, often integrated together with electronic circuitory. They are measured of micrometers, that is, millions of a meter. They are made in a similar fashion as computer chips. The advantage of this manufacturing process is not simply that a small structure can be achieved but a lso that thousands or even millions of system elements can be fabricated simultaneously. This allows systems to be both highly complex and extremely low- cost Micro-Electro-Mechanical Systems (MEMS) is the integration of mechanical elements, sensors, actuators and electronics on a common silicon substrate throu gh micro fabrication technology. While the electronics are fabricated using integrated ci rcuit (IC) process sequences (e.g. CMOS, Bipolar processes) the micromechanical components are fabricated using compatible micromachining processes that selectively etch away pa rts of the silicon wafer or add new structural layers to form the mechanical and electromechanical devices. MEMS realizes a complete system on chip technology. Microelectronic integrated circuits can be thought of as the brains of a system and allows Microsystems to sense and control the environment. Sensors gather information from the environment through measuring mechanical, thermal, biologic al, chemical, optical and magnetic phenomena. The electronics then process the infor mation derived from the sensors and through some decision making capability direct the actuators to respond by moving, positioning, regulating, and filtering, thereby controlling the environment for some desired purpose. Because MEMS devices are manufactured using batch fabrication techniques similar to those use for integrated circuits, unprecedented levels of functionality, reliability, add sophistication can be pl aced on a small silicon chip relatively low cost. The deep insight of MEMS is as a new Division of Computer Engineering

Smart Dust manufacturing technology, a way of making complex electromechanical systems usin g batch fabrication techniques similar to those used for integrated circuits, and uniting these electromechanical elements together with electronics. Historically, sensors and actuators are the most costly and unreliable parts of a sensor-actuator-electronics system s. MEMS technology allows a these complex electromechanical systems to be manufactured u sing batch fabrication techniques, increasing the reliability of the sensors and actu ators to equal that of integrated circuits. The performance of MEMS devices and systems i s expected to be a superior to macro scale components and systems, the price is pr edicted to be much lower. Division of Computer Engineering

Smart Dust

Figure 1: Structural Components of the Smart Dust Mote Division of Computer Engineering

Smart Dust SMART DUST TECHNOLOGY Integrated into a single package are: 1. MEMS sensors 2. MEMS beam steering mirror for active optical transmission 3. MEMS corner cube retroreflector for passive optical transmission 4. An optical receiver 5. Signal processing and control circuitory 6. A power source based on thick film batteries and solar cells This remarkable package has the ability to sense and communicate and is self powered. A major challenge is to incorporate all theses functions while maintain ing very low power consumption. Sensors collect information from the environment such as light, sound, temperature, chemical composition etc Smart dust employs 2 types of transmission schemes: passive transmission using corner cube retroreflector to transmit to base station and active transmission using a laser diode and steerable mirrors for mote to mote communication. The photo diode allows optical data reception. Signal processing and control circuitory consists of analog I/O, DSPs to control and process the incoming data The power system consists of a thick film battery, a solar cell with a charge integrating capacitor for a period of darkness. Division of Computer Engineering

Smart Dust OPERATION OF THE MOTE The Smart dust mote is run by a micro controller that is not only determines the tasks performed by the mote, but controls power to the various components of the system to conserve energy. Periodically the microcontroller gets a reading from one of the sensors, which measure one of a number of physical or chemical stimuli such as temperature, ambient light, vibration, acceleration, or air pressure, processes the data and stores it in memory. It also occasionally turns on the optical receiver to see i f anyone is trying to communicate wit it. This communication may include new programs or messages from other motes. In response to a message or upon its own initiative t he microcontroller will use the corner cube retroreflector or laser to transmit sen sor data or a message to the base station or another mote. The primary constraint in the design of the Smart Dust motes is volume, which in turn puts a severe constrain on energy since we do not have much room for batter ies or large solar cells. Thus, the motes must operate efficiently and conserve energy whenever possible. Most of the time, the majority of the mote is powered off with only a clock and few timers running. When a timer expires, it powers up a part of the mote to car ry out a job, then powers off. A few of the timers control the sensors that measure one o f the many physical or chemical stimuli such as temperature, ambient light, vibration, acceleration, or air pressure. When one of these timers expires, it powers up th e corresponding sensors, take a sample, and converts in to a digital word. If the data is interesting, it may either be stored directly in the SRAM or the microcontroller is powered up to perform more complex operations with it. When this task is complet e, everything is again powered down and the timer begins counting again. Another timer controls the receiver. When that timer expires, the receiver power s up and look for an incoming packet. If it doesn t see one after a certain length o f time, it is powered down again. The mote can receive several types of packets, including ones that are new program code that is stored in the program memory. This allows the user to change the behavior of the remotely. Packets may also include messages from the base

Division of Computer Engineering

Smart Dust station or other motes. When one of these is received, the micro controller is p owered up and is used to interpret the contents of the message. The message may tell the m ote to do something in particular, or it may be a message that is just being passed from o ne mote to another on its way to a particular destination. In response to a message or to a nother timer expiring, the microcontroller will assemble a packet containing a sensor data or a message and transmit it using either the corner cube retroreflector or the laser diode, depending on which it has. The laser diode contains the onboard laser which send s signals to base station by blinking on and off. The corner cube retroreflector t ransmits information just by moving a mirror and this changing the reflection of a laser beam from the base station. This technique is substantially more energy efficient than actually generation radiation. With the laser diode and a set of beam scanning mirrors, we can trans mit data in any direction desired, allowing the mote to communicate with other Smart dust motes. Division of Computer Engineering

Smart Dust COMMUNICATING WITH A SMART DUST COMMUNICATING FROM A GRAIN OF SAND Smart Dust s full potential can only be attained when the sensor nodes communicate with one another or with a central base station. Wireless communicat ion facilities simultaneous data collection from thousands of sensors. There are sev eral options for communicating to and from a cubic millimeter computer. Radio-frequency and optical communications each have their strengths and weakness. Radio-frequency communication is well understood, but currently requir es minimum power levels in the multiple milliwatt range due to analog mixers, filte rs, and oscillators. If the whisker-thin antennas of centimeter length can be accepted a s a part of a dust mote, then reasonably efficient antennas can be made for radio-frequency communication. While the smallest complete radios are still on the order of a fe w hundred cubic millimeters, there is active work in the industry to produce cubic millimeter radios. Moreover RF techniques cannot be used because of the following disadvantages: 1. Dust motes offer limited space for antennas, thereby demanding extremely short wavelength (high frequency transmission). Communication in this regime is not currently compatible with low power operation of the smart dust. 2. Furthermore radio transceivers are relatively complex circuits making it difficu lt to reduce their power consumption to required microwatt levels. 3. They require modulation, band pass filtering and demodulation circuitory. So an attractive alternative is to employ free space optical transmission. Studi es have shown when a line of sight path is available, well defined free space optical li nks require significantly lower energy per bit than their RF counterparts. Division of Computer Engineering

Smart Dust There are several reasons for power advantage of optical links: 1. Optical transceivers require only a simple base band analog and digital circuito ry 2. No modulators, active band pass filters or demodulators are needed. 3. The short wavelength of visible or near infra red light (of the order of 1 micro n) makes it possible for a millimeter scale device to emit a narrow beam (ie, high antenna gain can be achieved). As another consequence of this short wavelength, a Base Station Transceiver (BTS ) equipped with a compact imaging receiver can decode the simultaneous transmissio ns from a large number of dust motes from different locations within the receiver f ield of view, which is a form of space division multiplexing. Successful decoding of the se simultaneous transmissions requires that dust motes not block one another s line o f sight to the BTS. Such blockage is unlikely in view of the dust mote s small size. Semiconductors lasers and diode receivers are intrinsically small, and the corresponding transmission and detection circuitory for on/off keyed optical communication is more amenable to low-power operation than most radio schema. Perhaps most important, optical power can be collimated in a tight beam even fro m small apertures. Diffraction enforces a fundamental limit on the divergence of a beam, whether it comes from an antenna or a lens. Laser pointers are cheap examp les of milliradian collimation from a millimeter aperture. To get similar collimatio n for a 1-GHz radio-frequency signal would require an antenna 100 meters across, due to the difference in wavelength of the two transmissions. As a result, optical transmit ters of millimeter size can get antenna gains of one million or more, while similarly si zed radio-frequency antennas are doomed by physics to be mostly isotropic. Collimated optical communicate on has two major drawbacks. Line of sight is required for all but the shortest distances, and narrow beans imply the need for accurate pointing. Of these, the pointing accuracy can be solved by MEMS technology and c lever algorithms, but an optical transmitter under a leaf or a shirt pocket is little use to anyone. We have chosen to explore optical communication in some depth due to the potenti al for

extreme low power consumption. Division of Computer Engineering

Smart Dust OPTICAL COMMUNICATIONS We have explored two approaches to optical communications: passive reflective systems and active steered laser systems. In a passive communication system, the dust mote does not require an onboard light source. Instead a special configuration o f mirrors can either reflect or not reflect light to a remote source. Passive reflective systems The passive reflective communication is obtained by a special device called CCR (Corner Cube Retroreflector) consist of three mutually orthogonal mirrors. Light enters the CCR, bounces off each of the three mirrors, and is reflected back parallel t o the direction it entered. In the MEMS version, the device has once mirror mounted on a spring at an angle slightly a skew from perpendicularity to the other mirrors. I t is in this position, because the light entering the CCR does not return along the same path , little light returns to the source-a digital 0. Applying voltage between this mirror an d an electrode beneath it causes the mirror to shift to a position perpendicular to o ther mirrors, thus causing the light entering CCR to return to its source-a digital 1. The mir rors low mass allows the CCR to switch between these two states up to a thousands times p er second, using a less than a nano joule per 01 transition. A 1 0 transition, on the other hand, is practically free because dumping the charge stored on the electrode to the ground requires almost no energy. Our latest Smart dust is a 63-mm 3 autonomous bidirec tional communication mote that receives an optical signal, generates a pseudorandom seq uence based on this signal to emulate sensor data, and then optically transmits the re sult. The system contains a micromachined corner-cube reflector, a 0.078 mm3 CMOS chip tha t draws 17 microwatts, and a hearing aid battery. In addition to a battery based o peration, we have also powered the device using a 2 mm2 solar cell. This mote demonstrates Smart dusts essential concepts, such as optical data transmission, data processing, en ergy management, miniaturization, and system integration. Division of Computer Engineering

Smart Dust A passive communication system suffers several limitations. Unable to communicate with each other, motes rely on a central station equipped with a lig ht source to send and receive data from other motes. If a given mote does not have a clear line of sight to the central station, that mote will be isolated from the network. Also, because the CCR reflects only a small fraction of the light emitted from the base station, t hus system s range cannot easily extend beyond 1 kilometer. To circumvent these limita tions, dust motes must be active and have their own onboard light source. Active- steered laser systems For mote to mote communication, an active steered laser communication system use s an onboard light source to send a tightly collimated light beam towards an intended receiver. Steered laser communication has the advantage of high power density; for example , a 1milliwaat laser radiating into 1 milliradian (3.4 arc seconds) has a density of approximately 318 kilowatts per steradian (there are 4 . steradian in a sphere), as opposed to a 100-watt light bulb that radiates 8 watts per steradian isotropical ly. A Smart Dust mote s, emitted beam would have a divergence of approximately 1 milliradian, permitting communication over enormous distances using milliwatt of power. Each mote must carefully weigh the needs to sense, compute, communicate, and evaluate its energy reserve status before allocating precious nanojoules of energy to turn on its tr ansmitter or receiver. Because theses motes spend most of their time sleeping, with their rec eiver turned off, scheduling a common awake time across the network is difficult. If m otes don t wake up in a synchronized manner, a highly dynamic network topology and larg e packet latency results. Using burst mode communication, in which the laser opera tes at up to several tens of megabits per second for a few milliseconds, provides the m ost energy-efficient way to schedule this network. This procedure minimizes the mote s duty cycle and better utilizes its energy reserves. The steered agile laser transmitt er consists of a semiconductor diode laser coupled with a collimating lens and MEMS bean steeri ng optics based on a two degree of freedom silicon micro mirror. This system integr ates all optical components into an active 8 mm3 volume as the figure shows. Division of Computer Engineering

Smart Dust

CORNER CUBE RETROREFLECTOR These MEMS structure makes it possible for dust motes to use passive optical transmission techniques i.e., to transmit modulated optical signals without supp lying any optical power. It comprises of three mutually perpendicular mirrors of gold-coat ed polysilicon. The CCR has the property that any incident ray of light is reflecte d back to the source (provided that it is incident within a certain range of angles center ed about the cube s body diagonal). If one of the mirrors is misaligned, this retroreflector pr operty is spoiled. The micro fabricated CCR contains an electrostatic actuator that can de flect one of the mirrors at kilohertz rate. It has been demonstrated that a CCR illuminati on by an external light source can transmit back a modulated signal at kilobits per secon d. Since the dust mote itself does not emit light, passive transmitter consumes little po wer. Using micro fabricated CCR, data transmission at a bit rate upto 1 kilobit per second and upto a range of 150 meters, using a 5 milliwatt illuminating a laser is possible. It should be emphasized that CCR based passive optical links require an uninterrupted line of sight. The CCR based transmitter is highly directional. A CCR can transmit to the BTS only when the CCR body diagonal happens to point directly to wards the BTS, within a few tens of degrees. A passive transmitter can be made more om ni directional by employing several CCRs, oriented in different directions, at the expense of increased dust mote size. Division of Computer Engineering

Smart Dust

Figure 2:Free Space Optical Network The figure illustrates free space optical network utilizing the CCR based passiv e uplink. The BTS contains a laser whose beam illuminates an area containing dust motes. This beam can be modulated with downlink data including commands to wake up and query the dust motes. When the illuminating beam is not modulated, the dust mote s can use their CCRs to transmit uplink data back to the base station. A high frame ra te CCD video camera at the BTS sees the CCR signals as lights blinking on and off. It d ecodes these blinking images to yield the uplink data. Analysis shows that this uplink scheme achieves several kilobits per second over hundreds of meters in full sunlight. A t night, in clear, still air, the range should extend to several kilometers. Because the cam era uses an imaging process to separate the simultaneous transmissions from the dust motes a t different locations, we say it uses space division multiplexing . The ability for a video camera to resolve these transmissions is consequence of the short wavelength of visible or near infra red light. This does not require any coordination among the dust m otes. Division of Computer Engineering

Smart Dust ACTIVE OPTICAL TRANSMITTERS When the application requires dust motes to use active optical transmitters, MEMS technology can be used to assemble a semiconductor laser, a collimating len s and a beam steering micro mirror. Active transmitters make possible peer to peer communication between dust motes, provided there exists a line of path of sight between them. Power consumption imposes a trade off between bandwidth and range. The dus t motes can communicate over a long distances at low data rates or higher bit rate s over shorter distances. The relatively higher power consumption of semiconductor lase rs dictates that these active transmitters be used for short duration burst mode communication only. Sensor network using active dust mote transmitters will requ ire some protocol for dust motes to aim their beam towards the receiving parties. Division of Computer Engineering

Smart Dust LISTENING TO A DUST FIELD Many Smart Dust applications rely on direct optical communication from an entire field of dust motes to one or more base stations. These base stations mus t therefore be able to receive volume of simultaneous optical transmissions. Further, commun ication must be possible outdoors in bright sunlight which has an intensity of approxima tely 1 kilowatt per square meter, although the dust motes each transmit information wit h a few milliwatts of power. Using a narrow-band optical filter to eliminate all sunligh t expect the portion near the light frequency used for communication can partially solve this second problem, but the ambient optical power often remains much stronger than t he received signal power. Advantage of imaging receivers As with the transmitter, the short wavelength of optical transmission compared with radio frequency overcomes both challenges. Light from a large field of view field can be focused into a image, as in our eye or camera. Imaging receivers utilize this to analyze different portions of the image separately to process simultaneous trans missions from different angles. This method of distinguishing transmissions based on thei r originating location is referred to as space division multiple access (SDMA). In contrast, most radio-frequency antennas receive all incident radio power in a single signa l, which requires using additional tactics, such as frequency tuning or code division mul tiple access (CDMA), to separate simultaneous transmissions. Imaging receivers also offer the advantage of dramatically decreasing the ratio of ambient optical power to received signal power. Ideally, the imaging receiver wi ll focus all of the received power from a single transmission onto a single photo detecto r. If the receiver has an n n array pixels, then the ambient light that each pixel receive s is reduced by a factor n2 compared with a non imaging receiver Division of Computer Engineering

Smart Dust

Video camera A video camera is a straightforward implementation of an imaging receiver. If each member in a colony of Smart Dust motes flashes its own signal at a rate of a few bits per second, then each transmitter will appear in the video stream at a diff erent location in the image. Using a high speed camera and a dedicated digital signal processor to process the video signal achieves higher date rates. With modern cameras and DSPs, processing video about 1000 frames per second should be feasible. This would all ow communication at a few hundred bits per second, which is acceptable for many applications. Alternative receiver architecture provides a more elegant solution at much higher data rates, avoiding the need for computationally intensive video process ing and very high speed cameras. Integrating an imaging receiver onto a single microchip imposes severe constraints in silicon area and power consumption per pixel. Only recently have continuing reductions in transistors size allowed for sufficient r eductions in circuit are and power consumption to achieve this level of integration. Division of Computer Engineering

Smart Dust CORE FUNCTIONALITY SPECIFICATION Choose the case of military base monitoring where on the order of a thousand Sma rt Dust motes are deployed outside a base by a micro air vehicle to monitor vehicle move ment. The motes can be used to determine when vehicles are moving, what type of vehicl e it was, and possibly how fast it was traveling. The motes may contain sensors for v ibration, sound, light, IR, temperature, and magnetization. CCRs will be used for transmis sion, so communication will only be between a base station and the motes, not between mot es. A typical operation for this scenario would be to acquire data, store it for a day or two, then upload the data after being interrogated with a laser. However, to really see wh at functionality the architecture needed to provide and how much reconfigurability would be necessary, an exhaustive list of the potential activities in this scenario wa s made. The operations that the mote must perform can be broken down into two categories: th ose that provide an immediate action and those that reconfigure the mote to affect future behavior Proposed Architecture Looking through the functional specifications for the core, we realized that eac h operation is regulated by a timed event; hence a bank of timers forms the basis of the architecture. For minimum energy, a direct mapping of a particular function into hardware is generally best, but from the list of specifications it was clear tha t a certain amount of reconfigurability would be necessary. Thus, the timers enable setup me mories that configure functional blocks into data paths that provide only the capabilit ies necessary for that event. These paths are data-driven so that functional blocks are only powered up when their inputs are ready, minimizing standby power and glitching. A block diagram of this new architecture is shown in the figure Division of Computer Engineering

Smart Dust

The next figure details a section of the timer bank and setup memory. The timer is loaded from the timer value memory, setting its period. When the timer expire s, it enables setup memory 1, which configures the data path to perform the desired fu nction. When the data path has finished operation, setup memory1 will release its config uration and either the timer value can be loaded into the timer and the countdown restar ted or setup memory 2 can be enabled. Setup memory 2 will then configure the data path for another operation, thus fac ilitating multiple operations per timer event. Additional setup memory can be added for mo re involved sequence. Memory holds certain timer-independent configuration bits, su ch as timer enables. The sensors registers are used to store previous sensor readings to use in computing data changes. Various computation blocks can be included in the data p ath, such as an adder, comparator, and FFT unit. Division of Computer Engineering

Smart Dust

Multiple timer periods are desirable for several situations. For example, one mi ght want to sample a sensor at a slow rate until an interesting signal is detected. At th at point, the sampling rate should increase. In addition, the motes might be deployed without anyone coming back to talk to them for a day, so it would be desirable to be able to se t the receiver wake-up timer to not wake-up for 24 hours, but then it should decrease the period dramatically to 10 s seconds in case one doesn t make it back to talk to the mote at exactly the right time. The proposed architecture facilitates this by providing multiple timer values that can be loaded into the timer depending on the results of the d ata path computation. Another feature of this architecture is energy-driven operation modes. An energy monitoring unit selects between multiple banks of setup memory and timer values depending on the current level of the energy stores. Each bank can have differen t timer periods and algorithms to control energy expenditure. Two types of packets can b e sent to the mote, corresponding to the two types of operations. Immediate mode operation s use the packet body to configure the data path right away. Reconfiguration operation s load the packet body into the setup memory for future configuration. Division of Computer Engineering

Smart Dust The following figure shows the functional block included in the reconfigurable data path. For the communication back end, there is data recovery block, timing recovery block, FIR filter, packet encoder that does bits stuffing and adds the flag byte , packet decoder that does bit unstuffing, CRC block, and a FIFO. Incoming packets are st ored in the FIFO until the CRC can be verified, at which point the packet body will be u sed as described above. The global memory holds certain timer independent configuration bits, such as timer enables. The sensor registers are used to store previous sensor re adings to use in computing data changes. Various computation blocks can be included in the data path, such as an adder, comparator, and FFT unit. All of the functional units in the data path are data driven. The setup memory o nly powers up and enables the first set of units that are needed, such as sensor and ADC. Once theses units have done their job, they assert a done signal that is routed, based on the configuration memory, to the next unit, such as the adder, and powers it up and enables it. Likewise, when this unit has finished its job, it will power up and enable the next device in the chain. The last unit in the path will cause the timer to relo ad its value Division of Computer Engineering

Smart Dust and cause the setup memory to stop configuring the data path. The advantages of this data driven technique include minimizing the standby power by keeping components powe red down until exactly when they are needed, and ensuring that the inputs are stable before the next device is powered up, which minimizes glitches. It is significant to no te that since this architecture does not use shared busses as in traditional microcontro llers, the functional components can be configured for certain parallel operations. For exa mple, a sensor reading could be both stored in SRAM and transmitted wit the CCR, althoug h that is not necessarily a desirable capability. Division of Computer Engineering

Smart Dust MAJOR CHALLENGES 1. To incorporate all these functions while maintaining a low power consumption 2. Maximizing operating life given the limited volume of energy storage 3. The functionality can be achieved only if the total power consumption is limited to microwatts level 4. An unbroken line of sight of path should be available for free space optical lin ks. Division of Computer Engineering

Smart Dust APPLICATIONS 1. Civil and military application where chemical and biological agents in a battle field are detected. Smart dust can be used for monitoring activities in inaccess ible areas, accompany soldiers and alert them to any poisons or dangerous biological substances in the air. 2. Virtual keyboard: Glue a dust mote on each of your fingernails, accelerometers will sense the orientation and motion of each of your fingertips, and talk to th e computer in your watch. Combined with a MEMS augmented-reality heads-up display, your entire computer I/O would be invisible to the people around you. 3. Inventory Control Smart office spaces: The center for the built environment has fabulous plans for the offices of the future in which environmental conditions a re tailored to the desires of every individual. Maybe soon we ll all be wearing temperature, humidity, and environmental comfort sensors sewn into our clothes, continuously talking to our workspaces which will deliver conditions tailored to our needs. 4. Individual dust motes can be attached to the objects one wishes to monitor or a large number of dust motes may be dispersed in the environment randomly. 5. Dust motes may be used in places where wired sensors are unusable or may lead to errors. E.g. Instrumentation of semiconductor processing chambers, wind tunnels, rotating machinery etc. 6. May be used in biological research e.g.: to monitor movements and internal process of insects Division of Computer Engineering

Smart Dust HOW FAR THEY HAVE BEEN IMPLEMENTED 1. The optical receiver for the smart dust project is being developed. The receiver senses incoming laser transmission at up to 1 Mbits/s, for a power consumption o f 12 W. Although this is too high for continuous use in smart dust, it is reasonable figure for the download of small amounts of data such as 1 Kbit program. 2. For data transmission, the team is using corner cube retro-reflectors (CCRs) bui lt using MEMS techniques. CCRs are produced by placing three mirrors at right angles to each other to form the corner of a box that has been silvered inside. The key property of a CCR is that light entering is reflected back along the path it is entered on. For the smart dust system, the CCR is being built on a MEMS process with the two vertical sides being assembled by hand. When a light shone into the CCR, it reflects back to the sending position. By modulating the position of one of the mirrors, the reflected beam can be modulated, producing a low energy passive transmission. 3. The analog-digital converter (ADC) the 8 bit ADC has so far demonstrated with an input range of 1 V, equal to the power supply, and a 70 kHz sampling rate. Th e converter draws 1.8 W when sampling at that rate, or 27pJ for an 8 bit sample. 4. The latest smart dust mote, with a volume of just 16mm3, has been tested. It tak es samples from a photo-detector, transmits their values with the CCR and runs off solar cells. Division of Computer Engineering

Smart Dust SUMMARY Smart dust is made up of thousands of sand-grain-sized sensors that can measure ambient light and temperature. Each one of the sensors is called motes and they ha ve wireless communication devices attached to them and if you put a bunch of them n ear each other, they ll network themselves automatically. These sensors which would cost pennies each if mass-produced, could be plastered all over office building and homes. Each room in an office building mi ght have hundreds or even thousands light and temperature sensing motes, all of which wou ld tie into a central computer that regulates energy usage in the building. Taken together, the motes would constitute a huge sensor network of smart dust, a network that would give engineers insight into how energy is used and how it is conserved. In a dust-enabled building, computers would turn off lights and clima te control in empty rooms. During peak energy usage times, air conditioners that co ol servers, which drain a lot of tech world s power, would be automatically shut off, and then turned on if the server gets too hot. Thus it can very lead to world s energy conservation solutions. Division of Computer Engineering

Smart Dust REFERENCE 1. P.B. Chu, KSJ Pister- Optical communication using micro corner cube reflectors 10th IEEE Int l Workshop on Micro Electro Mechanical Systems 2. J. Kahn, R.H.Katz, KSJ Pister- Mobile Networking for Smart Dust 3. www.eecs.bekerly.com Division of Computer Engineering

Potrebbero piacerti anche

- Linearization and Efficiency Enhancement Techniques for Silicon Power Amplifiers: From RF to mmWDa EverandLinearization and Efficiency Enhancement Techniques for Silicon Power Amplifiers: From RF to mmWNessuna valutazione finora

- Smart Dust Technology Seminar ReportDocumento28 pagineSmart Dust Technology Seminar ReportBiswajit ParidaNessuna valutazione finora

- Digital Electronics, Computer Architecture and Microprocessor Design PrinciplesDa EverandDigital Electronics, Computer Architecture and Microprocessor Design PrinciplesNessuna valutazione finora

- ECE Smart Dust Report PDFDocumento36 pagineECE Smart Dust Report PDFDeepak DeepuNessuna valutazione finora

- What Is A Smart Dust?: Autonomous Sensing and Communication in A Cubic MillimeterDocumento32 pagineWhat Is A Smart Dust?: Autonomous Sensing and Communication in A Cubic MillimeterShruthi MudaliarNessuna valutazione finora

- Fundamentals of Electromigration-Aware Integrated Circuit DesignDa EverandFundamentals of Electromigration-Aware Integrated Circuit DesignNessuna valutazione finora

- What Is A Smart Dust?: Autonomous Sensing and Communication in A Cubic MillimeterDocumento33 pagineWhat Is A Smart Dust?: Autonomous Sensing and Communication in A Cubic MillimetertargetgateNessuna valutazione finora

- Embedded Deep Learning: Algorithms, Architectures and Circuits for Always-on Neural Network ProcessingDa EverandEmbedded Deep Learning: Algorithms, Architectures and Circuits for Always-on Neural Network ProcessingNessuna valutazione finora

- Smart Dust Technology Seminar ReportDocumento32 pagineSmart Dust Technology Seminar ReportSushan Upadhyay67% (3)

- Stretchable ElectronicsDa EverandStretchable ElectronicsTakao SomeyaNessuna valutazione finora

- What Is A Smart Dust?: Autonomous Sensing and Communication in A Cubic MillimeterDocumento31 pagineWhat Is A Smart Dust?: Autonomous Sensing and Communication in A Cubic MillimeterManjusha XalxoNessuna valutazione finora

- Mobile Processors: Seminar Report ONDocumento37 pagineMobile Processors: Seminar Report ONRohit SinghNessuna valutazione finora

- Smart Dust DocumentDocumento33 pagineSmart Dust DocumentGnan Chandu100% (1)

- Smart DustDocumento10 pagineSmart DustCherry CherryNessuna valutazione finora

- MEMS TechnologyDocumento22 pagineMEMS Technologyavishekghosh1985Nessuna valutazione finora

- JCGHVKL/JBKHJGHHDocumento34 pagineJCGHVKL/JBKHJGHHsonu sk100% (1)

- Final 2003Documento23 pagineFinal 2003api-3707156Nessuna valutazione finora

- Smart DustDocumento49 pagineSmart DustdhyankrishNessuna valutazione finora

- MEMS (Report)Documento48 pagineMEMS (Report)νιηαyαк нєgdє » Nαηdιкαl100% (6)

- Submitted By:saransh AgrawalDocumento20 pagineSubmitted By:saransh AgrawalSaransh AgrawalNessuna valutazione finora

- By A.Sravanthi 15271A05A7: Department of Computer Science and EngineeringDocumento21 pagineBy A.Sravanthi 15271A05A7: Department of Computer Science and EngineeringBHEEMREDDY VIVEKREDDYNessuna valutazione finora

- Smart DustDocumento31 pagineSmart DustUmamaheshwar ChNessuna valutazione finora

- Recent Trends and Advancements in The Field of Micro Electrical and Mechanical Systems (Mems) TechnologyDocumento10 pagineRecent Trends and Advancements in The Field of Micro Electrical and Mechanical Systems (Mems) TechnologyTJPRC PublicationsNessuna valutazione finora

- Smart Dust PDFDocumento25 pagineSmart Dust PDFEdwin VargheseNessuna valutazione finora

- The MICA2 Mote Uses 2 AA Batteries To Provide Power To The CPU/radio For Up To A YearDocumento17 pagineThe MICA2 Mote Uses 2 AA Batteries To Provide Power To The CPU/radio For Up To A Yearbalu54Nessuna valutazione finora

- M. Sahith Chandan Roll. No: 05P71A0438 B.TECH 4/4 E.C.E Ph. No: 9985066696Documento27 pagineM. Sahith Chandan Roll. No: 05P71A0438 B.TECH 4/4 E.C.E Ph. No: 9985066696D S RaoNessuna valutazione finora

- Applications of Mems in Robotics Using Psoc 5Documento5 pagineApplications of Mems in Robotics Using Psoc 5Sathisha BMNessuna valutazione finora

- Smart Dust Full ReportDocumento26 pagineSmart Dust Full ReportRavinder KumarNessuna valutazione finora

- Mems and Nanotechnology 2Documento12 pagineMems and Nanotechnology 2Sai Krishna100% (1)

- Smart Dust AbsDocumento8 pagineSmart Dust AbsSonia UpritNessuna valutazione finora

- Smart DustDocumento31 pagineSmart DustvaishaliNessuna valutazione finora

- Smart Dust: The Future of Communication and SecurityDocumento31 pagineSmart Dust: The Future of Communication and Securitystarssharath7397Nessuna valutazione finora

- Smart Dust: The Future of Communication and SecurityDocumento31 pagineSmart Dust: The Future of Communication and SecurityAmalla KuttyNessuna valutazione finora

- Sri Taralabalu Jagadguru Institute of Technology: Ranebennur-581115Documento12 pagineSri Taralabalu Jagadguru Institute of Technology: Ranebennur-581115Ejaz KNessuna valutazione finora

- Icro-Lectro - Echanical Ystems BY Veerabhadraswamy.N USN:4BD07ME114Documento29 pagineIcro-Lectro - Echanical Ystems BY Veerabhadraswamy.N USN:4BD07ME114Pradeep KumarNessuna valutazione finora

- Bapuji Institute of Engineering and Technology, DavangereDocumento14 pagineBapuji Institute of Engineering and Technology, DavangereMadan Tamraparni100% (1)

- MEMS Accelerometers-KoncnaDocumento17 pagineMEMS Accelerometers-KoncnaaryakushalNessuna valutazione finora

- Fmech 09 1142981Documento3 pagineFmech 09 1142981samirayasmin1117Nessuna valutazione finora

- Simulation and Analysis of MEMS Piezoresistive Pressure SensorDocumento62 pagineSimulation and Analysis of MEMS Piezoresistive Pressure SensorAravinda DevaramaneNessuna valutazione finora

- 2 Issue 3 2014Documento5 pagine2 Issue 3 2014vaishaliNessuna valutazione finora

- Prepared By: Kiran WaliaDocumento28 paginePrepared By: Kiran WaliaAdityaNessuna valutazione finora

- About Mems:: What Is MEMS Technology?Documento14 pagineAbout Mems:: What Is MEMS Technology?ashabiaNessuna valutazione finora

- The MICA2 Mote Uses 2 AA Batteries To Provide Power To The CPU/radio For Up To A YearDocumento17 pagineThe MICA2 Mote Uses 2 AA Batteries To Provide Power To The CPU/radio For Up To A YearHenry FordNessuna valutazione finora

- Fabrication, Sensing & Application of MEMS/NEMS Technology: I. BackgroundDocumento4 pagineFabrication, Sensing & Application of MEMS/NEMS Technology: I. BackgroundSanthosh Kumar ChittipoluNessuna valutazione finora

- 15ME745 Smart Materials Module 4Documento29 pagine15ME745 Smart Materials Module 4Yogananda Bangalore ShanthamurthyNessuna valutazione finora

- What Is MEMS TechnologyDocumento6 pagineWhat Is MEMS TechnologyMAHDILEE100% (2)

- SMARTDUSTDocumento4 pagineSMARTDUSTAastha SinghNessuna valutazione finora

- Report On Nems by G Somulu VNIT Nagpur Supervision of RM PatrikarDocumento46 pagineReport On Nems by G Somulu VNIT Nagpur Supervision of RM PatrikarvnitstudentNessuna valutazione finora

- Smart Dust Paper PresentationDocumento8 pagineSmart Dust Paper PresentationManjusha XalxoNessuna valutazione finora

- Smart DustDocumento9 pagineSmart DustAsaf HrelNessuna valutazione finora

- Minal Zia (Project Work # 5)Documento27 pagineMinal Zia (Project Work # 5)k shahNessuna valutazione finora

- Microsystems and Micro ElectronicsDocumento2 pagineMicrosystems and Micro Electronics2K19/CO/076 ARJUNessuna valutazione finora

- Smart Dust PPT ReportDocumento25 pagineSmart Dust PPT Reportsagar7wlNessuna valutazione finora

- SEMINAR ReportDocumento26 pagineSEMINAR ReportMadhura Medikeri0% (1)

- Mems Unit 1Documento48 pagineMems Unit 1CHETAN SETIYANessuna valutazione finora

- Ecsecuritybased-Safety Auto Brake System For Hill Station Vehicle Using Mems Sensor.Documento3 pagineEcsecuritybased-Safety Auto Brake System For Hill Station Vehicle Using Mems Sensor.kanchan bone100% (1)

- MicroDocumento17 pagineMicroShakeel EngyNessuna valutazione finora

- Smart Dust: Communicating With A Cubic-Millimeter ComputerDocumento36 pagineSmart Dust: Communicating With A Cubic-Millimeter ComputerKaustav BhattacharyaNessuna valutazione finora

- Spintronix: Spintronics or Spin-Based Electronics, Also KnownDocumento13 pagineSpintronix: Spintronics or Spin-Based Electronics, Also KnownAnkush KhereNessuna valutazione finora

- Revent Us 723 Hirez 1Documento2 pagineRevent Us 723 Hirez 1Umma NakhlunNessuna valutazione finora

- Physics of SoundDocumento33 paginePhysics of SoundijahsmkutNessuna valutazione finora

- Pollen and Spore Morphology, Plant Taxonomy - ErdtmanDocumento178 paginePollen and Spore Morphology, Plant Taxonomy - ErdtmanAndres Elgorriaga100% (1)

- A Review of Piezoelectric Energy Harvesting Based On VibrationDocumento13 pagineA Review of Piezoelectric Energy Harvesting Based On VibrationardnetirarhsimNessuna valutazione finora

- Grade 7 Mixtures and Solutions Full ReviewDocumento28 pagineGrade 7 Mixtures and Solutions Full Reviewblackcat657Nessuna valutazione finora

- Especificaciones Nivel PentaxDocumento2 pagineEspecificaciones Nivel PentaxVeronica SimonettiNessuna valutazione finora

- 171001Documento2 pagine171001vishalsanziraNessuna valutazione finora

- Hamerlug Unions (Anson)Documento15 pagineHamerlug Unions (Anson)Leonardo ViannaNessuna valutazione finora

- Some Aspects of Metallurgical Assessment of Boiler Tubes-Basic Principles and Case StudiesDocumento10 pagineSome Aspects of Metallurgical Assessment of Boiler Tubes-Basic Principles and Case StudiesmsdoharNessuna valutazione finora

- On A Stress Resultant Geometrically Exact Shell Model Part IDocumento38 pagineOn A Stress Resultant Geometrically Exact Shell Model Part IzojdbergNessuna valutazione finora

- Fesc 115Documento8 pagineFesc 115Sundeep GargNessuna valutazione finora

- 2013 Shear Strength of Brick Masonry Walls Assembled With Different Types of MortarDocumento8 pagine2013 Shear Strength of Brick Masonry Walls Assembled With Different Types of MortarCatherineNessuna valutazione finora

- Neon Genesis Evangelion ANIMA Vol. 4Documento262 pagineNeon Genesis Evangelion ANIMA Vol. 4jojo100% (2)

- Role of Physics in Daily LifeDocumento2 pagineRole of Physics in Daily LifeSadam MaharNessuna valutazione finora

- Biot-Savart's Law and Ampere's Law: R NQ N/amp/metre (D) R QDocumento24 pagineBiot-Savart's Law and Ampere's Law: R NQ N/amp/metre (D) R Qashok pradhanNessuna valutazione finora

- Ghaneeizad (2013)Documento25 pagineGhaneeizad (2013)alang_businessNessuna valutazione finora

- Engineering Material Specification: Approval From The Sheet Metal Tech ClubDocumento8 pagineEngineering Material Specification: Approval From The Sheet Metal Tech ClubaldairlopesNessuna valutazione finora

- Indoor Ballistic Test Ranges For Small Arms and Fragmentation Testing of Ballistic-Resistant ItemsDocumento4 pagineIndoor Ballistic Test Ranges For Small Arms and Fragmentation Testing of Ballistic-Resistant ItemsAlevj DbNessuna valutazione finora

- Unit 3 Moulding Processes: StructureDocumento18 pagineUnit 3 Moulding Processes: StructureChethan Madappady75% (4)

- Etoos Solid State PS SirDocumento27 pagineEtoos Solid State PS SirGyandeep KalitaNessuna valutazione finora

- Sean A. Hayward Et Al - Dilatonic Wormholes: Construction, Operation, Maintenance and Collapse To Black HolesDocumento9 pagineSean A. Hayward Et Al - Dilatonic Wormholes: Construction, Operation, Maintenance and Collapse To Black HolesDex30KMNessuna valutazione finora

- LG Lx-U250a Lxs-U250Documento55 pagineLG Lx-U250a Lxs-U250remanuel18Nessuna valutazione finora

- To Determine Resistance of A Galvanometer by Half-Deflection Method and To Find Its Figure of MeritDocumento3 pagineTo Determine Resistance of A Galvanometer by Half-Deflection Method and To Find Its Figure of Meritatikshpro3004Nessuna valutazione finora

- T316Documento5 pagineT316ANKIT SHARMA100% (1)

- Earthquake Research and Analysis - Seismology, Seismotectonic and Earthquake GeologyDocumento416 pagineEarthquake Research and Analysis - Seismology, Seismotectonic and Earthquake GeologyMiguel TorresNessuna valutazione finora

- Sorge 2015Documento18 pagineSorge 2015Masih LoghmaniNessuna valutazione finora

- RDM-chapter 1Documento35 pagineRDM-chapter 1Mat MatttNessuna valutazione finora

- White Paper - Hairline Cracking Within Concrete Block WallsDocumento7 pagineWhite Paper - Hairline Cracking Within Concrete Block WallsBirju ThakkarNessuna valutazione finora

- Interactive Powerpoint Presentation On QuadrilateralsDocumento3 pagineInteractive Powerpoint Presentation On QuadrilateralsSkoochh KooNessuna valutazione finora

- iPhone 14 Guide for Seniors: Unlocking Seamless Simplicity for the Golden Generation with Step-by-Step ScreenshotsDa EverandiPhone 14 Guide for Seniors: Unlocking Seamless Simplicity for the Golden Generation with Step-by-Step ScreenshotsValutazione: 5 su 5 stelle5/5 (3)

- Chip War: The Fight for the World's Most Critical TechnologyDa EverandChip War: The Fight for the World's Most Critical TechnologyValutazione: 4.5 su 5 stelle4.5/5 (82)

- Chip War: The Quest to Dominate the World's Most Critical TechnologyDa EverandChip War: The Quest to Dominate the World's Most Critical TechnologyValutazione: 4.5 su 5 stelle4.5/5 (229)

- Cyber-Physical Systems: Foundations, Principles and ApplicationsDa EverandCyber-Physical Systems: Foundations, Principles and ApplicationsHoubing H. SongNessuna valutazione finora

- CompTIA A+ Certification All-in-One Exam Guide, Eleventh Edition (Exams 220-1101 & 220-1102)Da EverandCompTIA A+ Certification All-in-One Exam Guide, Eleventh Edition (Exams 220-1101 & 220-1102)Valutazione: 5 su 5 stelle5/5 (2)

- Samsung Galaxy S22 Ultra User Guide For Beginners: The Complete User Manual For Getting Started And Mastering The Galaxy S22 Ultra Android PhoneDa EverandSamsung Galaxy S22 Ultra User Guide For Beginners: The Complete User Manual For Getting Started And Mastering The Galaxy S22 Ultra Android PhoneNessuna valutazione finora

- CompTIA A+ Complete Review Guide: Core 1 Exam 220-1101 and Core 2 Exam 220-1102Da EverandCompTIA A+ Complete Review Guide: Core 1 Exam 220-1101 and Core 2 Exam 220-1102Valutazione: 5 su 5 stelle5/5 (2)

- iPhone Unlocked for the Non-Tech Savvy: Color Images & Illustrated Instructions to Simplify the Smartphone Use for Beginners & Seniors [COLOR EDITION]Da EverandiPhone Unlocked for the Non-Tech Savvy: Color Images & Illustrated Instructions to Simplify the Smartphone Use for Beginners & Seniors [COLOR EDITION]Valutazione: 5 su 5 stelle5/5 (3)

- CompTIA A+ Complete Review Guide: Exam Core 1 220-1001 and Exam Core 2 220-1002Da EverandCompTIA A+ Complete Review Guide: Exam Core 1 220-1001 and Exam Core 2 220-1002Valutazione: 5 su 5 stelle5/5 (1)

- CompTIA A+ Complete Practice Tests: Core 1 Exam 220-1101 and Core 2 Exam 220-1102Da EverandCompTIA A+ Complete Practice Tests: Core 1 Exam 220-1101 and Core 2 Exam 220-1102Nessuna valutazione finora

- iPhone X Hacks, Tips and Tricks: Discover 101 Awesome Tips and Tricks for iPhone XS, XS Max and iPhone XDa EverandiPhone X Hacks, Tips and Tricks: Discover 101 Awesome Tips and Tricks for iPhone XS, XS Max and iPhone XValutazione: 3 su 5 stelle3/5 (2)

- Computer Science: A Concise IntroductionDa EverandComputer Science: A Concise IntroductionValutazione: 4.5 su 5 stelle4.5/5 (14)

- Cancer and EMF Radiation: How to Protect Yourself from the Silent Carcinogen of ElectropollutionDa EverandCancer and EMF Radiation: How to Protect Yourself from the Silent Carcinogen of ElectropollutionValutazione: 5 su 5 stelle5/5 (2)

- Jensen Huang's Nvidia: Processing the Mind of Artificial IntelligenceDa EverandJensen Huang's Nvidia: Processing the Mind of Artificial IntelligenceNessuna valutazione finora

- Raspberry PI: Learn Rasberry Pi Programming the Easy Way, A Beginner Friendly User GuideDa EverandRaspberry PI: Learn Rasberry Pi Programming the Easy Way, A Beginner Friendly User GuideNessuna valutazione finora

- Arduino and Raspberry Pi Sensor Projects for the Evil GeniusDa EverandArduino and Raspberry Pi Sensor Projects for the Evil GeniusNessuna valutazione finora

- A Beginner's Guide To IPhone 14 Pro Max Mastering: The Comprehensive User Guide And Illustrated Owner's Manual With Tips And Advanced Tricks For New BeDa EverandA Beginner's Guide To IPhone 14 Pro Max Mastering: The Comprehensive User Guide And Illustrated Owner's Manual With Tips And Advanced Tricks For New BeNessuna valutazione finora

- The comprehensive guide to build Raspberry Pi 5 RoboticsDa EverandThe comprehensive guide to build Raspberry Pi 5 RoboticsNessuna valutazione finora

- iPhone Photography: A Ridiculously Simple Guide To Taking Photos With Your iPhoneDa EverandiPhone Photography: A Ridiculously Simple Guide To Taking Photos With Your iPhoneNessuna valutazione finora

- Debugging Embedded and Real-Time Systems: The Art, Science, Technology, and Tools of Real-Time System DebuggingDa EverandDebugging Embedded and Real-Time Systems: The Art, Science, Technology, and Tools of Real-Time System DebuggingValutazione: 5 su 5 stelle5/5 (1)

- The User's Directory of Computer NetworksDa EverandThe User's Directory of Computer NetworksTracy LaqueyNessuna valutazione finora

![iPhone Unlocked for the Non-Tech Savvy: Color Images & Illustrated Instructions to Simplify the Smartphone Use for Beginners & Seniors [COLOR EDITION]](https://imgv2-1-f.scribdassets.com/img/audiobook_square_badge/728318688/198x198/f3385cbfef/1715193157?v=1)