Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Edsa Paladin

Caricato da

Iulian PârjoleanuCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Edsa Paladin

Caricato da

Iulian PârjoleanuCopyright:

Formati disponibili

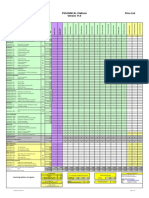

Electrical Systems Schedules Program with Copy, Paste, and Schedule Transfer Capabilities

EDSA MICRO CORPORATION 16870 West Bernardo Drive, Suite 330 San Diego, California 92127 U.S.A. Copyright 2008 All Rights Reserved

Version 2.95.00

October 2008

EDSA MICRO CORPORATION WARRANTY INFORMATION

There is no warranty, implied or otherwise, on EDSA software. EDSA software is licensed to you as is. This program license provides a ninety (90) day limited warranty on the diskette that contains the program. This, the EDSA Users Guide, is not meant to alter the warranty situation described above. That is, the content of this document is not intended to, and does not, constitute a warranty of any sort, including warranty of merchantability or fitness for any particular purpose on your EDSA software package. EDSA Micro Corporation reserves the right to revise and make changes to this User's Guide and to the EDSA software without obligation to notify any person of, or provide any person with, such revision or change. EDSA programs come with verification and validation of methodology of calculation based on EDSA Micro Corporation's inhouse software development standards. EDSA performs longhand calculation and checks the programs results against published samples. However, we do not guarantee, or warranty, any program outputs, results, or conclusions reached from data generated by any programs which are all sold "as is". Since the meaning of QA/QC and the verification and validation of a program methodology are domains of vast interpretation, users are encouraged to perform their own inhouse verification and validation based on their own inhouse quality assurance, quality control policies and standards. Such operations - performed at the user's expense will meet the user's specific needs. EDSA Micro Corporation does not accept, or acknowledge, purchase instructions based on a buyer's QA/QC and/or a buyer's verification and validation standards. Therefore, purchase orders instructions are considered to be uniquely based on EDSA's own QA/QC verification and validation standards and test systems.

TRADEMARK EDSA is a trademark of EDSA Micro Corporation.

COPYRIGHT Copyright 1989 - 2008 by EDSA Micro Corporation.

Please accept and respect the fact that EDSA Micro Corporation has enabled you to make an authorized disk as a backup to prevent losing the contents that might occur to your original disk drive. DO NOT sell, lend, lease, give, rent or otherwise distribute EDSA programs / User's Guides to anyone without prior written permission from EDSA Micro Corporation.

All Rights Reserved. No part of this publication may be reproduced without prior written consent from EDSA Micro Corporation.

Table of Contents Foreword ............................................................................................................................................. 1 1. 2. Introduction.......................................................................................................................................... 1 3. Purpose ............................................................................................................................................... 1 4. Capabilities.......................................................................................................................................... 1 5. How to Run the Program..................................................................................................................... 6 6. Panel ................................................................................................................................................. 23 7. Power Panel ...................................................................................................................................... 44 8. Motor Control Center......................................................................................................................... 50 9. Panelboard Worksheet...................................................................................................................... 55 10. Load Analysis .................................................................................................................................... 57 11. System Load Summary ..................................................................................................................... 64 12. Transformer....................................................................................................................................... 66 13. ATS.................................................................................................................................................... 69 14. Unit Substation .................................................................................................................................. 71 15. Bus Duct ............................................................................................................................................ 73 16. Primary Switch Gear ......................................................................................................................... 75 17. Cable ................................................................................................................................................. 77 18. Raceway............................................................................................................................................ 80 APPENDIX A............................................................................................................................................... 82

Table of Figures

Figure 1: Figure 2: Figure 3: Figure 4: Figure 5: Figure 6: Figure 7:

Phase 3 Wire ................................................................................................................................ 4 3 Phase 4 Wire ............................................................................................................................. 5 Sample Panel Schedule ............................................................................................................. 24 Circuit Breaker Panelboards....................................................................................................... 82 Wiring Diagrams ......................................................................................................................... 83 Circuit Breaker Panelboards....................................................................................................... 84 Wiring Diagrams ......................................................................................................................... 85

EDSA MICRO CORPORATION COPYRIGHT 2008 ALL RIGHTS RESERVED

ii

Electrical Systems Schedule Program

1. Foreword This discussion assumes that the user is a Professional Engineer familiar with the issues surrounding schedules in electric power systems. Determination of validity of the results, and whether the program is applicable to a system, is solely the responsibility of the user. This program is undergoing continuous development and refinement. As with all our products, EDSA is committed in making the program as current, comprehensive and easy to use as possible. Any comments, suggestions or errors encountered in either the results or documentation should be immediately brought to EDSA's attention. EDSA also assumes that the user is already familiar with the standard nomenclature and terms used in IBM class PC software (e.g. function, enter, Esc keys, filenames, etc.).

2. Introduction Designers of electrical distribution systems organize various distribution components by schedules. The Schedules Programs let the designer organize, enter, store, and print information by putting them into schedules related to their electrical distribution system. The program can perform certain calculations, such as summing up loads, and computing demand loads. There is also a built-in capability to transfer information among certain schedules.

3. Purpose The Schedules Programs provide a convenient way to enter and organize the distribution components used in an electrical system. Schedules are forms for grouping and organizing loads or devices of an electrical system for ease of reference and control of distribution system elements. Schedules help the engineers to locate Loads, Devices, Type, Size, Demand Factor, Voltage, etc., such that contractors, estimators and other designers could, in a minimum amount of time, have an exact feeling of the size and type of the system.

4. Capabilities The Schedules Programs let the user enter, edit, and print the following types of schedules: Panel, Power Panel, MCC, Panelboard Worksheet, Load Analysis, System Load Summary, Transformer, ATS,

Electrical Systems Schedule Program

Unit Substation, Bus Duct, Primary Switch Gear, Cable, Raceway.

In addition to the above, the Distribution Panel Schedule can be used for organizing Lighting and Receptacle loads. Individual schedules are identified by a Schedule ID (identifier). All schedules related to one job are grouped together for that particular job. Within each type of schedule, the schedule ID must be unique for each individual job. However, the same ID can be used in different types of schedules, and also for different jobs. Each schedule is provided with descriptive information about the schedule as a whole, such as: date, project name and number, and so forth. There is also a table containing information about all the components connected with that specific schedule. For example, for a distribution panel schedule there is a line of information for each circuit on the panel indicating the load for that circuit, the number of poles, and so on. Most schedules have sums or totals computed from the information in the table. Finally, where appropriate, there are footnotes. The Schedules Programs begin with a menu which enables users to select the necessary type of schedule. After type selection, a specific schedule may be selected for editing. If a selected schedule does not exist in the file, it can be added to it. A schedule can be printed, deleted, its values edited, saved, copied, or pasted. Footnotes can be edited or deleted. The programs use the EDSA standards for on-screen editing. Menu selections are made with the function keys. When editing values on a screen, TAB is used to skip to the next field without changing the current field. BACK TAB is used to skip back to the previous field without changing the current one. Information can be transferred from one schedule to another. The transferred information is the total load from the source schedule to one line in the target schedule. The following transfers are possible:

Panel Panel Panel Power Panel Power Panel MCC Load Analysis

Panel Power Panel MCC Power Panel MCC MCC Panel

Electrical Systems Schedule Program

Load Analysis Load Analysis

Power Panel MCC Load Analysis

Panelboard Worksheet

To transfer Schedule-To-Schedule, move the cursor to Load Served. Press F7, view the schedule lists. Select, then, transfer.

Electrical Systems Schedule Program

Panels are either single-phase or three-phase panels. Panels show the connection relationships of loads to different phases.

Figure 1: Phase 3 Wire Sample Wire Connection for Single-Phase Panels

Loads Loads Loads Loads

1+2 3+4 5+6 39+40

on Phase A on Phase B on Phase A on Phase B

Electrical Systems Schedule Program

Figure 2: 3 Phase 4 Wire Sample Wire Connection for Three-Phase Panels

Loads Loads Loads etc.

1+2 3+4 5+6

on Phase A on Phase B on Phase C

Electrical Systems Schedule Program

5. How to Run the Program

To run the Schedules program, press cursor on Selection. Select Panel and MCC Schedules.

Electrical Systems Schedule Program

Schedules Menu consists of: File; Edit; View; Tools; Tables; and Help.

Creates a new jobfile. Opens an existing jobfile. Saves this schedule.

Edits an existing schedule in this jobfile. Copies this circuit to internal clipboard.

Pastes circuit from internal clipboard.

Prints this schedule.

Help table of contents.

Electrical Systems Schedule Program

File lets you build: New Jobfile: Open Jobfile: Copy Jobfile: Close Jobfile: Delete Jobfile: Edit Schedule: Save: Save as: Export: Delete Schedule: Print: Batch Print: Print Setup: Exit: Creates a new jobfile. Opens an existing jobfile. Copies this jobfile to a new name. Closes this jobfile. Deletes this jobfile (including all schedules in it). Edits an existing schedule in this jobfile. Saves this schedule. Saves this schedule with a new name. Exports schedule to Microsoft Excel format. Deletes a schedule from this jobfile. Prints this schedule. Prints schedule group or all schedules. Sets up print characteristics. Quits application and prompts to save the schedule.

Electrical Systems Schedule Program

When you select New Jobfile, you will get the above screen asking you for File Name.

Once you have selected Open Jobfile, the existing schedule jobfiles File Name comes up. You can pick an existing schedule to edit, or build a new schedule. Schedule.dzx, and T123.dzx are existing schedules. These sample schedules are built to show you how to run the schedule program. You can have Standalone Schedules or Network Schedules. Schedules are located in the following directories: c:\edsajobs or c:\edsawin\samples or the directory you assigned when loading your CD-ROM .

Electrical Systems Schedule Program

When you select Copy Jobfile, the above screen comes up.

When you select Delete Jobfile, the above screen comes up.

10

Electrical Systems Schedule Program

When you select Save As, the above screen comes up to let you enter a new Schedule Name.

When you select Export, the above screen comes up to let you export schedule to Microsoft Excel format.

11

Electrical Systems Schedule Program

EDSAs Windows version of Schedules will also run an existing DOS Schedule. The Windows and DOS files have the same format. EDSAs Windows version of Schedules talks with the EDSA Jobfile Editor, AutoCad and Micro Station Interface programs.

Under Edit, you can: Copy Circuit: Paste Circuit: Clear Circuit: Cut: Copy: Paste: Copies this circuit to internal clipboard. Pastes this circuit from internal clipboard. Clears contents of the circuit row. Cuts the selection and puts it on the clipboard. Copies the selection and puts it on the clipboard. Inserts the clipboard contents at the insertion point.

To use the Edit functions, you must move the data entry box to the Circuit No. field, then move cursor to Copy, or Cut, move the data entry box to the target Circuit No., and select Cut or Paste.

12

Electrical Systems Schedule Program

You can use View and view the screen at: 200%: 100%: 75%: 50%: Sets window scale at 200% of original scale. Sets window scale to original scale. Sets window scale to 75% of original scale. Sets window scale to 50% of original scale.

Please select an existing schedule, then use all the icons and program functions to examine all of the program capabilities before trying to build your own schedule.

13

Electrical Systems Schedule Program

Tools menu consists of: Change DF Globally: Sort: Changes the Demand Factor for all schedules in a group. Sorts items in cable or raceway schedules.

14

Electrical Systems Schedule Program

Tables menu consists of: Demand Factors: Mounting Types: Power Factor: Starter Sizes: Starter Types: Voltages L-L: Voltages L-G: Amperage: Service Loads: Accesses demand factors table. Accesses mounting types table. Accesses power factor table. Accesses starter sizes table. Accesses starter types table. Accesses line-line voltage library. Accesses line-ground voltage library. Accesses amperage table. Accesses service loads table.

15

Electrical Systems Schedule Program

Demand Factor Table. You can add demand factor to, or delete demand factor from, the list.

Mounting Types Table. You can add mounting types to, or delete mounting types from, the NEC list.

16

Electrical Systems Schedule Program

Power Factor Table. You can add power factors to, or delete power factors from, the list.

Starter Sizes Table. You can add starter sizes to, or delete starter sizes from, the list.

17

Electrical Systems Schedule Program

Starter Types Table. You can add starter types to, or delete starter types from, the list.

Line-to-Line Voltage Library. You can add line-line voltages to, or delete line-line voltages from, the list.

18

Electrical Systems Schedule Program

Line-to-Ground Voltage Library. You can add line-to-ground voltages to, or delete line-to-ground voltages, from the list.

Amperages Table. You can add amperage to, or delete amperage from, the list.

19

Electrical Systems Schedule Program

Service Loads Table. You can add service loads to, or delete service loads from, the list.

Help menu consists of Contents, Using Help. and About.

20

Electrical Systems Schedule Program

If you select Contents, you will see the above electronic help Users Guide table of contents.

21

Electrical Systems Schedule Program

By selecting Using Help, you can see the above screen.

Schedules Version 2.95.00 Copyright 2008 All Rights Reserved.

By selecting About, you can see the program version number.

22

Electrical Systems Schedule Program

6. Panel

The Select Schedule screen lets you select existing schedules or build new schedules. When you build new schedules, you must enter Name of the schedule Alphanumeric.

23

Electrical Systems Schedule Program

Figure 3: Sample Panel Schedule

T123 is a sample QA/QC file. Lets build a Panel Schedule at Node/Bus #11.

24

Electrical Systems Schedule Program

Date: 6,20,1989 Project FFDS Name: Project #: 123

Location: MECH.LE VEL Node/Bus #: 11 Feeder #: 211 From: PP#2 Comment: Comment: Comment:

M.L.O. 75 Rating: Main OC Device: Mounting: N1-FLUSH Ground Bus: N Voltage L-L: Voltage L-G: Phase: Wire: 480 277 3 4

SC RMS: SC Asym: Avail. Fault: 9033 Comment: TEST FOR USERS GUIDE Cir. No. 1 3 5 7 9 11 13 15 17 19 21 23 25 27 Device Amps 20 20 20 20 20 20 20 30 20 30 20 30 30 40 30 40 30 40 40 40 40 20 40 20 20 20 # of Poles 1 1 1 1 1 1 1 3 1 3 1 3 3 3 3 3 3 3 3 3 3 3 3 3 1 1

Load Served LIGHTING-MAIN-LEVEL LIGHTING-INTERSTIC LIGHTING MAIN LEVEL LIGHTING MECH LEVEL LIGHTING MAIN LEVEL LIGHTING MECH LEVEL LIGHTING MAIN LEVEL WELD OUTLET RM 107 ELECT WATER HTR WELD OUTLET RM 107 SPARE WELD OUTLET RM 107 WELD OUTLET M.LEVEL TRANSFORMER T-LAHC WELD OUTLET M.LEVEL TRANSFORMER T-LAHC WELD OUTLET M.LEVEL TRANSFORMER T-LAHC TRA T-LAHA TRANSFORMER T-LAHC WELD OUTLET M.LEVEL TRAN T-LAHB TRA T-LAHA TRAN T-LAHB SPARE SPARE

# of Units 1 1 1 1 1 3 1 11 2 11 11 6 1 6 1 6 1 1 1 6 1 1 1

Unit Load 3500 3400 3500 1900 3360 500 1960 600 1000 600 600 1100 10000 1100 10000 1100 10000 15000 10000 1100 3000 15000 3000

VA 3500 3400 3500 1900 3360 1500 1960 6600 2000 6600 6600 6600 10000 6600 10000 6600 10000 15000 10000 6600 3000 15000 3000

DF 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100

Notes

Cir. No. 2 4 6 8 10 12 14 16 18 20 22 24 26 28

29 30 31 32 33 34 35 36 37 38 39 40 41 42 Cir. No. Device Amps # of Poles Phase A 57060 57060 Load Served Phase B 40200 40200 # of Units Phase C 46060 46060 Unit Load VA DF Notes Cir. No.

Connected Load: Demand Load:

Connected KVA / AMP: Demand KVA /AMP:

KVA 143.320 143.320

AMP 172 172

25

Electrical Systems Schedule Program

PANEL SCHEDULE at Bus #11 The sample on previous page is of a three-phase, four-wire panel schedule placed at Bus #11. If you are working with a jobfile network, enter project name, and project number. You can enter comments for general description of the panel and project. With the data entry box on Node/Bus #, move the cursor to the box, press F2 or cursor Right Button to import the node or bus number from the jobfile network where you wish to place the panel. When you select a Bus/Node, the available fault value will be transferred from the Short Circuit Answer Files to the schedule fields. If you do not have a Short Circuit jobfile, you can still build your schedules. Enter the available information, then come back later and complete the schedule information. Please note the help information at the bottom of the screen. Many of the fields, such as Device Amps, # of Poles, Load Served, and DF (Demand Factor), have libraries attached to them. Panels are single-phase or three-phase. In panels, you organize the loads with regard to: Circuit number; Device Amperes; Number of poles; Load being served; Number of load units; Unit load in Volt-Amperes; Demand factor; You can also assign note ID, then write your footnote(s) at the schedule bottom. For example, if we assign a label on Notes (e.g.: 123) then press F2, we get the following screen to enter Footnotes.

26

Electrical Systems Schedule Program

You can select the Node/Bus to which this schedule is tied from the Short Circuit jobfile (e.g. Bus #11, etc.). If you name your schedule file the same name as your jobfile for Short Circuit (e.g. T123), you can import information from jobfile T123 to Schedule file T123.dzx. You can also access the schedules from EDSA Jobfile Editor. Make sure that the schedule file has the same name as the Short Circuit jobfile. T123 is a network jobfile. User must first run T123 and generate a Short Circuit Answer File. X/R and Short Circuit values can be transferred from the T123 Short Circuit Answer File to the T123 Schedule file.

Select Bus #11. At the Node/Bus field, press F2 to select the Node/Bus where the schedule is located in order to transfer the proper short circuit values from the Short Circuit Answer file to Schedule. Enter Node/Bus for standalone schedules.

27

Electrical Systems Schedule Program

Note:

1.

You can build an independent schedule, name it as a network jobfile (e.g.: T123). Import Short Circuit from T123 Network to T123 Schedule. You can go to Jobfile Editor, select the Bus/Node, e.g.: Bus#11.

2.

3.

Enter Bus Label, enter SC Bus Code, Select #-Sched at Motor Unit. #-Schedule = Schedule.

28

Electrical Systems Schedule Program

4.

Select schedule type. Schedule Type consists of: D - Panel Schedule; P - Power Panel Schedule; M - MCC Schedule; W - Panelboard Worksheet.

5.

Select the Schedule ID you wish to transfer to the Short Circuit or Load Flow dialogue box.

29

Electrical Systems Schedule Program

6.

Note that the load transferred 143.32 KVA is the same as the total load for the schedule shown on Page 25. You can assign X, X/R values depending on the load type.

7.

30

Electrical Systems Schedule Program

Mounting, L-L Voltage, and L-G Voltage have picklists. User can add or modify the picklist libraries under Tables. Bus L-L voltage is 480 Volts. Short Circuit current value 9033 Amps for Bus #11, and is imported from the Short Circuit answer file into the schedule. Short Circuit value of 9033 Amperes was transferred when we selected Node/Bus #11 using F2 function.

Mounting picklist. All libraries are user-definable, and your type, description, etc., can be added to the tables.

Phase and Wire have picklists. To use copy, cut, and paste, move the data entry box to the circuit, select Edit icon, select Copy, move the data entry box to the circuit you wish to copy the information into, and select Paste.

31

Electrical Systems Schedule Program

For example, if we want to copy the data Circuit No.1: select the No. 1data entry box, then go to Edit.

Select Copy Circuit from Edit menu, move to the Circuit No. 27 data entry box, and select Paste Circuit to complete the process.

32

Electrical Systems Schedule Program

You can see the information from Circuit No. 1 has been copied into the data box of Circuit No. 27.

Press F2 on Phase to get the Phases picklist.

33

Electrical Systems Schedule Program

You can use the Tab key to move the data entry box from one field to another. Read the Helps at the bottom of the screen as you move the data entry box from one field to another. Fault value and Node/Bus data can be imported. Mounting, Demand Factor, Voltage L-L, Voltage L-G, Number of Phase, and Number of Wire have picklist libraries. Use screen side bar to move screen information to right, left, up, and down.

34

Electrical Systems Schedule Program

Sample Panelboard Worksheet. Please try opening picklists and using all icons and functions to learn about the program capabilities.

L = Lighting;

M = Motor;

R = Receptacle;

O = Other;

S = Spare;

H = Heat.

35

Electrical Systems Schedule Program

DF CIR NO

= = =

Demand Factor, Circuit, Number = = = 57060 VA 40200 VA 46060 VA

Circuit # 1 + 2 + 7 + 8 + 13 + 14 + 19 + 20 + 25 + 26 Circuit # 3 + 4 + 9 + 10 + 15 + 16 + 21 + 22 + 27 + 28 Circuit # 5 + 6 + 11 + 12 + 17 + 18 + 23 + 24 + 29 + 30

( 57060 + 40200 + 46060) = 143.32 KVA 1000 143.32 0.48 3 = 172 A I= KVA KV 3

At the AMP field, press F2 to select from the Amperages table. At the POLE field, press F2 to select poles. At the Load Served field, press F2 to select Load Type. Load Type is a user-definable library. You can build a library for loads to meet your everyday design requirements. At the Load Served field, press F7 to transfer data from a different schedule. At the DF (demand factor) field, press F2 to select a demand factor. Demand factor library is a userdefinable library. You can build your own demand factor library to meet your special design requirements.

36

Electrical Systems Schedule Program

How to Build a Panel for the Same Network File Called T123

Let us put a three-phase, four-wire panel schedule at Node/Bus = 21 of T123 jobfile network. 1. 2. 3. Select New Schedule. Assign a name: 21. Press Edit.

37

Electrical Systems Schedule Program

Date: 8,22,97 Project Name: 123ABC Project #: 123

Location: ROOF Node/Bus #: 21 Feeder #: F1 From: Comment: Comment: Comment: X/R=5

M.L.O. Rating: Main OC Device: Mounting: Ground Bus: Voltage L-L: Voltage LG: Phase: Wire:

100 BKR N1-FLUSH N 480 120 3 4

SC RMS: 10000 SC Asym: 11000 Avail. Fault: 9106 Comment: Cir. No. 1 3 5 7 Device Amps 20 20 20 20 20 20 # of Poles 1 3 2 3 2 3

Load Served EMERGENCY MOTOR GENERAL LIGHTING HALLWAY LIGHTING GENERAL LIGHTING INDUSTRIAL LIGHTING GENERAL LIGHTING

# of Units 1 2 2 2 2 2

Unit Load 3500 1000 500 1000 3000 1000

VA 3500 2000 1000 2000 6000 2000

DF 100 100 100 100 100 100

Notes

Cir. No. 2 4 6 8

9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 Cir. No. Device Amps # of Poles Phase A 5500 5500 KVA 16.500 16.500 Load Served Phase B 3000 3000 AMP 20 20 # of Units Phase C 8000 8000 Unit Load VA DF Notes Cir. No.

Connected Load: Demand Load:

Connected KVA / AMP: Demand KVA /AMP:

38

Electrical Systems Schedule Program

4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15.

Enter Date, Location, M.L.O. Rating, Project Name. With cursor at Node/Bus #, Press F2, and select Bus/Node 21. Available Fault 9106 Amperes is transferred from the T123 Short Circuit Answer File. Enter Voltage L-L and Voltage L-G. With cursor at Device Amps, press F2 or mouse Right Button to open Device Amps Library. With cursor at # of Poles, press mouse Right Button or F2 to open and select Number of Poles. With cursor at Load Served, press mouse Right Button or F2 to open the library for selection. With cursor at Load Served, press mouse Left Button or F7 to transfer other schedule load data to this schedule. Enter # of Units. Enter Unit Load in VA. Examine calculated VA. With cursor at DF (Demand Factor), press F2 or mouse Right Button to open the Demand Factor Library for selection. Repeat steps 1-14 to complete this schedule.

39

Electrical Systems Schedule Program

Let us build a new Panel called panel #22. Enter Name and press Edit.

40

Electrical Systems Schedule Program

Date: Project Name: 123ABC 123 Project #: SC RMS: SC Asym: Avail. Fault: Comment: Cir. No. 1 3 5 7 Device Amps 20 100 20 100 20 100 # of Poles 3 3 3 3 3 3 10000 11000 9106

Location: Node/Bus #: Feeder #: From: Comment: Comment: Comment:

ROOF 21 3C M.BUS

M.L.O. Rating: Main OC Device: Mounting: Ground Bus: Voltage L-L: Voltage L-G: Phase: Wire:

100 BKR N1-FLUSH N 480 277 3 4

Load Served GENERAL LIGHTING PANEL 21 GENERAL LIGHTING PANEL 21 GENERAL LIGHTING PANEL 21

# of Units 1 1 1

Unit Load 4000 4000 4000

VA 4000 5500 4000 5500 4000 5500

DF 100 100 100 100 100 100

Notes

Cir. No. 2 4 6 8

9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 Cir. No. Device Amps # of Poles Phase A 9500 9500 KVA 28.500 28.500 Load Served Phase B 9500 9500 AMP 34 34 # of Units Phase C 9500 9500 Unit Load VA DF Notes Cir. No.

Connected Load: Demand Load:

Connected KVA / AMP: Demand KVA /AMP:

Let us see if we can import Panel #21 into Panel #22 with 3 poles. With cursor on Circuit No. 2 at Load Served, press F7. Schedule 21 loads are transferred to Cir. #2, 4, & 6.

41

Electrical Systems Schedule Program

SAMPLE SINGLE PHASE PANEL SCHEDULE

Date: Project Name: ABC Project #: 123 Location: Node/Bus #: Feeder #: From: BROADWAY BRANCH 15 3#1,XHHW,CU,1.5"C 13 M.L.O. Rating: Main OC Device: Mounting: Ground Bus: Voltage L-L: Voltage L-G: Phase: Wire: 15 110 A FU FLUSH N 240 120 1 3

SC RMS: 10000 SC Asym: 10000 Avail. Fault: 6778 Comment: JOB FILE XYZ Cir. No. 1 3 5 Device Amps 15 15 15 15 15 15 7 15 15 # of Poles 1 1 1 1 1 1 1 1

Comment: ALL BKRS MUST BE Comment: SWITCH DUTY Comment:

Load Served LTS,STRIP (MAIN) LTS,SOFFIT (FRT) LTS,STRIP (MAIN) LTS,CEILING(CTR) LTS,HALL & RST RMS S.CASE/COV/CTR LTS RCPT,WEST WING RCPT,+BK STOR.LTS

# of Units 9 2 9 4 6 7 3 6

Unit Load 105 150 105 206 60 105 180 172

VA 945 300 945 824 360 735 540 1032

DF 100 100 100 100 100 100 100 100

Notes A A B

Cir. No. 2 4

6 C D&E

9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 Cir. No. Device Amps # of Poles Phase A 2340 2340 KVA 5.681 5.681 Load Served Phase B 3341 3341 AMP 24 24 # of Units Phase C Unit Load VA DF Notes Cir. No.

Connected Load: Demand Load:

Connected KVA / AMP: Demand KVA /AMP:

42

Electrical Systems Schedule Program

A: B:

945 + 300 + 360 + 735 945 + 824 + 540 + 1032 A + B = 5681 VA ,

= 2340 VA = 3341 VA A + B = 5.681 KVA

2340 + 3341 = 5681 VA = 5.681 KVA

I= KVA 5.681 = = 24 Ampere KV 0.240

Program results and longhand calculations match 100%.

L-L VOLTAGE is 480, 208. L-G VOLTAGE is 277, 120. M.L.O.: MAIN LUG ONLY. MAIN OVERCURRENT DEVICE: BKR, Fuse, ... etc. MOUNTING: SURFACE, FLUSH, COLUMN ..., etc. Branch Device Mounting information, such as PLUG IN or BOLT ON, may be entered in C COMMENT SPACES. Short Circuit RMS Rating SYM. and ASYM. and ampere ratings of the panel. ENCLOSURE: NEMA1, NEMA3R, NEMA4 ... etc. X/R Value (from EDSA Short Circuit study) may be entered in C COMMENT LINES. For Panel Schedules, if PHASE is 3, then the computed loads are divided into Phase A, Phase B, and Phase C. If PHASE is 1, then the computed loads are divided into Phase A and Phase B, without Phase C. L-L L-G = = Line to Line Line to Ground

43

Electrical Systems Schedule Program

7. Power Panel

Date: Project Name: Project #: Main Amps: 1200 SC RMS: 23000 Avail. Fault: Comment: TEST FOR USERS GUIDE Cir. No. 1 3 5 7 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 Cir. No. Load Served # of Poles KVA 15.000 15.000 KVA / HP AMP 657.0 657.0 Amps DF OC Device AMP Feeder Notes Cir. No. Load Served LP-G1,11,21 LP-31,41,51 LP-61,71 SPARE SF-5(2-SPEED) EF-9(2-SPEED) SPACE SPACE # of Poles 3 3 3 3 3 3 3 3 KVA / HP Amps 291.00 230.00 114.00 11.00 11.00 DF 100 100 100 100 100 OC Device S400A S400A S200A S200A S30A S30A S100A S100A AMP F400A F400A F200A F30A F30A Feeder 3.5"C,4#500,1#3GRD " 2.5"C,4#4/0,1#3GRD Notes Cir. No. 2 4 6 8 Location: Node/Bus #: Feeder #: 121 From: T1 Comment: X/R=5 Comment: M.L.O. Rating: Main OC Device: Mounting: Ground Bus: Voltage L-L: Voltage L-G: Phase: Wire: 1200 BKR SURFACE N 480 277 3 4

7.50 7.50

Connected KVA / AMP: Demand KVA /AMP:

Connected schedule Amp is 521 + 114 + 22 = 657 A, KVA = KV A 3 = 0.48 x 657 x 1.732 = 546 KVA. Program results and longhand calculations match 100%.

44

Electrical Systems Schedule Program

How to Build a Power Panel 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. Enter Date, Location, M.L.O. Rating, and Project Name. With cursor on Node/Bus #, Press F2 or mouse Right Button to access Network Bus #. If the Power Panel is a Standalone Power Panel, or if you have not yet built your jobfile network, leave Node/Bus # field blank. Enter Mounting Open Library for Selection. From indicates if the PP is connected to a XFMR (e.g.: T1 or connected and fed from Bus A, etc.). Ground Bus is Y (yes) or N (no). Main Ampere means main bus ampere rating. SC RMS means Power Panel RMS Short Circuit rating. Available Fault means the value of the fault at the panel from From S.C. Study. Voltages are L-L Volts or L-G Volts. Phase is 1 or 3. Wires are 3 or 4.

45

Electrical Systems Schedule Program

SAMPLE POWER PANEL SCHEDULE

You may enter KVA/HP, or override the calculation and enter AMP. In O.C. Device, you may enter Switch, BKR, etc., and in AMP, you may enter BKR amp rating or fuse amperes, etc. NT: means notes. You may enter note # (e.g. 1, 2, ... ), then press F1 to enter 2-line footnotes.

For the MOUNTING field, enclosures may be: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. NEMA Type 1 NEMA Type 1 NEMA Type 3 NEMA Type 3R NEMA Type 4 NEMA Type 3R, 7 & 9 NEMA Type 4X NEMA Type 6P NEMA Type 7 NEMA Type 9 NEMA Type 12 NEMA Type 13 For Hazardous Gas Locations Bolted Enclosure For Hazardous Dust Locations Unilock Enclosure For Hazardous Locations Non-Metallic, Corrosion-Resistant Fiberglass Reinforced Polyester General Purpose Surface Mounting Flush Mounting

O.C. Device C

= =

Over Current Device Comment

46

Electrical Systems Schedule Program

Power Panel Schedules are organized with regard to: Circuit Number; Load Served; Number of Poles; kVA/HP of Load; Amperes of Load; Demand Factor; Over Current Device; Amperes Setting; Feeder Number/Type; Notes.

47

Electrical Systems Schedule Program

Date: Project Name: TEST EXAMPLE Project #: 12345A

Location: RM 704 Node/Bus #: 03 Feeder #: 3(3"C,3#500,1#2GRD) From: T1

M.L.O. Rating: 1200 Main OC Device: BKR Mounting: SURFACE Ground Bus: N Voltage L-L: Voltage L-G: Phase: Wire: 480 277 3 4

Main Amps: 1200 SC RMS: 28000 Avail. Fault: 9776 Comment: TEST FOR USERS GUIDE Cir. No. 1 3 5 7 Load Served MIX LOAD 1 EQK INDUCTION MTR GEL SS2 ##PANEL 1 # of Poles 3 3 3 3 3

Comment: X/R=5 Comment:

KVA / HP 105.00 100.00 126.00 160.00 600.00 143.30

Amps 126.30 120.30 151.60 192.50 721.70

DF 100 100 100 100 50 100

OC Device BKR BKR BKR BKR BKR

AMP 200 200 400 400 600

Feeder

Notes

Cir. No. 2 4 6 8

9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 Cir. No. Load Served # of Poles KVA 1234.300 934.299 KVA / HP AMP 1312.4 951.5 Amps DF OC Device AMP Feeder Notes Cir. No.

Connected KVA / AMP: Demand KVA /AMP:

48

Electrical Systems Schedule Program

1:

You may transfer Panels into PP (shown in circuit number 6) panel ID:3. If KVA/HP is entered, the program calculates the AMP. The program may be overridden, and the user can enter the nameplate AMP. Not all information is needed to be entered at one time. Enter the known information; then edit the PP in the future, either to add or delete information. # of Poles means Number of Poles. DF means Demand Factor. X/R values are to be taken from the EDSA Short Circuit program. It is important to know the system X/R at the PP, because breaker and fuse manufacturers test their devices at X/R = 6.6 for low voltage and at X/R = 15 for medium and high voltage. If X/R is above the 6.6 in low voltage, and above 15 for medium and high voltage, refer to the PDC Users Guide and the Short Circuit Users Guide for further instructions.

2:

3:

4: 5: 6:

7:

From :

T1 means PP is fed from Transformer T1.

FEEDER NUMBER:

You may enter the number assigned to the feeder feeding the PP, or enter the number of feeders, sizes and conduit, etc. KVA = HP = 105 + 100 + 126 + 160 + 600 + 143.30 = 1234.30 AMP = 126.30 + 120.30 + 151.60 + 192.50 + 721.70 = 1312.40

Connected:

Demand:

KVA = 105 + 100 + 126 + 160 + 0.5 (600) + 143.30 = 934.30 AMP = 126.30 + 120.30 + 151.60 + 192.50 + 0.5 (721.70) = 951.50

Program results and longhand calculations match 100%.

49

Electrical Systems Schedule Program

8. Motor Control Center Motor Control Center Schedules are organized with regard to: Circuit Number; Load Served; HP/KVA of Motor Load; Full Load Amperes; Starter Size; Type; Over Current Device; Amperes Setting; Feeder and Conduit Size and Type; On Cover; Notes.

50

Electrical Systems Schedule Program

Date: Project Name: ABC Project #: 123

Location: PENTHOUSE Node/Bus #: Feeder #: SEE BUS SCHEDULE#1 From: T1 Comment: X/R=5 Comment:

Bus Amps: 600 SC RMS: 20000 Avail. Fault: Comment: TEST FOR USERS GUIDE Cir. No. 1 3 5 7 Load Served EF-3 EF-4 EF-5 EF-6 AHU-3 AHU-4 HP / KVA 5.00 5.00 3.00 7.50 60.00 60.00

M.L.O. Rating: Main OC Device: Mounting: Ground Bus: Demand Factor: Voltage L-L: Voltage L-G: Phase: Wire:

600 BKR FLR N 100 480 277 3 4

FLA 6.00 6.00 3.00 9.00 72.20 72.20

Size 1 1 1 1 4 4

Type

R.V R.V

OC Device S30 " " " 200 200

AMP F15 " F8A F20A 125 125

Feeder 3/4"C,3#12,1#12GRD " " " 2"C,6#2,1#6GRD "

On Cvr 1

Notes 1

Cir. No. 2 4

2 3

6 8

9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 Cir. No. Load Served HP / KVA KVA 140.500 140.500 FLA AMP 168.400 168.400 Size Type OC Device AMP Feeder On Cvr Notes Cir. No.

Connected KVA / AMP: Demand KVA /AMP:

1. 2.

Enter Date, Location, Main Log only Rating, Project Name. Node/Bus #:11, press F2 or the cursor Right Button to access the T123 Short Circuit Answer File to transfer short circuit value at Bus #11 to Available Fault in MCC Schedule.

51

Electrical Systems Schedule Program

Note:

1) 2) 3)

1 in ON COVER means HOA Hands Off Automatic; 2 means Push Button Starter. Switch / Fuse. R. V = Reduced Voltage Starter.

In the Column ON CV (on cover), you may enter 1, or any code indicating it is HOA (hands off automatic), or 2, or any code to indicate that it is PUSH BUTTON. Define and explain your own notes. In O.C. DEV Over Current Device and AMP, user may enter numbers only, and clarify their meaning in notes (e.g. Switch/Fuse ). NT = Note

for MCC ID:3 HP = = = FLA = = KVA 5 + 5 + 3 + 7.50 + 60 + 60 140.50 6 + 6 + 3 + 9 + 72.20 + 72.20 168.40

Program results and longhand calculations match 100%.

52

Electrical Systems Schedule Program

Date: Project ABC Name: Project #: 123

Location: RM 105 Node/Bus #: Feeder #: 12 From: T1 Comment: X/R=4.8 Comment:

M.L.O. Rating: 1200 Main OC Device: BKR Mounting: Ground Bus: Demand Factor: Voltage L-L: Voltage L-G: Phase: Wire: FLOOR N 100 480 277 3 4

Bus Amps: 1200 SC RMS: 30000 Avail. Fault: Comment: SAMPLE FOR USERS GUIDE Cir. No. 1 3 5 7 9 11 Load Served SCF-4 SCF-3 SCF-2 SCF-1 SAF-B CRP-3 FIRE PUMP FIRE PUMP 2 JOKEY PUMP P-36,37,38 R.O.PUMP CENTRAL VACUM IAC-1 MEDICAL AIR CO. PPANEL 3 HP / KVA 25.00 50.00 60.00 60.00 60.00 1.00 150.00 150.00 5.00 80.00 10.00 180.00 40.00 90.00 934.20

FLA 30.10 60.09 72.19 72.19 72.19 1.20 180.30 180.30 6.00 96.19 12.00 216.50 48.09 108.30 951.50

Size 2 3 4 3 4

Type

OC Device BKR BKR BKR BKR BKR BKR BKR BKR BKR BKR BKR BKR BKR BKR

AMP 70 125 125 125 125 20 600 600 20 200 30 400 100 200

Feeder

On Cvr

Notes

Cir. No. 2 4 6 8 10 12

13

14

15 17

16 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 Cir. No. Load Served HP / KVA KVA 1895.300 1895.300 FLA AMP 2107.440 2107.440 Size Type OC Device AMP Feeder On Cvr Notes Cir. No.

Connected KVA / AMP: Demand KVA /AMP:

Sample of a Motor Control Center Schedule with a Power Panel Schedule (Circuit No. 15) transferred to MCC Schedule.

53

Electrical Systems Schedule Program

DEV Total of HP

= = =

Device KVA 1895.3 2107

Total FLA

At Circuit #15, press F7 to pick up Power Panel 3.

Program results and longhand calculations match 100%.

54

Electrical Systems Schedule Program

9. Panelboard Worksheet

Select the Panelboard Worksheet menu.

Panelboard Worksheet is organized with regard to: Circuit Number; Phase A - Voltage Amperes; Phase A - Load Type; Phase B - Voltage Amperes; Phase B - Load Type; Phase C - Voltage Amperes; Phase C - Load Type; Pole; Amperes; Remarks; Notes.

55

Electrical Systems Schedule Program

Date: Project Name: SAMPSON HALL Project #: 123 Status: PRELIM By: A.M. Revision: 2 Comment: SAMPLE FOR USERS GUIDE Cir. No. 1 3 800 5 Ph A - VA 600 1500 Ph A - LD L H Ph B - VA

Node/Bus #: 20 Avail. Fault: From: T2 Voltage L-L: Voltage L-G: Phase: Wire: 208 120 3 4

Demand Factors Lighting: Receptacle: Motor: Heat : Other: Spare:

0.70 0.40 0.70 0.75 1.00 1.00

Ph B - LD

Ph C - VA

Ph C - LD

S R 600 S R

7 9 11 13 15 17

1100 1000

R L S S S S

640 800

L R 560 320 L L 1200 S R

19 21 23

800 1200

R R 800 1200 R R 1200 S R

25 27

910 1800

L R 1800 S R 1200 1800 R R

29 31 33 35 37 39 41 Cir. No. Ph A - VA Phase A Totals: Lighting 4030 KVA Totals: Receptacle 21700 Amps Motor Heat 17550 Dem. Amps Ph A - LD Phase B Ph B - VA Phase C Ph B - LD Panel Total 3610 2450 O H 5340 4200 O H 1200 1800 R R 1200 2500 R H

1200 2500

R H

4960 4400 Ph C - VA

O H Ph C - LD

Pole 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2 1 2 3 3 3 3 3 3 Pole

Amp 15 20 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 20 20 20 20 20 15 20 20 20 15 20 20 20 20 20 20 30 20 30 100 100 100 100 100 100 Amp

Remarks BATH LITES WASHER SPARE LOUNGE REC SPARE LOUNGE REC LOUNGE & SO CORR CORR LITES E & W SPARE SPARE SPARE SPARE DORM LITES W CORR & LAUNDRY DORM LITES E DORM LITES SO. SPARE PLUGMOLD W BATH REC PLUGMOLD W CORR.REC PLUGMOLD W SPARE PLUGMOLD W B-6 & NITELITES PLUGMOLD E SPARE PLUGMOLD E PLUGMOLD SO PLUGMOLD E PLUGMOLD S PLUGMOLD E PLUGMOLD S DRYER PLUGMOLD S DRYER LP-3-J LP-3-K LP-3-J LP-3-K LP-3-J LP-3-K Remarks

Notes

Cir. No. 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42

Notes

Cir. No.

Totals:

Other 13910

Spare

Dem. KVA

L = Lighting, R = Receptacle, S = Spare, H = Heat, M = Motor, O = Other. Units are VA, (4030 VA). KVAD = Demand KVA. AMPD = Demand Amperes. LD = Type of load.

56

Electrical Systems Schedule Program

10. Load Analysis

Select the Load Analysis menu. Load Analysis Schedule is organized with regard to: Panel; Demand Factor; Lighting Load; Receptacles Load; Motor Load; Heating Load; Other type of Loads; Spare; KVA; Amperes; Demand KVA; Demand Amperes; Notes.

57

Electrical Systems Schedule Program

Date: Project Name: ABC Project #: 123 Status: By: Revision: Group: PRELIM MAD 2 LP-L

Voltage L-L: Voltage L-G: Phase: Wire:

208 120 3 4

Comment: SAMPLE FOR USERS GUIDE

Panel LP-L DF ##13 DF LP-N DF DF DF DF DF DF DF DF DF DF DF DF DF DF DF DF DF DF DF DF DF DF DF DF DF

Lighting 4030 0.80 4030 0.70 1050 0.80

Recept. 21700 0.40 21700 0.40 2000 0.40

Motor 0.70 0.70 0.70

Heat 17550 0.75 17550 0.75 8000 0.75

Other 13910 1.00 13910 1.00 1.00

Spare 1.00

KVA 57 57

Amps 159 158 53

Dem KVA 39 39 8

Dem Amps 108 108 37

Notes

1.00 11 1.00

58

Electrical Systems Schedule Program

DF DF DF DF DF DF DF DF DF DF DF DF DF DF DF Panel Lighting Recept. Motor Heat Other Spare KVA Amps Dem KVA Dem Amps Notes

Totals:

Lighting 9110

Recept. 45400

Motor

Heat 43100

Other 27820

Spare

KVA 125.0

Amps 370.0

Dem KVA 86.0

Dem Amps 253.0

Panel called LP-L has: 4030 VA Lighting, 21700 VA Receptacle, 17550 VA Heat and 13910 VA Other type of loads. Total 57 KVA. LTG REC = = Lighting. Receptacle.

Demand Factor of 4030 is 80%. Demand Factor of 21700 is 40% .... KVAD = NT LTG = = = Demand KVA. Note 4030 + 4030 + 1050 9110

59

Electrical Systems Schedule Program

REC

= =

21700 + 21700 + 2000 45400 17550 + 17550 + 8000 43100 13910 + 13910 27820 Program results and longhand calculations match 100%.

HEAT = = OTHER = =

At the PANEL field, if you press F7, then you see the list of other Panel information that can be transferred to this schedule. 4030(0.7) + 21700(0.4) + 17550(0.75) + 13910 (1) = 39 KVAD

60

Electrical Systems Schedule Program

Let us transfer PanelBoard WrkSht #13 to the Load Analysis Schedule.

61

Electrical Systems Schedule Program

Date: Project Name: ABC Project #: 123 Status: PRELIM By: MAD Revision: 2 Group: LP-L Comment: SAMPLE FOR USERS GUIDE

Voltage L-L: 208 Voltage L- 120 G: Phase: 3 Wire: 4

Panel LP-L DF PBD 13 DF LP-N DF PBD 131 DF DF DF DF DF DF DF DF DF DF DF DF DF DF DF DF DF DF DF DF DF DF DF

Lighting 4030 0.80 4030 0.70 1050 0.80 1050 0.80

Recept. 21700 0.40 21700 0.40 2000 0.40 2000 0.40

Motor 0.70 0.70 0.70 0.70

Heat 17550 0.75 17550 0.75 8000 0.75 8000 0.75

Other 13910 1.00 13910 1.00 1.00 1.00

Spare 1.00

KVA 57 57

Amps 159 159 31 31

Dem KVA 39 39 8 8

Dem Amps 108 107 21 21

Notes

1.00 11 1.00 11 1.00

62

Electrical Systems Schedule Program

DF DF DF DF DF DF DF DF DF DF DF DF DF DF DF DF Panel Lighting Recept. Motor Heat Other Spare KVA Amps Dem KVA Dem Amps Notes

Totals:

Lighting 10160

Recept. 47400

Motor

Heat 51100

Other 27820

Spare

KVA 136.2

Amps 370.0

Dem KVA 93.6

Dem Amps 253.0

1.

When you transfer PanelBoard WorkSheet to Load Analysis, make sure to use the Tab key to complete the transfer of information. Current I =

KVA 3 KV

2.

e.g.:

57 3 0.208

158 Amperes

63

Electrical Systems Schedule Program

11. System Load Summary

Select System Load Summary Schedule.

System Load Summary is organized with regard to: Item; Type of Load; Connected KVA; Demand Factor; Power Factor Notes.

64

Electrical Systems Schedule Program

Date: Project Name: ABC Project #: 123 Location: BLDG 4 Summary For: SUB 5A Comment: SAMPLE FOR USERS GUIDE

Voltage L-L: 480 Voltage L-G: 277 System PF: 85

Item PP2A MCC1 PP32 EPP21 PPC2

Type of Load LIGHTING MTR LOAD MIX LOAD EMERG.MTR MIX IND LOAD

Cont. KVA 100 325 123 210 165

DF 100 75 50 75 70

PF 85 80 85 86 85

Notes

Item

Type of Load

Cont. KVA

DF

PF

Notes

Connected KVA / AMPS: Demand KVA /AMPS:

KVA 923.0 678.2

AMPS 1110.2 815.8

Sample System Load Summary Schedule. Connected KVA adds up to 923 KVA/110.2 A. Demanded KVA adds up to 678.2 KVA/815.8 A.

65

Electrical Systems Schedule Program

12. Transformer

Select Transformer menu.

Transformer Schedule is organized with regard to: Name; From Node; To Node; KVA - Phase - Type - of - Connection; Voltage (Primary); Voltage (Secondary); Tap Setting; Location; Mount; Z% (Transformer Impedance); Notes.

66

Electrical Systems Schedule Program

Date: Project Name: ABC Project #: 123 Comment: SAMPLE TEST FOR USERS GUIDE

Name T1 T2 TRP2

From Node 20 70 110

To Node 30 80 120

KVA-Ph-Type/Con. 2000-3-D/D-Y S 1000-3-D/D-Y S 500-3-D/D-Y S

Voltage (Pri) 13200 4160 4160

Voltage (Sec) 4160 480 480

Tap -2.5

Location MECH.RM BLDG 11 BLDG A2

Mount FLR FLR FLR

Z% 6.20 5.30 4.90

Notes

Name

From Node

To Node

KVA-Ph-Type/Con.

Voltage (Pri)

Voltage (Sec)

Tap

Location

Mount

Z%

Notes

You may create a schedule of all the transformers in the Job. You may ENTER the names (e.g. T1, TRP2, etc.). From node to node indicates the transformer location in the system.

67

Electrical Systems Schedule Program

KVA-PHASE-DRY or LIQUID type, D-D for Delta-Delta, or D-Y for Delta Y, S for solidly grounded, R for resistance grounded, etc. P S = = Primary Voltage Secondary Voltage

Location of Transformer or Physical Location (e.g. Mech.RM) Mounting Impedance Z in % 2000-3-D 1000-3-L D-Y-S = = = 2000 KVA, three-phase, dry type 1000 KVA, three-phase, liquid type Delta-Y, solidly grounded

68

Electrical Systems Schedule Program

13. ATS

Select ATS menu.

ATS Schedule is organized with regard to: Name; Voltage; For (What this ATS is used for); Rating; Pole; Notes.

69

Electrical Systems Schedule Program

Date: Project Name: ABC Project #: 123 S.C. RMS Rating: 15000 S.C. RMS Asym: 16000 Comment: SAMPLE FOR USERS GUIDE

Name ATS-1 ATS-2 ATS-3 ATS-4 ATS-5 ATS-6 ATS-7

Voltage 480/277V 480/277V 480/277V 480V 480 480V 480/277V

For PDP-EM1(LIFE SAFETY) PDP-CR2(CRITICAL) PDP-CR1(CRITICAL) PDP-EQ1(EQUIPMENT) MCC-C41(EQUIPMENT) PP-EL1(ELEVATORS) PDP-XEG1(X-RAY)

Rating 400A,4W+GRD 1000A,4W+GRD 800A,4W+GRD 800A,3W+GRD 1000A,3W+GRD 800A,3W+GRD 800A,4W+GRD

Pole 4 4 4 3 3 3 4

Notes 1

Name

Voltage

For

Rating

Pole

Notes

Sample ATS Schedule.

70

Electrical Systems Schedule Program

14. Unit Substation

Select Unit Substation menu.

ATS Schedule is organized with regard to: Feeder #; Load Served; Rating; Breaker Sensor Trip; Current Limiting Fuse; Connected KVA for Circuit; Connected Amperes for Circuit; Demand Factor; Feeder Description; Notes.

71

Electrical Systems Schedule Program

Date: Project Name: ABC Project #: 123

Node From: 20 Node To: 30

SC RMS: 28000 SC Asym: 29000 Feeder #: 211 Comment: SAMPLE TEST FOR USERS GUIDE Feeder # A A1 A2 A3 A4 A5 A6 A-B B B1 B2 B3 B4 B5 B6 Load Served MAIN SPARE PP-G6 PP-G4 PDP-CR1 SPACE SPACE TIE MAIN PDP-EM1 D.O.B.SW SPARE PDP-EQ1 SPACE SPACE Rating 3000 1600 800 800 800 1600 1600 2000 3000 800 1600 800 800 1600 1600 Bkr Snsr Trp 2500 1000 800 800 800 CL Fuse Con. KVA Con. Amps DF Feeder Notes

503 506 1062

100 100 100

2-3.5"C,4#500,1#3 G " "

1800 2500 400 1600 800 800

140 1200 610

100 100 100

3.5"C,4#500,1#3 G

2-3"C,3#500,1#3 G

Feeder #

Load Served

Rating KVA

Bkr Snsr Trp AMPS 4021 4021

CL Fuse

Con. KVA

Con. Amps

DF

Feeder

Notes

Connected KVA / AMPS: Demand KVA /AMPS:

Connected Amperes CL Fuse CON KVA

= = =

4021 A; Current Limiting Fuse; Connected KVA.

72

Electrical Systems Schedule Program

15. Bus Duct

Select Bus Duct menu.

Bus Duct Schedule is organized with regard to: Circuit #; For (What Circuit is used for); Rating; Breaker; Switch; Fuse; Feeder; Connected Amperage; Demand Amperage; Notes.

73

Electrical Systems Schedule Program

Date: Project Name: Project #: SC RMS: SC Asym: Feeder #: From: Comment: Cir. No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 Cir. No.

ABC 123 12000 13000 211 T1 SAMPLE FOR USERS GUIDE For T-2B FOR RP-2B LP-22 T-3B FOR RP-3B LP-32 T-4B FOR RP-4B LP-42 T-5B FOR RP-5B LP-52 T-6B FOR RP-6B LP-62 T-7B FOR RP-7B LP-72 LP-PH2 Breaker

Location: Neutral: Ground: Voltage L-L: Voltage L-G: # of Poles: Amps:

ELECT.CLODET SO 100% 50% 480 277 3 600

Switch 60 100 60 100 60 100 60 100 60 100 60 100 100

Fuse 40 100 40 100 40 100 40 100 40 100 40 100 100

Feeder 3/4"C,3#8,1#10GRD 1.5"C,4#1,1#6GRD " " " " " " " " " " "

Con Amps 30.00 42.50 30.00 42.50 30.00 42.50 30.00 42.50 30.00 42.50 30.00 42.50 23.00

Dem Amps 10.00 42.50 10.00 42.50 10.00 42.50 10.00 42.50 10.00 42.50 10.00 42.50 12.00

Notes

For

Breaker Amps 458.00

Switch Dem Amps 327.00

Fuse

Feeder

Con Amps

Dem Amps

Notes

Connected Totals:

Sample Bus Duct Schedule. Connected Amperes adds up to 458 A. Demand Amperes adds up to 327 A.

74

Electrical Systems Schedule Program

16. Primary Switch Gear

Select Primary Switch Gear.

Primary Switch Gear Schedule is organized with regard to: Feeder #; For (What Circuit is used for); Breaker Rating; Breaker Type; Tap; Time Dial; Switch Rate; Switch Fuse; Feeder; Notes.

75

Electrical Systems Schedule Program

Date: Project Name: ABC Project #: 123

Location: SOUTH GATE Voltage L-L: 13200 Voltage L-G: 7620

SC RMS: 4000 SC Asym: 4300

Comment: SAMPLE FOR USERS GUIDE Feeder No. 100 101 102 103 104 150 200 201 202 203 204 For MAIN SIDE C OF C-D SIDE J OF J-K SIDE A OF A-B SPACE TIE MAIN SIDE D OF C-D SIDE K OF J-K SIDE B OF A-B SPACE Bkr Rating 2000 1200 1200 1200 2000 2000 1200 1200 1200 Bkr Type IOC53 IOC53 IOC53 IOC53 IOC53 IOC53 IOC53 IOC53 IOC53 Tap 6 4 4 4 6 6 4 4 4 Time Dial Sw Rate Sw Fuse 5 5 5 5 5 5 5 5 5 Feeder 1-4"C,3#500,1#2 G 1-4"C,3#500,1#2 G " " Notes

" " " "

Feeder No.

For

Bkr Rating

Bkr Type

Tap

Time Dial Sw Rate Sw Fuse

Feeder

Notes

Sample Primary Switch Gear Schedule.

76

Electrical Systems Schedule Program

17. Cable

Select Cable menu.

Cable Schedule is organized with regard to: Cable #; Wire Size/Type; Material; Insulation; Length(ft); Voltage L-L; Qty/Ph; From (Where cable is coming from); To (Where cable is connected to); Interconnect Route.

77

Electrical Systems Schedule Program

Date: Project #: 5615

Comment: MENDOTA BIOMASS POWER, LTD. Comment: Comment:

Cable # B222-1 B224-1 B225-1 B226-1 B227-1 B228-1 B228-2 C232-1 C232-2 C233-1 C234-1 C234-2 C235-1 C235-2 C236-1 C236-2 C237-1 C238-1 C239-1 C239-2 C240-1

Wire Size/Type 3/C #1/0 3/C #1/0 3/C #1/0 3/C #1/0 3/C #1/0 3/C #1/0 3/C #1/0 1/C 750 1/C 750 1/C 750 1/C 750 1/C 750 1/C 750 1/C 750 1/C 750 1/C 750 1/C 350 1/C 350 1/C 350 1/C 350 1/C 350

Material Insulation CPPR CPPR CPPR CPPR CPPR CPPR CPPR ALUM ALUM ALUM ALUM ALUM ALUM ALUM ALUM ALUM ALUM ALUM ALUM ALUM ALUM XHHW XHHW XHHW XHHW XHHW XHHW XHHW XHHW XHHW XHHW XHHW XHHW XHHW XHHW XHHW XHHW XHHW XHHW XHHW XHHW XHHW

Length (ft) 175 350 350 320 320 400 400 190 190 190 190 190 190 190 500 500 375 350 190 190 380

Voltage L-L 480 480 480 480 480 480 480 480 480 480 480 480 480 480 480 480 480 480 480 480 480

Qty/Ph 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3

From 5KV 102A 5KV 103A 5KV 103B 5KV 104A 5KV 104B 5KV 105A 5KV 105A 480V S.2 480V S.2 480V S.3 480V S.4 480V S.4 480V S.5 480V S.5 480V S.6 480V S.6 480V S.2 480V S.3 480V S.5 480V S.5 480V S.4

To BFP-1A M CWP-1A M CWP-1B M TAF-1 MT PAF-1 MT IDF-1 MT IDF-1 MT MCC-C1 MCC-C1 MCC-C2 MCC-C3 MCC-C3 MCC-C4A MCC-C4A MCC-C5 MCC-C5 CTF-1A CTF-1B MCC-C4B MCC-C4B SAF-1 MT

Interconnect Route C-B113 TRN B-TRY DB188 C-B1 C-B109 TRN B-TRY DB PULL 10 C-B110 TRN B-TRY DB PULL 60 C-B105 TRN B-TRY DB / C-B C-B106 TRN B-TRY DB / C-B45 C-B100 TRN B-TRY DB / C-B45 C-B101 TRN B-TRY DB C-B456 C-C120 TRN C-TRY TC-CBL TRA C-C121 TRN C-TRY TC-CBL TRA C-C115 TRN C-TRY TC-CBL TRA C-C110 TRN C-TRAY TC CBL TR C-C111 C-C105 TRN C-TRY TC CBL TRA C-C105 TRN C-TRY TC CBL TRA C-C100 TRN C-TRY DB-D64 C-C100 TRN C-TRY DB-D65 C-C122 TRN C-TRY DB C-C603 C-C117 TRN C-TRY DB??? C-C6 C-C108 TRN C-TRAY DB??? C-C109 TRN C-TRAY DB??? C-C112 TRN C-TRY DB??/C-C46

Cable #

Wire Size/Type

Material Insulation

Length (ft)

Voltage L-L

Qty/Ph

From

To

Interconnect Route

Sample Cable Schedule.

78

Electrical Systems Schedule Program

Select Sort from the Tools menu.

Sort Cable Schedule screen.

79

Electrical Systems Schedule Program

18. Raceway

Select Raceway menu.

Raceway Schedule is organized with regard to: Conduit ID #; Type; Conduit Size; Length (ft); % Fill; Cable ID #; Wire Size/Type; Drawing #; Drawing Revision; From a Point ID; To a Point ID.

80

Electrical Systems Schedule Program

Date: Project #: 5615

Comment: MENDOTA BIOMASS POWER LTD Comment: Comment:

Conduit # C-B116 C-B450 C-B451 C-B452 C-B453 C-B455 C-B456 C-B600 C-B601 C-C001 C-C002 C-C003 C-C100 C-C101 C-C102 C-C103 C-C104 C-C105 C-C106 C-C107 C-C108 C-C109 C-C110 C-C111

Type PVC PVC PVC

Cond Size 4 4 4

Length (ft) 10 20 30

% Fill 9 9

Cable # B226-1 B227-1

Wire Size/Type SPARE 3/C #1/0 3/C #1/0

RS RS RS RS RS RS RS PVC PVC PVC PVC PVC PVC PVC PVC PVC PVC PVC PVC

4 4 2 2 3/4 3/4 1 5"C 5"C 5"C 4"C 4"C 4"C 4"C 4"C 4"C 4"C 5"C 5"C

15 15 10 35 25 15 70 15 15 15 15 15 15 15 15 15 15 15 15

9 9 25 25 35 29 42 40 40 38 38 24 24 38 38 40 40

B228-1 B228-2 B224-1 B225-1

C236-1 C236-2 C241-1 C241-2

3/C #1/0 3/C #1/0 3/C #1/0 3/C #1/0 3/C #10 3/C #12 3/C #8 1/C-750 1/C-750 SPARE 1/C-350 1/C-350

C239-1 C239-2 C234-1 C234-2

SPARE 1/C-350 1/C-350 1/C-750 1/C-750

Drawing # 32100 32450 32450 32450 32450 32451 32451 32600 32600 32000 32000 32000 32100 32100 32100 32100 32100 32100 32100 32100 32100 32100 32100 32100

Revision

From 5KV SW 102A TOTAL AIR FAN PRIM AIR FAN SPARE NO. SPARE NO. DUCT FR 5KV DUCT FR 5KV CWP-1B CWP-1A LGT XFM 10KVA EXHAUST FAN UNIT HEATER 480V SW/SCT 6 480V SW/SCT 6 480V SW/SCT 6 480V SW/SCT 6 480V SW/SCT 6 480V SW/SCT 5 480V SW/SCT 5 480V SW/SCT 5 480V SW/SCT 5 480V SW/SCT 5 480V SW/SCT 4 480V SW/SCT 4

To TRENCH-SPARE DB-283 FR 5KV DB-288 FR 5KV

IDF-1 IDF-1 PULL BX F 5KV PULL BX F 5KV PULL BOX PULL BOX PULL BOX CBL TRN C-TRY CBL TRN C-TRY CBL TRN SPARE CBL TRN C-TRY CBL TRN C-TRY CBL TRN C-TRY CBL TRN C-TRY SPARE CBL TRN C-TRY CBL TRN C-TRY CBL TRN C-TRY CBL TRN C-TRY

Conduit #

Type

Cond Size

Length (ft)

% Fill

Cable #

Wire Size/Type

Drawing #

Revision

From

To

Sample Raceway Schedule.

81

Electrical Systems Schedule Program

APPENDIX A Please Note: The following information has been copied from Crouse-Hinds Cooper with permission from Cooper Industries issued on 5/13/1994.

Circuit Breaker Panelboards

Figure 4: Circuit Breaker Panelboards

82

Electrical Systems Schedule Program

Figure 5: Wiring Diagrams

83

Electrical Systems Schedule Program

Circuit Breaker Panelboards

Figure 6: Circuit Breaker Panelboards

84

Electrical Systems Schedule Program

Wiring Diagrams

Figure 7: Wiring Diagrams

85

Electrical Systems Schedule Program

86

Potrebbero piacerti anche

- Quick Start Guide DesignBase 6.2Documento67 pagineQuick Start Guide DesignBase 6.2Antonio Olmedo Avalos100% (1)

- Work Practice Manual - Western PowerDocumento751 pagineWork Practice Manual - Western Powerjeb13100% (1)

- Creating Your Job File in Paladin Designbase™Documento107 pagineCreating Your Job File in Paladin Designbase™gilbertomjcNessuna valutazione finora

- Introduction To PSS SINCAL (Lab 08-Part 02)Documento19 pagineIntroduction To PSS SINCAL (Lab 08-Part 02)TalNessuna valutazione finora

- Edsa PaladinDocumento111 pagineEdsa PaladinDaniel GutierrezNessuna valutazione finora

- Professional Resume: Electrical Engineering Professional With Proven Industrial and Utilities SuccessDocumento5 pagineProfessional Resume: Electrical Engineering Professional With Proven Industrial and Utilities Successravirajsinhvaja100% (1)

- MicrogridDocumento22 pagineMicrogridraj100% (1)

- GensizDocumento27 pagineGensizinsan_soft6498Nessuna valutazione finora

- Edsa PaladinDocumento64 pagineEdsa PaladinIulian PârjoleanuNessuna valutazione finora

- Advanced Electromagnetic Transient Analysis Program: Capacitor EnergizationDocumento29 pagineAdvanced Electromagnetic Transient Analysis Program: Capacitor EnergizationgilbertomjcNessuna valutazione finora

- Sparkta User Manual PDFDocumento31 pagineSparkta User Manual PDFArianna IsabelleNessuna valutazione finora

- Introducing DesignBase 6Documento4 pagineIntroducing DesignBase 6gerrzen64Nessuna valutazione finora

- Protection of Structures Against LightningDocumento42 pagineProtection of Structures Against Lightningsani priadiNessuna valutazione finora

- DesignBase Quick StartDocumento56 pagineDesignBase Quick Startveljal6317Nessuna valutazione finora

- UC Aluminium Catalogue PDFDocumento31 pagineUC Aluminium Catalogue PDFserban_elNessuna valutazione finora

- Transformer Protection and Control RET615Documento8 pagineTransformer Protection and Control RET615maruf048Nessuna valutazione finora

- Doubly-Fed Induction Machine Models For Stability Assessment of Wind FarmsDocumento6 pagineDoubly-Fed Induction Machine Models For Stability Assessment of Wind FarmsArun RajendranNessuna valutazione finora

- Sam 600Documento2 pagineSam 600Rinda_RaynaNessuna valutazione finora

- 12 41 Rapport ScreenDocumento44 pagine12 41 Rapport ScreenVladimir PîrvanNessuna valutazione finora

- Siemens: PSS®SINCAL Platform Price ListDocumento1 paginaSiemens: PSS®SINCAL Platform Price ListJohnDoeNessuna valutazione finora

- 159 - Changes in IEEE80Documento6 pagine159 - Changes in IEEE80dmcalderoncNessuna valutazione finora

- HB 264-2003 Power Quality - Recommendations For The Application of As NZS 61000.3.6 and As NZS 61000.3.7Documento7 pagineHB 264-2003 Power Quality - Recommendations For The Application of As NZS 61000.3.6 and As NZS 61000.3.7SAI Global - APACNessuna valutazione finora

- Lci BrochureDocumento20 pagineLci BrochureSergey PavlovNessuna valutazione finora

- IEEE Microgrid Presentation 2016-05-11Documento27 pagineIEEE Microgrid Presentation 2016-05-11eshwar GNessuna valutazione finora

- Power Flow of Abule-EgbaDocumento21 paginePower Flow of Abule-EgbaCarlos RodasNessuna valutazione finora

- 00 Full Grid Code I5r21Documento700 pagine00 Full Grid Code I5r21Bogdan VicolNessuna valutazione finora

- Transient Recovery Voltages in Vacuum Circuit Breakers Generated by The Interruption of Inrush Currents of Large Motors (IPST)Documento8 pagineTransient Recovery Voltages in Vacuum Circuit Breakers Generated by The Interruption of Inrush Currents of Large Motors (IPST)cool_saklshpurNessuna valutazione finora

- Load Flow Analysis of 66 KV Substation Using ETAP SoftwareDocumento4 pagineLoad Flow Analysis of 66 KV Substation Using ETAP SoftwareNasser SabrNessuna valutazione finora

- 1mrk505172-Ben A en Busbar Differential Protection Ied Reb670 Pre-ConfiguredDocumento36 pagine1mrk505172-Ben A en Busbar Differential Protection Ied Reb670 Pre-ConfiguredBijaya Kumar MohantyNessuna valutazione finora

- StationWare 2018 Brochure enDocumento8 pagineStationWare 2018 Brochure enanonymNessuna valutazione finora

- 1 Cai Wan Tam Urban MicrogridsDocumento22 pagine1 Cai Wan Tam Urban Microgridscon_sultanNessuna valutazione finora

- NEPLAN v10 DescriptionDocumento8 pagineNEPLAN v10 DescriptionRUBIONessuna valutazione finora

- 3AH3 Vacuum Circuit-Breakers: Medium-Voltage EquipmentDocumento58 pagine3AH3 Vacuum Circuit-Breakers: Medium-Voltage Equipmentbrunofj1985Nessuna valutazione finora

- Wind Generator Power Flow Modeling GuideDocumento14 pagineWind Generator Power Flow Modeling Guidekunsridhar8901Nessuna valutazione finora

- Harmonic Analysis Exercise 1: ObjectiveDocumento3 pagineHarmonic Analysis Exercise 1: Objectiveashraf-84Nessuna valutazione finora

- DN02 S09011 e XK 1001 01Documento54 pagineDN02 S09011 e XK 1001 01ayemyothantNessuna valutazione finora

- Development of Grid Code For Wind Power Generation in India PowerpointDocumento37 pagineDevelopment of Grid Code For Wind Power Generation in India PowerpointgopiNessuna valutazione finora

- Battery and Charger SizingDocumento52 pagineBattery and Charger SizinggilbertomjcNessuna valutazione finora

- Characteristic Analysis of Subsynchronous Resonance in Practical Wind Farms Connected To Series-Compensated TransmissionsDocumento9 pagineCharacteristic Analysis of Subsynchronous Resonance in Practical Wind Farms Connected To Series-Compensated Transmissionsdiux96Nessuna valutazione finora

- Protecta-Ep PDFDocumento38 pagineProtecta-Ep PDFAlejandro Pedro Mundaca MalcaNessuna valutazione finora

- Dynamic Structural Rigid and Flexible Bus Design in Air Insulated SubstationsDocumento8 pagineDynamic Structural Rigid and Flexible Bus Design in Air Insulated SubstationsnashapkNessuna valutazione finora

- Modelling and Simulation of Power Electronic Converter Dominated Power Systems in PowerFactory-45-74Documento30 pagineModelling and Simulation of Power Electronic Converter Dominated Power Systems in PowerFactory-45-74Daniel ManjarresNessuna valutazione finora

- An Overview of Grid-Forming Control For Wind Turbine ConvertersDocumento6 pagineAn Overview of Grid-Forming Control For Wind Turbine ConvertersGabriel VilknNessuna valutazione finora

- DS 20220802 Sungrow Catalogue Thailand 2022-2023 V1.3 enDocumento72 pagineDS 20220802 Sungrow Catalogue Thailand 2022-2023 V1.3 enKrittamet NethwongeNessuna valutazione finora

- Solar Power ApplicationsDocumento1 paginaSolar Power ApplicationsJeremy CurtisNessuna valutazione finora

- Fast Bus Transfer Systems For Critical Process ContinuityDocumento11 pagineFast Bus Transfer Systems For Critical Process ContinuityamdatiNessuna valutazione finora

- Edsa PaladinDocumento52 pagineEdsa PaladinIulian PârjoleanuNessuna valutazione finora

- PVsyst - Tutorials - V7 - Stand AloneDocumento28 paginePVsyst - Tutorials - V7 - Stand Alonemazen absiNessuna valutazione finora

- Wind Farm ControlDocumento0 pagineWind Farm ControlDavid Jose Poma GuillenNessuna valutazione finora

- En Wind Turbine Generators 2009Documento22 pagineEn Wind Turbine Generators 2009evotavaNessuna valutazione finora

- Development and Analysis of Nordic32 Power System Model in PowerFactoryDocumento77 pagineDevelopment and Analysis of Nordic32 Power System Model in PowerFactorybubo28100% (1)

- Electrical Primary Design of 35 KVDocumento66 pagineElectrical Primary Design of 35 KVsamiaNessuna valutazione finora

- SeminarDocumento30 pagineSeminarDevender ChahalNessuna valutazione finora

- Fulltext01 PDFDocumento66 pagineFulltext01 PDFElenildo Oliveira da SilvaNessuna valutazione finora

- WhatsNew 2016 en PDFDocumento54 pagineWhatsNew 2016 en PDFMiguel CbNessuna valutazione finora

- 3D Photovoltaic Devices Complete Self-Assessment GuideDa Everand3D Photovoltaic Devices Complete Self-Assessment GuideNessuna valutazione finora

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsDa EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNessuna valutazione finora

- Edsa PaladinDocumento72 pagineEdsa PaladinIulian PârjoleanuNessuna valutazione finora

- Power Transmission LinesDocumento66 paginePower Transmission Linesaamir_janjua_3Nessuna valutazione finora

- Cable AmpacityDocumento81 pagineCable Ampacitysamsunglover50% (2)

- Ground Grid DesignDocumento63 pagineGround Grid DesignReza Torkaman100% (1)

- Edsa PaladinDocumento12 pagineEdsa PaladinIulian Pârjoleanu100% (1)

- Power Transmission LinesDocumento66 paginePower Transmission Linesaamir_janjua_3Nessuna valutazione finora

- Edsa PaladinDocumento35 pagineEdsa PaladinIulian PârjoleanuNessuna valutazione finora

- Edsa PaladinDocumento2 pagineEdsa PaladinIulian PârjoleanuNessuna valutazione finora

- Edsa PaladinDocumento52 pagineEdsa PaladinIulian PârjoleanuNessuna valutazione finora

- Edsa PaladinDocumento87 pagineEdsa PaladinIulian PârjoleanuNessuna valutazione finora

- Edsa PaladinDocumento13 pagineEdsa PaladinDaniel Gutierrez100% (1)

- Edsa PaladinDocumento33 pagineEdsa PaladinIulian PârjoleanuNessuna valutazione finora

- Edsa PaladinDocumento72 pagineEdsa PaladinIulian PârjoleanuNessuna valutazione finora

- DCSC PDFDocumento35 pagineDCSC PDFkolombo1776Nessuna valutazione finora

- 5.2 Schematics: MSP-EXP430G2 HardwareDocumento6 pagine5.2 Schematics: MSP-EXP430G2 HardwareIulian PârjoleanuNessuna valutazione finora

- Edsa PaladinDocumento50 pagineEdsa PaladinIulian PârjoleanuNessuna valutazione finora

- Cap SizeDocumento12 pagineCap Sizesa_125Nessuna valutazione finora

- Edsa PaladinDocumento204 pagineEdsa PaladinDaniel GutierrezNessuna valutazione finora

- Compact NS Schnider ElectricDocumento121 pagineCompact NS Schnider ElectricIulian PârjoleanuNessuna valutazione finora

- Launch PadDocumento178 pagineLaunch PadGabrielNessuna valutazione finora

- Electrical Codes Standards GordonDocumento60 pagineElectrical Codes Standards GordonDenny PanjaitanNessuna valutazione finora

- RtreterterDocumento419 pagineRtreterterMohammedNasserNessuna valutazione finora

- A Technical Report On Student IndustrialDocumento71 pagineA Technical Report On Student IndustrialVincentNessuna valutazione finora

- Underground Cable MCQDocumento42 pagineUnderground Cable MCQshukla dhavalNessuna valutazione finora

- SIWES Report of 2015 2016 SessionDocumento61 pagineSIWES Report of 2015 2016 Sessionmuhammad07066893449Nessuna valutazione finora

- Abb UnisecDocumento20 pagineAbb UnisecdraganpostaNessuna valutazione finora

- ESR - Rev 5.0 HSE-OC-01-05Documento105 pagineESR - Rev 5.0 HSE-OC-01-05balajiNessuna valutazione finora

- On Transformer ManufacturingDocumento25 pagineOn Transformer ManufacturingThakur Dhananjay Singh Gaur100% (1)

- Eds Unit 3-1Documento73 pagineEds Unit 3-1NayanNessuna valutazione finora

- GSM Based Scada Monitoring and Control System Substation EquipmentDocumento9 pagineGSM Based Scada Monitoring and Control System Substation EquipmentM Hassan BashirNessuna valutazione finora

- Guidance Notes For Synchronous Generators Grid ConnectionDocumento90 pagineGuidance Notes For Synchronous Generators Grid Connectionjung2008Nessuna valutazione finora

- DHBVN Sales Circular - D-7-2010Documento16 pagineDHBVN Sales Circular - D-7-2010col.asyadavNessuna valutazione finora

- Spectrum Power™ Distribution Network Applications (DNA) : Answers For EnergyDocumento2 pagineSpectrum Power™ Distribution Network Applications (DNA) : Answers For EnergykotiniNessuna valutazione finora

- Fundamentals of Electrical Transmission and DistributionDocumento29 pagineFundamentals of Electrical Transmission and DistributionKyla Belgado100% (1)

- APM30 User Guide (V200R301 - 01)Documento203 pagineAPM30 User Guide (V200R301 - 01)Thuan Nguyen100% (1)

- Installation and Estimation of Electrical Load PDFDocumento59 pagineInstallation and Estimation of Electrical Load PDFMohd AliNessuna valutazione finora

- Load Flow Analysis For Three Phase Unbalanced Distribution Feeders Using MatlabDocumento5 pagineLoad Flow Analysis For Three Phase Unbalanced Distribution Feeders Using MatlabEdna LópezNessuna valutazione finora

- Introduction To Grounding System DesignDocumento16 pagineIntroduction To Grounding System DesignRajendra Prasad ShuklaNessuna valutazione finora

- Accusine: Harmonic Filtering and Reactive Power CompensationDocumento20 pagineAccusine: Harmonic Filtering and Reactive Power CompensationlcatelaniNessuna valutazione finora

- Annual Report 2015-IESL SabaragamuwaDocumento37 pagineAnnual Report 2015-IESL SabaragamuwaChaminda KumaraNessuna valutazione finora

- AP DU STANDARDS - GUIDELINES For LINES - POLES VER 1.0.4Documento44 pagineAP DU STANDARDS - GUIDELINES For LINES - POLES VER 1.0.4Evander Sasarita MonteroNessuna valutazione finora

- PowerHour ParallelingSolutions 2019-08-22 PDFDocumento49 paginePowerHour ParallelingSolutions 2019-08-22 PDFthuanNessuna valutazione finora

- Science 9 Quarter 4 LASDocumento27 pagineScience 9 Quarter 4 LASFerd Reddick LeponNessuna valutazione finora

- AZ 2005-02-14 State Programme On Fuel and Energy Sector EngDocumento15 pagineAZ 2005-02-14 State Programme On Fuel and Energy Sector Engadams abdallaNessuna valutazione finora

- Electrical Notes: Electrical Design of Residential, Commercial and Industrial BuildingsDocumento5 pagineElectrical Notes: Electrical Design of Residential, Commercial and Industrial BuildingsIrish ArapocNessuna valutazione finora

- Deepak ReportDocumento25 pagineDeepak Reportanup kumarNessuna valutazione finora

- Working Principle of Earth Leakage Circuit Breaker ELCBDocumento4 pagineWorking Principle of Earth Leakage Circuit Breaker ELCBMD SahidNessuna valutazione finora