Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Edsa Paladin

Caricato da

Iulian PârjoleanuCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Edsa Paladin

Caricato da

Iulian PârjoleanuCopyright:

Formati disponibili

NEC Wire, Conduit & Ground Wire Sizing

EDSA MICRO CORPORATION

16870 West Bernardo Drive, Suite 330 San Diego, CA 92127 U.S.A.

Copyright 2008 All Rights Reserved

Version 3.10.00

October 2008

NEC Sire Sizing

EDSA MICRO CORPORATION

WARRANTY INFORMATION

There is no warranty, implied or otherwise, on EDSA software. EDSA software is licensed to you as is. This program license provides a ninety (90) day limited warranty on the diskette that contains the program. This, the EDSA Users Guide, is not meant to alter the warranty situation described above. That is, the content of this document are not intended to, and does not, constitute a warranty of any sort, including warranty of merchantability or fitness for any particular purpose on your EDSA software package. EDSA Micro Corporation reserves the right to revise and make changes to this User's Guide and to the EDSA software without obligation to notify any person of, or provide any person with, such revision or change. EDSA programs come with verification and validation of methodology of calculation based on EDSA Micro Corporation's inhouse software development standards. EDSA performs longhand calculation and checks the programs results against published samples. However, we do not guarantee, or warranty, any program outputs, results, or conclusions reached from data generated by any programs which are all sold "as is". Since the meaning of QA/QC and the verification and validation of a program methodology are domains of vast interpretation, users are encouraged to perform their own inhouse verification and validation based on their own inhouse quality assurance, quality control policies and standards. Such operations - performed at the user's expense will meet the user's specific needs. EDSA Micro Corporation does not accept, or acknowledge, purchase instructions based on a buyer's QA/QC and/or a buyer's verification and validation standards. Therefore, purchase orders instructions are considered to be uniquely based on EDSA's own QA/QC verification and validation standards and test systems.

TRADEMARK EDSA is a trademark of EDSA Micro Corporation.

COPYRIGHT Copyright 1989 - 2008 by EDSA Micro Corporation.

Please accept and respect the fact that EDSA Micro Corporation has enabled you to make an authorized disk as a backup to prevent losing the contents that might occur to your original disk drive. DO NOT sell, lend, lease, give, rent or otherwise distribute EDSA programs / User's Guides to anyone without prior written permission from EDSA Micro Corporation.

All Rights Reserved. No part of this publication may be reproduced without prior written consent from EDSA Micro Corporation.

NEC Sire Sizing

TABLE OF CONTENTS

I. II. III. IV. V. VI. VII. VIII. IX. X. 1.0 FOREWORD ..................................................................................................................................................1 CALCULATIONS ..........................................................................................................................................1 DATA TABLES..............................................................................................................................................1 FEATURES.....................................................................................................................................................2 GROUNDING ELECTRODE CONDUCTOR...............................................................................................2 MINIMUM SIZE EQUIPMENT GROUND CONDUCTOR ........................................................................2 GENERAL INFORMATION .........................................................................................................................3 RACEWAY CONFIGURATIONS FOR SIZING AND CONDUCTOR DERATING .................................3 VOLTAGE DROP CALCULATIONS...........................................................................................................4 SUPPLEMENTARY VALIDATION PROBLEMS.....................................................................................10 Network Based NEC Wire Sizing.................................................................................................................14 1.1 Feeder Type Option ........................................................................................................................21 1.2 Adding a Pre-Sized Feeder into an Existing Conduit .....................................................................22 1.3 Copying and Pasting Wire Sizing Studies ......................................................................................26 Standalone NEC Wire Sizing........................................................................................................................28 2.1 Adding a Pre-Sized Feeder into an Existing Conduit (Standalone Method)...................................34 2.2 Accessing Tables and Databases.....................................................................................................36 2.2.1 Wire Tables.......................................................................................................................37 2.2.2 Conductor Properties Tables.............................................................................................41 2.2.3 Raceway Tables ................................................................................................................44 2.3 Creating a New Master Wire Database .......................................................................................45 2.3.1 Assigning a New Default Master Wire Database .............................................................46

2.0

ii

NEC Sire Sizing

Tables Table 1..........................................................................................................................................................................6 Table 2..........................................................................................................................................................................7 Table 3..........................................................................................................................................................................8 Table 4..........................................................................................................................................................................9 Table 5..........................................................................................................................................................................9

Note:

You can view this manual using your CD as an Adobe Acrobat PDF file. The file name is:

NEC Wire Sizing

NEC_Wire_Sizing.pdf

You will find the Test/Job files used in this tutorial at the following location: C:\DesignBase\Samples\NECWireSz = NEC Wire Sizing

Test Files:

EDSA_WS, WIRE_SA

Copyright 2008 All Rights Reserved

iii

NEC Wire Sizing

I.

FOREWORD

The Wire Sizing program accepts user's information regarding the components to be used for an electrical system. Based on this information, the program computes the smallest allowable wire size which meets user's specifications. The program also computes the conduit size required, and the voltage drop in Volts and in percentages. The program allows the user to define many sets of data and to perform the corresponding calculations on each individual set. Each set is called a "branch". Thus, the program maintains the user's list of branches with the calculations for each branch.

II.

CALCULATIONS

The program can: Size power conductors according to NEC for the following conditions: Any number of conductors in a single conduit or raceway. Additional power conductors can be added to the conduit to affect the derating of the conductor. Circuits involving multiple conductors per phase. Single conductor cables in a cable tray.

Size system grounding electrode conductors. Size equipment grounding conductors. Calculate voltage drop at design load for single-phase two- and three-wire circuits, and three-phase three-wire and four-wire circuits. Size conduits, raceways and cable trays for all power conductor conditions listed above.

III.

DATA TABLES

All data tables used by the program are completely accessible and can be edited by the user. They are as follows: Ampacity tables; Ambient temperature and multiple conductor adjustments; AC resistance and reactance of conductors; Conductor dimensions; Insulation properties; Conduit, raceway, and cable tray dimensions. Multiple wire table data files can be maintained to meet the needs of different projects.

Conduit, raceway and cable tray dimensions can be input by the user to match any desired system. Several generic types are supplied by EDSA.

NEC Wire Sizing

IV.

FEATURES

The user interface is completely menu driven. Calculations are done on-screen with a Windows spreadsheet style editing screen. Default parameters can be set at two levels to control wire and conduit sizing: MASTER DEFAULTS Master defaults are stored in the wire sizing table file. These values are used to initialize a new job file, and can be customized by the user. JOB DEFAULTS The default parameters can be further customized for each individual job file without affecting the master default settings. All of these defaults may be overridden for each individual circuit in the job file. A wire size can be specified by the user. In this case, the program calculates the voltage drop, and checks the actual derated ampacity against the load. If a conduit size is specified by the user, the actual fill is checked against the allowable fill for the given size. Additional wires of a given size, or type, can be specified as running in the same conduit with the circuit being sized. These wires can be specified as power conductors, in which case they affect both conduit fill and ampacity, or as control wires, in which case they affect only the conduit fill.

V.

GROUNDING ELECTRODE CONDUCTOR

This part of the program computes the size of the required grounding electrode conductor for a specified service entrance. First, define the service entrance conductor(s) by specifying the type "S" (to instruct the program to size a service entrance based on a given load), or "PS" (to directly input a service entrance conductor size). Next, define the grounding electrode conductor by specifying a type "SG" wire. Be sure to select the material ("AL" or "CU") from the detail screen. (AL = Aluminum, CU = Copper) The program will select a grounding electrode conductor based on the total area of all type "S" and "PS" wires. (See Article 250-94 NEC 2000.)

VI.

MINIMUM SIZE EQUIPMENT GROUND CONDUCTOR

This part of the program computes the minimum size equipment grounding conductors for grounding raceway and equipment if given the rating of the automatic overcurrent device, and the material of the conductor. Select an equipment ground conductor by specifying a type "EG" wire. The value entered in the load column will be used as the rating, or overcurrent, device setting to select the conductor. See NEC 2000, Article 250-95.

NEC Wire Sizing

VII.

GENERAL INFORMATION

Ampacities and ambient correction factors are based on the Table #310-16 and #310-17, NEC 2000. Derating due to the number of conductors in a conduit is based on the Table on page 70-166, NEC 2000. Derating due to temperature is based on Table #310-16 and #310-17, NEC 2000. Conduit, raceway, and cable tray selections are based on the total wire area plus insulation based on Table #5, Chapter 9, NEC 2000. Bare wire area is based on Table #8, Chapter 9, NEC 2000. Voltage drops are calculated for single-phase two- or three-wires; three-phase three- or four-wires. See IEEE Std and Beeman. AC resistance and reactance are based on Table #9, Chapter 9, NEC 2000. Types of loads: A = current to be specified, in amps; KW to be specified; KVA to be specified; horsepower with the percentage efficiency to be specified.

KW = KVA = HP =

Note that the current required must be determined. If known, the current can be directly entered. Otherwise, user can enter KW, KVA, or HP. The program will then compute how much current is generated by the specified load and will take 125% of the computed load current for wire size calculations. (125% value can be changed by user to any desired percentage.) For KW, program uses % Power Factor (Job Default). For KVA, user must enter KVA. For HP, user must enter horsepower. Program uses percentage Power Factor and percentage Efficiency (Job Default). The generated current will be computed using these quantities and the above mentioned voltage and phase. Next, user must enter information about the additional conductors which will share the conduit. For each conductor, user will enter its number and type, its wire size, and its type of insulation.

VIII.

RACEWAY CONFIGURATIONS FOR SIZING AND CONDUCTOR DERATING

Four configurations of raceways/cable trays are supported. Define the configuration for each

NEC Wire Sizing

raceway data set by selecting the Tables/Raceway Data menu and entering one of the following codes in the type field: C P Single conduit for all conductors; Separate parallel conduits for each set of phase conductors. (Each conduit contains one of each phase conductors, plus neutral.); Raceway; Cable Tray.

R T

The four EDSA supplied raceway data sets provide typical examples of each of the four configuration types.

The selection of each configuration affects the following calculations: 1. For automatic calculation of the area, conduits are assumed to be round and raceways rectangular. Note that the calculated area can be overridden. Conductor derating for conduits follows Note 8, Ampacity Tables in Article 310, NEC 2000. Conductor derating for raceways follows Article 362-5, NEC 2000. Conductor derating for cable trays must be entered directly by the user in the wire detail screen. Refer to Article 318, NEC 2000. Conduit and raceway sizing is based on fill ratio: the ratio of the sum of all wire crosssectional areas to the cross-sectional area of the raceway. Refer to Chapter 9, Table 1, NEC 2000. Cable sizing is based on Article 318-10, NEC 2000.

2. 3. 4.

5.

6.

IX.

VOLTAGE DROP CALCULATIONS

Voltage drop calculations are based on AC resistance and reactance tables derived from Table #9, Chapter 9, NEC 2000. The method of calculation is based on Beeman.

NEC Wire Sizing

The above diagram indicates the magnitude of error when using the following equations: Line-to-neutral voltage drop = I(R cos + X sin ). (11)

Equation 11 can be converted to calculate the percent voltage drop as follows: Percent voltage drop =

KVA (R cos + X sin ) * 100 (kv ) 2

(12)

where KVA is three-phase KVA and KV is line-to-line kiloVolts. For single-phase circuits the percentage drop is twice this value. AC resistance is corrected for operating temperatures as follows: Resistance at lower temperature R1 = R 2

I Z R + T1 I Z R + T2

I Z R + T2 I Z R + T1

(13)

Resistance at higher temperature R2 = R1 where: T1 T2 IZR IZR IZR = = = = = Low temperature; High temperature;

(14)

Inferred zero resistance temperature; -234.5 for copper; -236.0 for aluminum.

NEC Wire Sizing

Conduit, raceway, and cable tray selections are based on Article 300-3b, NEC* 2000. All conductors of the same circuit, plus neutral and equipment grounding conductors, are contained within the same conduit. Conduits are selected according to Article 345-7, NEC 2000. Conductor ampacity derating for conduits is according to Note 8, Article 310 of NEC 2000. Raceways are selected according to Article 362-5, NEC 2000. Cable trays are selected according to Article 318-10, NEC 2000. Conductor ampacity is adjusted according to Article 318-11 (b), NEC 2000.

NOTE: National Electric Code and NEC are registered trademarks of the National Fire Protection Association, Quincy, Massachusetts 02269, U.S.A.

Table 1 MATERIAL TEMPERATURE FOR ZERO RESISTANCE (C) -236.0 -234.5

Aluminum Copper A circular mil is a circle 0.001 inch in diameter. A mil is one thousandth of an inch (0.001 inch) C mils = = R where: A d L r R = = = = = Area in C mils; Diameter in mils; Length of wire in feet; Specific resistance of material; Resistance of wire. = square mils 1.273 square mils C mils 0.7854.

r L d

2

= r

L A

(15)

NEC Wire Sizing

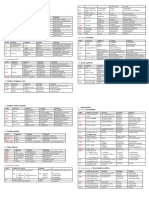

Table 2 CONDUCTOR DERATING FACTORS FOR MORE THAN THREE CONDUCTORS IN A RACEWAY CONDUCTOR DERATING FACTOR WITH LOAD DIVERSITY Factor 0.8 0.7 0.6 0.5 Number of Conductors in Raceway 4 to 6 7 to 24 25 to 42 43 or more

CONDUCTOR DERATING FACTOR WITHOUT LOAD DIVERSITY Factor .8 .7 .5 .45 .40 .35 Number of Conductors 4 to 6 7 to 9 10 to 20 21 to 30 31 to 40 41 to 60

Please read Section 8. Adjustment Factors, on pages 70-196 of NEC Article 310. When you size conductors for loads, if you consider neutral as a conductor, the conductors are derated with regard to the above NEC table.

NEC Wire Sizing

Table 3 BASIC CLASSIFICATIONS OF INSULATION TYPES IN GENERAL USE

Type R RH RHH

Material and Characteristics Rubber Heat-resistant rubber Higher-temperature, heatresistant rubber Heat- and moisture-resistant rubber Thermoplastic Heat-resistant thermoplastic Heat- and moisture-resistant thermoplastic

Application Dry Locations Dry Locations

Maximum Operating Temperature (F) 140 167

Dry Locations Dry or Wet Locations Dry Locations Dry Locations Dry or Wet Locations Dry or Wet Locations

194

RHW

167 140 167

T TH THW

167

THWNa Heat- and moisture-resistant thermoplastic with nylon covering

167

NEC Wire Sizing

Table 4 Table 5

AMPACITY OF SINGLE INSULATED CONDUCTORS IN FREE AIR. AMPACITY OF THREE (OR FEWER) CONDUCTORS IN A CABLE OR RACEWAY

Size AWG or MCM

Copper R,T,TW TW 60C (140F)

RH,RHW THWN,THW 75C (167F)

Aluminum R,T,TW RH,W,T 60C THW,THWN (140F) 75C (167F)

Size AWG or MCM

Copper R,T,TW 60C (140F)

RH,RHW THWN,THW 75C (167F)

Aluminum R,T,TW RH,W,T 60C THW,THWN (140F) 75C (167F)

14 12 10 8 6 4 AWG 3 2 1 0 00 000 0000

20 25 40 55 60 105 120 140 165 195 225 260 300

20 25 40 65 95 125 145 170 195 230 265 310 360

_ 20 30 45 60 80 95 110 130 150 175 200 230

_ 20 30 55 75 100 115 135 155 180 210 240 280 AWG

14 12 10 8 6 4 3 2 1 0 00 000 0000

15 20 30 40 55 70 80 95 110 125 145 165 195

15 20 30 45 65 85 100 115 130 150 175 200 230

_ 15 25 30 40 55 65 75 85 100 115 130 155

_ 15 25 40 50 65 75 90 110 120 135 155 180

250 300 350 400 500 MCM 600 700 750 800 900 1000

340 375 420 455 515 575 630 655 680 730 780

405 445 505 545 620 690 755 785 815 870 935

265 290 330 355 405 455 500 515 535 580 625

315 350 395 425 485 545 595 620 645 700 750 MCM

250 300 350 400 500 600 700 750 800 900 1000

215 240 260 280 320 355 385 400 410 435 455

255 285 310 335 380 420 460 475 490 520 545

170 190 210 225 260 285 310 320 330 355 375

205 230 250 270 310 340 375 385 395 425 445

NEC Wire Sizing

X.

A.

SUPPLEMENTARY VALIDATION PROBLEMS

VERIFY SENSITIVITY OF THE PROGRAM TO CONDUCTOR TEMPERATURE RATING. Refer to jobfile "OPTEMP" for examples. Given the following circuit: Load: Length Voltage Ambient 400 amps 500 ft. 480 /three-phase 30 c

select the appropriate conductor, and calculate the voltage drop for insulations rated at 60c, 75c, 85c and 90c. a. 60c (insulation TW) We wish to limit our selection to 500 kcmil to smaller cable. This will require two cables per phase since the design ampacity of 500 amps is greater than the capacity of a single 500 kcmil cable. Multi-conductor derating from note 8, Article #310, NEC 2000: 0.80 Try 2-400 kcmil: (ampacities from Article 310-16), NEC 2000 280 x 2 x 0.80 = 448 Try 2-500 kcmil: 320 x 2 x 0.80 = 512 THIS WILL WORK (not enough)

Voltage drop: (impedance from Table # 9, Chapter # 9, NEC 2000) Z = 0.050 x (60 + 234.5) / (75 + 234.5) = 0.0476 vd = 200 x (.0476 /1000) x 500 = 4.76 Volts (Program result: 2-500 kcmil cables, voltage drop of 4.87 Volts)

b. 75c (insulation THWN) Try 2-400 kcmil: 335 x 2 x 0.80 = 536 THIS WILL WORK

10

NEC Wire Sizing

Try 2-350 kcmil: 310 X 2 X 0.80 = 496 (not enough)

Voltage drop: VD = 200 X (.056 / 1000) X 500 = 5.6Volts (Program result: 2-400 kcmil cables, voltage drop of 5.56 Volts)

c. 85c (insulation V) Try 2-350 kcmil: 340 x 2 x 0.080 = 540 Try 2-300 kcmil: 310 x 2 x 0.80 = 496 Voltage drop: Z = 0.60 x (85 + 234.5) / 75 + 234.5) = 0.062 vd = 200 x (.056 /1000) x 500 = 6.2 Volts (Program result: 2-350 kcmil cables, voltage drop of 6.06 Volts) (not enough) THIS WILL WORK

d. 90c (insulation V) Try 2-300 kcmil: 320 x 2 x 0.80 = 512 Try 2-250 kcmil: 290 x 2 x 0.80 =464 Voltage drop: Z = 0.065 x (90 + 234.5) / (75 + 234.5) = 0.068 vd = 200 x (.056 / 1000) x 500 = 6.8 Volts (Program result: 2-300 kcmil cables, voltage drop of 6.7 Volts) The above results for cable selection exactly match the program results. This is to be expected since the program uses a table look-up method that follows the manual procedure for using Table # 310 in NEC 2000. Voltage drops calculated by the program are within 2 percent, or less, of the manual calculations. (not enough) THIS WILL WORK

11

NEC Wire Sizing

B.

VERIFY CABLE TRAY SELECTION Note that the cable tray selection capability in the current version on NEC wire sizing is a very basic, first effort at providing automated cable tray selection. Of the many possible configurations of cable in cable trays, only the fill configuration of Article 318-10 (a) NEC 2000 and the ampacity calculation of 318-11 (b) (1) and (2) NEC 2000 are supported. Note that for ampacity calculations, the user must select the appropriate derating factor from 318-11 (b) NEC 2000 depending on conductor size and decide whether the tray is covered. Refer to jobfile "CBLTRAY" for examples.

a. Select a cable tray for the following cables: 8 - 500 kcmil XHHW 6 - 4-0 XHHW 3 - 250 kcmil XHHW

Since there are conductors in the 1-0 to 4-0 range, selection is governed by Article 318-110 (a) (4) NEC 2000. The sum of diameters of all cables is: Number and Size 8 - 500 kcmil XHHW 6 - 4-0 XHHW 3 - 250 kcmil XHHW Diameter 0.955 0.646 0.716 Total 7.64 3.876 2.148 13.664 inches

This requires a cable tray larger than 12 inches, and the next size in our catalog is 18 inches. ( Calculation agrees with program result.)

b. Select a cable tray for the following cables: 4 - 750 kcmil XHHW 4 - 1000 kcmil XHHW 4 - 1750 kcmil XHHW Since there are conductors both larger than, and smaller than 1000 kcmil, Article 310-10 (a) (3) of NEC 2000, governs.

12

NEC Wire Sizing

Number and Size 4 - 750 kcmil XHHW

Diameter or Area 1.0936 in2

Total 4.374 in2 5.32 in 6.96 in

4 - 1000 kcmil XHHW 1.330 in 4 - 1750 kcmil XHHW 1.740

Try 12 inch cable tray. From Table # 318-10, NEC 2000, the maximum fill for cables less than 1000 kcmil is: 13.0 - (1.1 [5.32 = 6.96]) = 5.99 in Try 18 inch cable tray: 19.5 - (1.1[5.32 = 6.96]) = 5.99 in2 Since this is greater than the 4.374 square inch area to be accommodated, 18 inch is OK. (This agrees with the program result.)

2

13

NEC Wire Sizing

1.0

Network Based NEC Wire Sizing ork

Step 2. Before proceeding with the actual wire sizing exercise, select the Wire Sizing Tools icon in order to get familiar with the functions included in this application.

Step 3. Once the Wire Sizing Tools command is invoked, the tools menu will appear in this position.

Step 1. Proceed to open the file EDSA_WS.axd located in the Design Base 2.0 NECwiresz Samples folder.

14

NEC Wire Sizing

The Analysis pick-list, allows the user to select the type of wire sizing methodology to be used.

The Defaults command sets the base calculation parameters for the analysis (Voltage, etc.).

The Edit command allows the user to enter and/or edit data for the selected feeder.

The Delete command allows the user to delete the cable sizing data for the selected feeder.

The Copy command allows the user to copy the cable sizing data from the selected feeder.

The Paste command allows the user to assign previously copied data to the selected feeder.

The View command allows the user to view a list of all the feeders assigned to the job file.

The Store command allows the user to save the cable sizing data being added to the selected feeders.

15

NEC Wire Sizing

Step 4. Proceed to size a 3-phase / 3-wire feeder for MCC-1 as shown here. To begin, click on the cable once to select it.

Step 5. Proceed to define the default analysis parameters by selecting the Defaults icon.

16

NEC Wire Sizing

Step 6. Select the Settings tab.

Step 7. Proceed to specify the voltage, phase/wire configuration, cable temperature rating, ambient temperature, and maximum allowable voltage drop as applicable. For this example, use the values suggested here.

Step 9. Define the load diversity factor, cable tray derating factor, load power factor, and motor efficiency defaults. For this example, use the values suggested here. Step 10. Select the Conduit tab.

Step 8. Define the wire material, insulation type and maximum wire gauge to be used in the design. For this example, use the values suggested here.

Step 11. From the pick-lists, select the type of conduit to be used and its respective material. Also specify the maximum fill limit for the conduit. For this example, use the values suggested here.

Step 12. Select OK to complete the default settings.

17

NEC Wire Sizing

Step 13. When prompted to save the file, select Yes.

Step 15. The connectivity data is automatically loaded from the single line diagram as shown in these fields.

Step 14. Before proceeding, make sure that the feeder under study is still selected in the single line diagram (verify Step 4). Select the Edit icon.

Step 16. From the pick list, select the category of the cable based on the NEC classification. For this example, select Feeder.

Step 17. Enter and/or verify the length of the feeder under study.

Step 18. Enter the load value and select its respective units as indicated.

Step 19. Once all the data has been entered, press the Tab button on your keyboard to run the analysis. The required cable size and number of conductors per phase are shown here. Also the actual design ampacity, voltage drop in volts/% are shown in the gray boxes. Step 20. Select Wire Detail.

18

NEC Wire Sizing

Step 21. The results of the wire and conduit sizing exercise are shown here.

Step 22. Select the Settings tab to review and/or modify the default settings for the file.

Step 23. Select the Conduit tab to review and/or modify the selected conduit data.

Step 25. Select the OK to accept and return to the Edit Wire Segment dialog box. Once there, select OK to return the single line diagram.

Step 24. Select the Detail tab to add additional wires into the newly sized conduit. This feature will be explained in subsequent sections of this tutorial.

19

NEC Wire Sizing

Step 26. To add additional cables, repeat the same procedure shown in steps 1 through 26. To view all the cables in the job file, select the View icon.

Step 27. All the wire segments in the file would be listed here. To view a report on a specific segment, select it and press View. To view all of the listed segments, select View All. To edit a specific wire segment, select it and press Edit.

Step 28. Select Done to exit.

20

NEC Wire Sizing

1.1

Feeder Type Option

This section is intended to clarify the different feeder Type options that are available in the Edit Wire Segment menu.

F Feeder This option will automatically size a feeder branch cable based on the latest NEC requirements. The program will calculate the cable size, number of conductors per phase required, design amps, and voltage drop. PF Pre-sized Feeder This option allows the user to manually enter (pre-size) a cable for the branch feeder under study. The program will calculate design amps, and voltage drop based on the cable and load specified by the user. S Service Entrance This option will automatically size a service entrance cable based on the latest NEC requirements. The program will calculate the cable size, number of conductors per phase required, design amps, and voltage drop. PS Pre-Sized Service Entrance This option allows the user to manually enter (pre-size) a cable for the service entrance under study. The program will calculate design amps, and voltage drop based on the cable and load specified by the user. SG System Ground This option will automatically size a ground conductor for a specified service entrance cable based on the latest NEC requirements. The user enters the ampacity of the service entrance cable, and the program will calculate the size of an NEC compliant ground cable. EG Equipment Ground This option will automatically size a ground conductor for a specified service feeder cable based on the latest NEC requirements. The user enters the ampacity of the feeder cable, and the program will calculate the size of an NEC compliant equipment ground cable. CW Control Wire This option allows the user to specify a control wire cable.

21

NEC Wire Sizing

1.2

Adding a Pre-Sized Feeder into an Existing Conduit

Step 1. In this example, we will manually add an additional pre-sized feeder cable into the feeder/conduit previously sized in section 1.0 of this tutorial. Proceed by clicking on this feeder once, in order to select it.

Step 2. Once the existing feeder has been selected, press the Edit icon.

22

NEC Wire Sizing

Step 3. Select Wire Detail.

Step 4. Select Add.

Step 5. From the pick-list, select a 4 AWG, THHN single conductor. From the Type menu select PF-Pre-sized Feeder to indicate that this cable is being entered manually by the user. Select OK.

23

NEC Wire Sizing

Step 7. To update the wire count and the conduit size if necessary, select OK.

Step 6. The newly added cable is now listed on the table. The cable can be edited or deleted, by simply selecting it from the table and pressing either the Edit or Delete buttons.

Step 8. Select Wire Detail again to review the updated calculation.

24

NEC Wire Sizing

Step 9. The updated results are shown here.

25

NEC Wire Sizing

1.3

Copying and Pasting Wire Sizing Studies

Step 1. In this example, we will copy the wire sizing study performed on MCC-1 Feeder and paste it onto MCC-2 Feeder. The assumption here is that both cables will be designed as identical feeders.

COPY

Step 2. Select the feeder to be copied, by clicking on it once as indicated here. Select MCC-1 Feeder.

Step 3. Once the existing feeder has been selected, press the Copy icon.

26

NEC Wire Sizing

Step 6. The operation has now been completed. To verify the successful addition of the new study, select the View icon.

Step 5. Select the Paste icon.

Step 4. Select MCC-2 Feeder by clicking on it once.

Step 7. The new study is listed in the table, as shown here.

27

NEC Wire Sizing

2.0

Standalone NEC Wire Sizing

Step 1. Invoke the EDSA Technical program.

Step 2. Open the Selection menu.

Step 3. Select the Wire Sizing NEC option.

Step 4. Proceed to create a new standalone file by selecting File/New.

Step 5. Name the new file and select Save.

Step 6. Proceed to assign the default analysis parameters by selecting Edit/Job Defaults.

28

NEC Wire Sizing

Step 7. Select the Settings tab.

Step 8. Proceed to specify the voltage, phase/wire configuration, cable temperature rating, ambient temperature, and maximum allowable voltage drop as applicable. For this example, use the values suggested here.

Step 10. Define the load diversity factor, cable tray derating factor, load power factor, and motor efficiency defaults. For this example, use the values suggested here. Step 11. Select the Conduit tab.

Step 9. Define the wire material, insulation type and maximum wire gauge to be used in the design. For this example, use the values suggested here.

Step 12. From the pick-lists, select the type of conduit to be used and its respective material. Also specify the maximum fill limit for the conduit. For this example, use the values suggested here.

Step 13. Select OK to complete the default settings.

29

NEC Wire Sizing

Step 14. Select the Save icon in order to save the new settings.

Step 15. Proceed to add the required wire segments by selecting Edit/Wire Segments.

Step 16. To add a wire segment, select Add.

30

NEC Wire Sizing

Step 17. Specify the labels for the From Node, To Node and the wire Segment. Proceed as indicated here.

Step 18. From the pick list, select the category of the cable based on the NEC classification. For this example, select Feeder.

Step 19. Enter and/or verify the length of the feeder under study.

Step 20. Enter the load value and select its respective units as indicated.

Step 21. Once all the data has been entered, press the Tab button on your keyboard to run the analysis. The required cable size and number of conductors per phase are shown here. Also the actual design ampacity, voltage drop in volts/% are shown in the gray boxes. Step 22. Select Wire Detail.

31

NEC Wire Sizing

Step 23. The results of the wire and conduit sizing exercise are shown here.

Step 24. Select the Settings tab to review and/or modify the default settings for the file.

Step 25. Select the Conduit tab to review and/or modify the selected conduit data.

Step 27. Select the OK to accept and return to the Edit Wire Segment dialog box. Once there, select OK to return the single line diagram.

Step 26. Select the Detail tab to add additional wires into the newly sized conduit. This feature will be explained in subsequent sections of this tutorial.

32

NEC Wire Sizing

Step 29. Next, lets add an equipment ground for the previously sized feeder MCC-1 Feeder

Step 28. The newly sized cable is listed in the Wire Segment table, as shown here.

Step 30. Repeat steps 1 through 28, using the entries shown here for an Equipment Ground wire.

Step 31. The required equipment ground is shown here.

Step 32. Select OK to continue.

Step 33. The newly added Equipment Ground wire is shown here.

33

NEC Wire Sizing

2.1

Adding a Pre-Sized Feeder into an Existing Conduit (Standalone Method)

Step 1. Select the conduit in which to add an additional pre-sized feeder.

Step 2. Select Detail.

Step 3. Select the Detail tab.

Step 4. Select Add.

Step 5. From the pick-list, select a 4 AWG, THHN single conductor. From the Type menu select PF-Pre-sized Feeder to indicate that this cable is being entered manually by the user. Select OK.

34

NEC Wire Sizing

Step 6. The newly added cable is now listed on the table. The cable can be edited or deleted, by simply selecting it from the table and pressing either the Edit or Delete buttons.

Step 7. To update the wire count and the conduit size if necessary, select OK.

Step 8. Select Detail again to review the updated calculation.

35

NEC Wire Sizing

2.2

Accessing Tables and Databases

The Tables menu allows the user to gain access to the various databases used in the calculations for viewing and editing purposes.

WARNING This section (2.2) shows how to modify the data in the current database. The current database is designated as the Master Database for the program. The default Master database is called WIRETBLS.NEC and contains the most current NEC compliant data. Any changes to this database will affect the NEC compliance of the results.

36

NEC Wire Sizing

2.2.1 Wire Tables

The Wire Tables database, allows the user to view and modify, if required, values for all the parameters shown here.

The Wire Parameters table allows the user to modify base parameters for the wire and conduit sizing calculations. Refer to section 2.0, steps 7 to 13 for details.

The Ambient Correction Factors table, allow the user to view the current code compliant data. By selecting Add, Edit or Delete the user can make modifications to the existing data as required.

37

NEC Wire Sizing

The Multi-Conductor table allows the user to verify and/or edit the ampacity based on the number of conductors within a raceway. Two tables are available for this purpose; with and without taking into account diversity factors.

38

NEC Wire Sizing

The Insulation Classes table allows the user to view and/or edit the temperature rating for each type of insulation.

The Equipment Ground table allows the user to view and/or edit the ground wire size required for a feeder based on the over-current protection setting.

39

NEC Wire Sizing

The Small Motors table allows the user to specify current ratings for motors based on 120 V and 240 V voltage applications.

40

NEC Wire Sizing

2.2.2 Conductor Properties Tables

In the Wire Sizes section, the user can view, modify or add cable AWG gauges and their respective cross section in Circular Mils.

In the Base Ampacities table, the user can view and/or modify the current rating for each cable for different insulation temperatures. Both Copper and Aluminum cables are included in the table.

41

NEC Wire Sizing

The Conductor Dimensions table allows the user to view and/or modify the cross section area of all insulated conductor sizes. Aluminum and Copper are included.

The Impedance table allows the user to view and/or modify the AC Resistance and AC Reactance of the cables in the database. Aluminum and Copper are included.

42

NEC Wire Sizing

The System Ground table allows the user to view/modify the ground conductor sizes that correspond to specific service entrance ampacity ratings. Both Aluminum and Copper are included.

43

NEC Wire Sizing

2.2.3 Raceway Tables

The Raceway Tables allow the user to designate numbers and ids to different types of raceways that are to be used in different design applications.

The Data Set table allows the user to view, add or modify the physical dimensions of conduits based on their trade size designation.

44

NEC Wire Sizing

2.3

Creating a New Master Wire Database

Step 1. To create a new database, select File/New Master Wire Table.

Step 2. Assign a new name to the database, and press Open.

Step 3. Select in sequence Wire Tables, Conductor Properties & Raceway Tables and populate the empty tables of the new database with the new default data. Proceed as indicated in section 2.2 of this document.

45

NEC Wire Sizing

2.3.1 Assigning a New Default Master Wire Database

Step 1. To assign a new default database, select File/Select Master Wire Table.

Step 2. From the list, select the new table to use, and press Open.

46

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Edsa PaladinDocumento12 pagineEdsa PaladinIulian Pârjoleanu100% (1)

- Edsa PaladinDocumento64 pagineEdsa PaladinIulian PârjoleanuNessuna valutazione finora

- Edsa PaladinDocumento35 pagineEdsa PaladinIulian PârjoleanuNessuna valutazione finora

- Edsa PaladinDocumento66 pagineEdsa PaladinIulian PârjoleanuNessuna valutazione finora

- Edsa PaladinDocumento15 pagineEdsa PaladinIulian PârjoleanuNessuna valutazione finora

- Edsa PaladinDocumento52 pagineEdsa PaladinIulian PârjoleanuNessuna valutazione finora

- Power Transmission LinesDocumento66 paginePower Transmission Linesaamir_janjua_3Nessuna valutazione finora

- Edsa PaladinDocumento30 pagineEdsa PaladinIulian PârjoleanuNessuna valutazione finora

- Edsa PaladinDocumento54 pagineEdsa PaladinIulian PârjoleanuNessuna valutazione finora

- Edsa PaladinDocumento89 pagineEdsa PaladinIulian PârjoleanuNessuna valutazione finora

- Edsa PaladinDocumento17 pagineEdsa PaladinIulian Pârjoleanu100% (1)

- Edsa PaladinDocumento47 pagineEdsa PaladinIulian PârjoleanuNessuna valutazione finora

- Edsa PaladinDocumento49 pagineEdsa PaladinIulian PârjoleanuNessuna valutazione finora

- Edsa PaladinDocumento151 pagineEdsa PaladinIulian Pârjoleanu100% (1)

- Edsa PaladinDocumento2 pagineEdsa PaladinIulian PârjoleanuNessuna valutazione finora

- Edsa PaladinDocumento13 pagineEdsa PaladinDaniel Gutierrez100% (1)

- Edsa PaladinDocumento33 pagineEdsa PaladinIulian PârjoleanuNessuna valutazione finora

- GensizDocumento27 pagineGensizinsan_soft6498Nessuna valutazione finora

- Edsa PaladinDocumento25 pagineEdsa PaladinIulian PârjoleanuNessuna valutazione finora

- Edsa PaladinDocumento57 pagineEdsa PaladinIulian PârjoleanuNessuna valutazione finora

- Ground Grid DesignDocumento63 pagineGround Grid DesignReza Torkaman100% (1)

- Edsa PaladinDocumento87 pagineEdsa PaladinIulian PârjoleanuNessuna valutazione finora

- DCSC PDFDocumento35 pagineDCSC PDFkolombo1776Nessuna valutazione finora

- Edsa PaladinDocumento72 pagineEdsa PaladinIulian PârjoleanuNessuna valutazione finora

- Cap SizeDocumento12 pagineCap Sizesa_125Nessuna valutazione finora

- Cable - Pulling Edsa ManualDocumento48 pagineCable - Pulling Edsa Manualmapasabc100% (3)

- Edsa PaladinDocumento111 pagineEdsa PaladinDaniel GutierrezNessuna valutazione finora

- Cable AmpacityDocumento81 pagineCable Ampacitysamsunglover50% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Module 4 - What Is The Required Rate of ReturnDocumento2 pagineModule 4 - What Is The Required Rate of ReturnEthics BAENessuna valutazione finora

- Bobcat Technical Information Bulletin - CompressDocumento2 pagineBobcat Technical Information Bulletin - Compressgerman orejarenaNessuna valutazione finora

- 3RP15 05-1aDocumento3 pagine3RP15 05-1atycristinaNessuna valutazione finora

- Astm D5501Documento3 pagineAstm D5501mhmdgalalNessuna valutazione finora

- SIEMENS-7SA522 Setting CalculationDocumento20 pagineSIEMENS-7SA522 Setting Calculationnaran19794735Nessuna valutazione finora

- Displaymax JR 1500 SpecsDocumento1 paginaDisplaymax JR 1500 SpecsFRANCISCONessuna valutazione finora

- View DsilDocumento16 pagineView DsilneepolionNessuna valutazione finora

- WPS Office 2016Documento22 pagineWPS Office 2016Muhammad Aliff SyukriNessuna valutazione finora

- College of Information Technology Dmmmsu-Mluc City of San FernandoDocumento9 pagineCollege of Information Technology Dmmmsu-Mluc City of San FernandoZoilo BagtangNessuna valutazione finora

- THKDocumento1.901 pagineTHKapi-26356646Nessuna valutazione finora

- The Professional DesktopDocumento318 pagineThe Professional Desktopalintuta2Nessuna valutazione finora

- FM Chapter2Documento3 pagineFM Chapter2Drkumar SwamyNessuna valutazione finora

- Affixation (Landscape)Documento4 pagineAffixation (Landscape)difafalahudinNessuna valutazione finora

- © Ncert Not To Be Republished: AlgebraDocumento12 pagine© Ncert Not To Be Republished: Algebrakritagyasharma29Nessuna valutazione finora

- Five Factors of CleaningDocumento2 pagineFive Factors of CleaningKimberly Bruce De CastroNessuna valutazione finora

- PDS OperatorStationDocumento7 paginePDS OperatorStationMisael Castillo CamachoNessuna valutazione finora

- Green Synthesis of Zinc Oxide Nanoparticles: Elizabeth Varghese and Mary GeorgeDocumento8 pagineGreen Synthesis of Zinc Oxide Nanoparticles: Elizabeth Varghese and Mary GeorgesstephonrenatoNessuna valutazione finora

- PresiometroDocumento25 paginePresiometrojoseprepaNessuna valutazione finora

- HI-8592, HI-8593, HI-8594: Single-Rail ARINC 429 Differential Line DriverDocumento14 pagineHI-8592, HI-8593, HI-8594: Single-Rail ARINC 429 Differential Line DriversameeppaiNessuna valutazione finora

- BetaDocumento16 pagineBetaAkshita Saxena100% (2)

- Iso 10042Documento5 pagineIso 10042Nur Diana100% (3)

- CD IK Tools v1.5 Plugin for C4D 9.6Documento20 pagineCD IK Tools v1.5 Plugin for C4D 9.6Syed Aal-HussainNessuna valutazione finora

- Reliability EngineeringDocumento9 pagineReliability Engineeringnvaradharajan1971Nessuna valutazione finora

- This HandoutDocumento11 pagineThis HandoutAnonymous QM0NLqZONessuna valutazione finora

- Rochor Station Pile Design CalculationsDocumento15 pagineRochor Station Pile Design CalculationsDifa LiuNessuna valutazione finora

- e-GP System User Manual - Tender Evaluation Committee UserDocumento82 paginee-GP System User Manual - Tender Evaluation Committee UserMd. Jakaria ApuNessuna valutazione finora

- Seksioni I Kabllos Per Rrymat e Lidhjes Se ShkurteDocumento1 paginaSeksioni I Kabllos Per Rrymat e Lidhjes Se ShkurteDukagjin Ramqaj100% (1)

- 4495 10088 1 PBDocumento7 pagine4495 10088 1 PBGeorgius Kent DiantoroNessuna valutazione finora

- Smart Dustbin using ArduinoDocumento22 pagineSmart Dustbin using ArduinoEr Dinesh TambeNessuna valutazione finora

- QAF10A200S TheTimkenCompany 2DSalesDrawing 03 06 2023Documento1 paginaQAF10A200S TheTimkenCompany 2DSalesDrawing 03 06 2023LeroyNessuna valutazione finora