Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

LG Service Manual

Caricato da

Patti MeggittDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

LG Service Manual

Caricato da

Patti MeggittCopyright:

Formati disponibili

DISHWASHER

SERVICE MANUAL

BEFORE SERVICING THE UNIT, PLEASE READ THIS MANUAL CAREFULLY

FOR SAFETY AND CORRECT SERVICES.

NOTE

MODEL : LDS4821(WW,BB,ST)

- 3 -

1. CAUTION......................................................................................................................... 4

2. SPECIFICATIONS ........................................................................................................... 5

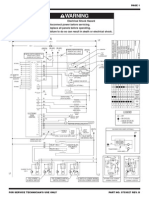

3. WIRING DIAGRAM........................................................................................................ 6

4. FEATURES & TECHNICAL EXPLANATION ................................................................... 7

5. PARTS NAME ................................................................................................................ 11

6. PROGRAM CHART ..................................................................................................... 12

7. HOW TO DISASSEMBLE ............................................................................................ 13

8. TROUBLE SHOOTING METHODS.............................................................................. 21

A. TROUBLE SHOOTING ACCORDING TO DISPLAYED ERROR MESSAGE...........21

B. TROUBLE DIAGNOSES AND REPAIR BY SYMPTOM........................................... 23

9. INSTALLATION INSTRUCTION ................................................................................... 27

10. EXPLODED VIEW .......................................................................................................34

11. REPLACEMENT PART LIST .......................................................................................41

CONTENTS

- 4 -

DISCONNECT POWER CORD BEFORE SERVICING

RECONNECT ALL GROUNDING DEVICES

IMPORTANT SAFETY NOTICE !

This service information is intended for individuals

possessing adequate backgrounds of electrical,

electronic and mechanical experience.

Any attempt to repair this appliance may result in

personal injury and property damage.

The manufacturer or seller can not be responsible

for the interpretation of this information, nor can it

assume any liability in connection with its use.

CAUTION !

- 5 -

2. SPECIFICATION

Rated Voltage / Frequency AC 120V/60Hz

Installation Built-In

Place Settings 16

Product Dimension(in) 23 3/4x 24 5/8x 33 5/8

Product Weight(lbs) 89lbs

Door Color White, Black, Stainless

Tub Material Stainless Steel

Control Electronic

Rated Power(Watt) 1,350

Heater Power(Watt) 1,200

Programs 4

Upper Rack Position manual

Lower Rack Fixed Tines

Water Consumption 10-26 (Normal)

Power Consumption(kWh/year) 285-310

Operating Time (min) 101-135 (Normal)

Fan Dry System Yes

Delay Start Function No

Auto-Off Power Switch Yes

Process Monitor Yes

Wash Level 5

Racks Nylon Coating

Operating Water Pressure (Bar) 20-120 (140-830kPa)

ITEM SPECIFICATION

- 6 -

LDS4821 serise

3. WIRING DIAGRAM

- 7 -

4. FEATURES & TECHNICAL EXPLANATION

4-1. Product Features

If you raise the Upper Rack, you can load large dishes in the Lower Rack.

(Max. 14 in.)

The tall tub provides large dishes loading as well as large capacity.

LG dishwashers let you load oversized items in the Lower and Upper Rack.

Newly introduced Slim Direct Inverter motor is inverter-controlled. Speed is

controlled based on program selection. It also offers high energy efficiency to

minimize energy loss.

This is one of the best performance solutions for drying dishes because it

minimizes venting humid air to the outside of the dishwasher. In addition, this

system ensures better drying results compared to the condensing drying

system.

Because of alternating water spray between the Upper and Lower

Rack, the water pressure allows superior performance and reduced

consumption of water and electricity.

For best wash results, the self-cleaning filter system continuously cleans the

water as it circulates. Your LG dishwasher has a self-cleaning filter that grinds

food into small particles before it goes down the drain.

Ultra Big Capacity

Slim Direct Motor

TM

Hybrid Drying System

Vario Spray System

Self Cleaning Filter

Moist

Air

Dry

Air

Mixed

Air

to

Upper

Arm

to

Lower

Arm

Soil Sensor

Fine Mesh

to Drain

- 8 -

4-2. Display Panel LDS 4821 Series

PROCESS INDICATOR (SignaLight

TM

)

Current program phase is indicated.

INDICATOR

Child Lock( ): Lamp will turn on when Child Lock setting is on.

Rinse Aid( ): Refill with rinse aid when Lamp turns on.

TIME REMAINING

Indicates normal run time for the cycle selected.

During the cycle, the estimated time remaining for the selected cycle will be displayed.

RINSE

Repeated pressing of the Rinse button will select Sanitary, Extra Rinse or both.

If you select the Sanitary Function, Sanitary Light blinks when the water temperature meet sanitary

Temp. and illuminates at the end of cycle when Conditions have been met to achieve sanitization.

When you select Extra Rinse, an additional rinse cycle is added.

NOTE These high temperature rinse sanitizes dishware and glassware in accordance with NSF/ANSI Standard 184 for

Residential Dishwashers. Certified residential dishwashers are not intended for licensed food establishments.

- 9 -

PROGRAM

Press the program that corresponds to your desired wash cycle.

CANCEL & CHILD LOCK

To cancel a running cycle, open the door, then press and hold the POWER SCRUB and NORMAL

buttons together for 3 seconds. The drain pump will be activated and the cycle will be canceled.

To lock/unlock the buttons, press QUICK and RINSE ONLY simultaneously for 3 seconds. When

CHILD LOCK is set, all buttons are disabled.

POWER

Pressing the POWER button turns on power to the control.

After the cycle is complete, the power automatically switches off after 4 minutes for safety and

economy.

If there is an unusual Power surge or disturbance, the power will be automatically turned off for safety

and the cycle will have to be started over.

POWER SCRUB

NORMAL

QUICK

RINSE ONLY

This program is for very heavily soiled loads.

This program is for normally soiled, every loads.

This program is for that quick wash of lightly soiled, recently used dishes

and cutlery.

This program is for just a quick rinse dishes. No detergent is used.

NOTE Only sanitary cycle have been designed to meet the requirements of performance for soil removal and sanitization

efficacy. There is no intention, either directly or indirectly, that all cycle on a certified machine have passed the

sanitization performance test.

Normal Water Level : 270

- 10 -

4-3. TEST MODE LDS4821 Series

CHECK PROGRAM

BUTTON

The number of

pushing button

Top

Display

Load and Checking points

Door open/

closed

RINSE+NORMAL

+POWER S/W

1 TIME n : 3H/U00 All LEDs are lighting

All LEDs are lighting

All LEDs are lighting

All LEDs are lighting

All LEDs are lighting

Soil Sensor

Wash Pump

Drain Pump

Inlet Valve

Dispenser

Heater (for 10 sec)

Fan

Thermistor

Lower Nozzle(VARIO)

Upper Nozzle(VARIO)

Auto-Off(Wash-Drain-Water Supply)

Both

Both

Both

Both

Both

Closed

Closed

Both

Closed

Closed

Closed

Both

Closed

Closed

Closed

POWER SCRUB

NORMAL

QUICK

RINSE ONLY

RINSE

1 TIME

1 TIME

1 TIME

1 TIME

1 TIME

2 TIME

3 TIME

4 TIME

5 TIME

6 TIME

7 TIME

8 TIME

9 TIME

10 TIME

11 TIME

12 TIME

1:11

2:22

3:33

4:44

Soil Level

n:32

n:33

Frequency

n:35

n:36

n:37

n:38

Temp.()

n:3a

n:3b

n:3c

Both

- 11 -

5. PARTS NAME

The appearance and specifications may be varied without notice according to localities.

5-3. LDS 4821 Series

INSTALL BRACKET WOOD SCREW

Control Panel

Front Display

Door Handle

Power Button

Front Cover

Lower Cover

Leveling Foot

Base

Top Spray Arm

Upper Spray Arm

Lower Spray Arm

Detergent & Rinse Aid Dispenser

Vapor Vent Cover

Upper Rack

Cutlery Basket

Lower Rack

- 12 -

6. PROGRAM CHART(SCHEMATIC DIAGRAM)

P

r

o

g

r

a

m

c

h

a

r

t

LDS 4821 Series

- 13 - - 13 -

BEFORE DISASSEMBLING THE DISHWASHER ;

1) Remove the cord from electric outlet to avoid electric shock.

2) Close the Water Tap (faucet).

3) Remove all dishes and items in the dishwasher.

4) Remove the Lower Rack and the Upper Rack.

5) Remove the inlet hose and drain hose connetion to avoid the hose damages.

6) Prepare some towels to avoid floor wet by the water left in the dishwasher.

7. HOW TO DISASSEMBLE

7-1. FULL DISASSEMBLE

1. Lower Cover and Lower Felt

1) Remove the front 2 screws.

2) Remove the Inlet Hose and Power Supply

Cable.

2. Tub Felt

1) Tub Felt

Lower Cover

Tub Felt

- 14 - - 14 -

Controller

Latch Assembly

Controller

3-1. Door Assembly

1) Front Cover

Open the door.

Remove 6 screws(stainless).

2) Control Panel Assembly

Remove 8 screws(Stainless).

Remove the wire connections.

Be sure the wiring should not be

changed in reassembling

Remove the Latch assembly.

Remove the Front Display.

Remove 8 screws for Controller.

Control Panel Front Cover

- 15 - - 15 -

Fan Assembly

Inner Cover Gasket

Flange

Hose

Detergent

Dispenser

Door Hinge

Air Duct

Door Bracket

Hinge Bracket

Hinge Spring

3) Fan Assembly

Open the door.

Remove 4 screws and a earth screw for

Door Bracket.

Remove the wire connetions.

Remove the Air Duct.

Turn the Inner Cover counterclockwise.

4) Detergent Dispenser

Close the door

Remove the wire connections.

Remove 6 screws with brackets.

Push the Detergent slowly pulling up the

the Flange by Standard Screwdriver.

5) Door Spring (Right & Left)

Push the Spring upwards and take it off

from the Hinge Bracket.

Be careful not to be injured by the

sharpedge of Tub.

Take off the Hinge Link from the Hinge.

6) Door Liner

Open the door.

Pull the Door Liner and take it off from

the Hinge Supporter.

Door Liner Assembly

Hinge Supporter

- 16 - - 16 -

Lead Wire Holer Hook

Lead Wire Holer

Lower Frame

Drain Hose

Drain Hose

Holder

4. Lower Frame

1) Press the holder hook as shown in figure.

2) Remove 4 screws.

6. Drain Hose Holder

1) Press the holder hook as shown in figure.

2) Pull the Drain Hose and remove the Drain

Hose Holder.

5. Put the Dishwasher upside down.

- 17 - - 17 -

7. Base Cover

1) Remove 2 screws.

2) Pull the Base Cover out.

8. Harness & Hose Assembly

1) Remove the wiring connections.

2) Remove the Hose connections from

Sump Assembly.

You can see the information of Wiring

Diagram at the back of Lower Cover.

Cabinet Base

Base Cover

- 18 - - 18 -

Inlet Valve

Cabinet Base

Air Braker

Nut

Gasket

Air Braker

Assembly

9. Cabinet Base

1) Remove 8 screws.

2) Lift it upward.

10. Inlet Valve

1) You can disassemble the lnlet Valve by

removing the 2 screws.

11. Air Braker Assembly

1) Disconnect the 3 hoses assembly.

2) Turn the Air Braker Nut counterclockwise.

Be careful the o-ring should not be lost.

Cabinet Base

- 19 - - 19 -

Sump Holder

Hook

Sump

Assembly

1) Heater & Drain Motor

Pull the Heater out of the Sump after

releasing the nut.

Remove 3 screws.

2) Vario Motor

Remove 2 screws for Vario Motor.

Pull the Vario Motor and Micro S/W.

3) Soil Sensor

Pull the Soil Sensor.

12. Sump Assembly

Remove 2 screws.

Remove the Sump Holder and push the

Sump Assembly down with pulling aside

Hook.

Be careful not to drop the Sump

Assembly to the bottom.

Drain Pump

Heater

Vario Motor

Micro

S/W

Soil

Sensor

- 20 - - 20 -

13. Holder Supporter, Tub Packing

and Hinge Supporter Assembly.

When you reassemble the Sump Assembly, be

careful not to kink, tear and take off the seals.

You must take off Stopper Roller(F117) by

screwdriver to change the Rail Assembly.

(Stopper Roller could be broken while you are

taking off. So you should be careful not to be

hurt and have extra stopper rollers ready at

servicing at all times)

Rotate the screwdriver, after slide it into the

gap between Stopper Roller and Rail Roller.

- 21 - - 21 -

A. TROUBLE SHOOTING ACCORDING TO DISPLAYED ERROR MESSAGE

ERROR MESSAGE

POSSIBLE CAUSE

REMEDY

FOR ERROR OCCURRENCE

The Water Supply Tap is closed.

The Water Supply is shut off.

The Inlet Hose is kinked.

The Water Pressure is very low.

(below 10 psi)

Inlet Valve is OK?

The filter of Inlet Valve is clogged

by impure water.

The Hall sensor is OK?

The Impeller of Air Guide is bound.

The Drain Hose kinked or blocked.

Wiring connection is OK?

The drain outlet of sump is

blocked.

The Drain Pump/Motor or circuit is

troubled.

Water leakage in Hose connections.

Water is leaked by damages.

The Motor Water Seal leakage of

Sump assembly.

The height of Drain Hose connection

(sink-Drain Hose) is not over 20.

Impeller of the Washing Pump is

worn away.

Remove the cause of kink or block.

Check the wiring connection.

Measure the electric resistance of

Drain Motor. (20-40 )

Replace the Drain Motor or repair

the Circuit.

Replace the connections of Hose.

Check the point of damages and

repair or replace the related parts.

Read the Installation Instructions

(page 9) and fix it to the

recommended Height.

Replace the Impeller of the

Washing Pump.

Take action on Water Supply

device.

Measure the electric resistance of

Inlet Valve. (950-1300 )

Clean the filter of Inlet Valve.

Check the frequency of Inlet Water

by the Test Mode.

Replace the Air Braker.

Not reached to the nor-

mal water level in spite

of 10 min. water supply

INLET ERROR

displayed

Condition

Not fully drained out in

spite of 5 min. drain

operation

The excessive RPM of

Washing Motor

happened during Wash

cycle due to water

leakage.

DRAIN ERROR

displayed

Condition

LEAKAGE ERROR

displayed

Condition

8.TROUBLE SHOOTING METHODS

- 22 - - 22 -

ERROR MESSAGE

POSSIBLE CAUSE

REMEDY

FOR ERROR OCCURRENCE

The Inlet Valve is troubled.

The Controller is troubled.

The Inlet Water Temperature is

very high. (over 194 )

Wiring connection is OK?

The Thermistor is OK?

Wiring connection is OK?

The Impeller of Washing Pump is

locked.

The rotor of Washing Motor is

locked.

The Blade is locked.

Check the temperature. (Test Mode)

If the temperature is displayed,

adjust the Inlet Water

Temperature to 120 .

If the temperature is not

displayed,

check the wiring connection.

check the electric resistance

of Thermistor.

(11~14k at 77 )

Replace the PCB.

Replace the Inlet Valve.

Repair or replace the Controller.

Excessive water is sup-

plied than normal water

level.(Automatically drain

Pump operated.)

EXCESS ERROR

displayed

Condition

The resistance of ther-

mistor not normally out put.

THERMAL ERROR

displayed

Condition

Check the wiring connection.

Replace the cause of restriction.

Replace the Washing Motor.

Replace the PCB.

The Motor is working

abnormally.

MOTOR ERROR

displayed

Condition

- 23 - - 23 -

No Power on when the power button pressed.

The Power connection

is correctly connected.

The Fuse or

Circuit Breaker

of house is O.K?

The Power Switch or

the Circuit is O.K?

Re-connect the Powr connection.

Check the electricity is failed or not.

Replace the Fuse or Circuit Breaker of house.

Check the Power Switch or the circuit and repair it.

Check t he Cont r ol l er. ( Power Ci r cui t )

B. TROUBLE DIAGNOSES AND REPAIR BY SYMPTOM

NO

NO

YES

YES

YES

NO

- 24 - - 24 -

The Wash Pump/Motor does not run.

The Door is tightly

closed?

The Wiring connections

is OK?

The Blade is not locked

by a small and sharp

object?

close the Door tightly.

Check the Door Switch in Latch Handle.

Re-connect the wiring connections related to the

Washing Motor.

Remove the cause of lock or replace the Blade.

Replace the Wahing Pump/Motor

NO

NO

NO

YES

YES

YES

- 25 - - 25 -

Washing Results are not Satisfactory

After washing, are there still

White deposits or streaks on

the dishes?

NO

After washing, are there still

food soils on the dishes?

YES

Check that : - the amount of detergent Correctly used or not

- Filters clogged or not.

- the holes of spray arms blocked or not.

- Utensils are correctly arranged or not.

- Utensils are overloaded or not.

- the spray arm rotating is obstructed or not.

- the program is correctly selected or not.

Reduce the amount of Rinse-Aid

(for Streak)

YES

Dry Results are not satisfactory

Increase the amount of Rinse-Aid.(Set the number higher)

Select the Program that the Rinse temperature is higher.

- 26 - - 26 -

Power Button not automatically off after operation.

Check the button is blocked by foreign materials.

Check the Power Switch.(Replace it, if necessary.)

Check the Controller.(Replace it, if necessary.)

- 27 - - 27 -

9. INSTALLATION INSTRUCTION

Step 1: PREPARE CUPBOARD OPENING

1. This dishwasher is designed to fit a standard dishwasher opening as shown below.

2. Select a location as close to sink as possible for easy connections to water and drain lines.

3. The dishwasher should not be installed more than 10 ft. (3m) from the sink for proper

drainage.

4. If dishwasher is to be installed in a corner, a minimum of 2 in. (50mm) is required between

the dishwasher and an adjacent a wall.

Ensure the floor under the dishwasher is at the same level as the rest of the room to

allow for any service requirements.

If dishwasher will sit directly on

subflooring, subfloor should be

sealed with a waterproof paint or

sealer to prevent damage from

steam.

Drill a 1-1/2(38mm) dia hole or cut

out for drain hose, inlet hose and

electrical cables on either side.

approx. 4(100mm, W) X 4(100mm, H)

These openings must be within 4

(100mm) from the floor and 1-5/8

(40mm) from the back wall. If there is

a floor in the cabinet under the sink,

it will also be necessary to drill or cut

through the floor to connect the

water and drain under the sink.

- 28 - - 28 -

WARNING

For personal safety, remove house fuse or open circuit breaker before installation.

Do not use an extension cord or adapter plug with this dishwasher.

Electrical and grounding connections must comply with the national electrical

code/provincial and municipal code and/or other local codes.

Figure A

Step 2: PREPARE THE ELECTRICAL WIRING

1. This appliance must be operated with correct voltage as shown in this manual and on the

rating plate, and connected to an individual, properly grounded branch circuit, protected

by time delay fuse. Wiring must be 3 wires including ground.

2. The wiring or cord should be in an accessible location adjacent to, and not behind the

dishwasher and within 4 ft. (1.2m) of the dishwasher side.

3. The wiring or cord must be grounded properly, if in doubt, have it checked by a qualified

electrician. No other appliance shall be connected to the same outlet by a double adapter

or similar plug.

4. The wiring or cord must be oriented as shown in Figure A below.

5. Check the dishwasher for any damage before trying to install it.

6. Make sure water line and Electrical line are oriented in the bottom channels as shown in

the figure below.

If you find any damage to the dishwasher, Please contact your dealer or builder

immediately.

- 29 - - 29 -

Step 3: PREPARE THE WATER SUPPLY CONNECTION

1. This dishwasher may be connected to either hot or cold water. If the water can not be

maintained below 149 (65), the dishwasher must be connected to cold water.

2. When connecting the dishwasher water line, sealing tape or compound should be used to

avoid leaks.

3. When connecting the dishwasher water line, the house supply should be shut off.

4. The Water Supply Tube must be oriented as shown in Figure A on page 6.

Step 4: PREPARE DISHWASHER FOR INSTALLATION

1. Adjust the legs to the required height to fit properly under the countertop as shown below.

2. Check the level of dishwasher by using level.

- 30 - - 30 -

1. Remove the Lower Cover and orient dishwasher as shown below.

2. Before sliding the dishwasher into the cupboard opening, make all necessary height

adjustments using the legs.

3. Slide the dishwasher into the cabinet opening carefully. Make sure that the drain hose

inside the cabinet is not kinked.

4. Follow the instruction as in Figure B.

Step 5: INSTALL THE DISHWASHER IN CUPBOARD

- 31 - - 31 -

Step 6: DRAIN LINE CONNECTION

1. If the end of the drain hose does not fit to the drain line, use an adapter (not supplied) that

must be resistant to heat and detergent and may be obtained from a plumbing shop.

2. There are 2 typical connections as shown in Figures C & D.

There may be other options than shown here for connection the drain hose. The drain

connection must meet local plumbing regulations.

The S trap spigot must be drilled out cleanly and free of obstruction to its maximum

internal diameter, if used for drainage.

To prevent syphoning, one of the following instruction methods must be followed:

Follow local codes and ordinances.

Do not exceed 10 ft. (3m) distance

to drain.

Do not connect drain lines from

other devices to the dishwasher

drain hose.

Drain Requirements

Figure C: Connection to Disposer or waste Tee.

Figure D: Connection to Air Gap.

- 32 - - 32 -

Step 7: WATER SUPPLY CONNECTION

1. When connecting, sealing tape or

sealing compound should be

used to avoid water leaks.

2. Before connecting, turn off the water

supply.

3. After fitting the Elbow into the

Inlet Valve, slide the Flexible

Stainless Tube or Copper Tube

into the Elbow.

4. Tighten the nut and make sure

that the line is not kinked or

sharply bent.

Inlet Valve

Water Supply Tube

Elbow

1. Before beginning, turn off electrical

power to the unit at the circuit breaker.

2. Remove the Junction Cover and then

Install the Strain Relief.

3. Twist Wire Connectors tightly on the

wires. Wrap each connection with

Electrical tape.

4. Check again and make sure that all

wires are connected correctly, black to

black, white to white, green to green

(ground to ground).

5. Replace the Junction Cover.

Junction Cover

Wire Connector

Junction Case

Strain Relief

black to black

(ground to ground)

green to green

white to white

Step 8: ELECTRICAL POWER CONNECTION

- 33 - - 33 -

Step 9: FINAL CHECKS

1. Turn electrical power back on at the circuit breaker.

2. Turn house water supply back on.

3. Operate the dishwasher through one cycle (Quick cycle is recommended) to check for

water leaks and operating conditions.

4. Replace the Lower Cover.

- 34 - - 34 -

ACCESSORIES

E005

10. EXPLODED VIEW

- 35 - - 35 -

F101

E005

E010

F103

F102

F001

M210

A040

M262

M270

M261

M260

A160

A130

EXPLODED VIEW

- 36 -

M086

F045

F060

F050

F022

M090

F043

F011

F013

F117

F144

F110

F132

F143

F117

F210

F011

F013

M006

M005

F171

F014

F041

F040

F042

EXPLODED VIEW - TUB ASSEMBLY

- 37 -

A110

A050 F191

F192

F004

F005

A070

A060

A074

A073

A150

A140

A141

A142

A151 A152

A080

A101

A102

A103

EXPLODED VIEW - RACK ASSEMBLY

K260

K252

K254

K262

K200

K230 K220

K201

K006

K251

K203

EXPLODED VIEW - PANEL ASSEMBLY

- 38 -

K002

A120

K030

K001

K122

K110 K121

K101

F174

F142

F141

K124

K140

K100

- 39 -

EXPLODED VIEW - DOOR ASSEMBLY

- 40 -

M001

M110

M038

M025

M035

M130

M036

M007

M087

M060

M081

M120

M034 M088

M027

M028

M026

M050

M221

M031

M220

EXPLODED VIEW - SUMP ASSEMBLY

- 41 -

11. REPLACEMENT PART LIST

*001 MANUAL ASSEMBLY,OWNERS AFN31666748 1

*002 BOX,CARTON 3890DZ3015A 1

*003 MANUAL,SERVICE MFL37554804 0

E005 ACCESSORY ASSEMBLY 5001DD4001A 1

1

1

A040 COVER ASSEMBLY,LOWER 3551DD2001G 1

3551DD2001H 1

3551DD2001J 1

A050 NOZZLE ASSEMBLY AGB32598301 LOWER NOZZLE 1

A060 NOZZLE ASSEMBLY 5249DD1001A UPPER NOZZLE 1

A070 GUIDE ASSEMBLY 4975DD1002A UPPER NOZZLE 1

A073 WASHER,COMMON 1WZZDD3001A 1

A074 SHAFT,NOZZLE 4370ED3007A 1

A080 RACK 3750DD2001A CUP SHELF 2

A101 DECOR,HANDLE 3806DD3004A STS 1

A102 HANDLE 3650DD3001A FRONT 1

A103 HANDLE 3650DD3002A REAR 1

A110 BASKET ASSEMBLY,SPOON 5005DD1001A 1

A120 HARNESS,MULTI EAD35070402 1

A130 HOSE ASSEMBLY,DRAIN AEM30700301 INNER PHI 15, 21 1

A140 RACK ASSEMBLY AHB55759501 LOWER RACK 1

A141 RACK MGR47998601 1

A142 ROLLER ASSEMBLY 4581DD3003B 8

A150 RACK ASSEMBLY AHB55759501 UPPER RACK 1

A151 RACK MGR47998501 1

A152 ROLLER ASSEMBLY 4581DD3002A 10

A160 FILTER ASSEMBLY 6201EC1006A 1

A301 SCREW,TAPTITE 1SBF0402418 3

E010 BUSH 4830ED4001A 2

F001 FRAME, LOWER 3210ED1003A 1

F004 NOZZLE ASSEMBLY 5249DD2001A TOP NOZZLE 1

F005 SHAFT,NOZZLE 4370ED3006A TOP NOZZLE 1

F011 SPRING,HINGE 4970ED4004D 2

F013 CONNECTOR ASSEMBLY 4933DD3001A 2

F014 BRACKET,HINGE 4810ED4004A 2

F022 SENSOR ASSEMBLY 6501DD2001A 1

F040 GUIDE ASSEMBLY 4975DD1001A 1

F041 HOSE,INLET 5214DD3001A 1

F042 HOSE,CONNECTOR 5214DD3003A 1

F043 HOSE,CONNECTOR 5214DD3002A 1

F045 COVER,PROTECT 3550DD2001A 1

F050 NUT,COMMON 4020FD3641C 1

F060 GASKET 4986DD3001A 1

DESC PART No. COMMENTS QTY LOC

LG MODEL: D1607(WB,BB,TB)

YOUR MODEL: LDS4821(WW,BB,ST)

Run_Date : 2008-04-20

SPECIFICATION: 120V 60Hz

CAUTION : BEFORE REPLACING ANY OFTHESE COMPONENTS.

READ CAREFULLY THE SAFETY PRECAUTIONS IN THIS MANUAL

NOTE : S(SAFETY PARTS), AL(ALTERNATIVE PARTS)

WB

BB

ST

- 42 -

F101 PACKING 3920DD3002A TOP 1

F102 PACKING MFZ42591601 SIDE RIGHT 1

F103 PACKING MFZ42591701 SIDE LEFT 1

F110 RAIL ASSEMBLY 5219DD2002A 1

F117 STOPPER,ROLLER 4620ED3001A 2

F132 PACKING 3920DD3005A TUB PACKING 1

F141 HINGE ASSEMBLY 4775DD2002A DOOR RIGHT 1

F142 HINGE ASSEMBLY 4775DD2001A DOOR LEFT 1

F143 HINGE ASSEMBLY 4775ED3004A TUB RIGHT 1

F144 HINGE ASSEMBLY 4775ED3003A TUB LEFT 1

F171 LOCKER,LOCK 4026DD3001A 1

F174 BRACKET,HINGE 4810DD1001A DOOR FRAME 1

F191 GUIDE,WATER MEA36937101 1

F192 GUIDE,NOZZLE 4974DD3001A 1

F210 RAIL ASSEMBLY 5219DD2001A 1

K001 DISPENSER 4924FD2123E 1

K002 BRACKET ASSEMBLY 4810FD3805A FIX DISPENSER TO DOOR LINER 2

K006 DECOR,HANDLE MCR42565801 1

MCR42565802 1

MCR42565802 1

K030 COVER ASSEMBLY,FRONT ACQ36969701 1

ACQ36969702 1

ACQ36969703 1

K100 DOOR LINER ASSEMBLY 4937DD1001D DOORLINER+CASING+VENT+DISPENSER 1

K101 PARTS ASSEMBLY AGM34891602 DOORLINER+DAMPING SHEET+GASKET 1

K110 CASING ASSEMBLY ABT35083801 BLOWER 1

K121 GASKET 4986DD3003A BLOWER GASKET 1

K122 COVER,BLOWER 3550ED3011A 1

K124 VENT MJZ39902101 1

K140 HOSE 5214ER4001S HOSE, NEW BLOWER 1

K141 CLAMP 4861FR3068M HOSE ~ BLOWER 1

K200 PANEL ASSEMBLY,CONTROL AGL36868101 1

AGL36868102 1

AGL36868103 1

K209 BUTTON,CONTROL MBG42564701 CONTROL BUTTON 1

MBG42564702 1

MBG42564703 1

K203 WINDOW MKC42565001 DISPLAY WINDOW 1

K230 WINDOW MKC42606301 PROGRESS WINDOW 1

K251 PCB ASSEMBLY,MAIN EBR33469402 1

K252 PCB ASSEMBLY,DISPLAY EBR43245901 1

K254 PCB ASSEMBLY,DISPLAY EBR33469702 PROGRESS DDISPLAY 1

K260 LOCKER ASSEMBLY 4027ED3002D 1

K262 HANDLE MEB42566001 1

MEB42566002 1

MEB42566003 1

K303 Screw,Customized 1SZZED3002A LATCH ~ PANEL 8

K304 Screw,Customized 1SZZED3003A DOORLINER ~ FRONT COVER 6

M001 HOLDER 4930DD3002A 1

DESC PART No. COMMENTS Q'ty LOC

BB

WB

WB

BB

ST

WB

BB

ST

ST

BB

WB

ST

BB

WB

ST

- 43 -

DESC PART No. COMMENTS Q'ty LOC

M005 GASKET MDS37912401 SUMP GASKET 1

M006 SUMP ASSEMBLY AJH31248602 2

M007 SUMP AJH32598001 1

M025 VALVE,CHECK MJX32862501 VARIO 1

M026 MOTOR ASSEMBLY,AC,DRAIN 4681ED3001B VARIO MOTOR 1

M027 SWITCH,MICRO 3W40025C CHECK THE POSITION OF THE VARIO(CAM) 1

M028 CAM,SWITCH MBJ32856401 1

M031 PACKING 3920ED4009B VARIO PACKING 1

M034 BLADE 5832DD4001A 1

M035 PACKING MFZ32863101 1

M036 HOLDER 4930DD3008A SUMP ASM ~ TUB LOW 2

M038 HOLDER 4930DD3012A WATER GUIDE ~ SUMP 1

M050 MOTOR ASSEMBLY,AC,PUMP 4681EA2002D DRAIN MOTOR 1

M060 MOTOR ASSEMBLY,DC 4681ED1004A WASHING MOTOR 1

M081 HEATER ASSEMBLY 5301DD1001A 1

M086 SWITCH,MICRO 3W40025P 1

M087 SENSOR ASSEMBLY 6501ED2002F SOIL SENSOR 1

M088 COVER 3740ED3003A HOLDER HEATER 1

M090 FLOAT ASSEMBLY 4769DD2001A 1

M110 FILTER ASSEMBLY,MESH ADQ32598201 1

M120 CASE ASSEMBLY ABQ32598101 PUMP CASE 1

M130 IMPELLER ASSEMBLY 5911ED3003A 1

M210 VALVE ASSEMBLY,INLET 5221DD1001A 0

M220 VALVE,CHECK 5220ED4004A DRAIN 1

M221 COVER MCK32863301 DRAIN COVER 1

M260 BASE,CABINET MAM34326301 1

M261 COVER ASSEMBLY,BASE ACQ31707201 1

M262 CASE 3110DD3002A JUNCTION BOX 1

M270 LEG 4778DD3001A 4

M300 ACCESSORY ASSEMBLY 5001DD2001D LEVELING KIT 1

M301 SCREW,CUSTOMIZED 4W51229F BASE + HINGE SUPPORT 4

M302 SCREW,CUSTOMIZED 1SZZED3005A SUMP FILTER 8

M303 SCREW,CUSTOMIZED 1SZZED3006A IMPELLER 1

M304 SCREW,CUSTOMIZED 1SZZFA4305A SUMP ~ DRAIN PUMP 3

M305 SCREW,CUSTOMIZED 4W51194D SUMP ~ MOTOR 4

P/No. : MFL37554804

Potrebbero piacerti anche

- WD-1238C Service ManualDocumento35 pagineWD-1238C Service ManualenrocerNessuna valutazione finora

- LG Washer Service ManualDocumento43 pagineLG Washer Service Manualianalucy100% (4)

- LG Washer Wm2487hwmDocumento43 pagineLG Washer Wm2487hwmMuttata MeataNessuna valutazione finora

- LG Service Manual - Washing MachineDocumento41 pagineLG Service Manual - Washing Machineaimeekate13100% (3)

- ServiceManuals LG Washing WD1015FB WD-1015FB Service ManualDocumento35 pagineServiceManuals LG Washing WD1015FB WD-1015FB Service ManualMicu Adrian DanutNessuna valutazione finora

- LG Wm2277hw ManualDocumento44 pagineLG Wm2277hw ManualmaildaveNessuna valutazione finora

- Washing Machine: Service ManualDocumento41 pagineWashing Machine: Service ManualTinhmotdem BoysaigonNessuna valutazione finora

- WD-1470FD Service ManualDocumento36 pagineWD-1470FD Service Manuals_samirkumar1008Nessuna valutazione finora

- 796.40272900 LG Washer Service Manual PDFDocumento60 pagine796.40272900 LG Washer Service Manual PDFJasonNessuna valutazione finora

- LG - DW - LDF6810 Service ManualDocumento65 pagineLG - DW - LDF6810 Service ManualJames HarpoleNessuna valutazione finora

- LG F14a8tdsa Series Service ManualDocumento56 pagineLG F14a8tdsa Series Service ManualOle Bole100% (1)

- LG Washing Machine Service Manual PDFDocumento42 pagineLG Washing Machine Service Manual PDFMadhuritha RajapakseNessuna valutazione finora

- LG Refrigerator Bottom Freezer LRBC22522 Service ManualDocumento65 pagineLG Refrigerator Bottom Freezer LRBC22522 Service ManualJohn TrippNessuna valutazione finora

- Service Manual Samsung Wak914wm16Documento48 pagineService Manual Samsung Wak914wm16SuhengNessuna valutazione finora

- LG LWD3081ST 30" ELECTRIC CONVECTION BUILT-IN OVEN Sm.Documento64 pagineLG LWD3081ST 30" ELECTRIC CONVECTION BUILT-IN OVEN Sm.tunet1106Nessuna valutazione finora

- GN-234SQA Service Manual LG FriziderDocumento42 pagineGN-234SQA Service Manual LG Friziderpodunavko101100% (2)

- Whirlpool FL 244Documento8 pagineWhirlpool FL 244varol66Nessuna valutazione finora

- ServiceManuals - LG - Washing - WD1227RD - WD-1227RD Service Manual PDFDocumento44 pagineServiceManuals - LG - Washing - WD1227RD - WD-1227RD Service Manual PDFPTcmNessuna valutazione finora

- WM2077CW Service ManualDocumento44 pagineWM2077CW Service ManualMichael David SharkeyNessuna valutazione finora

- Service Manual w11169652 Reva 27in Front Load WashersDocumento94 pagineService Manual w11169652 Reva 27in Front Load WashersSunny SonawaneNessuna valutazione finora

- Rs22hd Fast TrackDocumento9 pagineRs22hd Fast Trackdan themanNessuna valutazione finora

- KitchenAid Range KESC3008WH11 - Service ManualDocumento6 pagineKitchenAid Range KESC3008WH11 - Service ManualplasmapeteNessuna valutazione finora

- DV Service ManualDocumento44 pagineDV Service Manualer3456dfNessuna valutazione finora

- Service Manual (Hwd-C1200txve-U Ce0gd3e0d00)Documento31 pagineService Manual (Hwd-C1200txve-U Ce0gd3e0d00)Roberto Augusto Aristizabal MorenoNessuna valutazione finora

- LG Lrg30 30 RangeDocumento78 pagineLG Lrg30 30 Rangedan themanNessuna valutazione finora

- DV5471A DV5451A Samsung Dryer Manual DC68 02800A PDFDocumento130 pagineDV5471A DV5451A Samsung Dryer Manual DC68 02800A PDFRoberto Augusto Aristizabal Moreno33% (3)

- MFL30574776 F1403RD EukDocumento51 pagineMFL30574776 F1403RD EukApril Scott100% (1)

- Frigidaire Affinity Front Load Washer Error CodesDocumento2 pagineFrigidaire Affinity Front Load Washer Error CodesSamurai Appliance Repair Man100% (5)

- Bosch DishwasherDocumento32 pagineBosch DishwasherJaime Parker100% (1)

- WM3632xx Service ManualDocumento43 pagineWM3632xx Service ManualJeffrey JimenezNessuna valutazione finora

- Washing Machine Training (Alliance Laundry Systems)Documento0 pagineWashing Machine Training (Alliance Laundry Systems)Doru RazvanNessuna valutazione finora

- DAEWOO RefrigeradorDocumento83 pagineDAEWOO RefrigeradorMihaela Caciumarciuc100% (2)

- Samsung Washer Wa17l9wDocumento65 pagineSamsung Washer Wa17l9wfixioncj100% (2)

- LG Electric Dryer ManualDocumento38 pagineLG Electric Dryer ManualAzraelsrlNessuna valutazione finora

- Frigidaire LTF2940ES1 Tech SheetDocumento6 pagineFrigidaire LTF2940ES1 Tech SheetSamurai Appliance Repair Man100% (2)

- Maytag Neptune StackDocumento132 pagineMaytag Neptune StackdanfurlanoNessuna valutazione finora

- Washing Machine - HaierDocumento30 pagineWashing Machine - HaierAnonymous MdSl5BhmNessuna valutazione finora

- DLG2524 Service ManualDocumento43 pagineDLG2524 Service ManuallixiuserNessuna valutazione finora

- Samsung Refrigerator ManualDocumento132 pagineSamsung Refrigerator ManualaaaaNessuna valutazione finora

- LG WM3575CW Washer Service ManualDocumento55 pagineLG WM3575CW Washer Service ManualAppliance 799100% (3)

- Rf265aars Rf266aars Rf26nbrs1rf265aabp Rf266aabp Rf26nbbp1rf265aawp Rf266aawp Rf26nbsh1rf265aash Rf266aash PDFDocumento126 pagineRf265aars Rf266aars Rf26nbrs1rf265aabp Rf266aabp Rf26nbbp1rf265aawp Rf266aawp Rf26nbsh1rf265aash Rf266aash PDFAlexNessuna valutazione finora

- Whirlpool Dishwasher Motor-Pump Assembly ReplacementDocumento3 pagineWhirlpool Dishwasher Motor-Pump Assembly ReplacementSamurai Appliance Repair ManNessuna valutazione finora

- Whirlpool Calypso Service ManualDocumento68 pagineWhirlpool Calypso Service ManualBrian D Smith100% (1)

- FrigidaIre Front Load Washer Rear Bearing ReplacementDocumento7 pagineFrigidaIre Front Load Washer Rear Bearing ReplacementSamurai Appliance Repair Man100% (1)

- f1 - nd1 Servicing ManualDocumento36 paginef1 - nd1 Servicing ManualEhab MohamedNessuna valutazione finora

- W10240504 Maytag Bravos MVWX600XW0 MCT Washer Tech SheetDocumento44 pagineW10240504 Maytag Bravos MVWX600XW0 MCT Washer Tech SheetJason ArnoldNessuna valutazione finora

- InductionDocumento44 pagineInductionmooorthuNessuna valutazione finora

- LDF7774 SVCDocumento68 pagineLDF7774 SVCDamon BrungerNessuna valutazione finora

- Whirlpool TrainingDocumento108 pagineWhirlpool Trainingbioteky100% (1)

- DLEX3570W Secadora Colega Tecnico LG de GasDocumento64 pagineDLEX3570W Secadora Colega Tecnico LG de GasEdison EspinalNessuna valutazione finora

- MVWC 400 XWDocumento84 pagineMVWC 400 XWMike HelveyNessuna valutazione finora

- Xl44 ERC Diagnostic TestDocumento2 pagineXl44 ERC Diagnostic TestSamurai Appliance Repair Man100% (8)

- Wd-1290rd Service Manual (Wd-12320 (5) RD, Wd-1290rd, Wd12311rda)Documento42 pagineWd-1290rd Service Manual (Wd-12320 (5) RD, Wd-1290rd, Wd12311rda)Klema Hanis100% (1)

- LDS5811 Service ManualDocumento55 pagineLDS5811 Service Manuallarry1553Nessuna valutazione finora

- LDS5811 ServiceDocumento103 pagineLDS5811 ServiceDavid EricksonNessuna valutazione finora

- LG WM2032ServiceManualDocumento47 pagineLG WM2032ServiceManualmorrispaul2Nessuna valutazione finora

- Lavadora LG WD-3274RHD Manual de ServicioDocumento43 pagineLavadora LG WD-3274RHD Manual de Serviciogandaras69832653Nessuna valutazione finora

- LG Front Load WasherDocumento44 pagineLG Front Load WasherbrannansapplianceNessuna valutazione finora

- Washing Machine: Service ManualDocumento45 pagineWashing Machine: Service ManualArturo NavaNessuna valutazione finora

- WM1814 Service ManualDocumento41 pagineWM1814 Service ManualRanjith KumarNessuna valutazione finora

- VAV BoxDocumento2 pagineVAV BoxCatherine MarianoNessuna valutazione finora

- Heat PacDocumento2 pagineHeat PacTasha GutierrezNessuna valutazione finora

- Wood Plastic Composites Made From Corn Husk Fiber and Recycled Polystyrene FoamDocumento12 pagineWood Plastic Composites Made From Corn Husk Fiber and Recycled Polystyrene FoamPedro AlbanNessuna valutazione finora

- DVS Technical Codes and BulletinsDocumento10 pagineDVS Technical Codes and BulletinsAsif SarwarNessuna valutazione finora

- Bed CoilDocumento8 pagineBed CoilMahadev KovalliNessuna valutazione finora

- 12 Marking Scheme: Worksheet (AS) : R I V RDocumento1 pagina12 Marking Scheme: Worksheet (AS) : R I V RRuby ChongNessuna valutazione finora

- Design of Piping SupportsDocumento15 pagineDesign of Piping SupportsWaleed EzzatNessuna valutazione finora

- Microwave Welding For Thermoplastics..Documento4 pagineMicrowave Welding For Thermoplastics..Jessica GonzalezNessuna valutazione finora

- Metric Bolt Properties, Grades, and StrengthDocumento7 pagineMetric Bolt Properties, Grades, and Strengthgemo_n_fabrice69Nessuna valutazione finora

- Civil: ANSYS, Inc. Proprietary © 2004 ANSYS, Inc. © 2004 ANSYS, IncDocumento62 pagineCivil: ANSYS, Inc. Proprietary © 2004 ANSYS, Inc. © 2004 ANSYS, IncSalam FaithNessuna valutazione finora

- 360 Dome Projection Big Dome Tent For Commercial Exhibition Event-SHELTER ARCHITECTURE TECHNOLOGY (GUANGDONG) CO.,LTDDocumento12 pagine360 Dome Projection Big Dome Tent For Commercial Exhibition Event-SHELTER ARCHITECTURE TECHNOLOGY (GUANGDONG) CO.,LTDMahesh GopalakrishnanNessuna valutazione finora

- Avances en Soldadura de Materiales DisimilesDocumento5 pagineAvances en Soldadura de Materiales DisimilesDebora ChavezNessuna valutazione finora

- Green Buildings Operation and Maintenance: Case Study On Obstacles and OptimizationDocumento16 pagineGreen Buildings Operation and Maintenance: Case Study On Obstacles and OptimizationAbuNessuna valutazione finora

- Preheat and Heat Input To Reduce Hydrogen Cracking Risk - TWIDocumento4 paginePreheat and Heat Input To Reduce Hydrogen Cracking Risk - TWIFarid Ahmed KhwajaNessuna valutazione finora

- Design of Reinforced Concrete StructuresDocumento11 pagineDesign of Reinforced Concrete Structuresnabinniraula33% (3)

- Overview of The Cement Manufacturing ProcessDocumento26 pagineOverview of The Cement Manufacturing ProcessMahmoud RashadNessuna valutazione finora

- Steel Portal Frame DrawingsDocumento1 paginaSteel Portal Frame Drawingsamirriyyah100% (3)

- Sky Frame Brochure 2010 enDocumento8 pagineSky Frame Brochure 2010 envidas6666Nessuna valutazione finora

- Alloy Selection For Dilute and Medium Concentration Sulfuric Acid NACE CORROSION OnePetroDocumento5 pagineAlloy Selection For Dilute and Medium Concentration Sulfuric Acid NACE CORROSION OnePetroYaroo YarooNessuna valutazione finora

- Effect of Casting Speed On Continuous Casting of Steel Slab: January 2014Documento12 pagineEffect of Casting Speed On Continuous Casting of Steel Slab: January 2014Prakash SarangiNessuna valutazione finora

- En 764-4-2002Documento44 pagineEn 764-4-2002Marija IvanovskaNessuna valutazione finora

- Project Based Multimedia BTLED IA 3ADocumento22 pagineProject Based Multimedia BTLED IA 3AJoevan VillaflorNessuna valutazione finora

- PhotoLitho and SputteringDocumento2 paginePhotoLitho and SputteringAndre KostroNessuna valutazione finora

- VT DDR - Main Report (EN) HTHDocumento142 pagineVT DDR - Main Report (EN) HTHMr_TitanNessuna valutazione finora

- ARE Non-Stick Utensils Safe For HumanDocumento13 pagineARE Non-Stick Utensils Safe For HumanSoft TechNessuna valutazione finora

- Internship Report Mohammad AktharDocumento39 pagineInternship Report Mohammad AktharJunaid KhanNessuna valutazione finora

- Shree Chintamani Developers, Kadakpada (R4)Documento4 pagineShree Chintamani Developers, Kadakpada (R4)Jai GaneshNessuna valutazione finora

- Sihp3wg4 Product ManualDocumento2 pagineSihp3wg4 Product ManualPál HústalzNessuna valutazione finora

- Theory of Indeterminate Structure by Syed Ali Rizwan PDFDocumento470 pagineTheory of Indeterminate Structure by Syed Ali Rizwan PDFZain Ashfaq100% (2)

- Building Materials in Ancient RomeDocumento5 pagineBuilding Materials in Ancient RomeShaikh AvaisNessuna valutazione finora